Quality standard of standardized bupleurum extract

A technology of extract and bupleurum, which is applied in the field of standardization and preparation of Chinese herbal medicine extracts, can solve the problems of low extraction rate, poor therapeutic effect, and loss of medicinal components, and achieve good reproducibility, strong specificity, The effect of reliable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

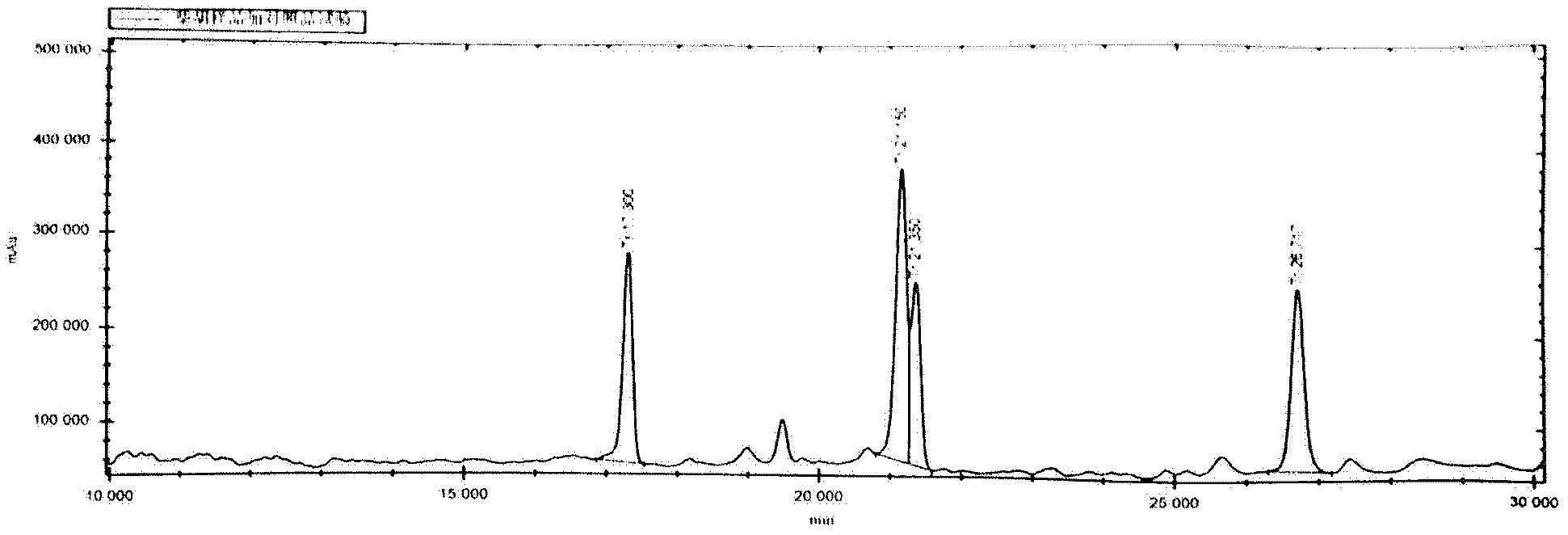

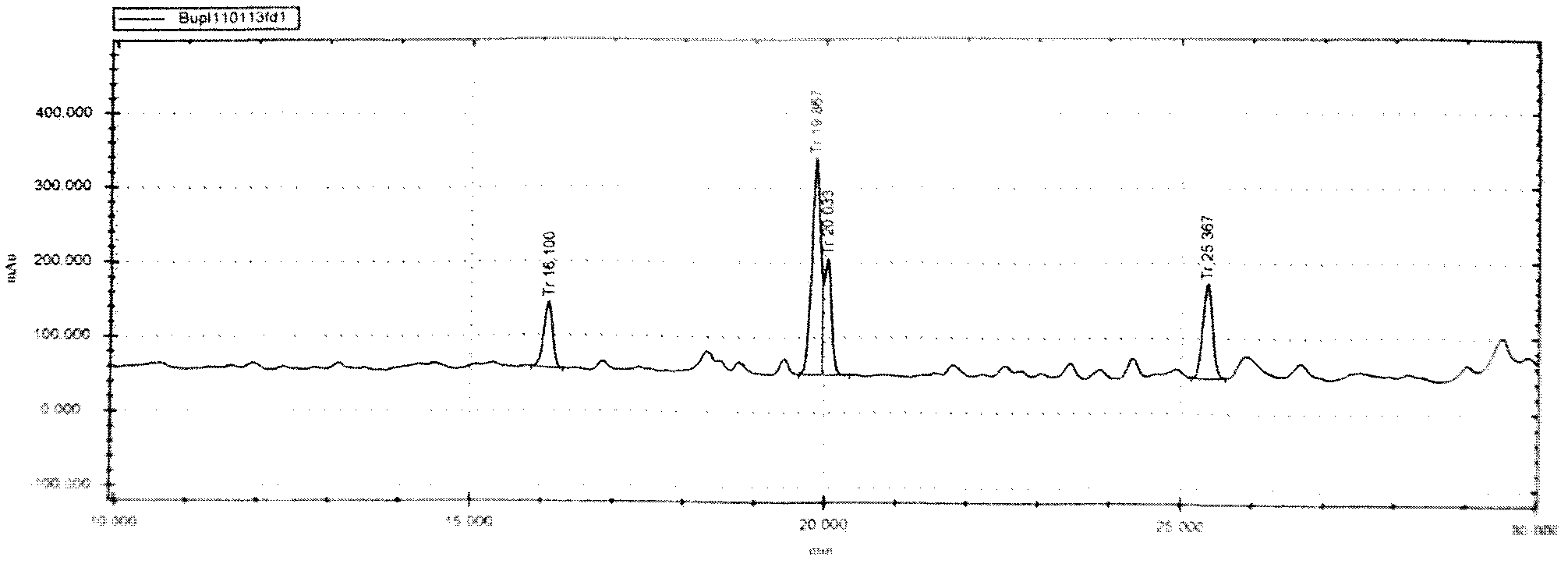

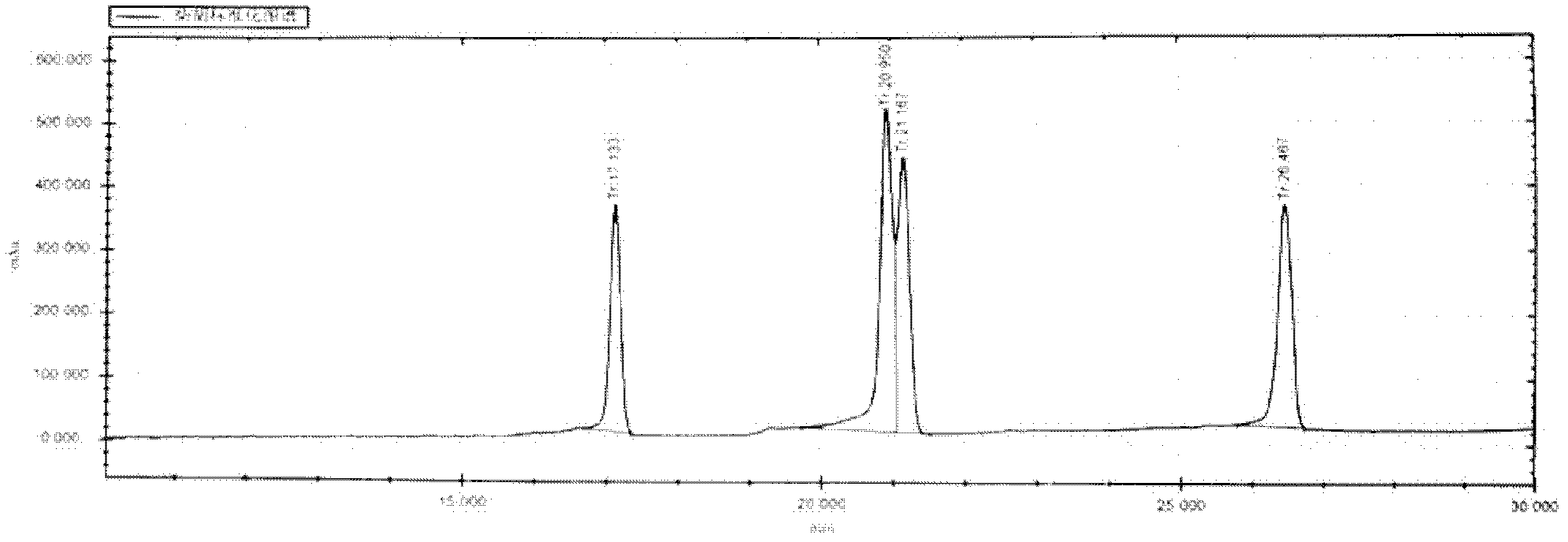

Image

Examples

Embodiment 1

[0032] Embodiment 1: Three batches of stability scale-up tests

[0033] Standardized extract of Bupleurum radix semi-bionic combined ultrasonic preparation method: Take 250g of Bupleurum chinensis and crush it into a coarse powder, add appropriate amount of 60% ethanol, adjust the pH to 8 with a stabilizer (1.5% KOH), infiltrate for 8 hours, and store at a temperature of 40°C , ultrasonic (power 250W, 50kHz) extraction 3 times, 40 minutes each time, add 8 times the amount of ethanol each time, adjust PH=8 with a stabilizer (1.5% KOH), filter, combine the filtrates, reclaim the ethanol until there is no alcohol smell , concentrated to a relative density of 1.10 (60 ° C) spray drying or microwave vacuum drying, that is (see Table 2).

[0034] The average powder extraction rate of three batches of scale-up experiments was 15.35%, the average extract content was 1.874%, the average yield was 0.288%, and the extraction rate was 84.706% based on the total content of saikosaponin abc...

Embodiment 2

[0047] The quality standards of Bupleurum extract include the identification of Bupleurum extract, the determination of saikosaponin content, the characteristic spectrum and the determination of characteristic peak matching spectrum and other items.

[0048] The method for identification and content determination of Bupleurum bupleuri extract, the steps are as follows:

[0049] (1) Preparation of Bupleurum extract: take 250 g of Bupleurum chinensis and crush it into a coarse powder, add an appropriate amount of 60% ethanol, adjust the pH to 8 with a stabilizer (1.5% KOH), infiltrate for 8 hours, and at a temperature of 40 ° C, ultrasonic ( Power 250W, 50kHz) extraction 3 times, 40 minutes each time, add 8 times the amount of ethanol each time, adjust the pH=8 with a stabilizer (1.5% KOH), filter, combine the filtrates, recover the ethanol until it has no alcohol smell, concentrate to Relative density 1.10 (60 ℃) spray drying or microwave vacuum drying, that is (see Table 2). ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com