Universal rotary milling and drilling tool with functions of horizontal movement and positioning of hoop

A horizontal movement, milling and drilling technology, applied in the field of milling machines, can solve the problems of complex movement and positioning operations, difficulty in ensuring accurate positions, and low processing and maintenance efficiency, so as to improve construction efficiency and construction accuracy, facilitate fast and accurate movement, Ease of maintenance and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

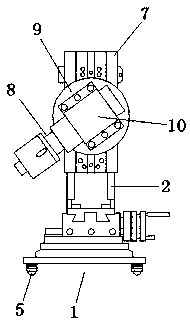

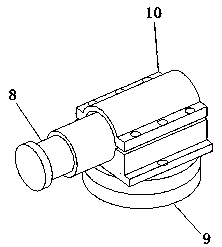

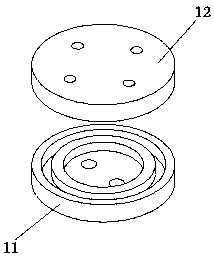

[0033]Example. Horizontal movement positioning hoop universal rotary milling and drilling tools, such as Figure 1 to Figure 12 As shown, it includes a mobile base device 1, a guide rail is provided below the mobile base device 1, and a column 2 is provided above the mobile base device 1. The mobile base device 1 includes a base plate 4, and an electromagnet is provided at the bottom center of the base plate 4. A group of ball screws 5 are provided at the four corners below the base plate 4, and the setting positions of the ball screws 5 are aligned with the guide rails; a positioning installation turntable 6 is provided above the base plate 4, and a rotary knife feed seat is provided above the positioning installation turntable 6; the positioning installation turntable 6 is provided with a bolt gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com