Bag filter

A technology of bag filters and filter baskets, which is applied in the direction of fixed filter element filters, filtration separation, chemical instruments and methods, etc. It can solve the problems that affect product quality, must be scrapped, cannot be repaired, etc., and solve the problem of internal leakage of products , Reliable guarantee of product quality, and the effect of preventing excessive load bearing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

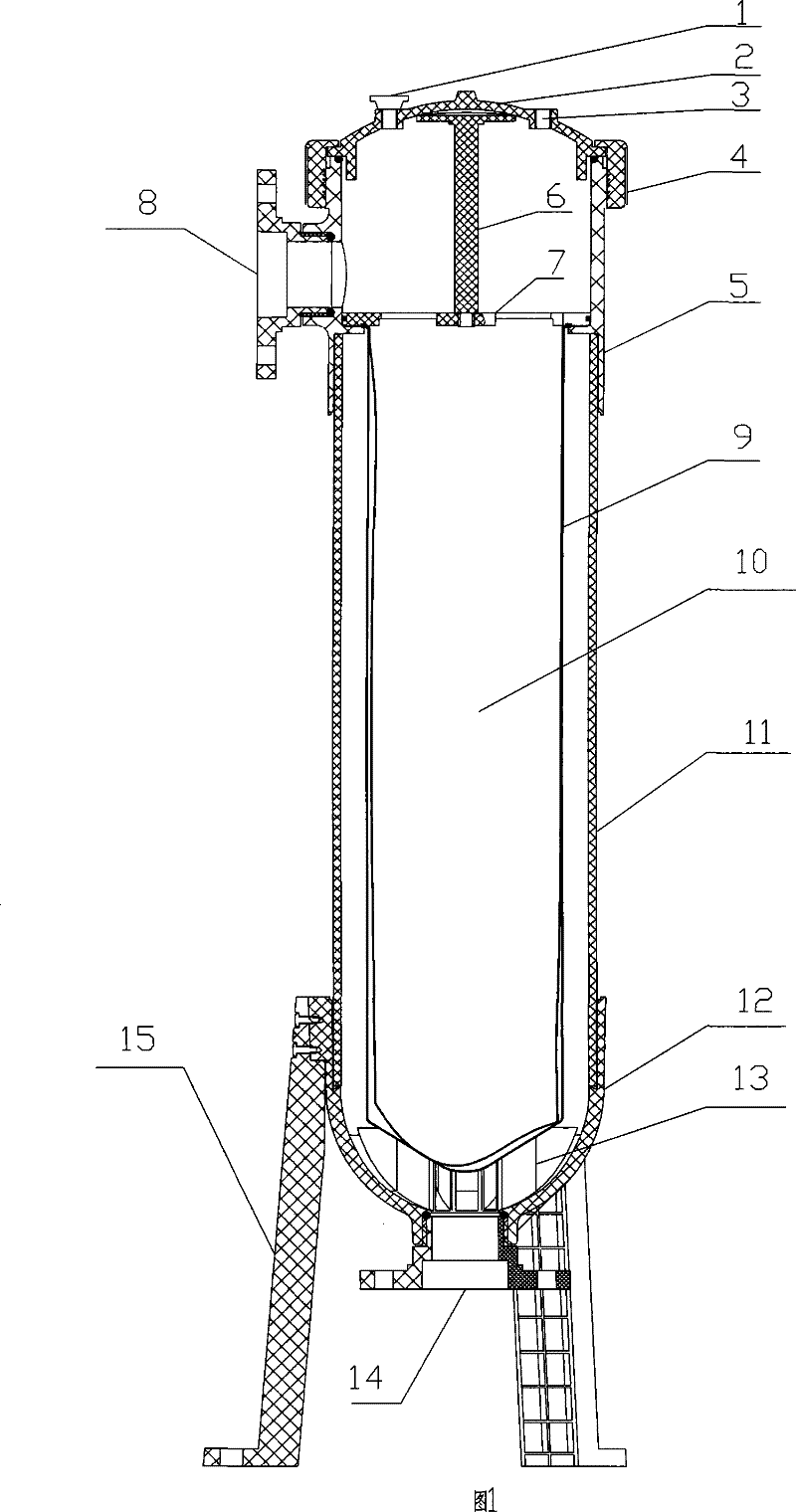

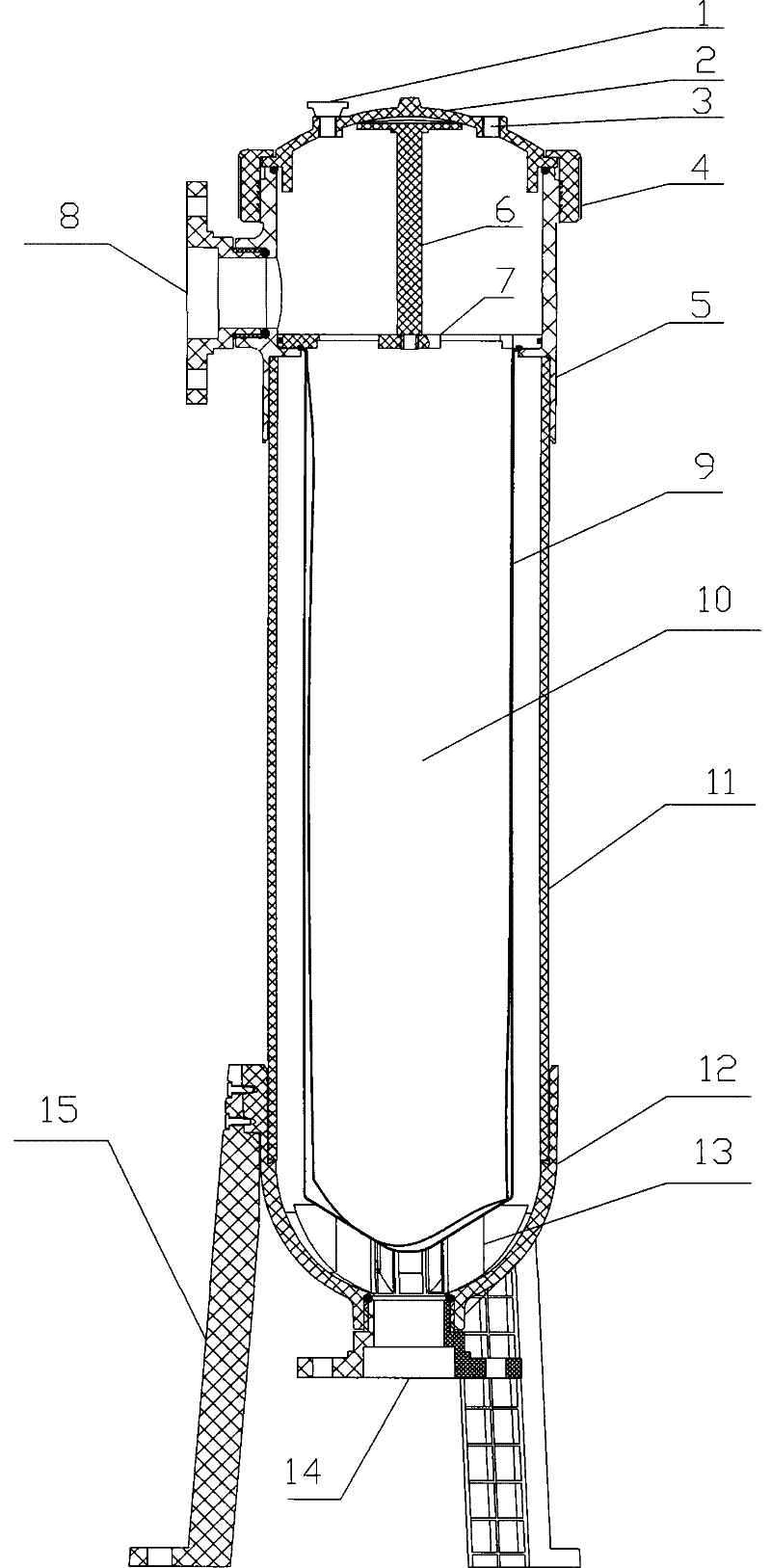

[0014] refer to figure 1 , a bag filter, comprising a filter basket 9, a filter bag 10, a cylinder 11, and several support feet 15, the filter bag 10 is arranged on the inner wall of the filter basket 9, the filter basket 9 is fixed in the cylinder 11, and the support feet 15 is supported on the bottom of the cylinder 11, and also includes an upper liquid inlet 5, a lower pressure plate 7, and a top cover 2. The inner wall of the upper liquid inlet 5 is provided with positioning ribs, and the side is provided with a liquid inlet hole. 5 is fixed on the mouth of the cylinder body 11 through positioning ribs, a liquid inlet flange 8 is installed at the liquid inlet hole, the top cover 2 is sealed above the upper liquid inlet part 5, and the bottom of the cylinder body 11 is provided with a lower support liquid outlet part 12. There is a liquid outlet hole on the lower holder liquid outlet part 12, and a liquid outlet flange 14 is installed at the liquid outlet hole. At the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com