Manufacturing process of screw nut

A manufacturing process and screw nut technology, applied to bolts, threaded fasteners, connecting components, etc., can solve the problems of wasting raw materials, adding redundant processes, labor and time, etc., to achieve reliable product quality assurance and reduce labor intensity , the effect of cost control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention is described below in conjunction with accompanying drawing.

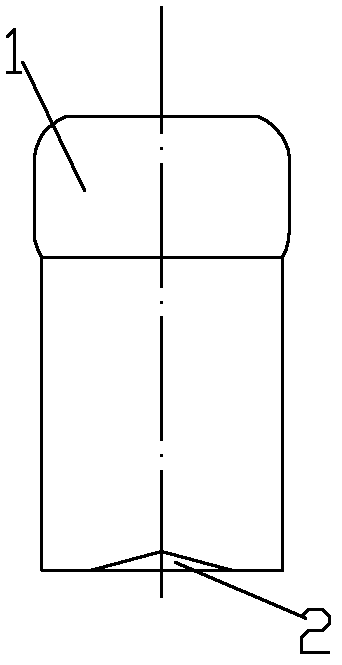

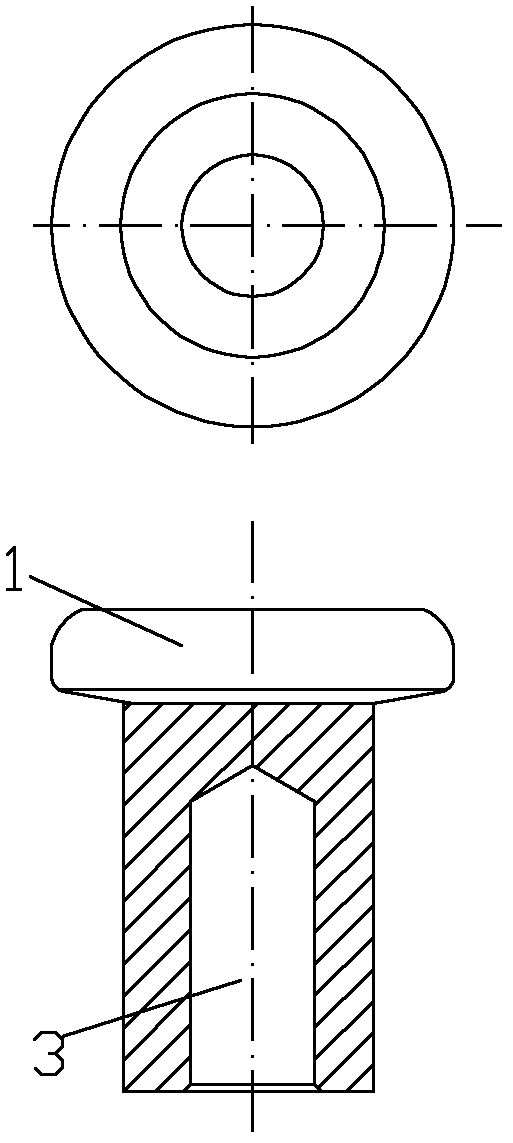

[0019] as attached figure 1 Shown is the screw nut manufacturing process of the present invention, taking the product specification of M5ⅹ7.5ⅹ∮8.6ⅹ17㎜ as an example, the metal wire is cut to 17.5mm, so that its volume is equal to the volume of the formed screw nut; Then use a general-purpose multi-station cold heading machine to pre-upset one end of the blank, and upset the head 1 of the female nail, so that the size of the head 1 of the female nail is slightly larger than the diameter of the remaining cylindrical surface, and at the same time punch out the bottom of the remaining cylindrical surface. Locate the small hole 2 and fillet the outer end face of the head with a bullnose; the third step is to use the method of punching and drawing a hole with a mold to draw a deep hole 3 of ∮4.68ⅹ10㎜ at the bottom of the female nail, and at the same time pour the inner end face of the head A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com