Installing method of extendable latticed shell structure

An installation method and reticulated shell technology are applied in building structure, building material processing, construction, etc., which can solve problems such as unsatisfactory industrial buildings and unsatisfactory functions of public buildings at the level of industrial production technology, and achieve high practical value and installation The effect of simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

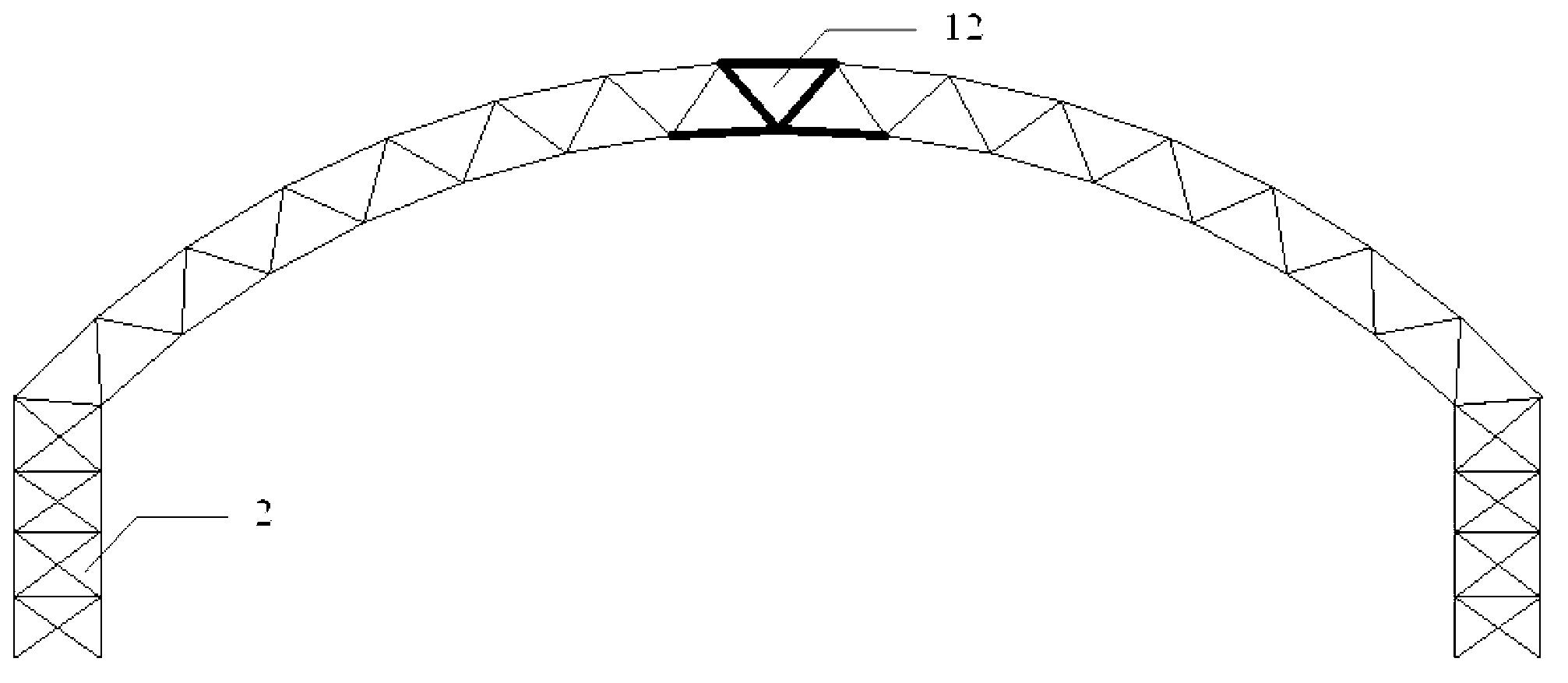

[0029] Such as Figure 1-12 As shown, the installation method of the expandable reticulated shell structure of the present invention is specifically:

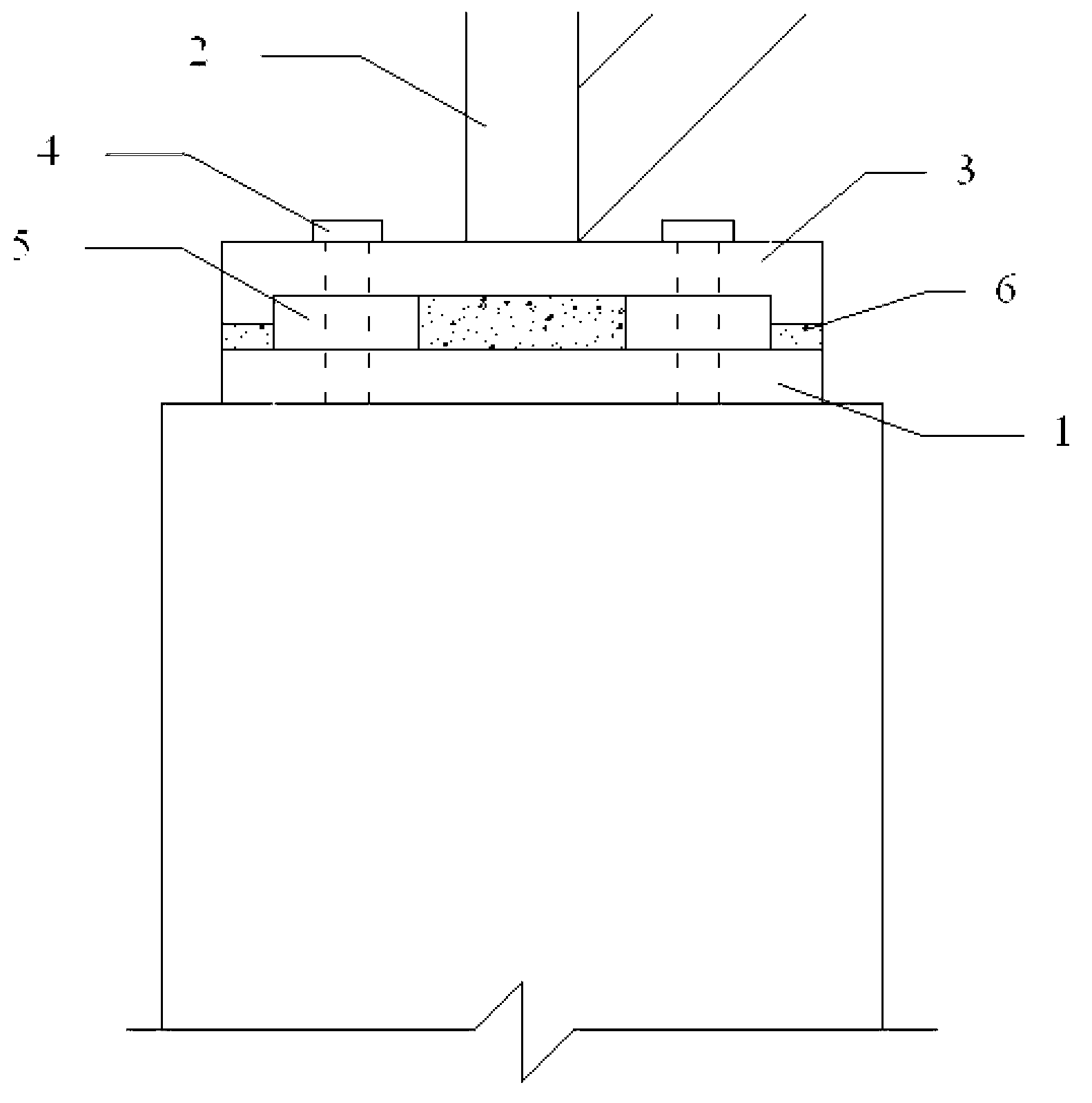

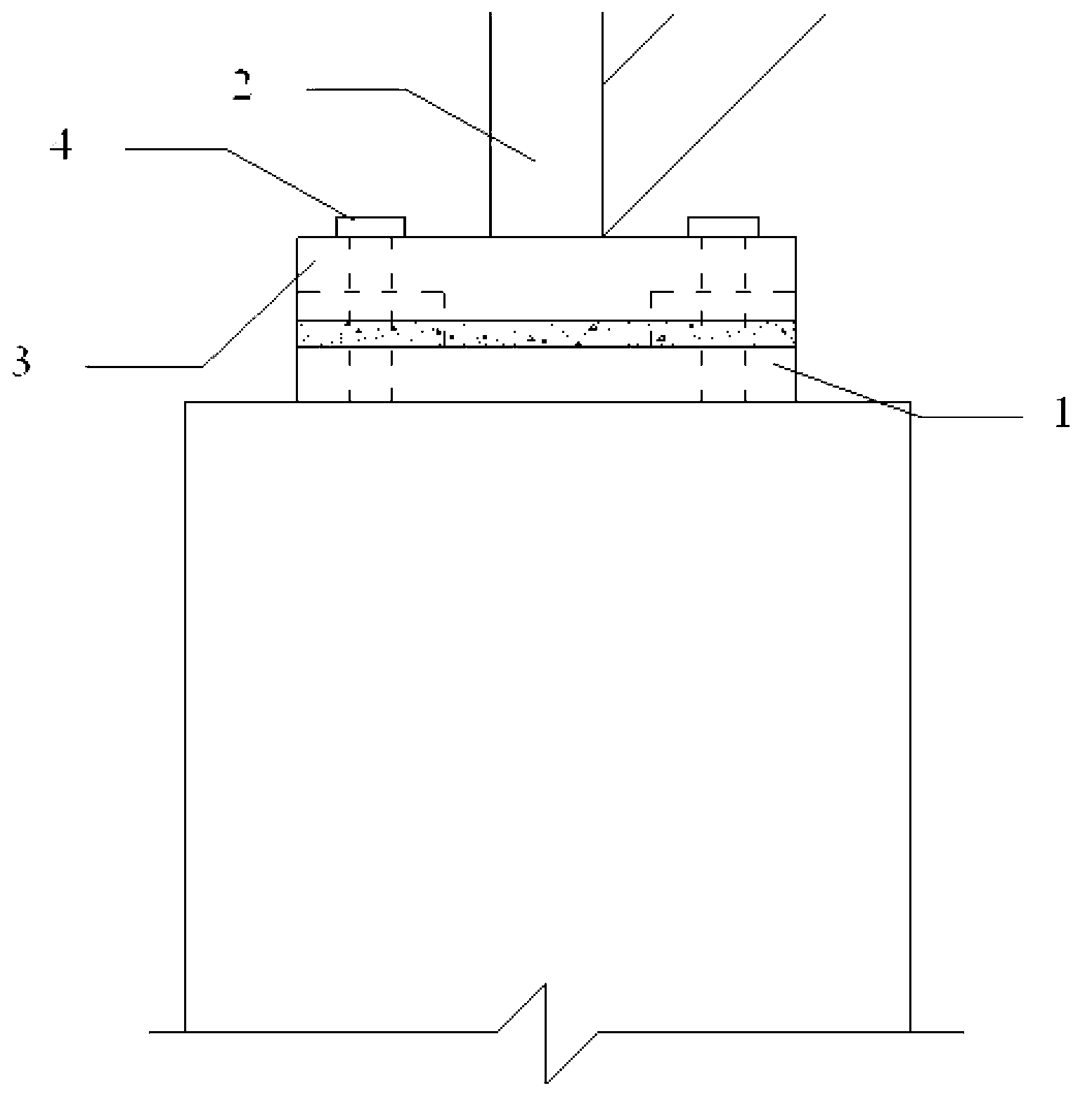

[0030] 1. Construct an independent foundation. There is an embedded part 1 on the top of the independent foundation. The lattice column 2 and the foundation adopt a detachable connection structure. The base of the lattice column 2 is provided with a grooved steel plate 3 and connected with the independent foundation by bolts 4 . The plain concrete filler 6 is used to fill the gap between the channel-shaped steel plate 3 at the column foot and the independent foundation.

[0031] 2. Install the lattice column 2 on an independent foundation. The lattice column is composed of cast steel nodes 7, vertical bars 8, and web bars 9. The cast steel nodes 7 and the vertical bars 8 are connected by an outer sleeve 10 with a threaded buckle. Connect and fix with web bar 9.

[0032] 3. After the lattice column 2 is installed, several ret...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com