Load simulation test device of oil pumping unit

A technology of load simulation and test device, applied in the direction of measuring device, testing of machine/structural components, instruments, etc., can solve the problem of inability to apply tower pumping units, achieve optimization of structure and control program, improve accuracy, improve The effect of accuracy and real-time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

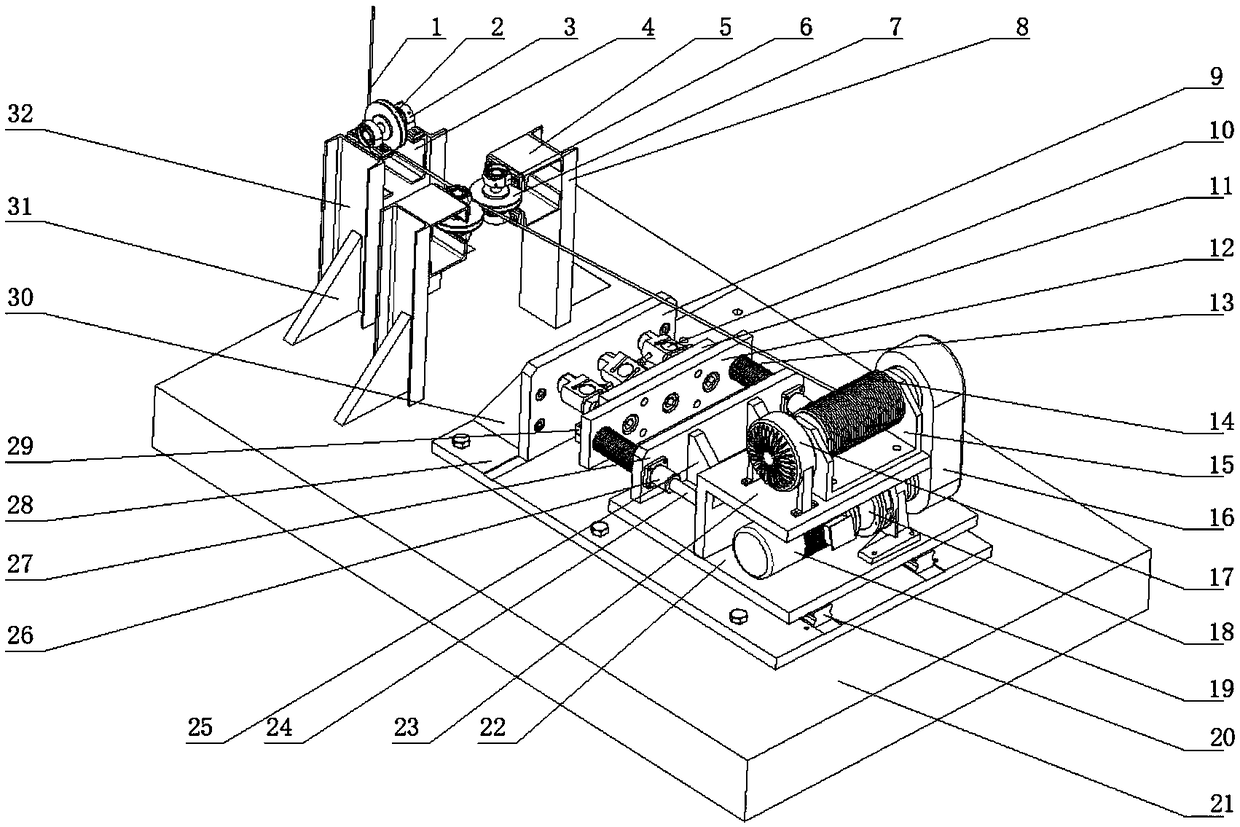

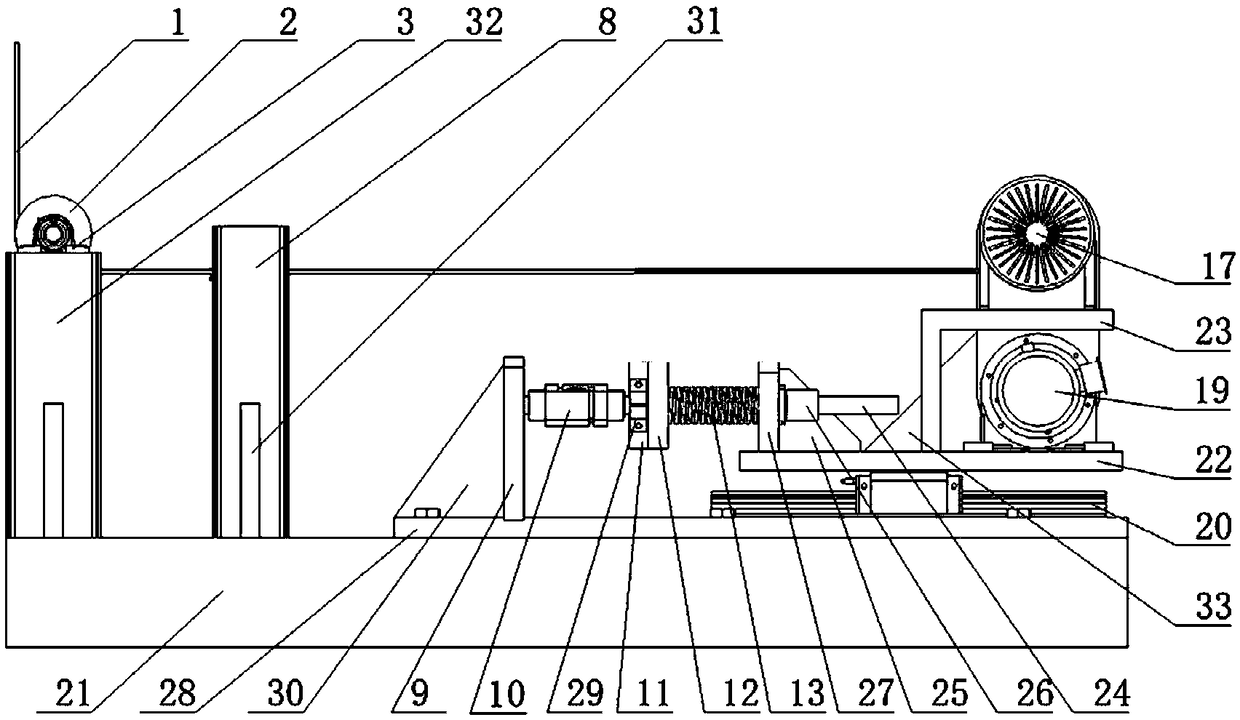

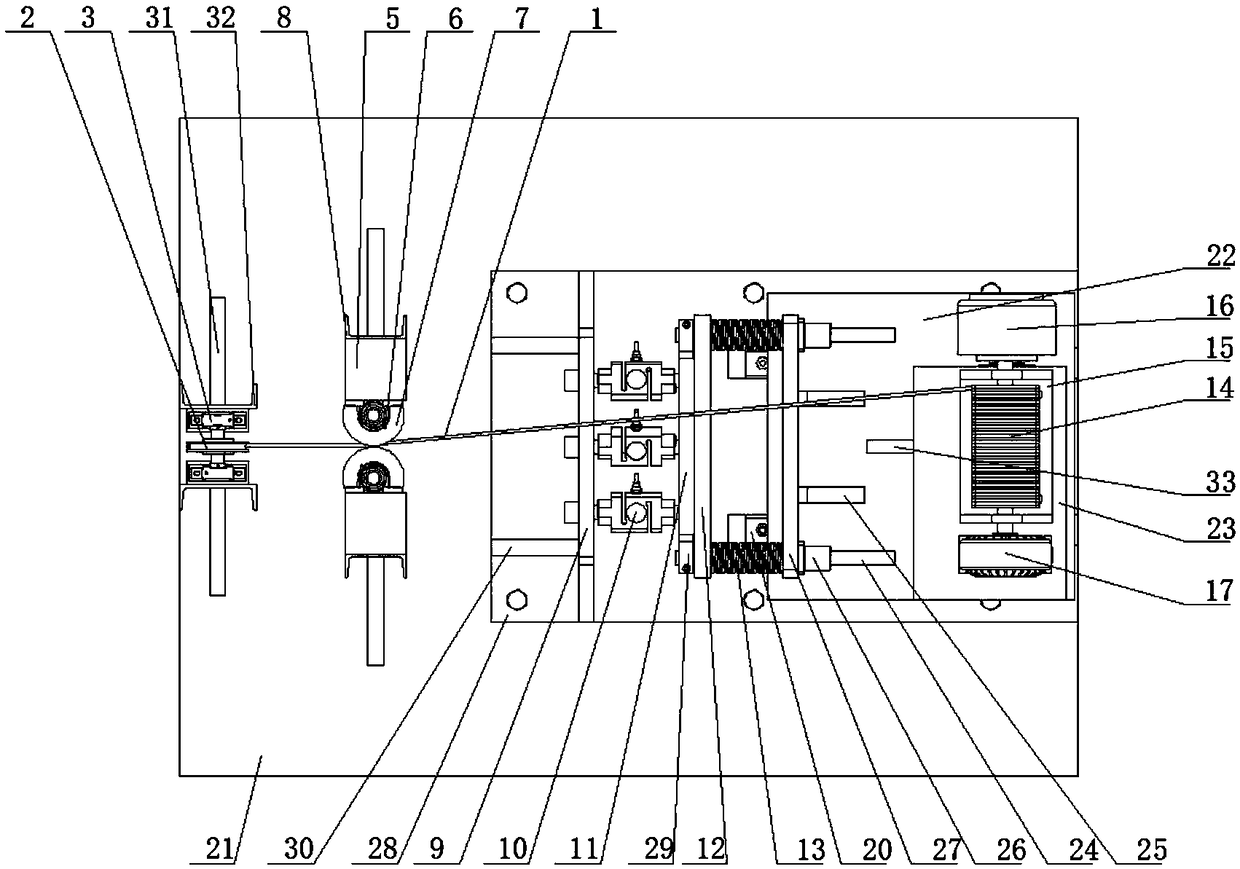

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, a pumping unit load simulation test device includes a control system, a load simulation system, a vibration-damping force-measuring platform, and a load-guiding mechanism.

[0029] The vibration-damping force-measuring platform includes a sensor support vertical plate 9, a load cell 10, a sensor baffle 11, a spring baffle 12, a mold spring 13, a spring floating plate 27, a slide rail plate 22, a linear slide rail assembly 20, and a damper. Vibration force platform bottom plate 28, cylindrical guide rod 24, linear bearing 26, cylindrical guide rod fixed support seat 29.

[0030]The base plate 28 of the vibration-reducing force-measuring platform is fixed on the cast iron platform 21 through bolt connection. The base plate 28 of the vibration-reducing force-measuring platform is processed with milling grooves for installing the sensor support vertical plate 9 and the linear slide rail assembly 20. The sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com