Dual flush device for toilet water tank

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

The First Embodiment

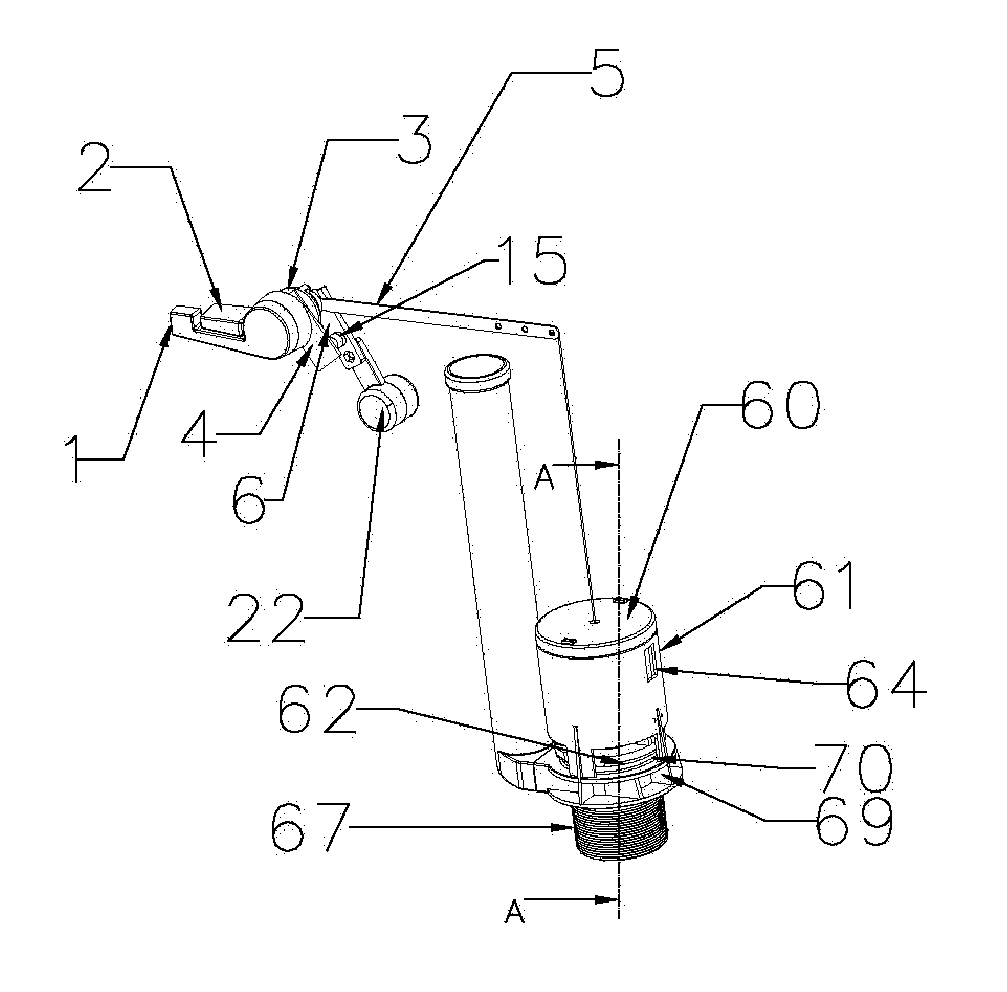

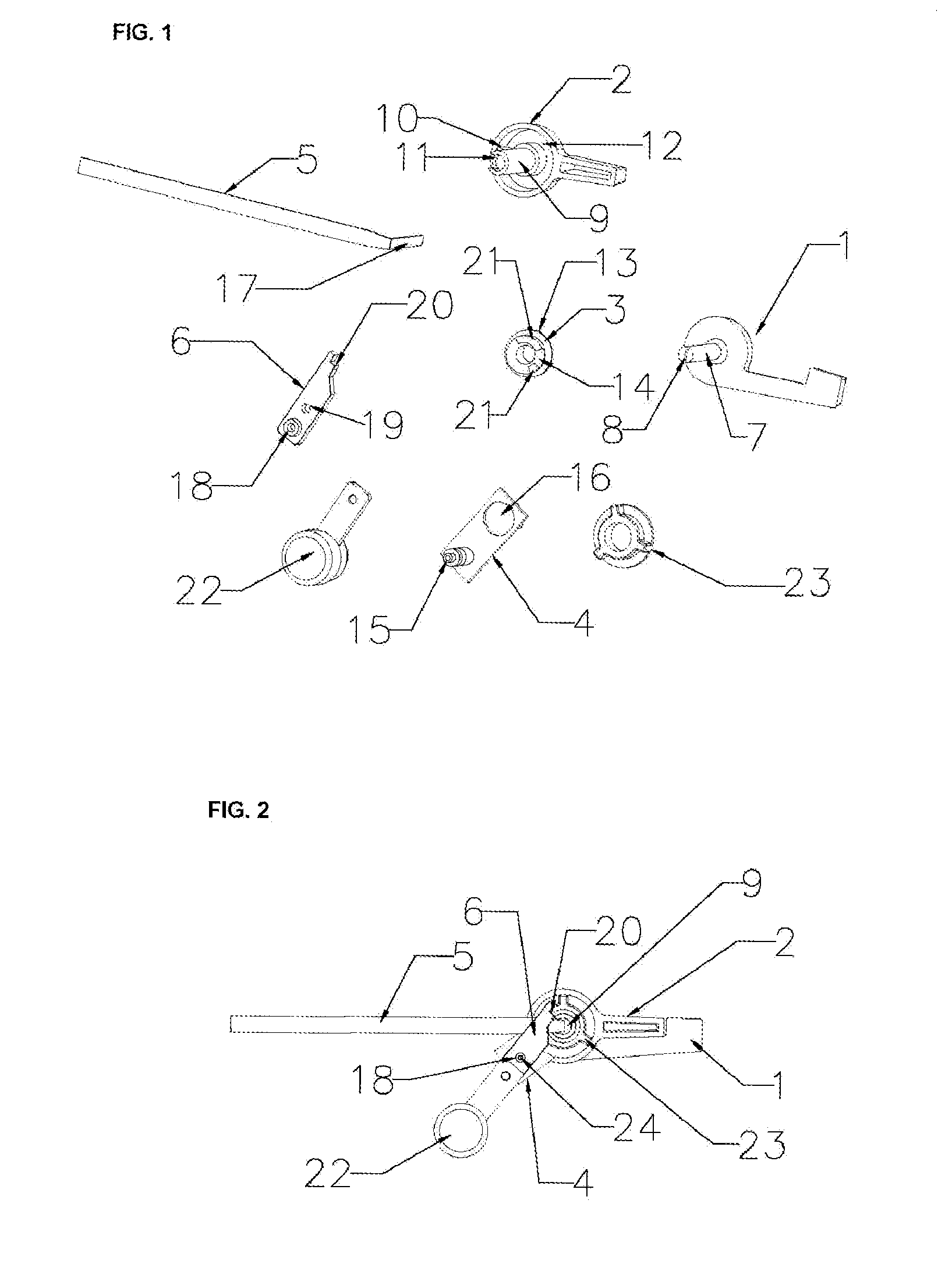

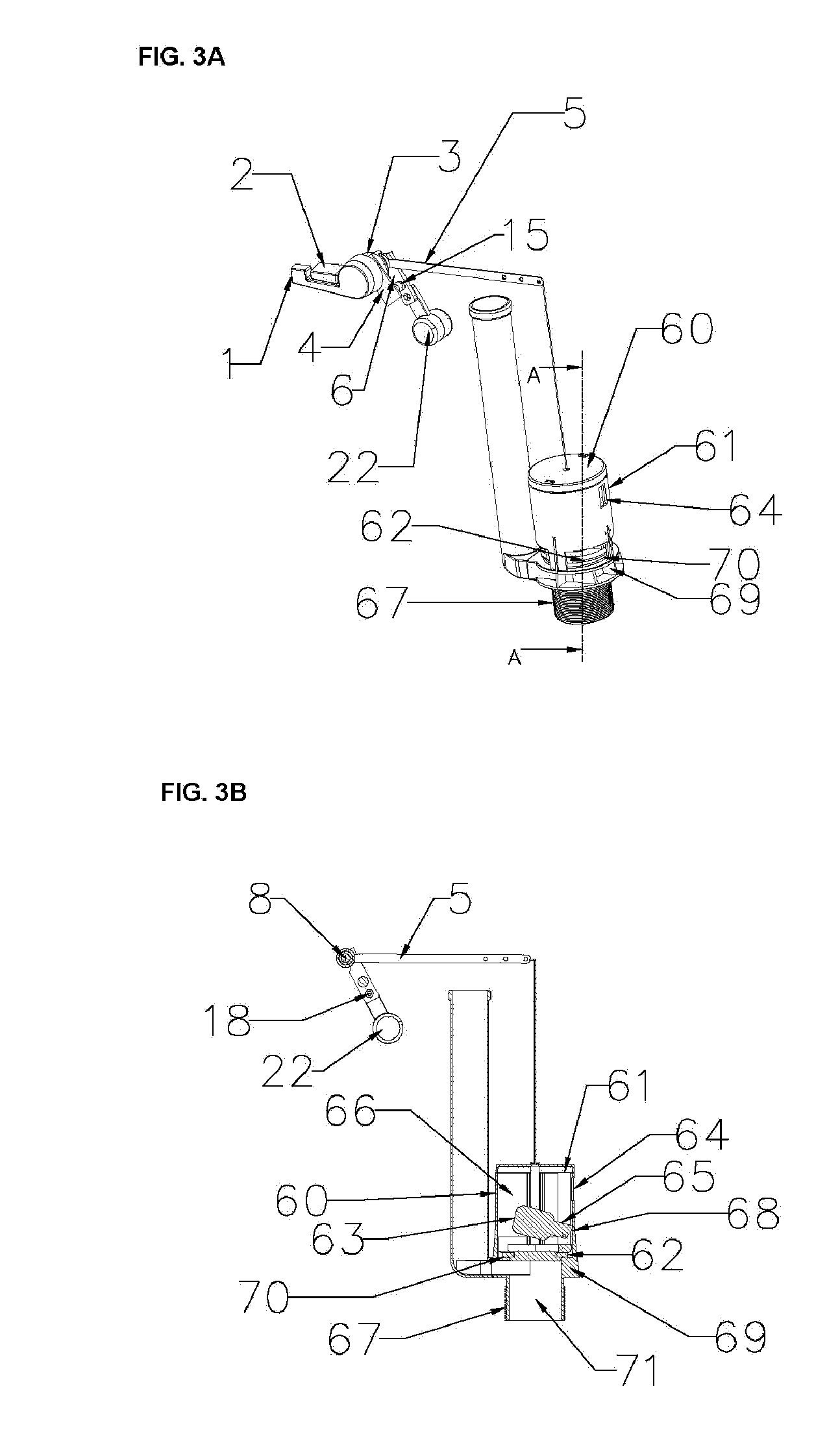

[0022]Referring now to FIG. 3A, there is illustrated a dual flush device for a toilet water tank according to the present invention. At one side wall of a water tank there is provided a manually-operated press handle, (FIGS. 1, 2 and FIG. 11). The press handle comprises a first switch-bar (2) and a second switch-bar (1). A dent or depressed surface (12) sits inside the first switch-bar (2), and a pivot (9) is at the center of the dent (12). Within the pivot (9) there is a hollow roundness with a notch (11) at upper side. A retaining blockade (10) is set inside the dent (12) and connected with the pivot (9). A axial stick or axle (7) which has a axial hole (8) inside, is installed at the central part of one end of second switch-bar (1). When the axial stick (7) is put into the hollow roundness of the pivot (9), the first switch-bar (2) is mounted on the second switch-bar (1).

[0023]On the first switch-bar (2), there is a hollow bed (3) comprising a protruding tube ...

second embodiment

The Second Embodiment

[0027]Moreover, now referring to FIGS. 5, 9, and 10, there is provided a dual flush device for a toilet water tank. In this dual flush device, there is installed a manually-operated press button switch (31) (FIG. 4) at the lid of the water tank. The device comprises a water-drainer (60) as described in the first embodiment. The press button switch (31) includes a first depressor (33) and a second depressor (34). Under the first depressor (33) there is located a retaining blockade (35), but there is no retaining blockade located under the second depressor (34). The first depressor (33) and the second depressor (34) are fixed in the inner space of a box (38). A movable driving-rod (36) is set under them. In the middle of box (38) there is provided a round hole to allow the driving-rod (36) move forward and backward.

[0028]On a mandrel (53) of the driving-rod (36) there is set a coil spring (52) (FIG. 4). A fixation bed (50) has a hollow outer screw thread (51). The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com