Composite fireproof honeycomb panel

A technology of composite materials and honeycomb panels, which is applied in the field of composite material refractory honeycomb panels, can solve the problems of affecting structural performance, poor fire resistance, and easy fires, and achieves the effects of low heat release rate, good flame retardancy, and not easy to fire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following descriptions are only preferred embodiments of the present invention, and do not limit the scope of the present invention.

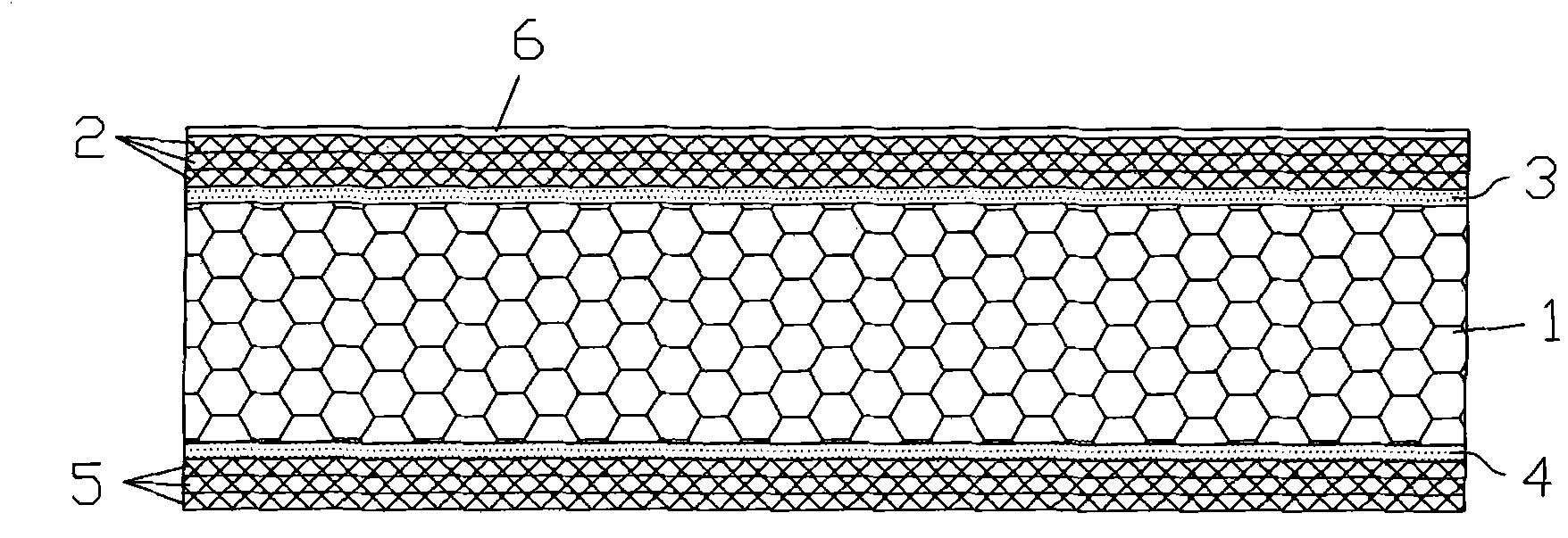

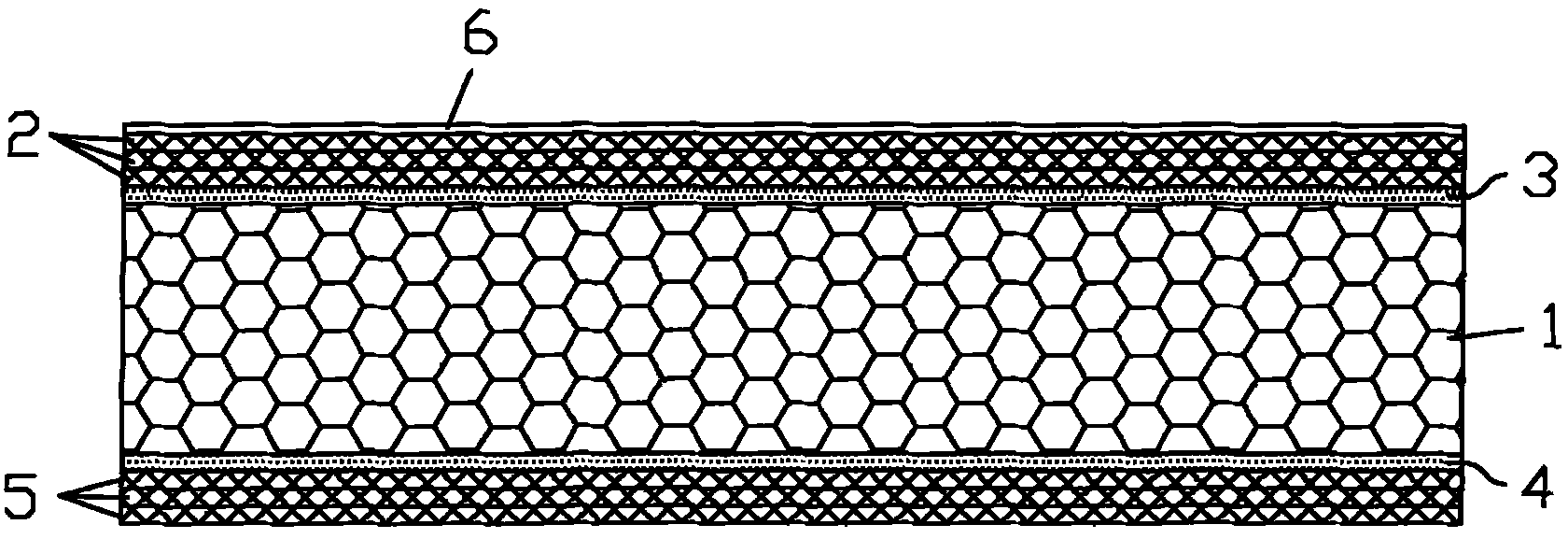

[0018] Examples, see attached figure 1 A composite fire-resistant honeycomb panel, including a honeycomb core 1, the upper surface of the honeycomb core is fixed with an upper flame-retardant layer 2. A wear-resistant layer 6 is coated on the upper flame retardant layer.

[0019] The upper flame-retardant layer is bonded and fixed by the adhesive layer 3 and the honeycomb core.

[0020] The upper flame retardant layer is composed of one or more layers of glass fiber fabric or asbestos.

[0021] The lower surface of the honeycomb core is fixed with a lower flame retardant layer 4 .

[0022] The lower flame-retardant layer is bonded and fixed by the adhesive layer 5 and the honeycomb core.

[0023] The lower flame retardant layer is composed of one or more layers of glass fiber fabric or asbestos.

[0024] The honeycomb core is an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com