Roller coating machine

A technology of roller coating machine and frame, which is applied in the direction of coating, liquid coating device on surface, surface pretreatment, etc. It can solve problems such as nozzle clogging, product quality cannot be effectively guaranteed, and human health is violated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0076] The present invention will be further described below in conjunction with specific drawings and embodiments.

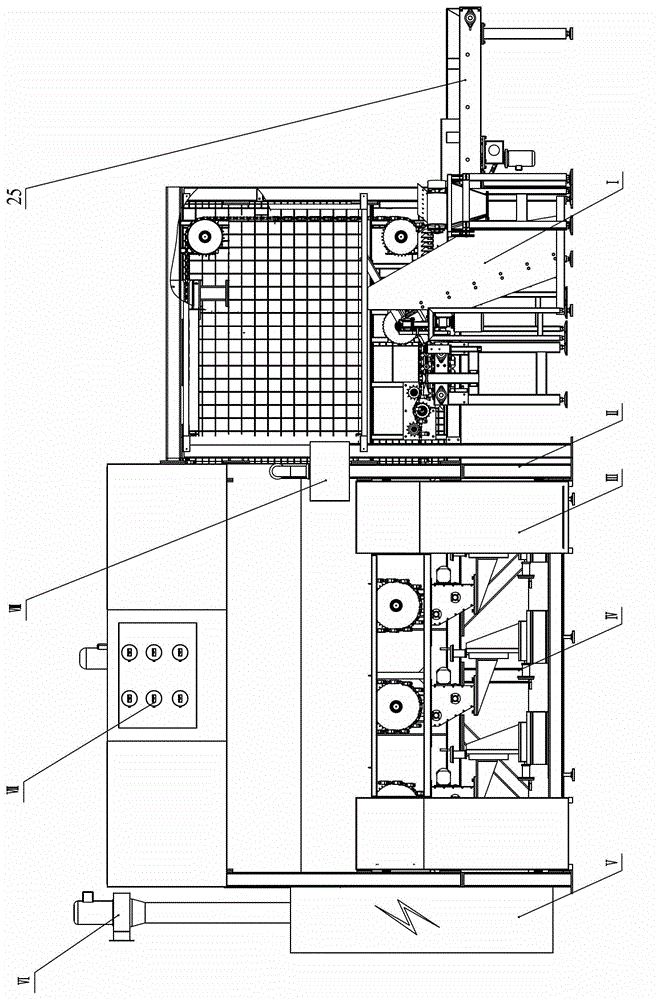

[0077] As shown in the figure: the roller coating machine in the embodiment is mainly composed of the feeding system Ⅰ, the workpiece transmission frame Ⅱ, the glue preparation device Ⅲ, the automatic glue rolling device Ⅳ, the electric control cabinet Ⅴ, the exhaust system Ⅵ, and the drying device VII, operation panel VIII and feeding mechanism 25 etc. are composed.

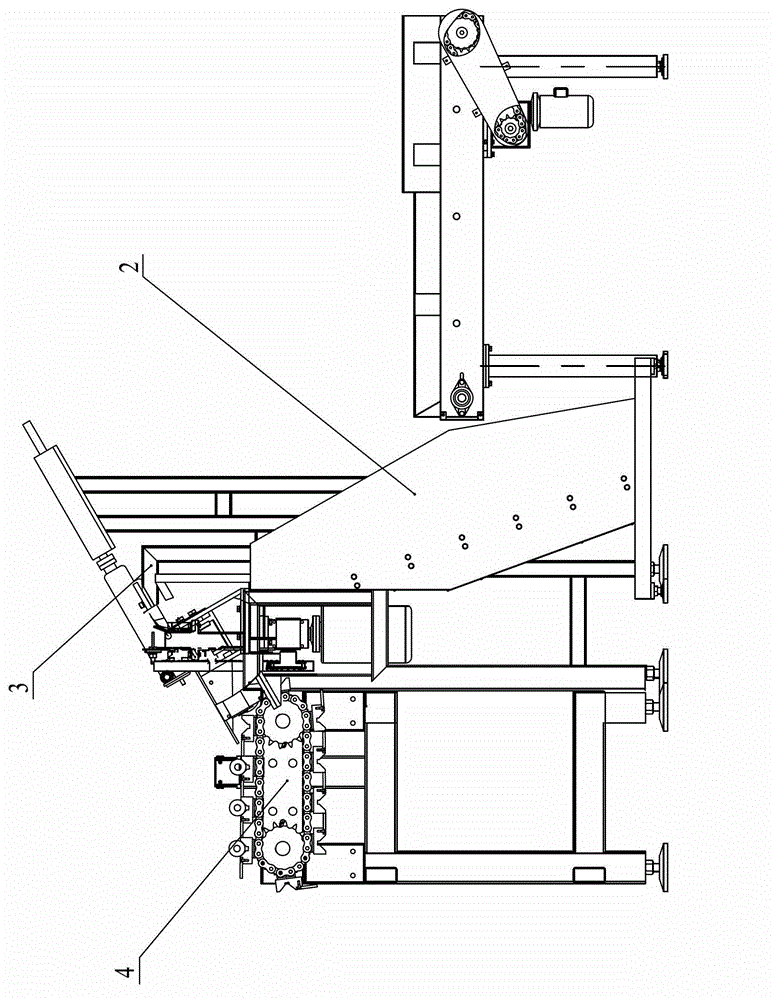

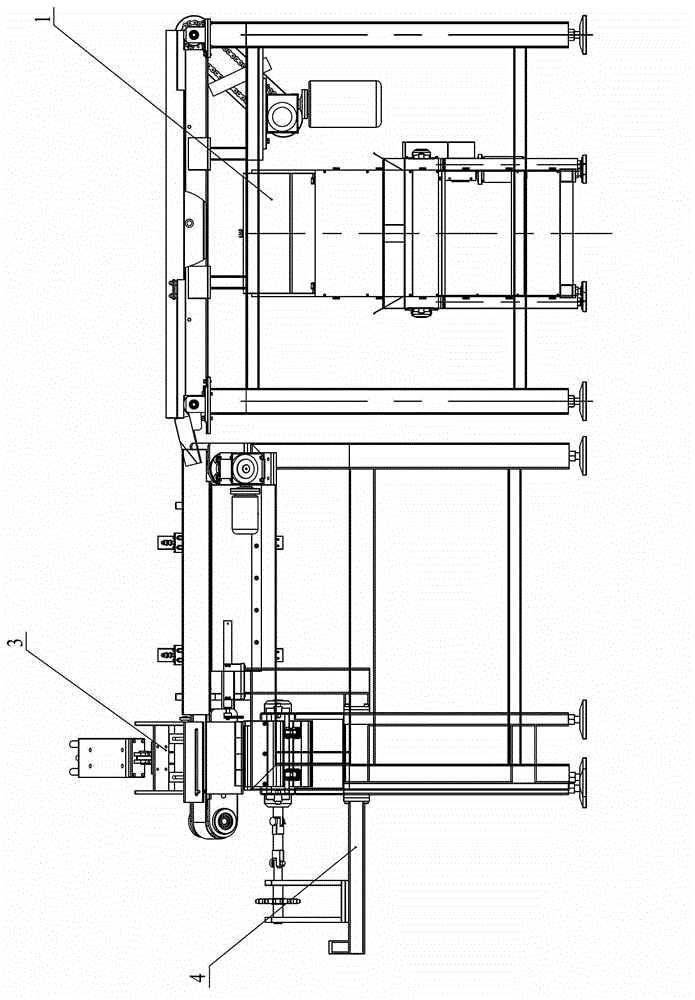

[0078] like Figure 2.1 , Figure 2.2 As shown, the feeding system I is mainly composed of a turning mechanism 1, a discharging mechanism 2, a synchronous pushing mechanism 3 and a synchronous feeding mechanism 4, and the workpiece to be coated is pushed into the turning frame of the turning mechanism 1 by a transport vehicle. 1.14, the turning mechanism 1 rotates the turning frame 1.14, turns over the workpiece and pours it into the hopper 1.12, and transports it to the storage hopper of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com