Mounting method for extending single-layer latticed shell structure

An installation method and single-layer reticulated shell technology are applied in building construction, building material processing, construction, etc., which can solve problems such as poor economy, loss of flexibility, and cost of materials, and achieve simple installation methods and high practical value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

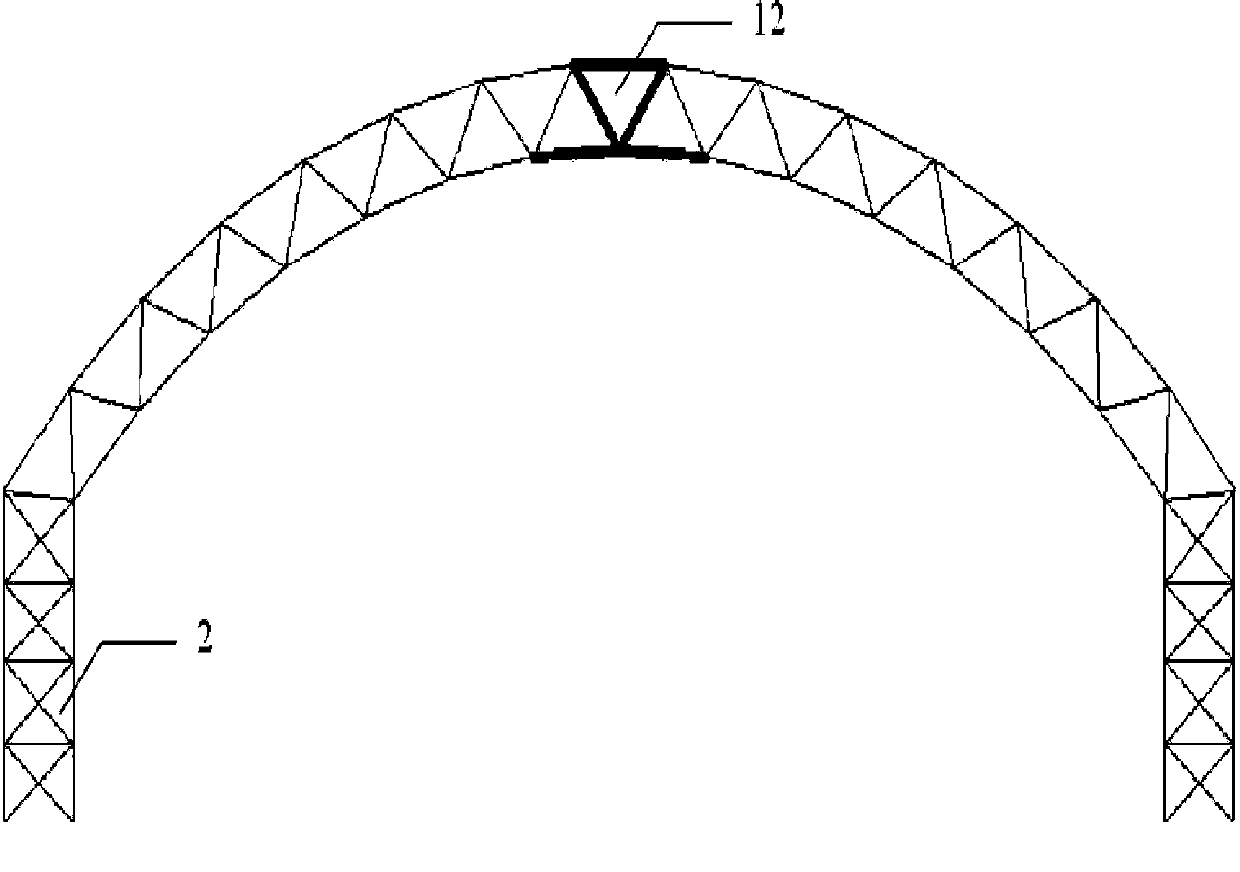

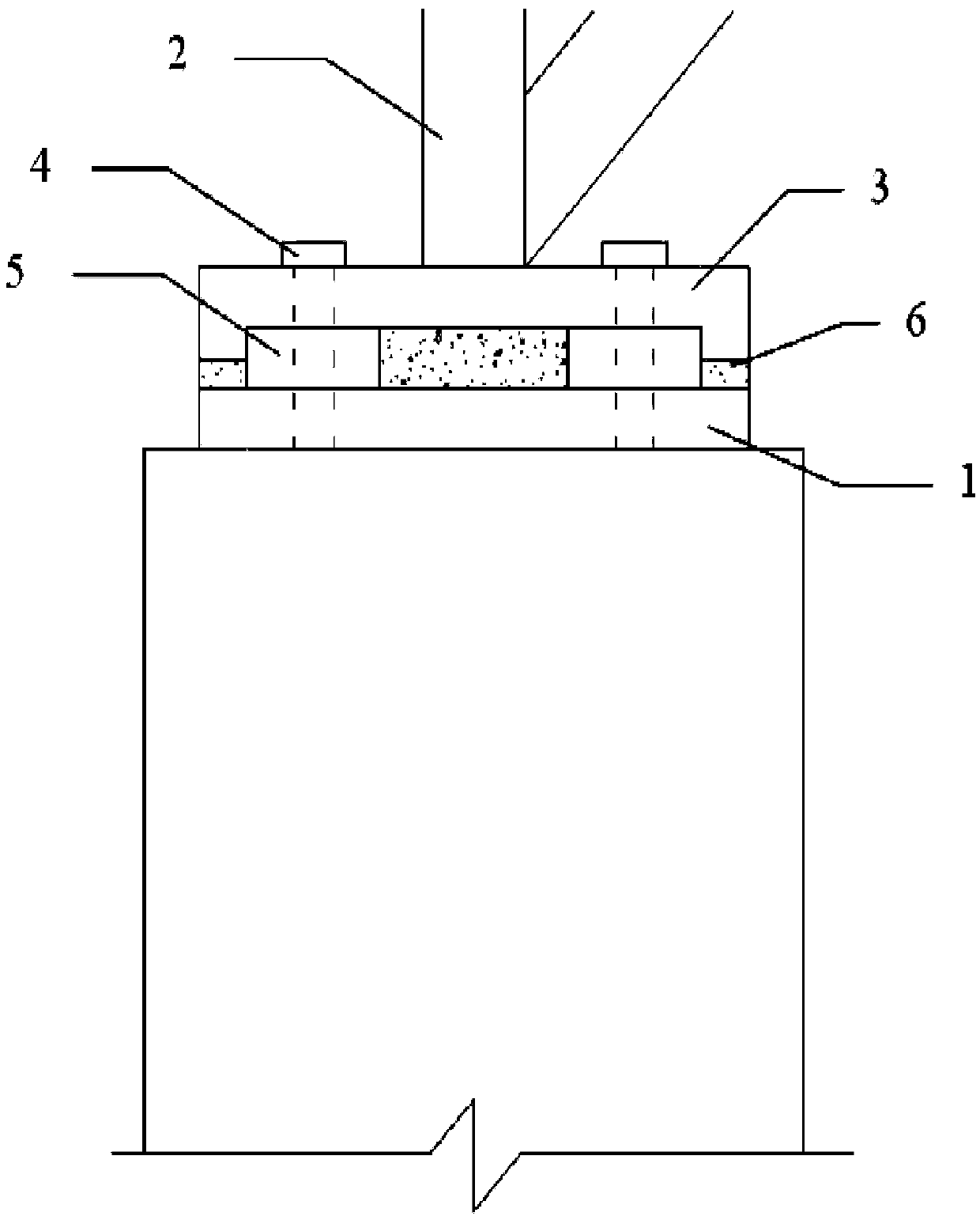

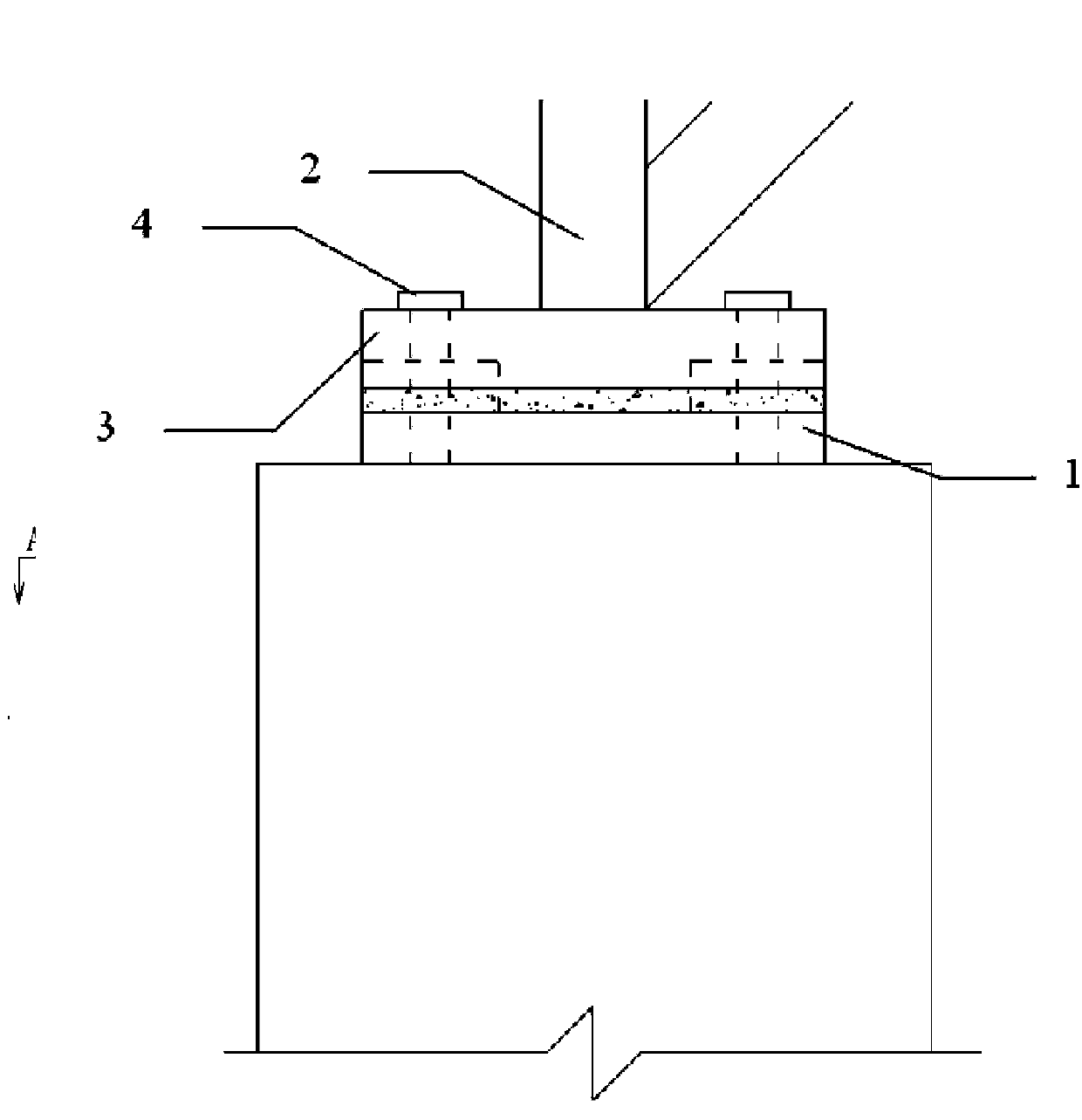

[0038] Such as Figure 1-12 As shown, the installation method for expanding the single-layer reticulated shell structure of the present invention is specifically:

[0039] An installation method for expanding a single-layer reticulated shell structure, characterized in that: the installation method mainly includes an installation construction process and a translation expansion process, wherein the main steps of the installation construction process include foundation construction, installation of lattice columns, Installing the upper reticulated shell structure, the main steps of the translation expansion process include the removal process of the rods in the middle of the reticulated shell, the disassembly process of the column feet, the traction process, and the process of supplementing the reticulated shell rods. The specific steps of the installation method are as follows:

[0040] Step 1: Construct an independent foundation, leave embedded parts (1) on the top of the indep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com