Acoustic shielding backing plate and concrete thereof

A sound barrier and concrete technology, which is applied in construction, noise absorption devices, etc., can solve problems such as noise pollution, the inability to arrange steel bars on the back panel, large fluctuations in product size and performance, etc., and achieve high safety, enhanced support stability and Excellent sound insulation effect and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

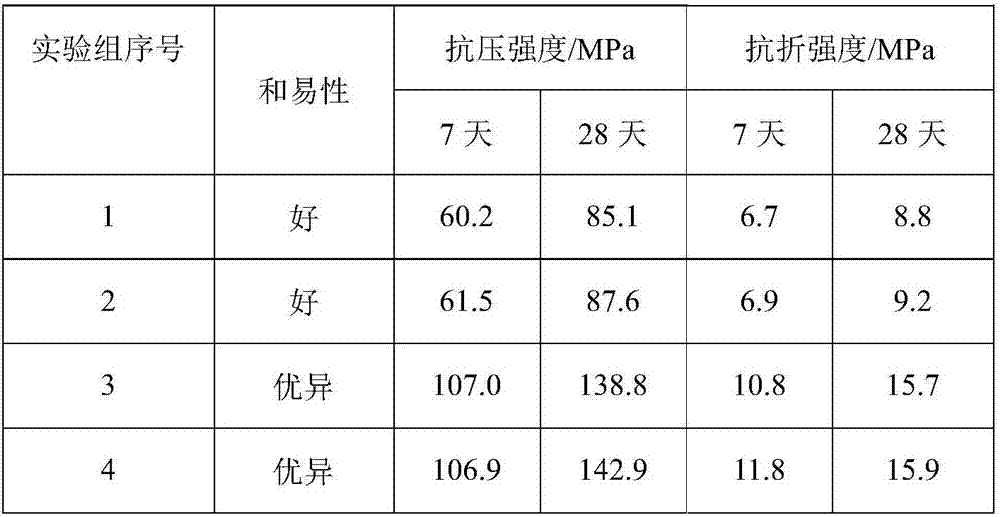

[0030] This embodiment provides a concrete for the sound barrier backboard, the raw materials of which include 15 parts of salt cement, 40 parts of stone, 20 parts of natural sand, 10 parts of admixture, 0.5 part of steel fiber, and polycarboxylate superplasticizer 0.05 parts, 0.05 parts of water-retaining agent, 0.05 parts of retarder, 0.05 parts of early strength agent, 0.08 parts of toughening agent, 0.02 parts of efflorescence inhibitor, and 0.2 parts of expansion agent;

[0031] The structure of the sound barrier backboard 100 prepared in this embodiment is as follows:

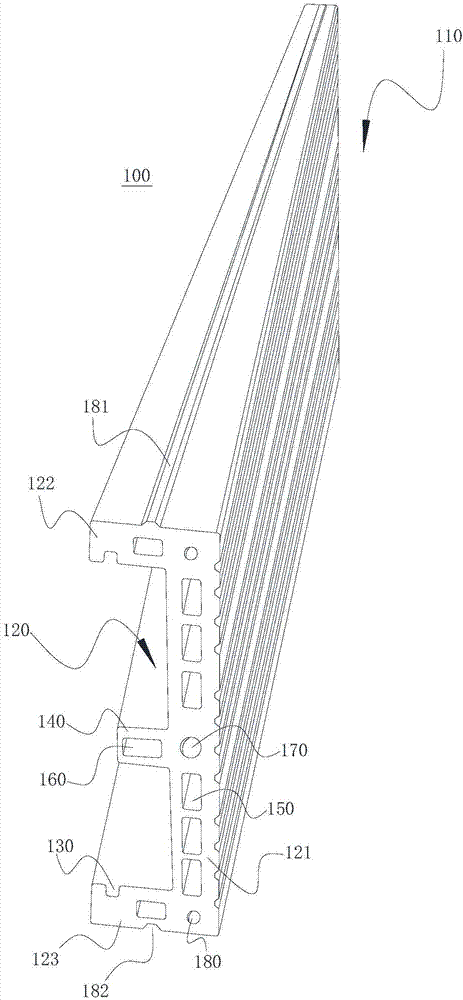

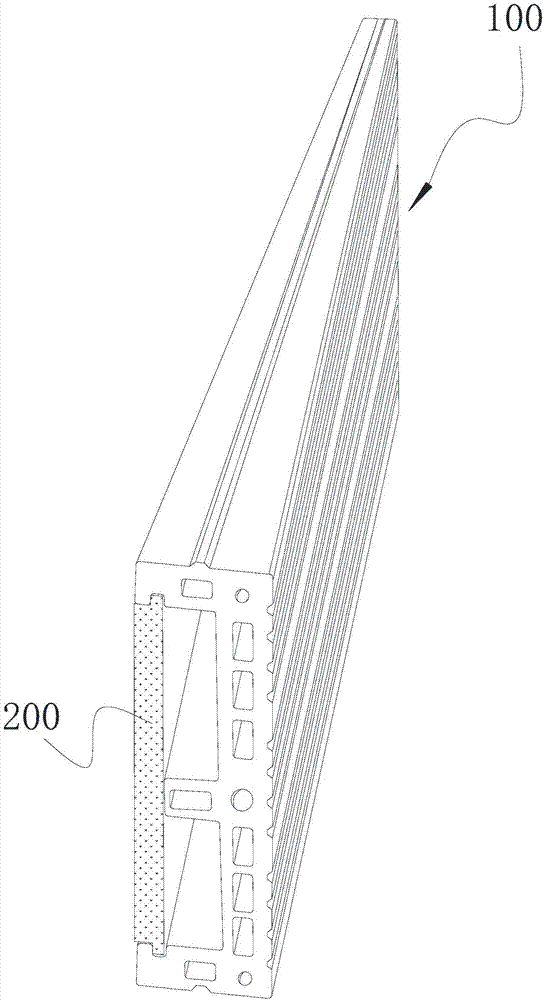

[0032] as attached figure 1 And attached figure 2 As shown, a strip-type backplane body 110 is included. In this embodiment, in consideration of reducing its own weight, preferably, the backplane body 110 is provided with a sound insulation groove 120, and the location of the sound insulation groove 120 is not specifically limited, as preferably, the sound insulation groove 120 is arranged along the ba...

Embodiment 2

[0040] This embodiment provides a concrete for the sound barrier backboard, the raw materials of which include 15 parts of sulphoaluminate cement, 60 parts of ceramsite, 30 parts of machine-made sand, 15 parts of admixture, 3 parts of polypropylene fiber, polycarboxylic acid 0.5 parts of high-efficiency superplasticizer, 0.5 parts of water-retaining agent, 0.1 part of retarder, 0.25 parts of early strength agent, 0.05 parts of toughening agent, 0.02 parts of efflorescence inhibitor, and 0.08 parts of expansion agent;

[0041] For the structure of the sound barrier backboard 100 prepared in this embodiment, please refer to Embodiment 1.

Embodiment 3

[0043] This embodiment provides a concrete for a sound barrier backboard, the raw materials of which include 12 parts of magnesite cementitious material, 50 parts of ceramsite, 25 parts of vitrified microspheres, 12 parts of admixture, 2 parts of lignin fiber, 0.25 parts of carboxylic acid superplasticizer, 0.25 parts of water-retaining agent, 0.1 part of retarder, 0.25 parts of early strength agent, 0.05 part of toughening agent, 0.02 part of efflorescence inhibitor, and 0.08 part of expansion agent;

[0044] For the structure of the sound barrier backboard 100 prepared in this embodiment, please refer to Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com