Flow-velocity-decreasing multi-drum type film waste plastic recycling method

A waste plastic, drum-type technology, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of complex components, large volume, broken and difficult cleaning and purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

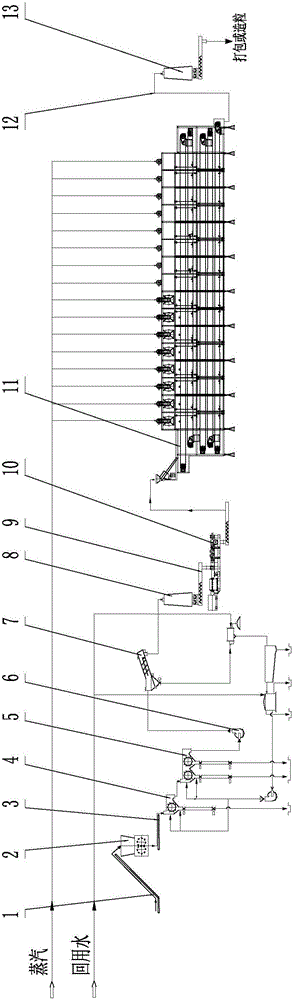

[0056] Example 1: Recycling of agricultural mulch film waste plastics

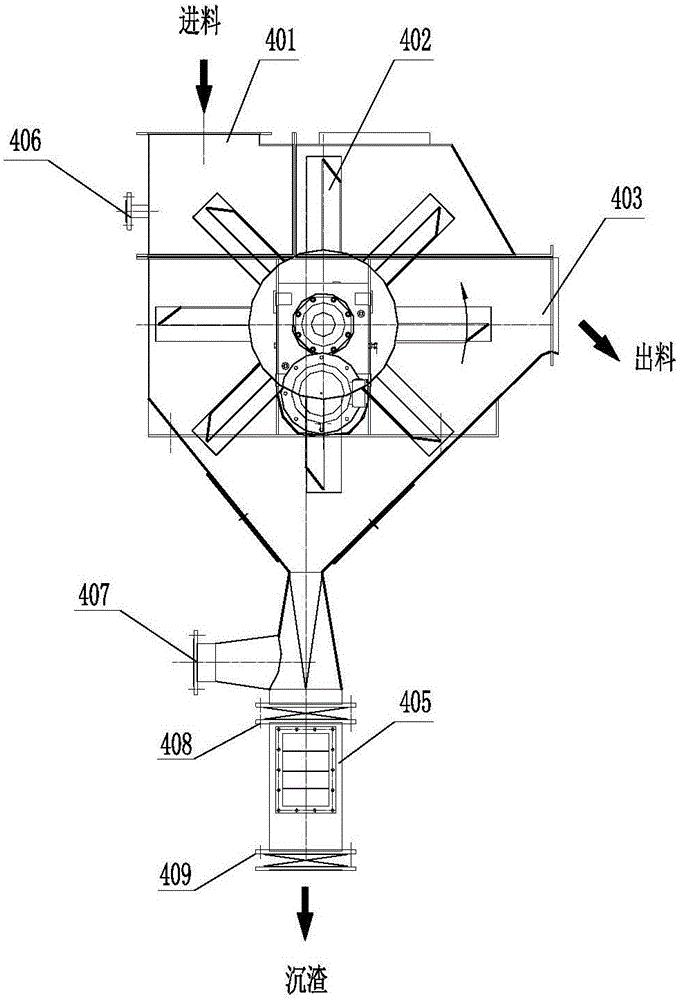

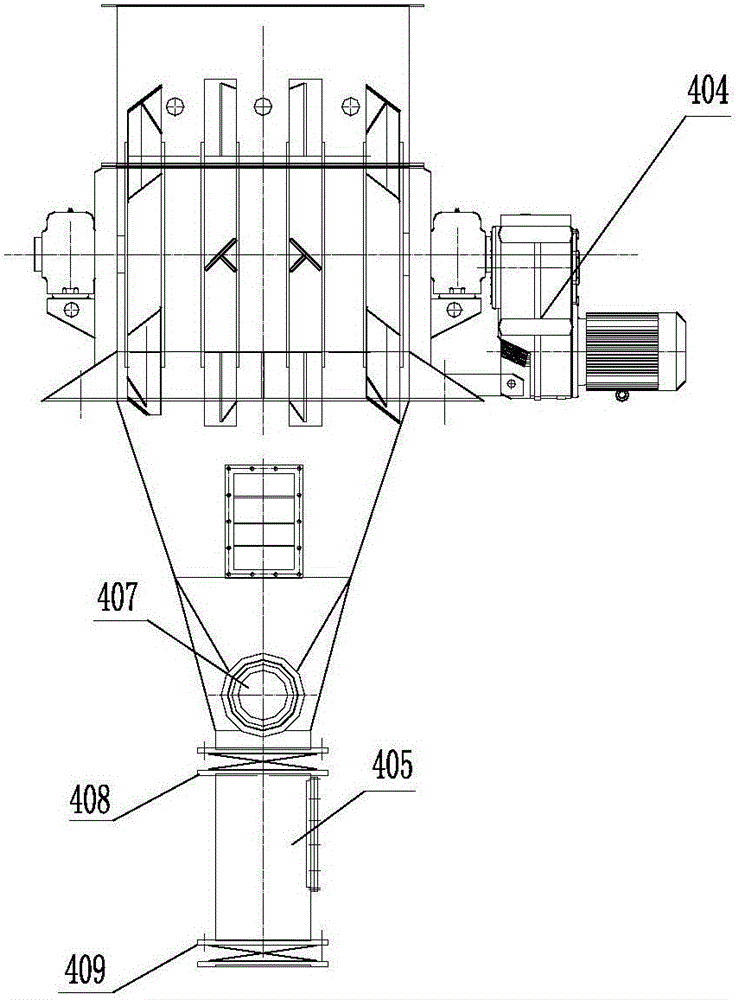

[0057] The materials mainly composed of agricultural film waste plastics are conveyed by the first conveying equipment 1 to the shredder 2, and are crushed into pieces with a side length of 20-50 mm; The drum washing machine 4 washes and removes harmful impurities such as metal objects, stones and sand mixed in the tablet through the sediment pipe, and the sediment enters the solid waste treatment system with a washing concentration of 3%; after washing, the tablet and water flow into the multi-rotation Drum type washing and separating device 5, while injecting washing water from the upper water inlet of the multi-drum type washing and separating device, inject washing water with an upward flow rate of 0.3m / s from each lower water inlet, wash again and separate out the Light impurities, such as paper, etc. Then the plastic tablet and water are pumped together by the tablet pump 6 to the inclined screw deh...

Embodiment 2

[0059] Example 2: Recycling of woven bag waste plastics

[0060] The material mainly consisting of woven bag waste plastics is conveyed to the shredder 2 by the first conveying equipment 1, and is crushed into pieces with a side length of 20-50 mm; then the crushed pieces are conveyed to the Drum washing machine 4 washes and removes harmful impurities such as metal objects, stones and sand particles mixed in the tablet through the sediment pipe, and the sediment enters the solid waste treatment system with a washing concentration of 4%; after washing, the tablet and water flow into multiple Drum type washing and separating device 5, when washing water is injected from the upper water inlet of the multi-drum type washing and separating device, washing water with an upward flow rate of 0.2m / s is injected from each lower water inlet, and the material containing Light impurities, such as paper, etc. Then the plastic tablet and water are pumped together by the tablet pump 6 to the...

Embodiment 3

[0062] Example 3: Recycling and comprehensive utilization of solid waste in paper mills

[0063] The paper mill solid waste materials mainly composed of waste paper, polypropylene, polyethylene and other film-type waste plastics are transported from the first conveying equipment 1 to the shredder 2, and are shredded into pieces with a side length of 20-50 mm; and then The second conveying equipment 3 transports the crushed material to the drum washing machine 4 for washing, and removes harmful impurities such as metal objects, stones and sand mixed in the material through the sediment pipe, and the sediment enters the solid waste treatment system for washing. The concentration is 5%; after washing, the tablet and water flow into the multi-drum washing and separating device 5 together, and the washing water is simultaneously injected from the upper water inlet and each lower water inlet of the multi-drum washing and separating device. In the horizontal conveying direction of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com