Pipeline corner connector and application method thereof

A technology for corner joints and pipelines, applied in the direction of pipes/pipe joints/pipes, branch pipelines, pipes, etc., can solve the problems of difficult subsequent processing, complex flange structure, large space occupation, etc., and achieve simple machining. , the structure is simple, the effect of occupying a small space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

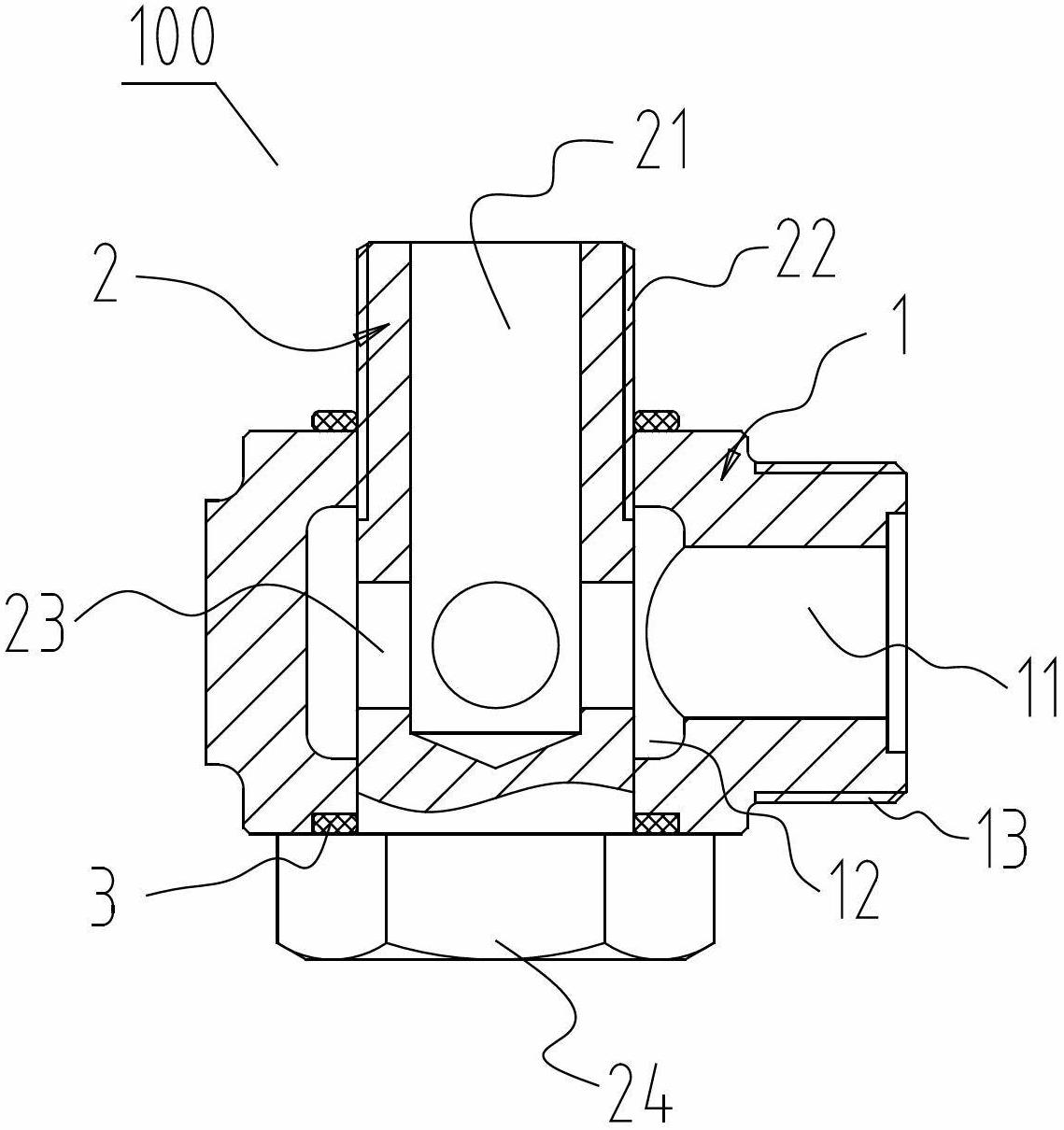

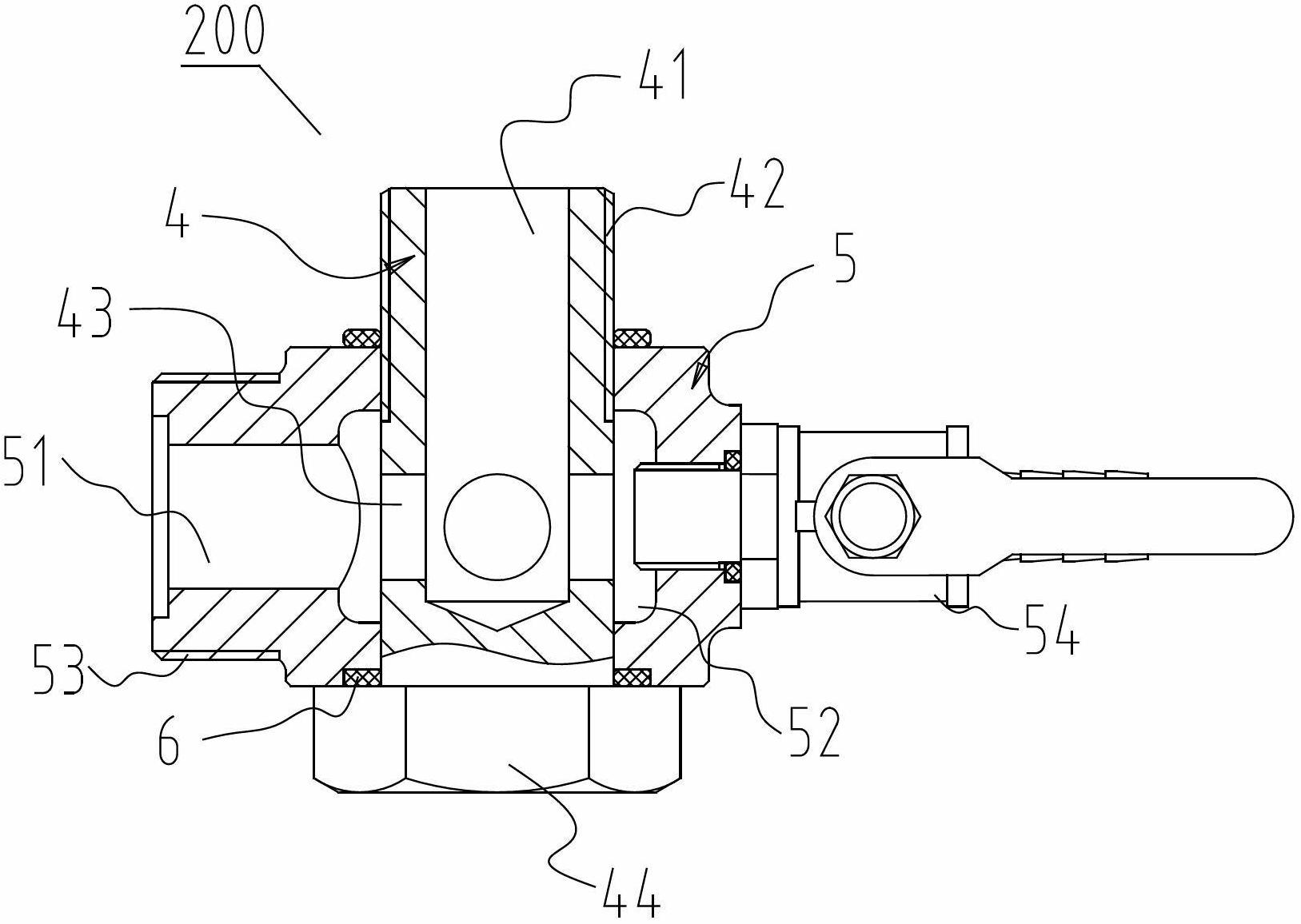

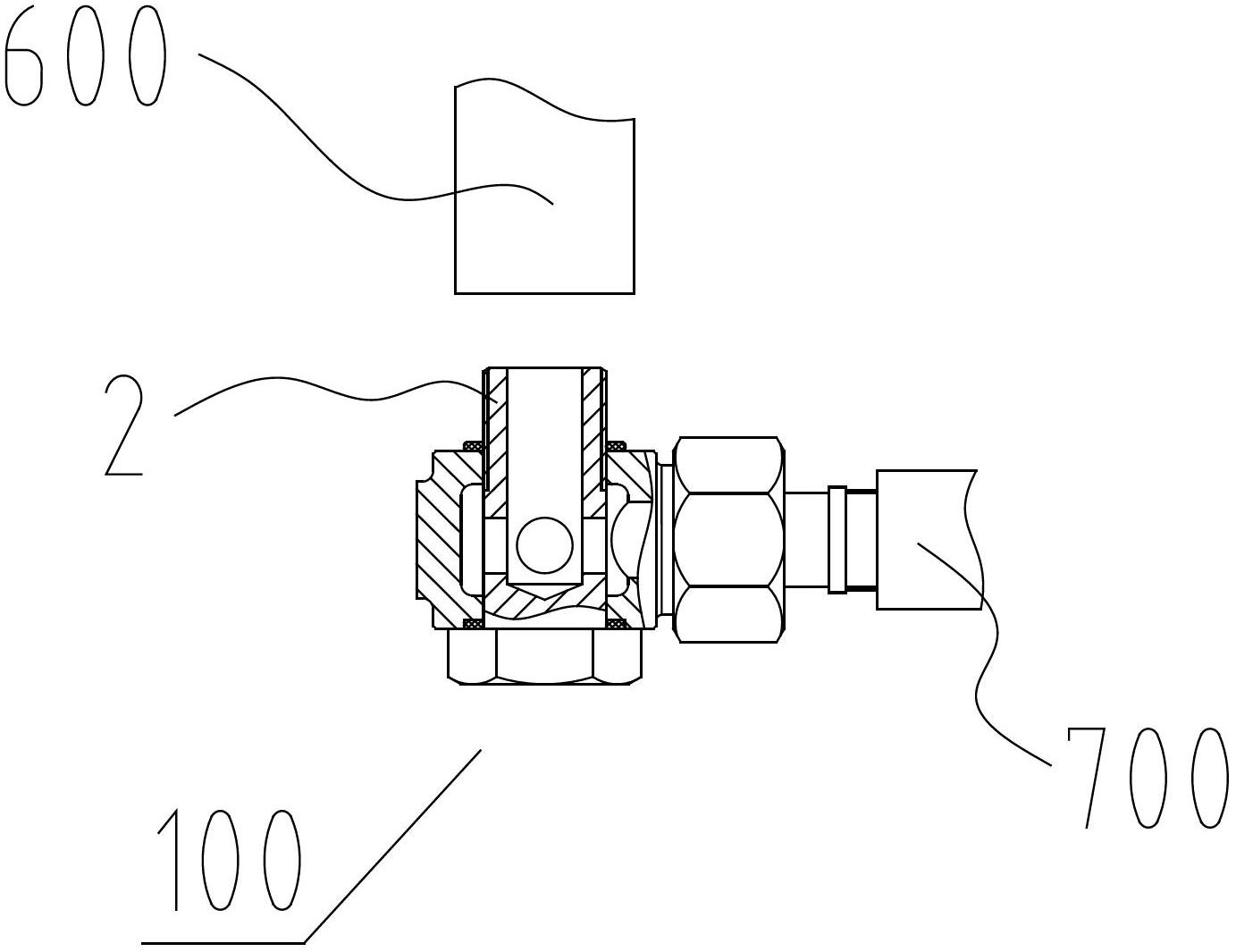

[0037] Example 1: Take the installation of the pipeline corner joints 100 and 200 between the two pipelines, that is, between the main pipe 600 and the branch pipe 700, as an example for illustration.

[0038] Including the following steps,

[0039] a. Fix the main pipe 600 connected with the branch pipe 700 on the wall or at a predetermined position through pipeline fixing nails in advance;

[0040] b. Screw the joint bodies 1, 5 on the pipeline corner joints 100, 200 to the aforementioned branch pipe 700;

[0041] c. Determine the relative installation position of the branch pipe 700 according to the position of the aforementioned main pipe 600;

[0042] d. Turn the tool tightening parts 24, 44 of the connectors 2, 4 on the joint body 1, 5 by a wrench or other installation tools, and make the connector body 1, 5 and the branch pipe 700 stationary 2,4 are connected with the main pipe 600 threads.

[0043]Wherein, between step c and step d, or after step d, the position of ...

example 2

[0044] Example 2: The installation of the pipe corner joints 100 and 200 in a pressure regulator will be described. Such as figure 1 , figure 2 , Figure 5 shown.

[0045] a. Two main circuit voltage regulators 400 and 500 are fixedly installed in advance.

[0046] b. The pipeline corner joints 100, 200 are respectively arranged at both ends of a sub-circuit pressure regulator 300, wherein, the connecting thread 13 of the joint body 1 on the pipeline corner joint 100 and the connection thread 13 of the sub-circuit pressure regulator 300 One end is threadedly connected, and the connecting thread 53 of the joint body 5 on the pipeline corner joint 200 is threadedly connected with the other end of the secondary pressure regulator 300 .

[0047] c. After the pipeline corner joints 100, 200 are fixedly connected with the auxiliary road pressure regulator 300 to form a part, the main road pressure regulators are respectively connected to the connecting pieces 2 and 4 on the pip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com