Automobile longitudinal beam inner plate assembly

A technology for automobile longitudinal beams and longitudinal beams, which is applied to vehicle components, substructures, transportation and packaging, etc., can solve the problems of poor energy absorption, insufficient strength, and high cost, and can reduce the acceleration peak and avoid serious problems. The effect of bending and improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with accompanying drawing.

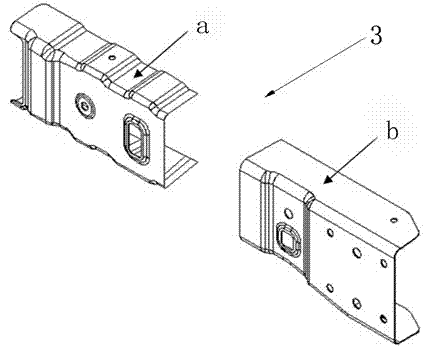

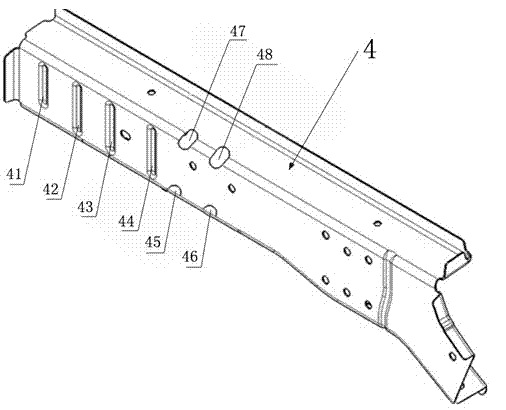

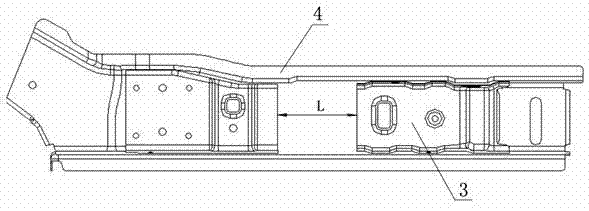

[0019] Such as figure 1 , figure 2 , image 3 As shown, the existing longitudinal beam inner panel assembly includes the existing reinforcement 3 and the existing longitudinal beam inner panel 4, the existing reinforcement 3 is connected to the inner side of the existing longitudinal beam inner panel 4 by bolts, and the existing longitudinal beam inner panel 4 The upper end of the beam inner plate 4 is connected with the wheel cover, and the lower end is connected with the suspension mounting plate. The existing reinforcing member 3 consists of two parts a and b. When they are connected to the inner side of the stringer, there is a distance L of tens of millimeters between the two parts. When a collision occurs, bending deformation is likely to occur at this place, thus Affecting the energy absorption of the front section of the longitudinal beam, four existing longitu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com