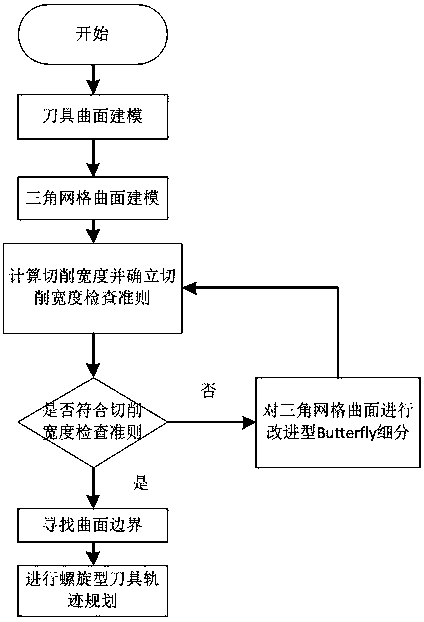

Mesh Freeform Surface Annular Tool Path Planning Method Based on Improved Butterfly Subdivision

A tool path, improved technology, applied in the field of milling, can solve problems such as poor tool path continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

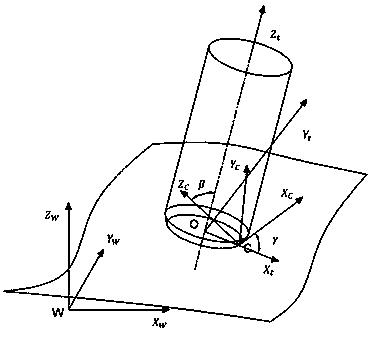

Method used

Image

Examples

Embodiment

[0106] use Figure 7 The triangular mesh model of the face shown is used to verify the circular tool trajectory planning method based on the improved Butterfly subdivision triangular mesh surface. The face STL model contains a total of 879 vertices and 1689 triangular patches. It has concave surface features and convex surface features, and the curvature changes greatly. It can effectively verify the triangular mesh surface ring tool trajectory planning method based on the improved Butterfly subdivision.

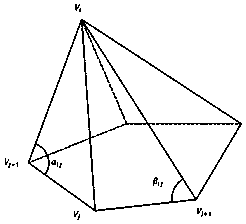

[0107] (1) First, analyze the surface features of the STL model of the face, and first solve the curvature of each vertex of the STL model. Each vertex on the surface and its adjacent vertices form a facet triplet, and each vertex V i The triplet corresponding to the patch pair V i Curvatures are affected at and include the vertex V i The larger the area of the triangle surface, the vertex V i The greater the influence of the curvature, then to contain the vertex V i T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com