Environment-friendly heat-insulation building block

A technology for thermal insulation blocks and construction, which is applied in the direction of construction, building materials, building components, etc. It can solve the problems of reducing construction efficiency of construction workers and poor thermal insulation effect of thermal insulation blocks, and achieves convenient construction, extended length, and increased thermal insulation performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

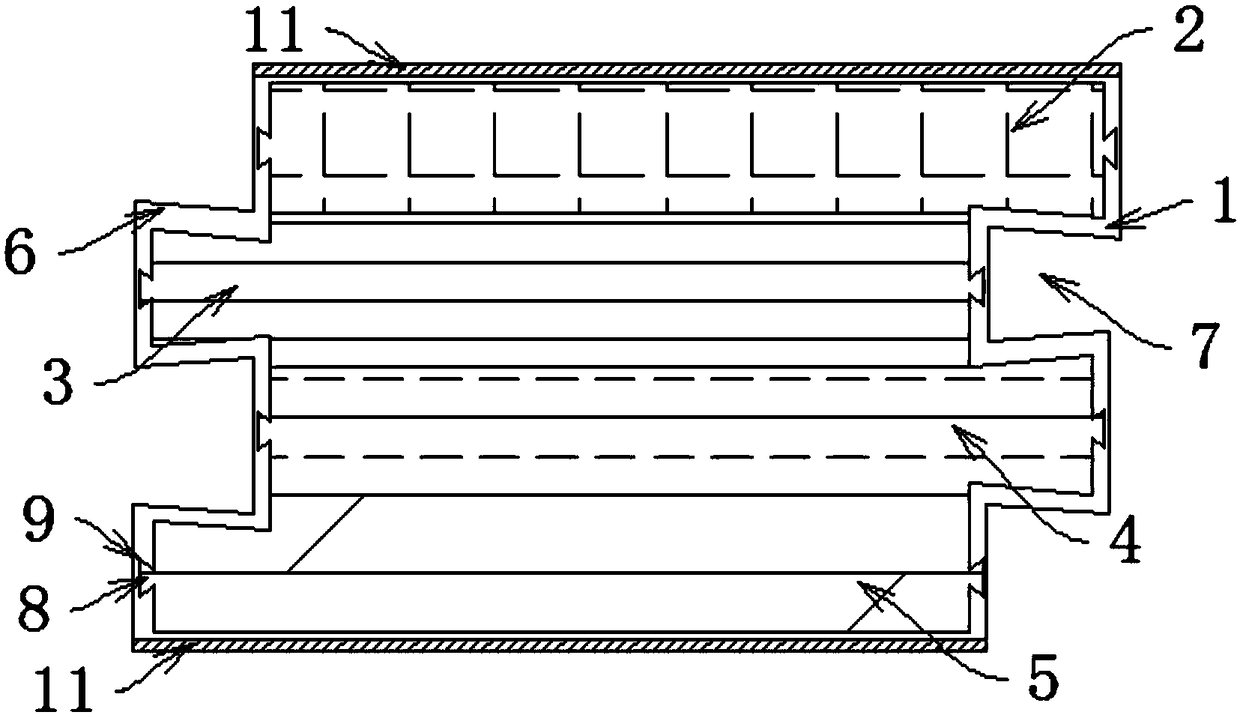

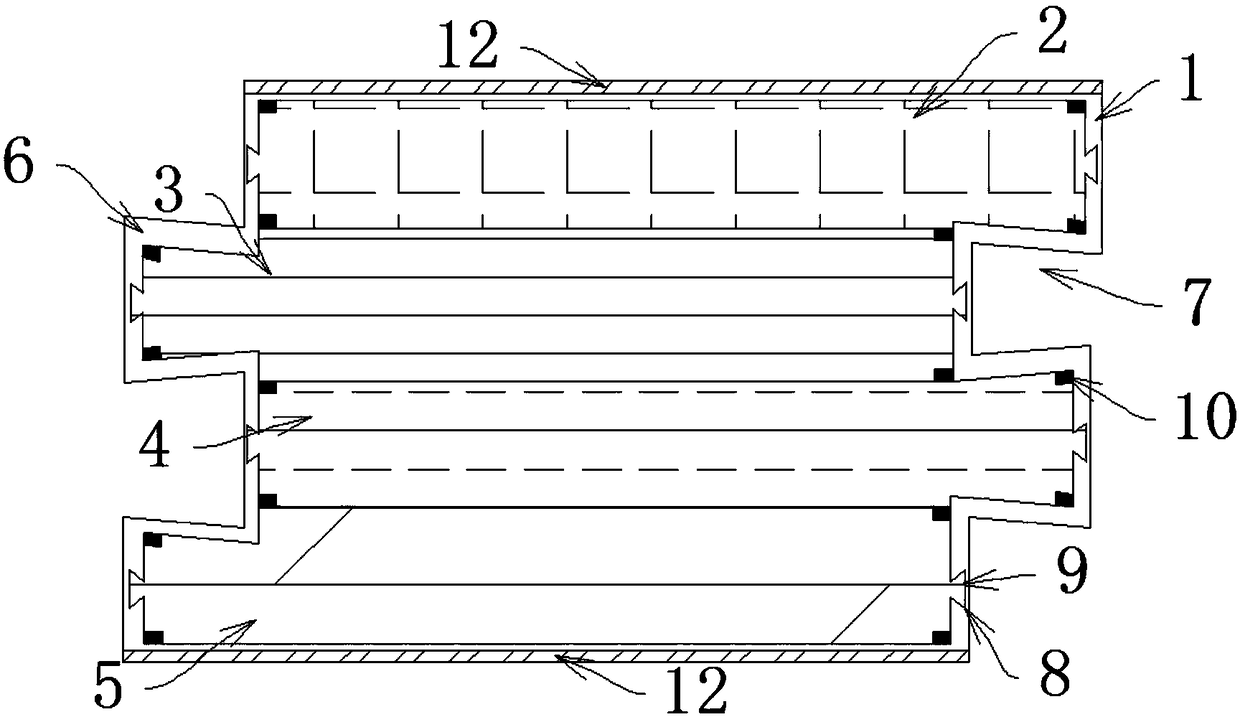

[0016] An environmentally friendly thermal insulation block for construction, comprising a block body 1, characterized in that the left and right end surfaces of the brick body 1 are in a zigzag structure, and the convex parts and concave parts of the left and right end surfaces of the brick body 1 correspond to each other, so that The inside of the brick body 1 forms a zigzag cavity formed by several rectangular staggered arrangements, and each of the rectangular cavities is sequentially installed with a thermal insulation board 2, a sound insulation board 3, a fireproof board 4, and a waterproof board 5. Each of the functional boards is flexibly connected to the cavity wall inside the brick body 1 through a connection structure, and the left and right ends of the heat preservation board 2, sound insulation board 3, fireproof board 4 and waterproof board 5 are provided with a second Two dovetail-shaped bumps 8, the cavity walls at the left and right ends of the brick body 1 ar...

Embodiment 2

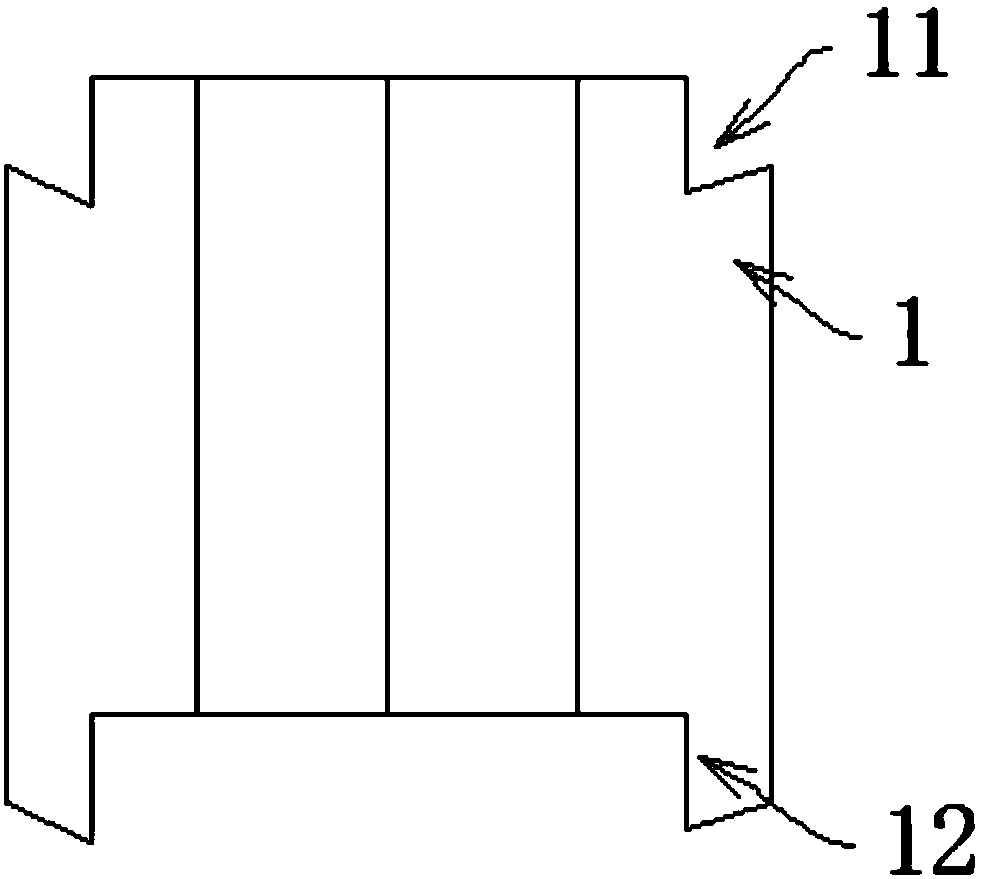

[0019] The convex part formed on the left and right end surfaces of the brick body 1 is the first dovetail-shaped bump 6, and the concave part formed on the left and right end surfaces of the brick body 1 is the first dovetail that matches the first dovetail-shaped bump 6. Reinforcing ribs are embedded inside the front and rear end faces of the brick body 1, and positioning devices are provided on the front and rear end faces of the brick body 1, and the positioning device includes a The positioning groove 11 formed by the depression and the positioning piece 12 formed by protruding downward from the lower end of the front and rear end faces of the brick body 1 and matching the positioning groove 11, the positioning groove 11 and the positioning piece 12 are both Ladder structure.

[0020] During the stacking process, the first dovetail-shaped protrusions 6 on the left and right end faces of adjacent blocks cooperate with the first dovetail-shaped grooves 7, and the positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com