Feeding mechanism, cutter cutting assembly and wood shaving machining device

A feeding mechanism and cutting tool technology, which is applied in the field of shaving processing, can solve the problems of low processing efficiency and achieve the effects of prolonging service life, high space utilization and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

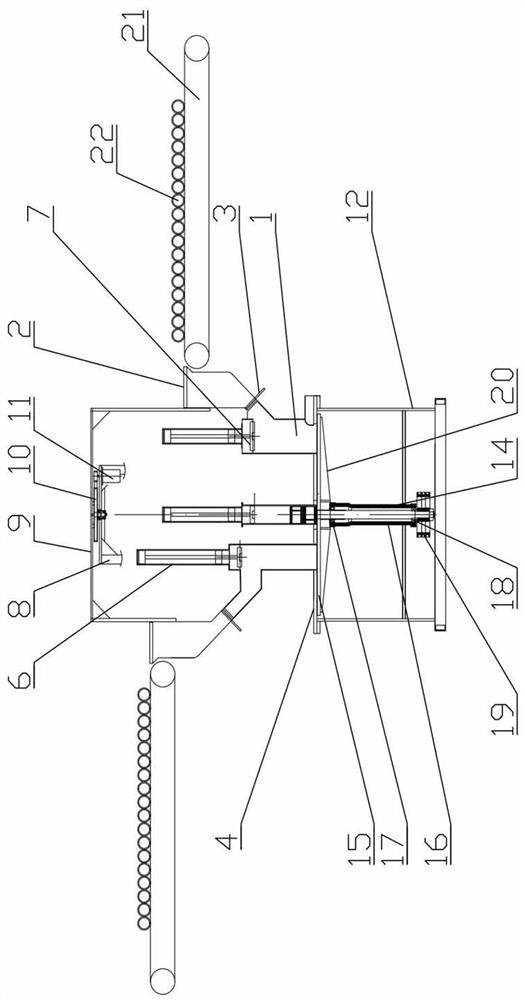

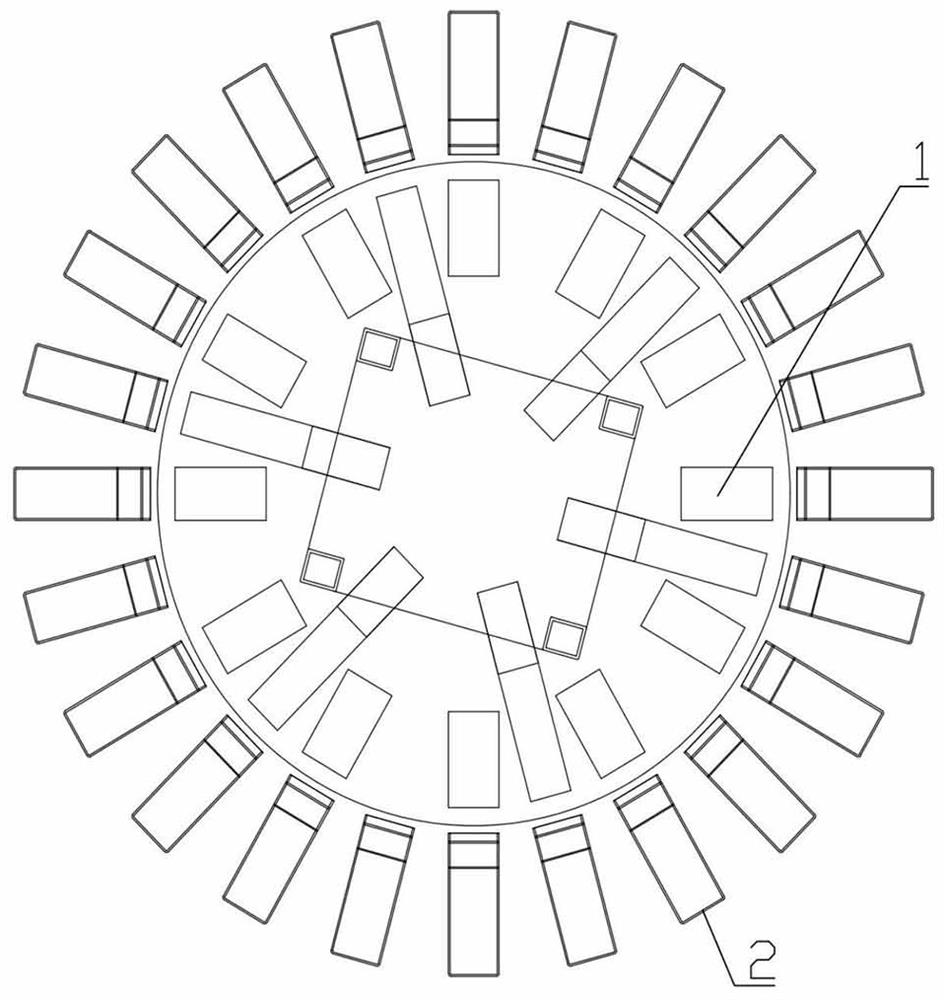

[0039] Embodiment one: as attached Figure 1-3As shown, the feeding mechanism includes a pressing bin 1, a rotating feeding bin 2 and a material baffle 3, and establishes a horizontal reference plane and a reference axis perpendicular to the horizontal reference plane, which are distributed from inside to outside on the outside of the reference axis. There are at least two reference rings, and each reference ring includes at least two reference points spaced around the reference axis along the circumference, and the horizontal reference plane, reference axis, reference ring and reference point are all virtual; corresponding to each Each reference point position is provided with a press bin 1 whose outlet is located at the reference point, the end faces of the outlets of all press bins 1 are located on the horizontal reference plane, and the top of the press bin 1 is provided with a feed port, each A rotary feeding bin 2 is provided at the feeding port, and all the rotating fee...

Embodiment 2

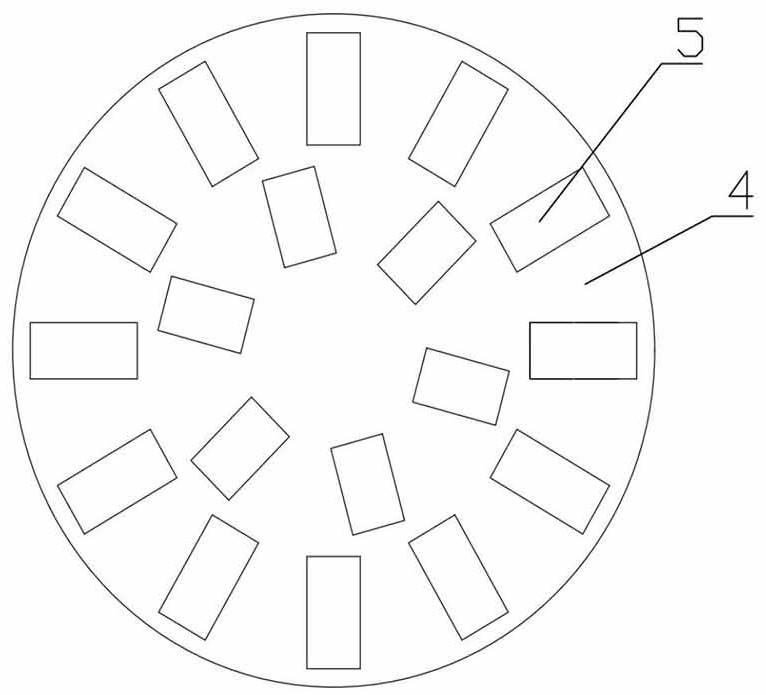

[0051] Embodiment 2: The difference between this embodiment and Embodiment 1 is: as attached Figure 4 As shown, the reference ring has three inner, middle and outer rings. The inner reference ring includes 4 reference points evenly spaced along the circumferential direction, and the middle reference ring includes 8 reference points evenly spaced along the circumferential direction. The reference ring of the outer ring includes 16 reference points evenly distributed along the circumferential direction, that is, the processing opening 5 is also three circles in the inner, middle and outer circles, and the inner ring includes 4 processing openings 5 evenly distributed along the circumferential direction. The ring includes 8 processing openings 5 evenly distributed along the circumferential direction, and the outer ring includes 16 processing openings 5 evenly distributed along the circumferential direction, thereby further increasing the material area that can be planed whe...

Embodiment 3

[0052] Embodiment 3: The difference between this embodiment and Embodiment 1 is that each processing port 5 is provided with a processing port baffle that can be opened and closed. The processing port baffle can cover the processing port 5, and a driving structure capable of reciprocating motion can be selected. For example, a cylinder drive can be selected. The driving of the processing port baffle is controlled according to the position signal of the piston rod of the corresponding pressing cylinder 6. When the position signal When it is in the original position, the processing port baffle covers the processing port 5 to prevent the material from bouncing up due to the contact between the material and the tool. When the position signal is at the original position again, the processing port baffle moves laterally again until covering the processing port 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com