Foaming cement composite plates with dovetail groove type steel edge rib structures and connecting method thereof

A foamed cement and connection method technology, applied in building components, building structures, buildings, etc., can solve the problems of complicated welding process equipment, cumbersome secondary anticorrosion, low work efficiency, etc., and achieve excellent sound insulation performance and excellent fire prevention. Performance, easy installation and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

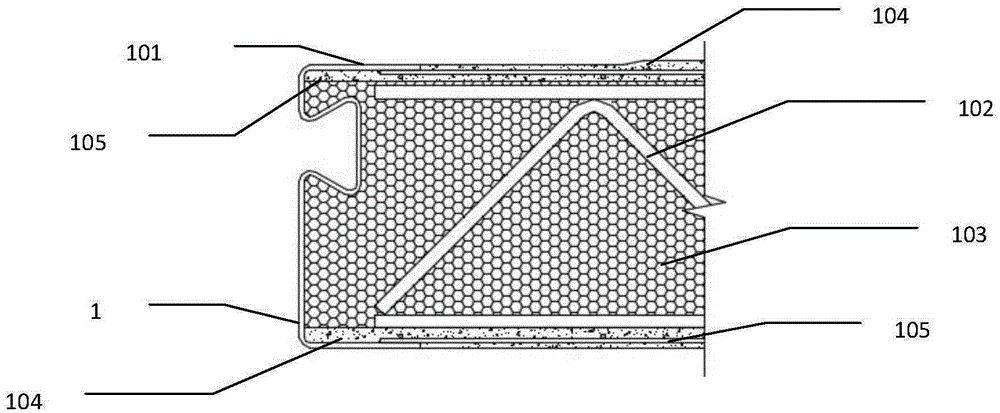

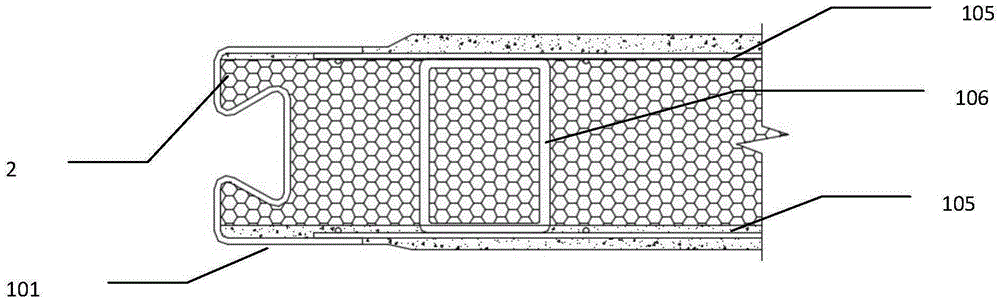

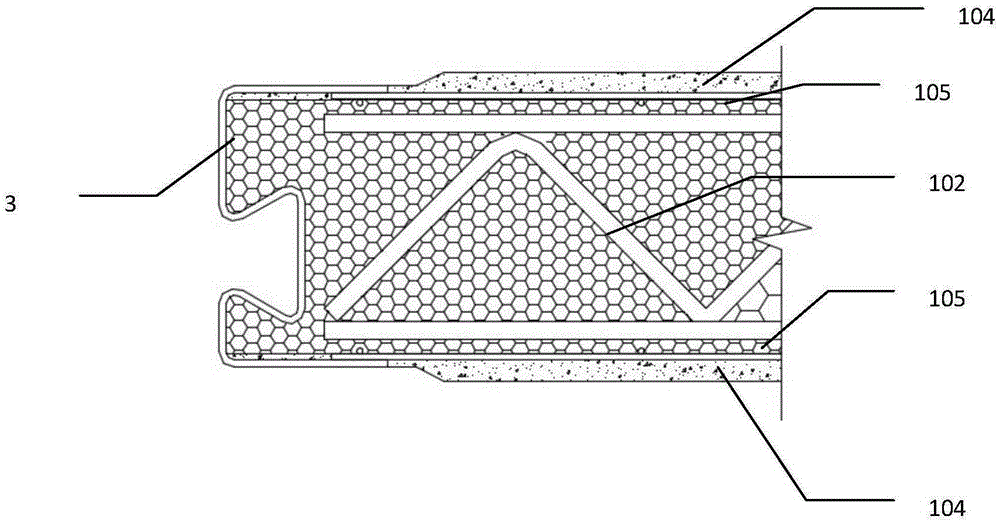

[0051] Such as Figure 1-1 to Figure 1-4 , Figure 2-1 to Figure 2-3 , Figure 3 to Figure 5 As shown, the present invention includes: a foamed cement composite bottom board 1 , a foamed cement composite wallboard 2 , and a foamed cement composite top board 3 . In the foamed cement composite bottom plate 1 or the foamed cement composite wallboard 2 or the foamed cement composite top plate 3, a dovetail groove type steel frame side rib 6 is arranged; the described dovetail groove type steel frame side rib 6 is composed of The upper and lower flanges and the rib groove 61 of the dovetail groove; and the embedded part wedge block 7 is arranged in the rib groove 61 of the dovetail groove; The hole 70 and the slot 71 where a nut 73 can be placed.

[0052] The connection between the foamed cement composite base plate 1 and the described foamed cement composite wallboard 2 is to pass through the right-angled connector 8 and the nut 73 placed in the wedge block 7 to be connected an...

Embodiment 2

[0068] Such as Figure 1-1 to Figure 1-4 , Figure 6-1 to Figure 6-2 , Figure 7 As shown, the present invention includes: a foamed cement composite bottom plate 1, a foamed cement composite wallboard 2, and a foamed cement composite top plate 3 as described in Example 1. In the foamed cement composite bottom plate 1 or the foamed cement composite wallboard 2 or the foamed cement composite top plate 3, a dovetail groove type steel frame side rib 6 is arranged; the described dovetail groove type steel frame side rib 6 is composed of The upper and lower flanges and the rib groove 61 of the dovetail groove; and the embedded component wedge block 7 is arranged in the rib groove 61 of the dovetail groove; and the threaded hole matched with the bolt 74 is provided in the wedge block 7 72.

[0069] The connection between the foamed cement composite bottom plate 1 and the described foamed cement composite wallboard 2 is through the wedge-shaped connecting piece 8 and the rib groove...

Embodiment 3

[0082] Such as Figure 1-1 to Figure 1-4 , Figure 8-1 to Figure 8-2 , Figure 9 As shown, the differences between the present embodiment 3 and the embodiment 1 are: 1. Another structure of the wedge block 7 is that the wedge block 7 is provided with a bolt 74 that cooperates with a nut 73 . Second: add a rib plate 82 to the right-angled connecting piece 8 to meet the strength of the plate connection by enhancing the strength of the connecting piece. Other features of Embodiment 3 are the same as those of Embodiment 1 above, so details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com