Conveyer belt apparatus

A conveyor belt and equipment technology, applied in the field of conveyor belt equipment, to achieve the effect of reducing the number of rollers, reducing maintenance costs, and improving impact deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

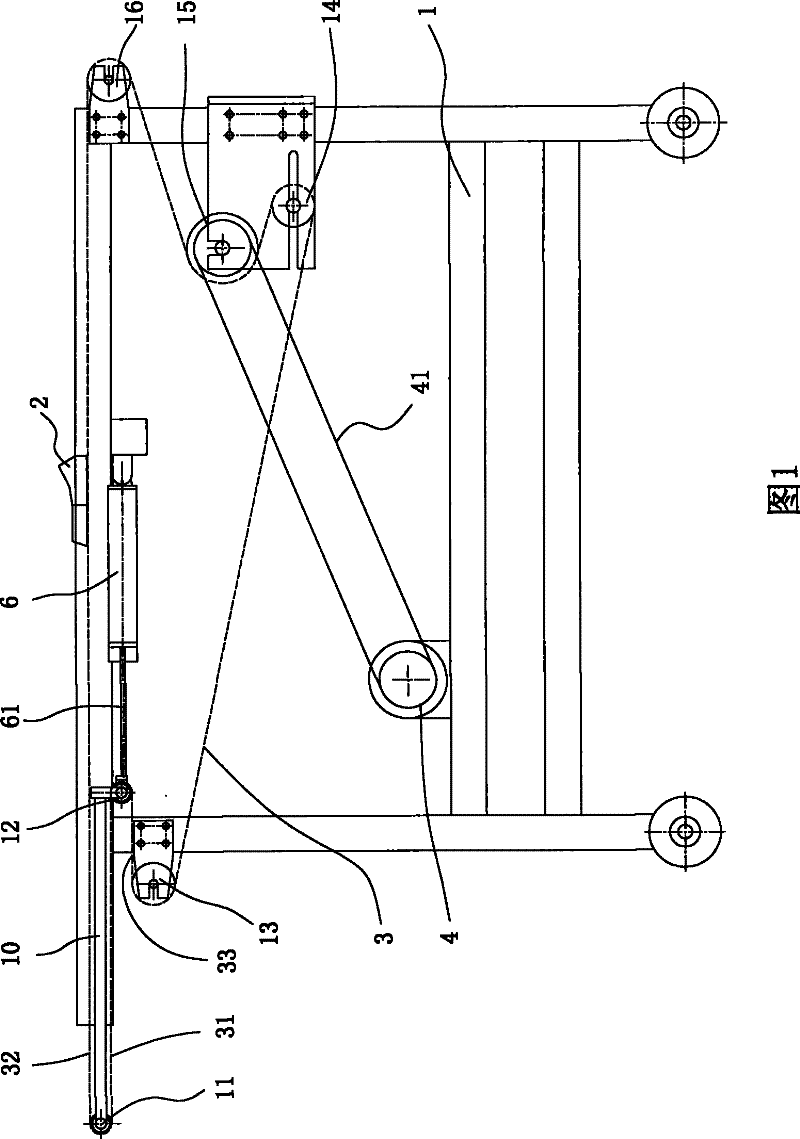

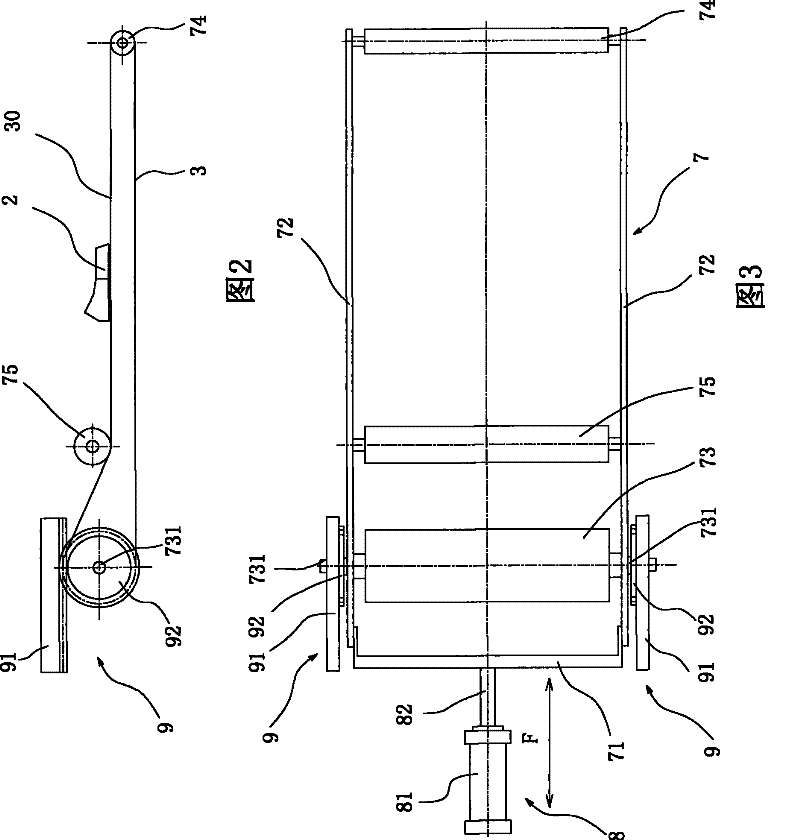

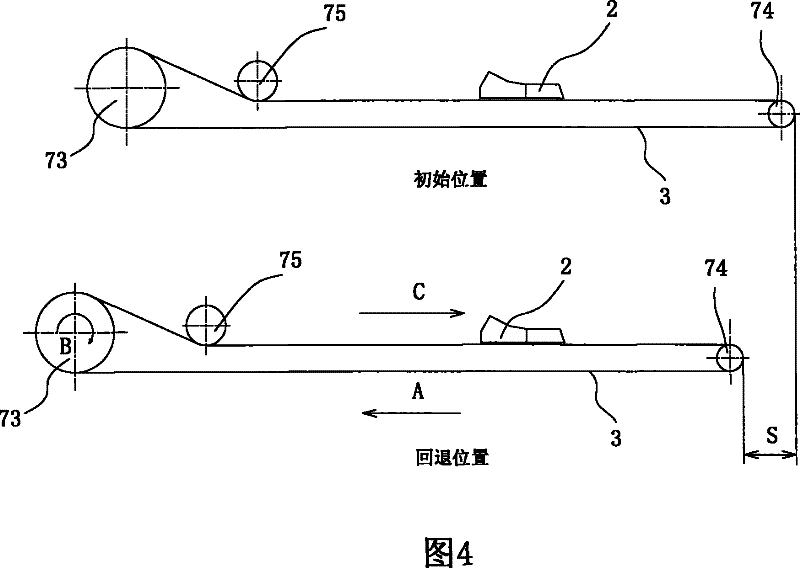

[0029] As shown in Figures 2 and 3, the present invention provides a conveyor belt device, comprising:

[0030] Mobile frame 7, this mobile frame 7 comprises connecting plate 71 and two side plates 72, and the whole is a frame; On the two side plates 72 of this mobile frame 7, a power roller 73 and a static roller 74 are pivotally arranged, and In the present invention, the power roller 73 preferably adopts an electric roller that can be purchased on the market, and the roller skin can be rotated relative to the roller shaft 731 through the magnetic force. Driving the power drum 73 to rotate can simplify the structure of the whole transmission belt equipment. The motor drum is a known part and will not be described in detail; Distance, power drum 73 and static drum 74 are arranged on two side plates 72 inside of mobile frame 7 along the moving direction F of vertical mobile frame 7, and transmission belt 3 is set around power drum 73 and static drum 74; A limit roller 75 can ...

Embodiment approach 2

[0037] As shown in Figure 5, the principle, structure and effect of this embodiment and Embodiment 1 are basically the same, the difference is that: the power drum 73 is not an electric drum that can provide rotational force by itself, but needs to be additionally connected with a rotating mechanism 5 for It provides turning force.

[0038] The power drum 73 is connected with the output shaft of the rotary mechanism 5, and the rotary mechanism 5 is preferably a servo motor, and the output shaft of the servo motor is directly driven and connected with the roller shaft 731 at one end of the power drum 73 through couplings such as a shaft coupling 50. Bracket 51 connects and fixes rotating mechanism 5 on the mobile frame 7 and can move back and forth together with it; Although it is shown in Fig. 5 The type of double-shaft output can be adopted, and the rollers 731 at both ends of the power roller 73 can be driven at the same time, so that the force on the power roller 73 can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com