Flat bump type non-metal cutting package process and package structure thereof

A planar bump type and packaging technology, which is applied in semiconductor/solid-state device components, semiconductor devices, electrical components, etc., can solve problems such as poor reliability and fast tool wear, and achieve small cutting stress, simple process, and reliable chips sex enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Such as Figure 1-12 , a planar bump type metal-free cutting packaging process, the steps are as follows:

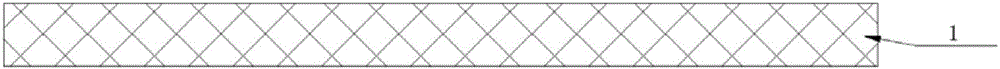

[0057] 1) Take a metal substrate 1;

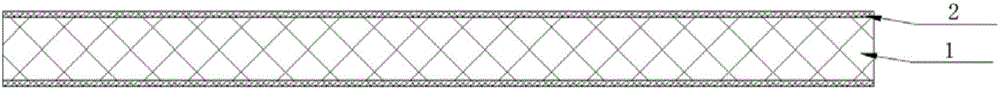

[0058] 2) Paste a dry film layer 2 on the front and back of the metal substrate 1 to protect the subsequent etching process;

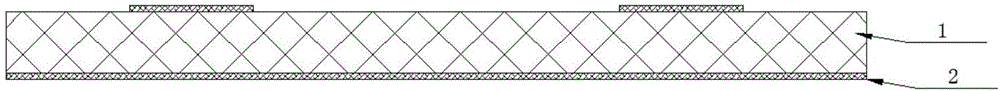

[0059] 3) Remove part of the dry film layer 2 on the front of the metal substrate 1, and prepare to form the base island 6, ribs, and pins 5 on the metal substrate 1;

[0060] 4) The front metal layer 3 is plated on the front side of the base island 6, connecting ribs, and pin 5 areas prepared to be formed on the metal substrate 1, and the front metal layer 3 of the base island 6 and pin 5 is made of gold, silver, copper, and nickel or nickel palladium metal. In order to facilitate the close combination of the metal wire and the chip area and the pins in the wire bonding during the subsequent wire bonding, the silver plating on the ribs is used for subsequent electroplating and tin plating of the co...

Embodiment 2

[0074] A planar bump-type metal-free cutting package structure, including a chip carrier base, a wire-bonded inner foot carrier base, a chip 7, a metal wire, and a plastic package body 8, and the chip carrier base includes a base island 6 and a metal layer on the front side of the base island 3. The carrying base of the wiring inner foot includes the pin 5 and the front metal layer 3 of the pin, the metal layer 3 is on the connecting rib, and the chip 7 is implanted on the front metal layer 3 of the chip carrying base, and the front side of the chip 7 and the The front metal layer 3 of the pin 5 is respectively connected with both ends of the metal wire to form a semi-finished package structure. The front side and the outer peripheral edge of the package structure semi-finished product are encapsulated with a plastic package 8, and the back of the base island 6 and the pin 5 protrude from the plastic package. 8, the base island 6 protruding from the plastic package body 8, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com