Light roller cage ear with gas spring hydraulic damper

A technology of hydraulic damping and gas spring, applied in the direction of spring, spring/shock absorber, shock absorber, etc., can solve problems such as easy oil leakage, difficult replacement of wear-resistant rollers, and large impact of shock absorber on tank road, etc., to achieve Prevent the wear-resistant roller and the hub from sliding relative to each other, replace the wear-resistant roller conveniently and quickly, and overcome the inconvenience of mechanical adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment is preferentially used in low-load working conditions.

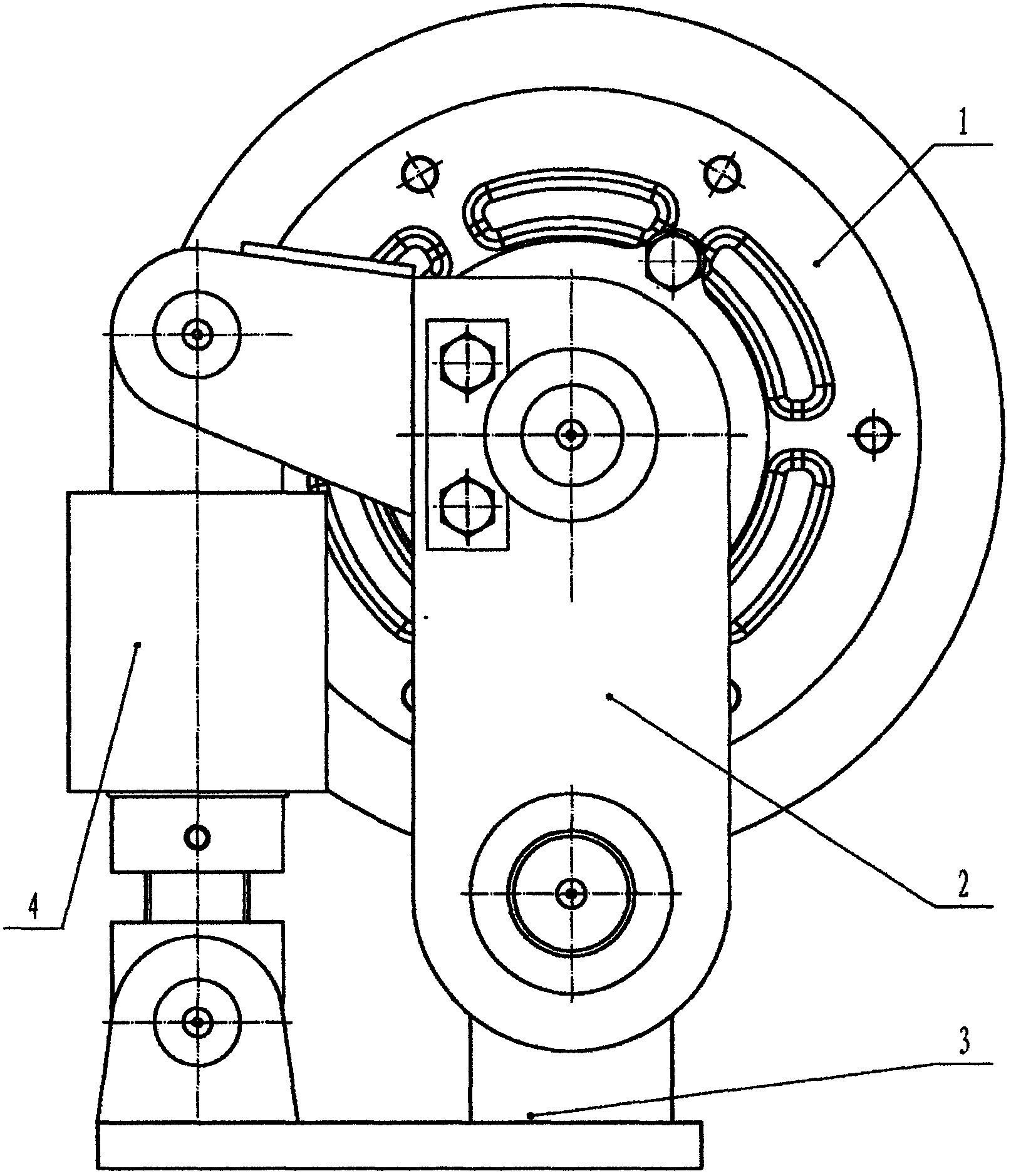

[0053] A gas spring hydraulic damping light-duty roller tank lug is composed of a base (3), a bracket (2), and a shock absorber (4) hingedly connected, and a roller assembly (1) is installed on the bracket (2).

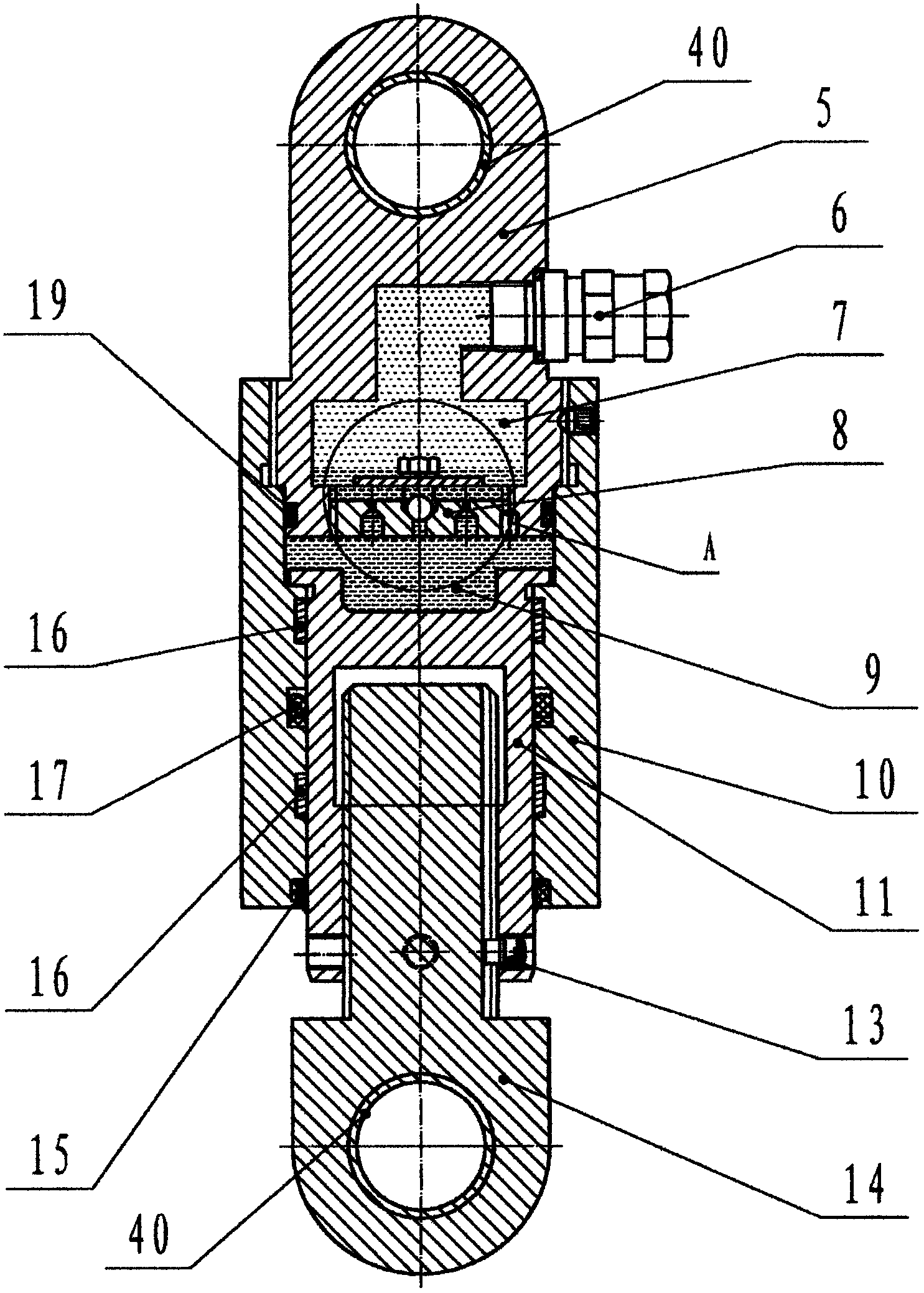

[0054] Shock absorber (4) is made of cylinder body (18), shock-absorbing damping valve (8), plunger (11) and sealing device, and cylinder body (18) is positioned at the top during work, and plunger (11) is positioned at the bottom, and damping The air chamber (7) of the vibrator (4) is located inside the cylinder head above the cylinder body (18), and an air charging valve (6) is installed on the upper part of the air chamber (7). The damping valve (8) is mechanically connected and fixed above the interior of the cylinder (18) and below the air chamber (7), the plunger (11) is located below the interior of the cylinder (18), and is connected to the cylinder ( 10) The inner cylindrical hol...

Embodiment

[0068] This embodiment is preferentially used in high-speed, heavy-load, and high-load working conditions.

[0069] In this embodiment, the cylinder body is an integral cylinder body, and the blank can be formed by casting or by welding a cylinder head and a cylinder barrel. In order to realize the installation of the plunger, a different downstroke limit method is adopted from that in Example 1. In order to meet the requirements of high working pressure and low leakage of the system, a step seal is added to the sealing device, and a shock-absorbing damping method is exemplified. For the valve solution, the hub adopts a cast aluminum hub, and the other technical solutions are the same as in Embodiment 1.

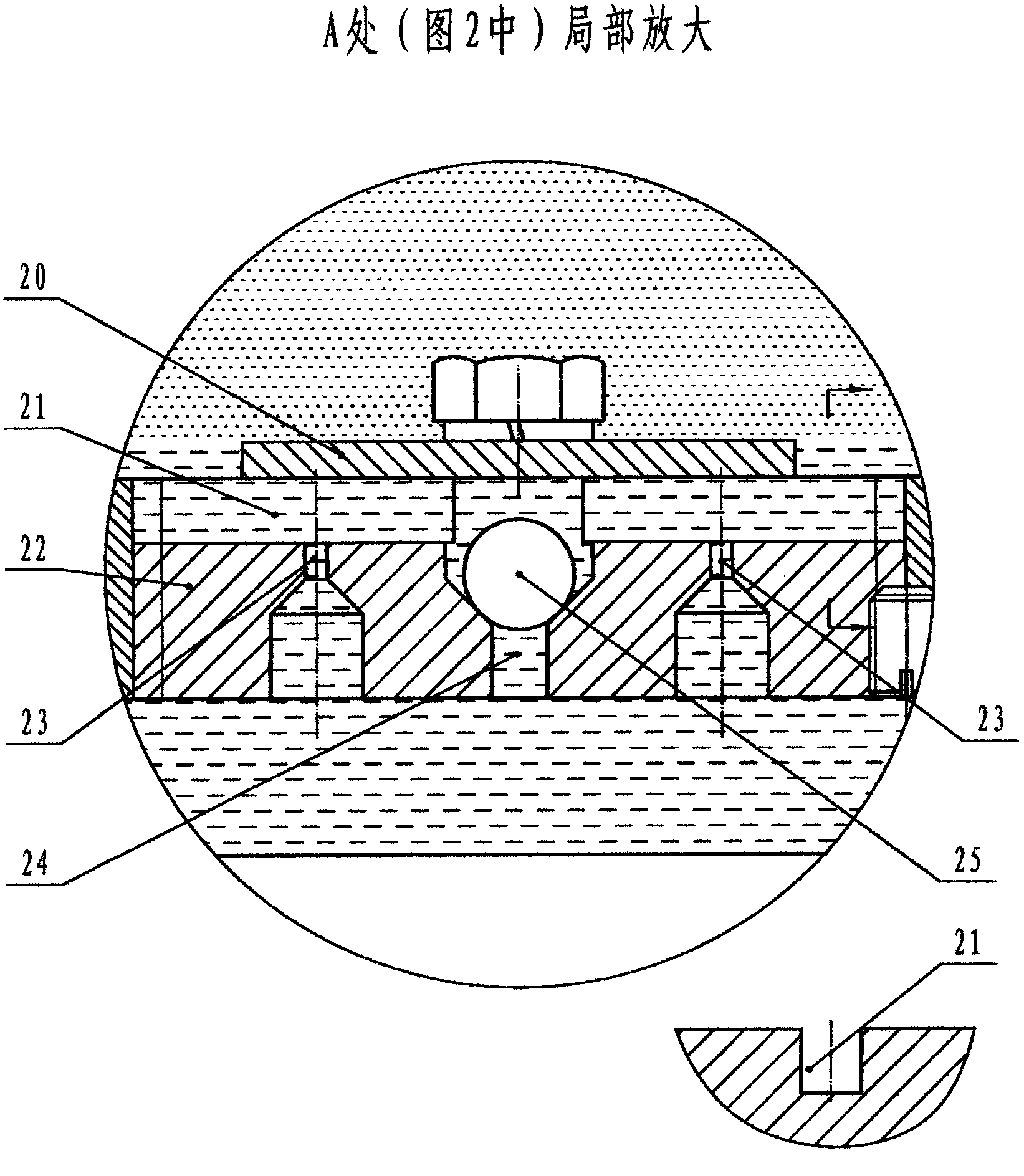

[0070] The damping damping valve (8) is constituted in the following manner: the damping damping valve comprises a disc valve body (22) a one-way valve valve plate (35), and a guide post (37) is formed, and the guide post (37) is mechanically connected and fixed on the circl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com