CNC large engine crankshaft angle oil hole drilling rig mechanism

A crankshaft angle, engine technology, applied in the direction of boring/drilling, large fixed members, drilling/drilling equipment, etc., can solve the problems of high labor intensity of operators, low equipment efficiency, etc., to ensure automation and quality accuracy requirements, reliable product quality assurance, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

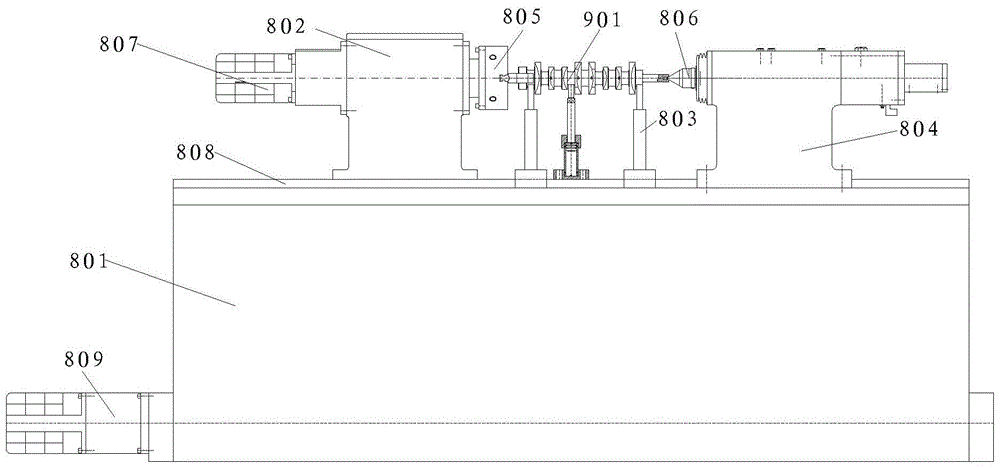

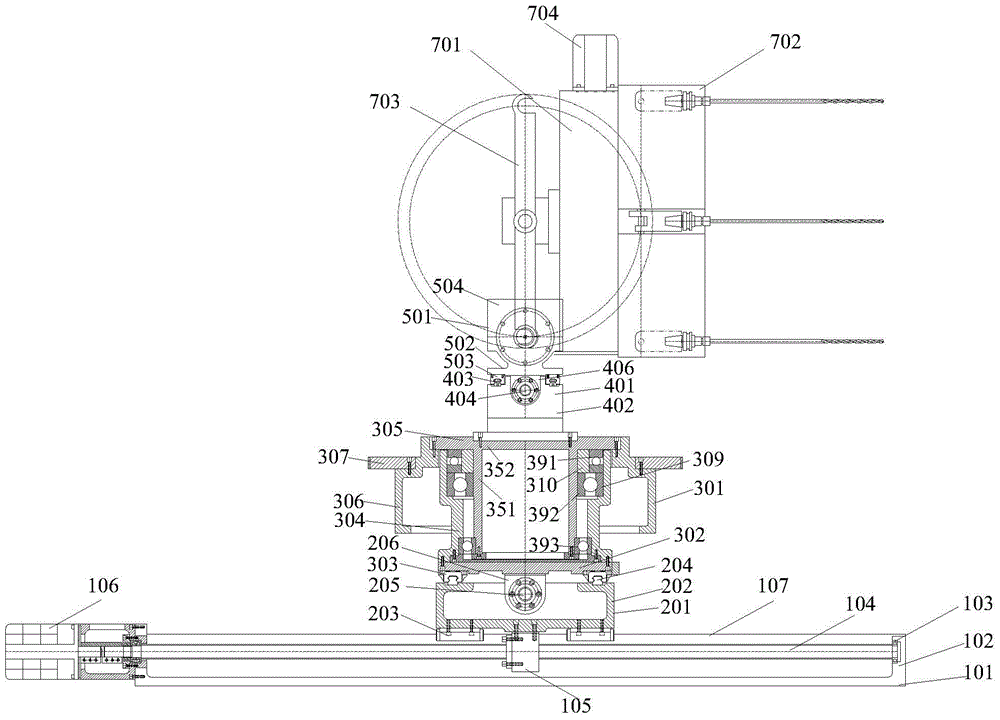

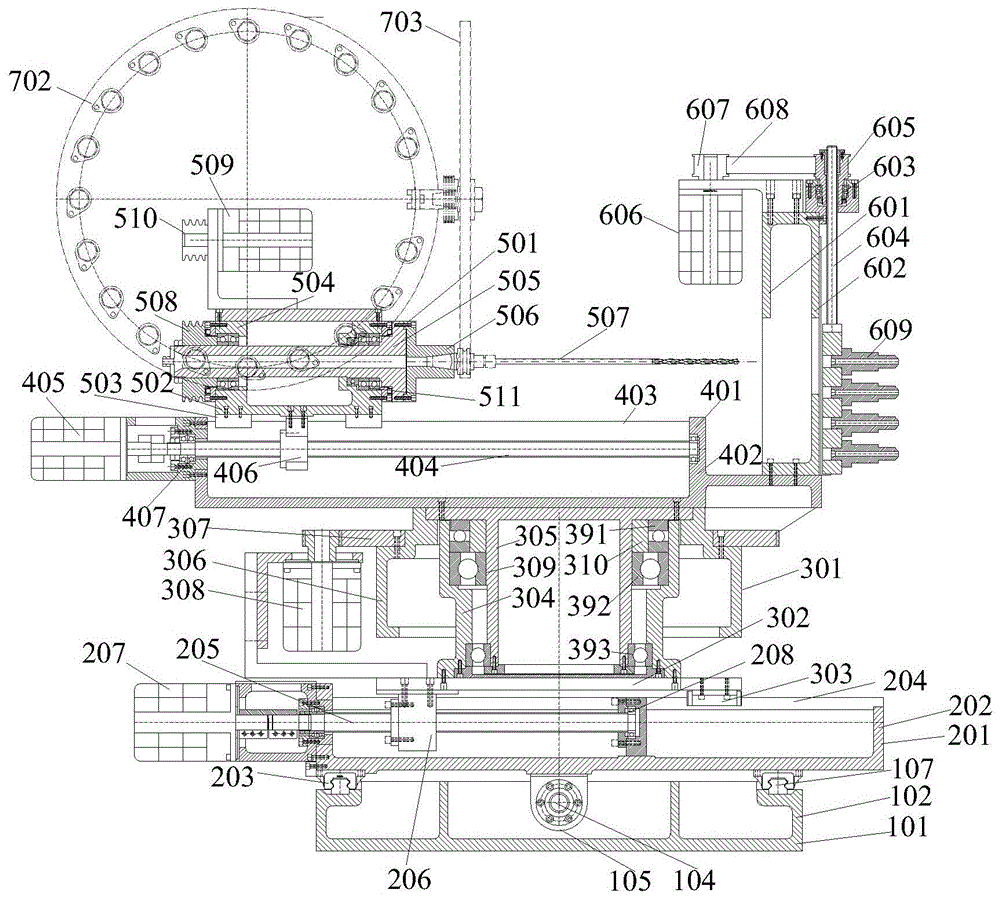

[0021] Such as figure 1 — Figure 4 As shown, the present invention includes a main frame 801 and a drill mechanism. The main frame 801 is provided with a head frame 802, a crank bracket 803 and a tail frame 804. The end of the head frame 802 is fixed with a clamp for clamping a workpiece 901. 805, the end of the tail frame 804 is provided with a top 806, the other end of the head frame 802 is connected with an eighth motor 807, the main frame 801 is provided with a fourth guide rail 808, and the head frame 802 is slidably connected to the second On the four guide rails 808, the inside of the main frame 801 is provided with a driving mechanism 809 that drives the head frame 802 to slide on the fourth guide rail 808; There is a l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com