Fabricated light steel structure residential building system

A light steel structure and residential building technology, applied in the direction of buildings, building components, building structures, etc., can solve the problems of insufficient load-bearing capacity, unsuitable for high-floor residences, etc., to achieve increased load-bearing capacity, low cost, and increased load-bearing effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

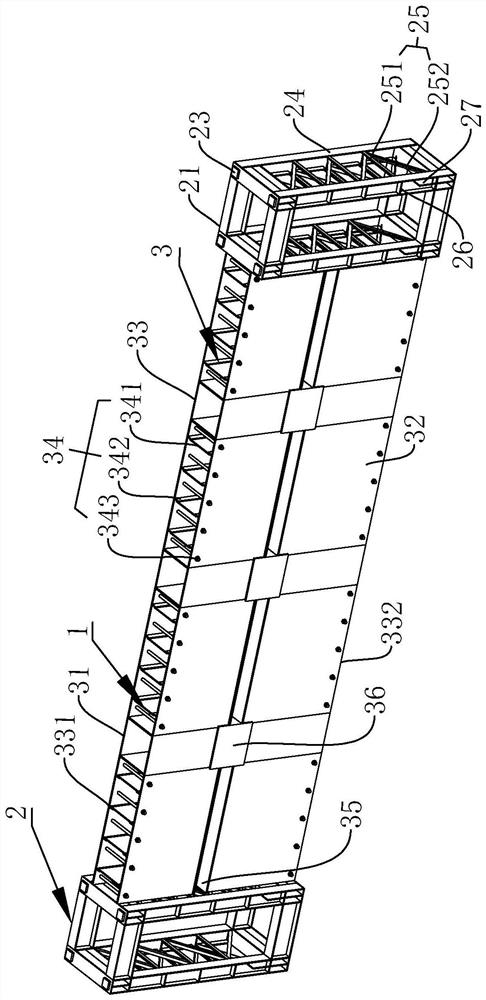

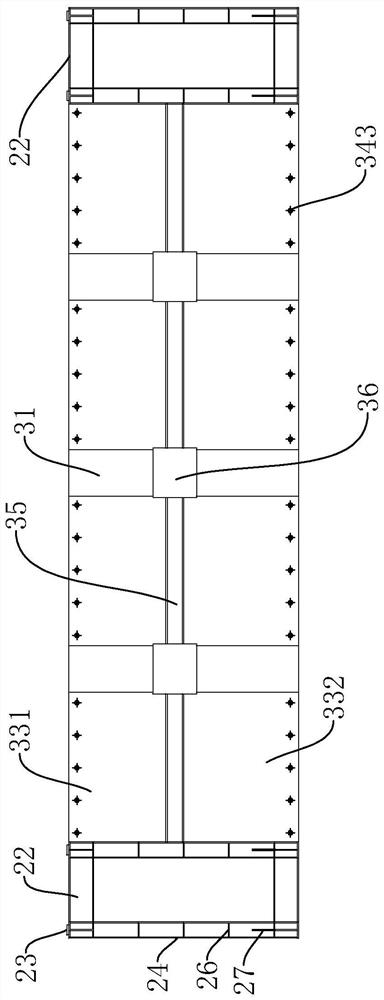

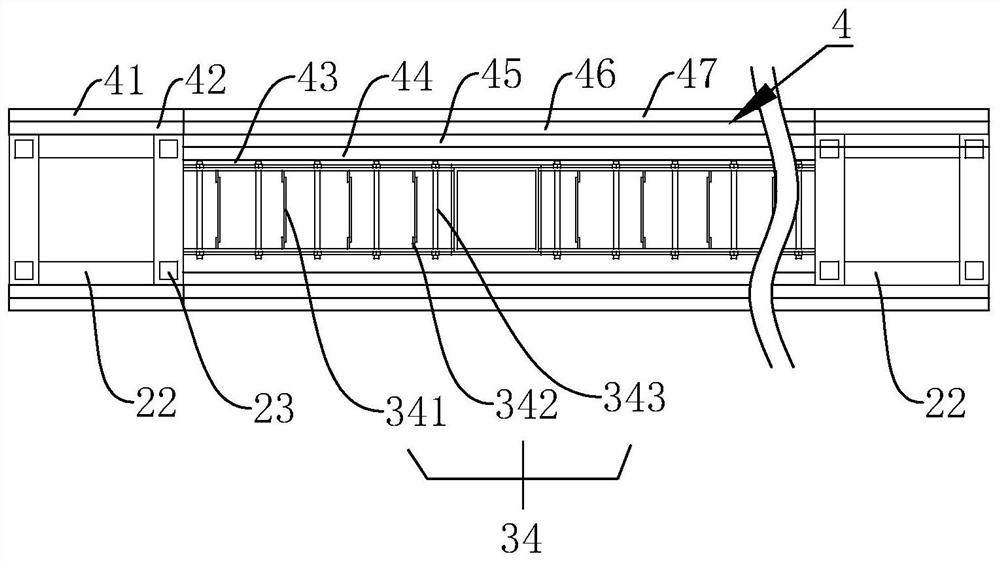

[0040] Such as figure 1 As shown, the present invention provides a prefabricated light-steel structure residential building system, including multi-layer floors stacked on the concrete foundation, each floor is assembled by horizontal floor slabs (not shown in the figure) and vertical walls 1 become. The present invention mainly aims at the problem that the existing prefabricated light steel structure houses have poor load-bearing capacity, and the height of the whole light steel structure houses generally does not exceed 10 meters, and adopts a structure with stronger load-bearing capacity, so that the assembly The type light steel structure residence can be applied to small high-rise residences.

[0041] The present invention mainly improves the structure of the vertical wall 1 to make its load-bearing capacity stronger. Specifically, the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com