Continuous forming mold for manufacturing triangular cramp and continuously formed triangular cramp

A technology for forming molds and forming molds, which is applied in the field of continuous forming molds and continuous forming triangular nails, which can solve problems such as labor and material costs, low efficiency, and difficult quality assurance, and achieve reliable product quality assurance, high strength, and work efficiency. Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

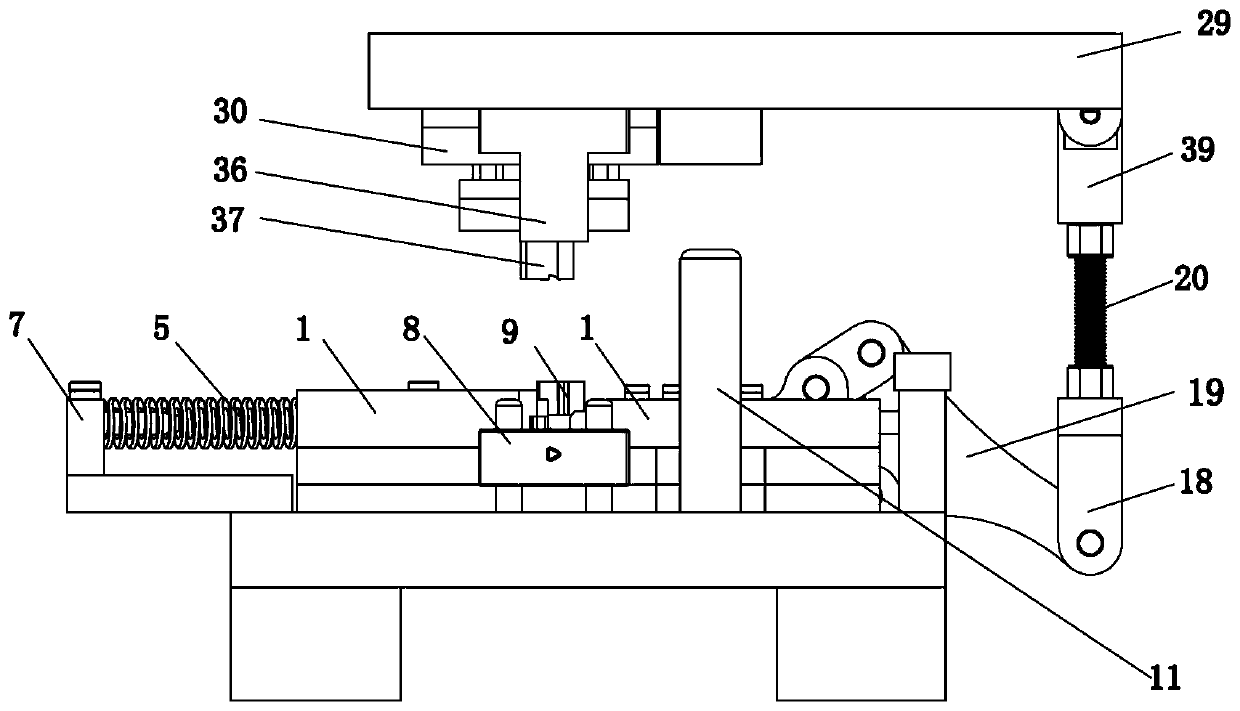

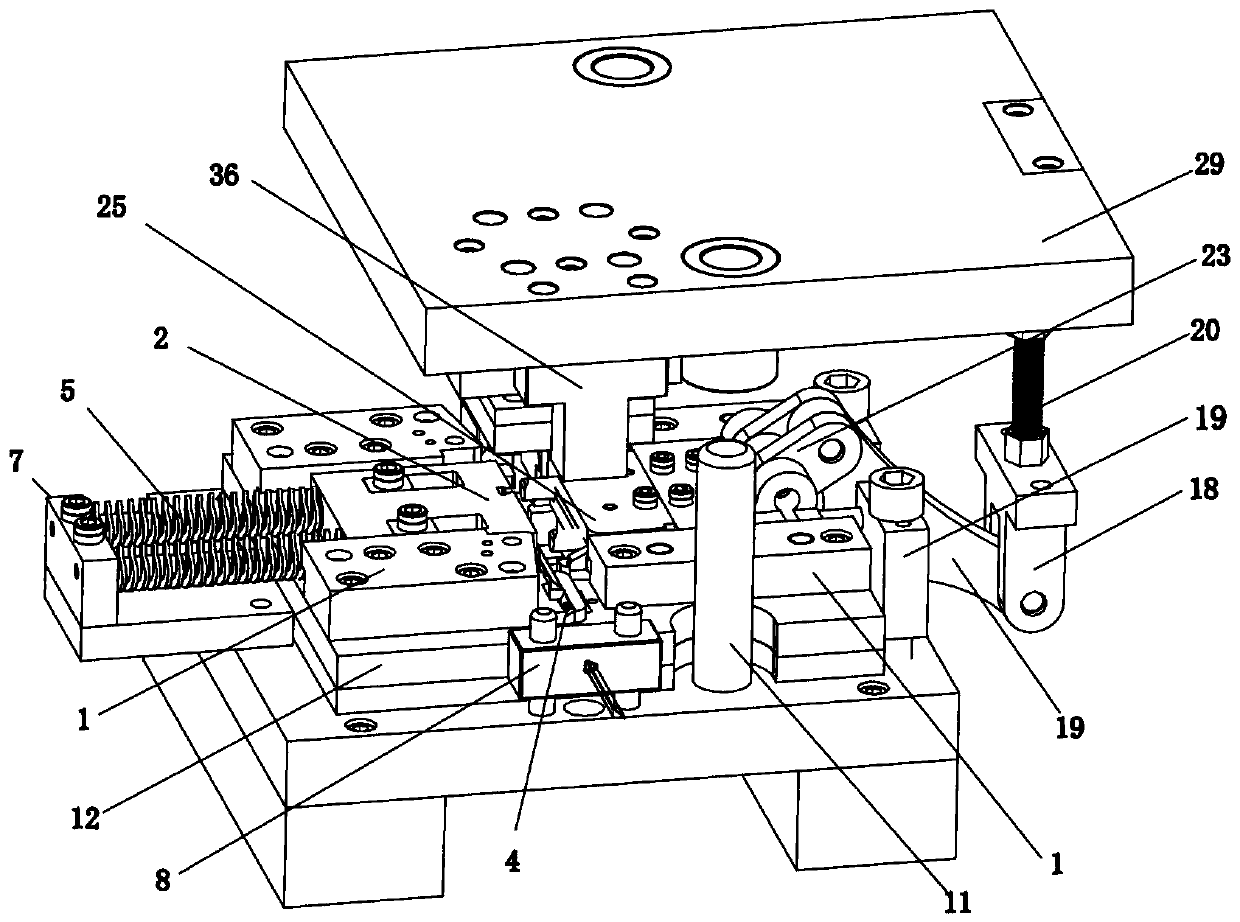

[0026] The basic structure of the continuous molding die for the manufacture of triangular nails in this embodiment is as follows: figure 1 and figure 2 As shown, it consists of upper mold assembly and lower mold assembly.

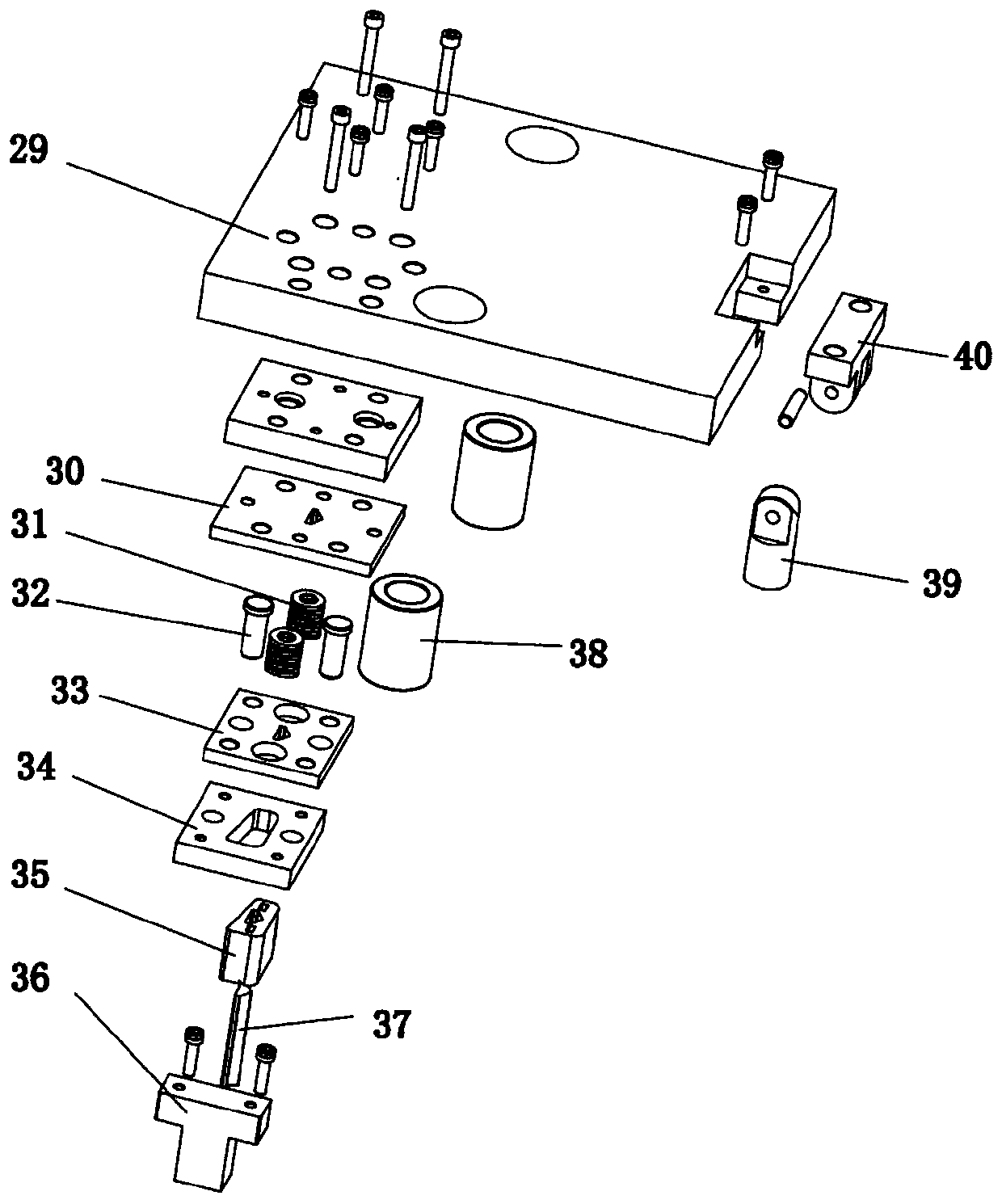

[0027] upper die assembly see image 3 , including an upper fixed plate 30 fixed on one end of the lower surface of the upper mold base 29, the upper fixed plate 30 is equipped with an upper stop plate 33 that constitutes a moving pair with the vertical upper guide column 32, and the upper stop plate 33 lower surface is fixedly installed The upper stripping plate 34 and the lower end pass through the cutter sheath 35 of the upper stripping plate 34, and the upper fixing plate 30 is fixedly installed with the lower V-shaped cutting edge of the cutting knife 37 passing through the cutting knife sheath; the upper fixing plate 30 and the upper stop plate Back-moving spring 31 is housed between 33; In addition, the upper mold base 29 is also equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com