One-way clutch bearing

A technology of one-way clutches and bearings, which is applied in the direction of one-way clutches, clutches, bearings, etc., can solve the problems of unguaranteed product quality, complicated processing technology, and difficult production technology, and achieves wide application range, good processing technology, and structural simple compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

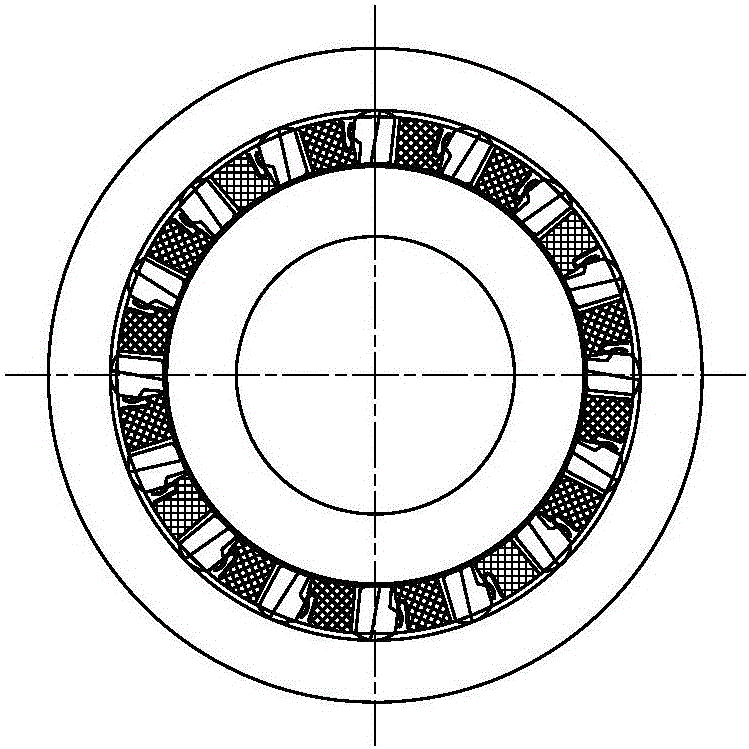

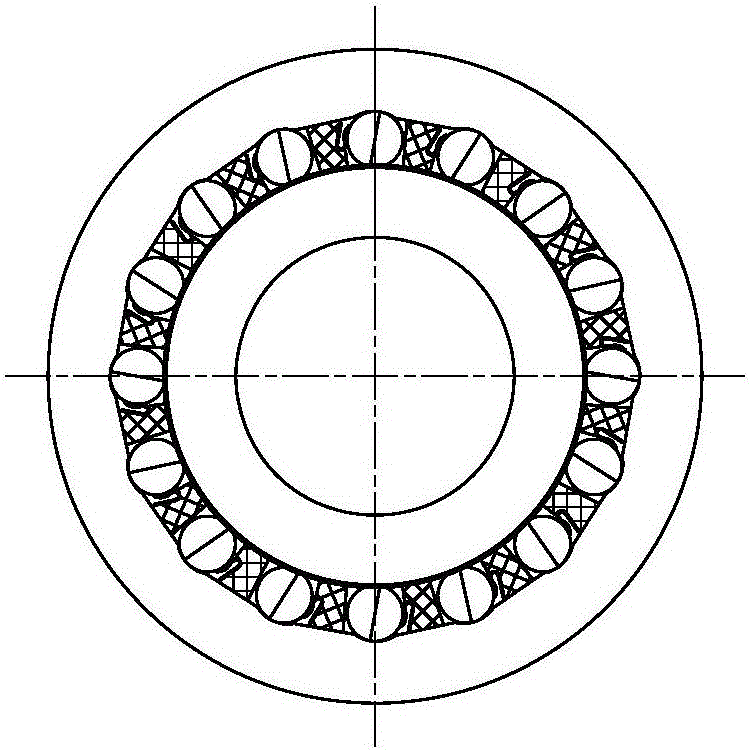

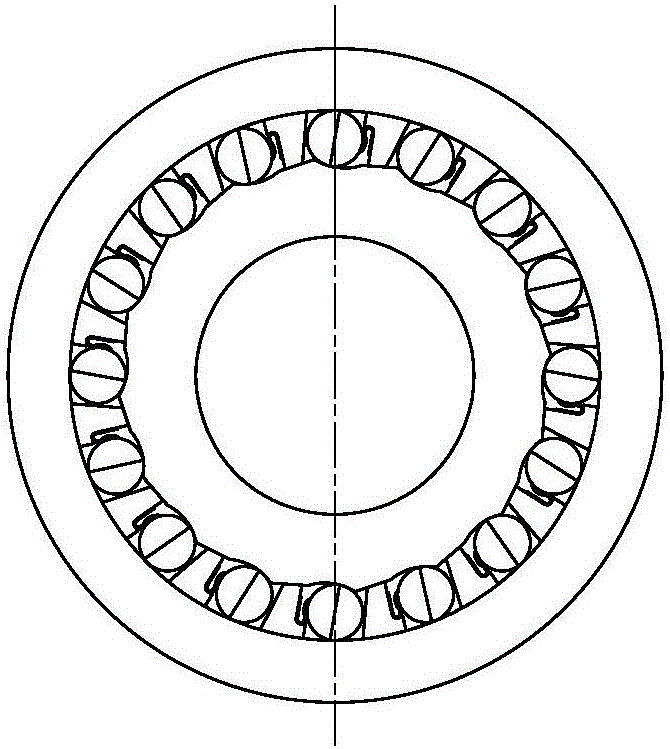

[0023] like Figure 4~Figure 6 As shown, the one-way clutch bearing in the embodiment is mainly composed of an outer ring 1, an inner ring 2 and a rolling support structure arranged between the two. The rolling support structure is mainly composed of a rolling body 3, a rolling body cage 4, The needle roller cage 5 and the needle roller group are composed.

[0024] like Figure 4~Figure 6 As shown, the outer ring 1 and the inner ring 2 are axially divided into a rolling element installation section a and a needle roller installation section b, and rolling element installation sections a are provided with rollers on the inner wall of the outer ring 1 and the outer wall of the inner ring 2 Several rolling elements 3 are arranged in the raceway on the outer ring 1 and the inner ring 2, and the rolling element cage 4 evenly separates the sever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com