Vibration and centrifugation composite-testing equipment

A kind of test equipment and centrifugal compound technology, which is applied in vibration test, machine/structural component test, measuring device, etc. It can solve the problems of compound test, single vibration or centrifugal test that cannot carry out vibration and centrifugal at the same time, and reduce disadvantages Influence, guaranteed service life, reliable effect of circuit wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

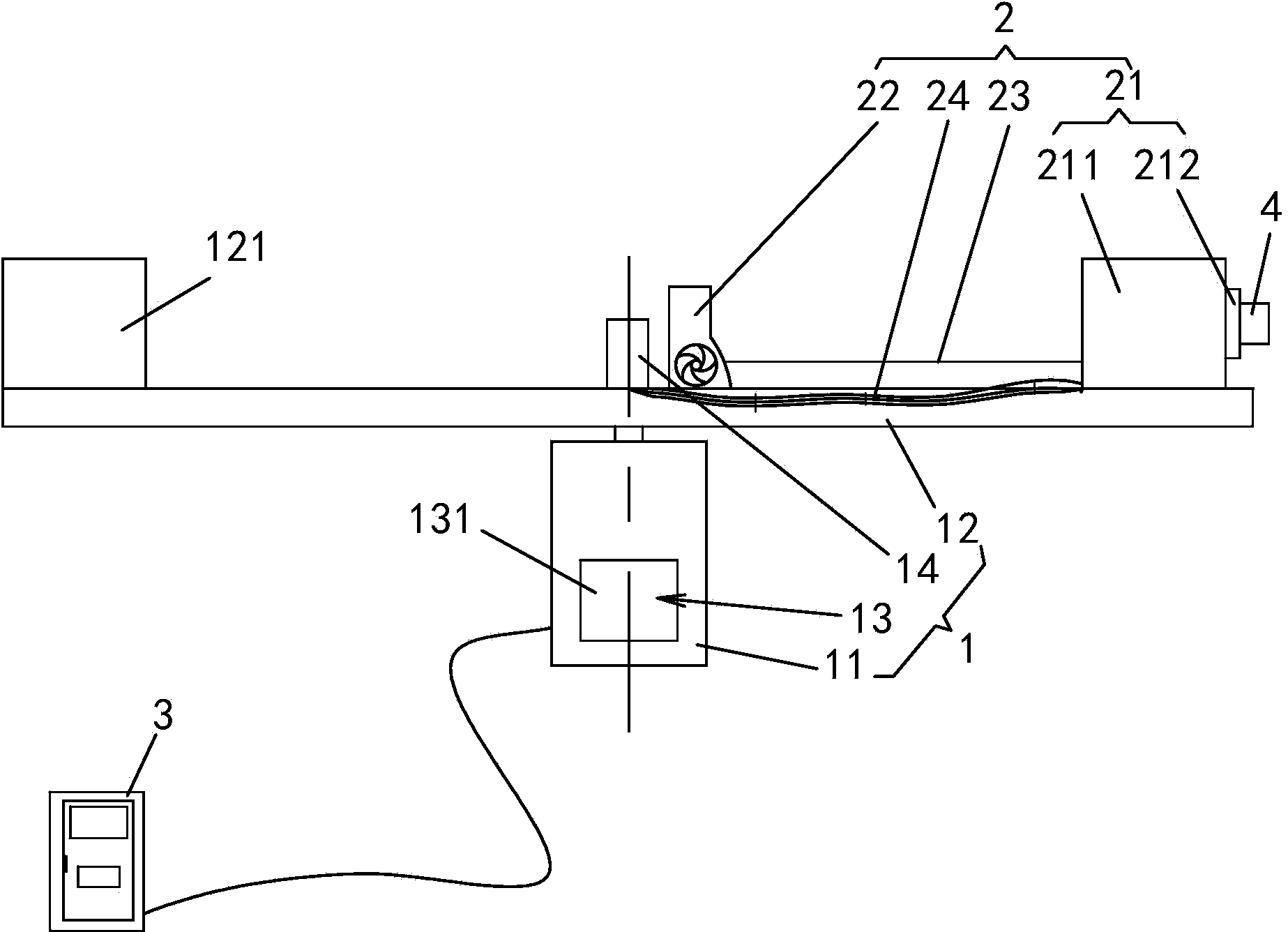

[0017] Example: see figure 1 Shown:

[0018] A vibration and centrifugal compound test equipment includes a centrifuge 1, an air-cooled electric vibration table 2 and an electric control box 3.

[0019] See figure 1 As shown, the centrifuge 1 includes a base 11, on which a rotating arm 12 is arranged in the horizontal direction, and the middle part of the rotating arm 12 is connected to rotate around the vertical direction relative to the base 11; on the rotating arm 12 A driving device 13 acts, and the rotating arm 12 is driven to rotate relative to the base 11 by the driving device 13 . Both ends of the rotating arm 12 extend outward, one end is used as a load end, and the other end is provided with a balance block 121 as a balancing end, and a brush 14 is provided at the rotation center of the rotating arm 12 .

[0020] The driving device 13 can adopt various power devices for driving rotation, and the preferred driving device 13 is composed of a motor 131 and a gear set...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com