Strong anti-thickening anti-sand hydraulic feedback oil pump with long plug ring seal and oil inlet sand deposition path

A hydraulic feedback and oil well pump technology, applied to pumps with flexible working elements, parts of pumping devices for elastic fluids, pumps, etc., can solve problems such as irreparable wear, difficult processing, and different standards , to achieve the effect of long operation period, simple operation and good sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 2

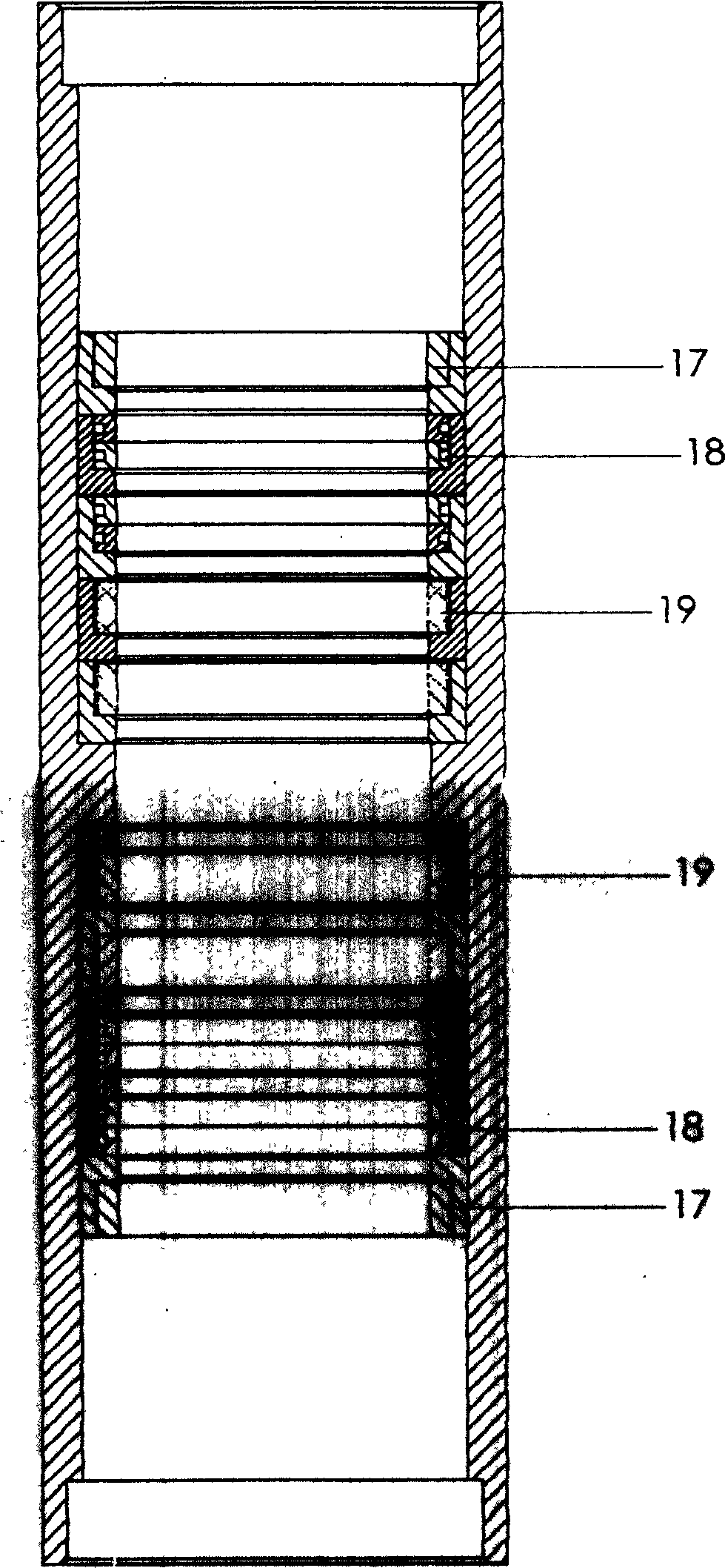

[0020] Example 2. One sand scraping ring 17, three metal rings 18 and three non-metal rings 19 are set.

example 3

[0021] Example 3, the metal ring 18 is an automatic compensation metal ring; the non-metal ring 19 is an automatic compensation non-metal ring.

[0022] The sand scraping ring 17 is made of cemented carbide, and the gap with the plunger is very small, and the horizontal direction can move to ensure that the plunger is not jammed after being lowered, and its effect prevents sand from entering the sealing section.

[0023] The metal ring 18 can be made of high wear-resistant and corrosion-resistant metal material with automatic compensation function, which can compensate the wear and pressure of the seal ring at any time, so the seal is durable and is an important link to ensure high pump efficiency and long service life.

[0024] The non-metallic ring 19 can be a sealing ring with automatic compensation function made of high wear-resistant, corrosion-resistant and high-temperature-resistant (≤300°C) materials. Due to the sand scraping at the front end and the protection of the m...

example 4

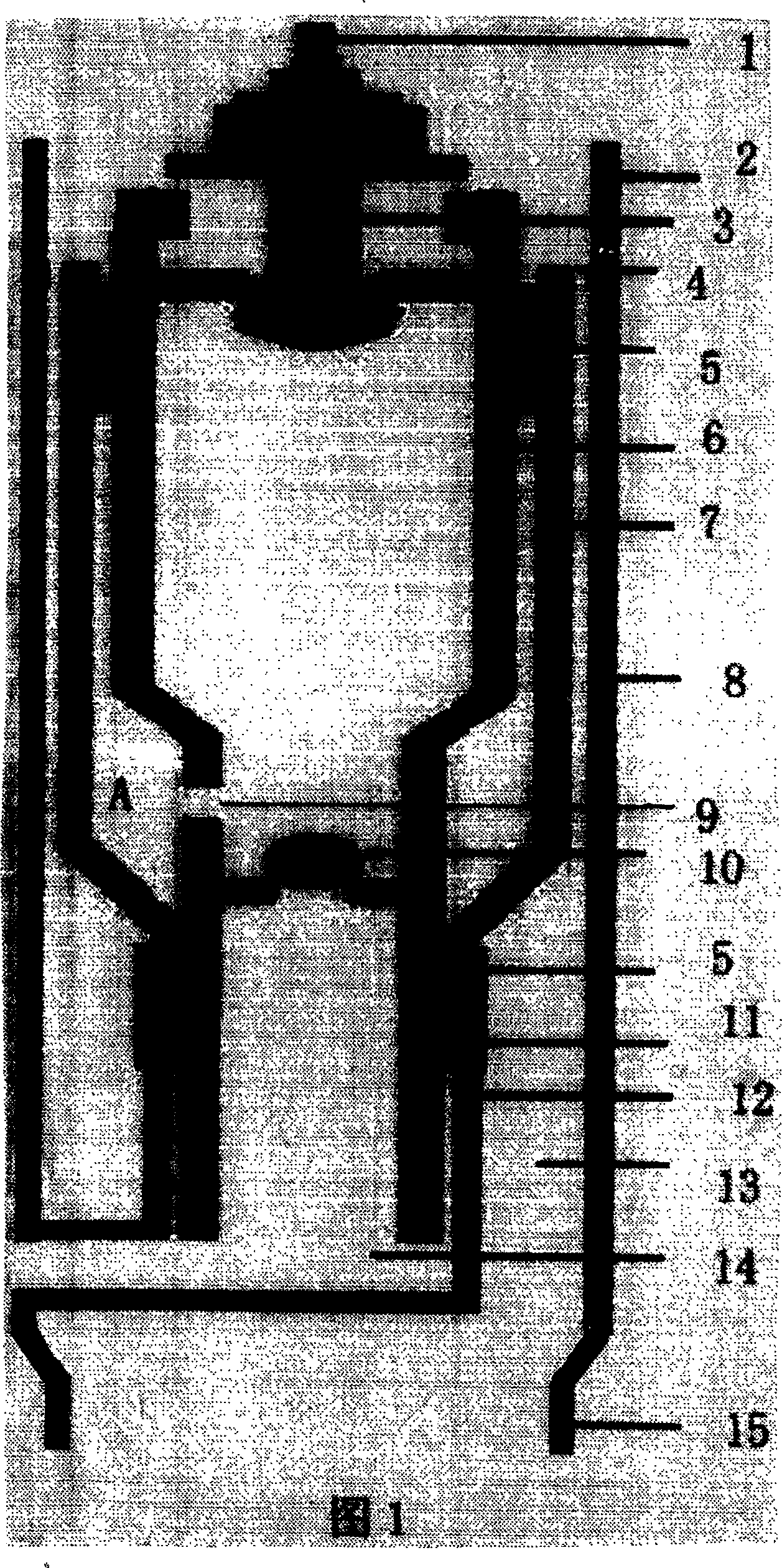

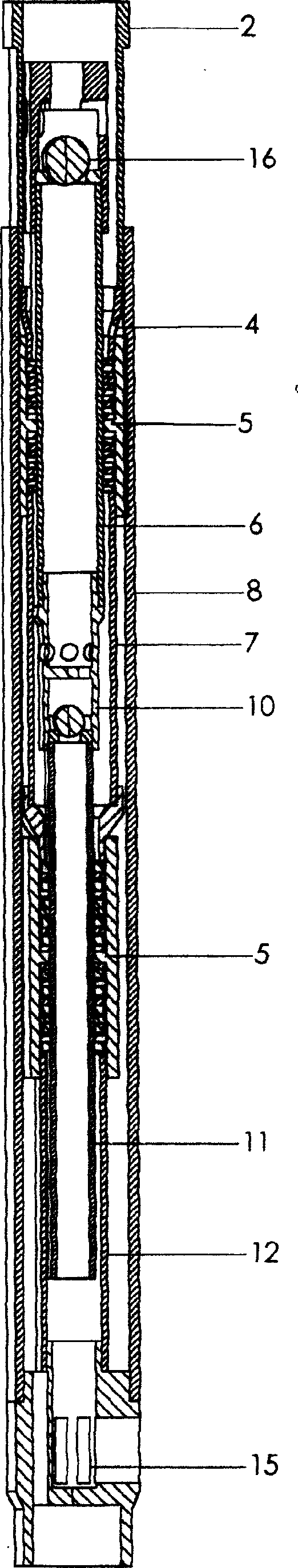

[0025] Example 4. For a powerful anti-thickness and anti-sand hydraulic feedback oil well pump with a long plug ring seal and an oil inlet and sand setting channel, a sand discharge hole 4 is provided between the outer pump barrel 8 and the upper pump barrel 7, and the outer pump barrel 8 and the upper pump barrel 7 and the lower pump barrel 12 are provided with a sand setting channel 13, and a well fluid sand settling double-pass mechanism 14 is set at the bottom of the lower plunger 11 and the lower pump barrel 12.

[0026] The oil-inlet sand settling channel is composed of the inner pump head, the annular space of the inner and outer pump barrels and the oil-inlet sand settling structure, so that the accumulated sand particles sink into the sand storage pipe under the pump to ensure that the plunger is not buried or stuck, thereby greatly improving service life.

[0027] The technology of the present invention is that the hydraulic feedback oil well pump is provided with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com