Heating body installing structure of energy-saving mini-sized electric cooker

An installation structure and electric rice cooker technology, applied in heating devices, cooking utensils, household utensils, etc., can solve the problems of low production efficiency, easy loosening or even falling off of the electric heating body, achieve stable work, and reduce waste of heat , the effect of firm connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

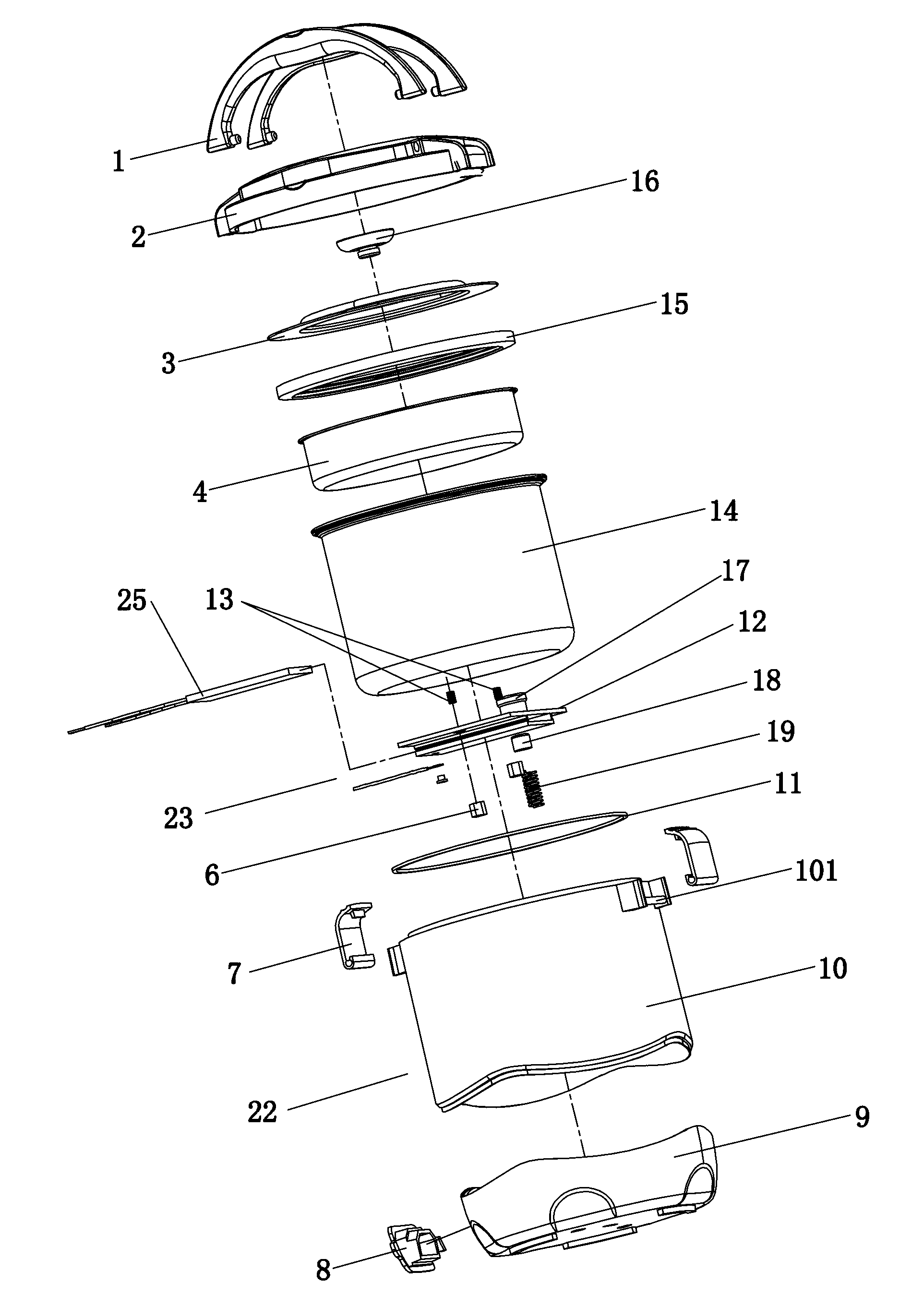

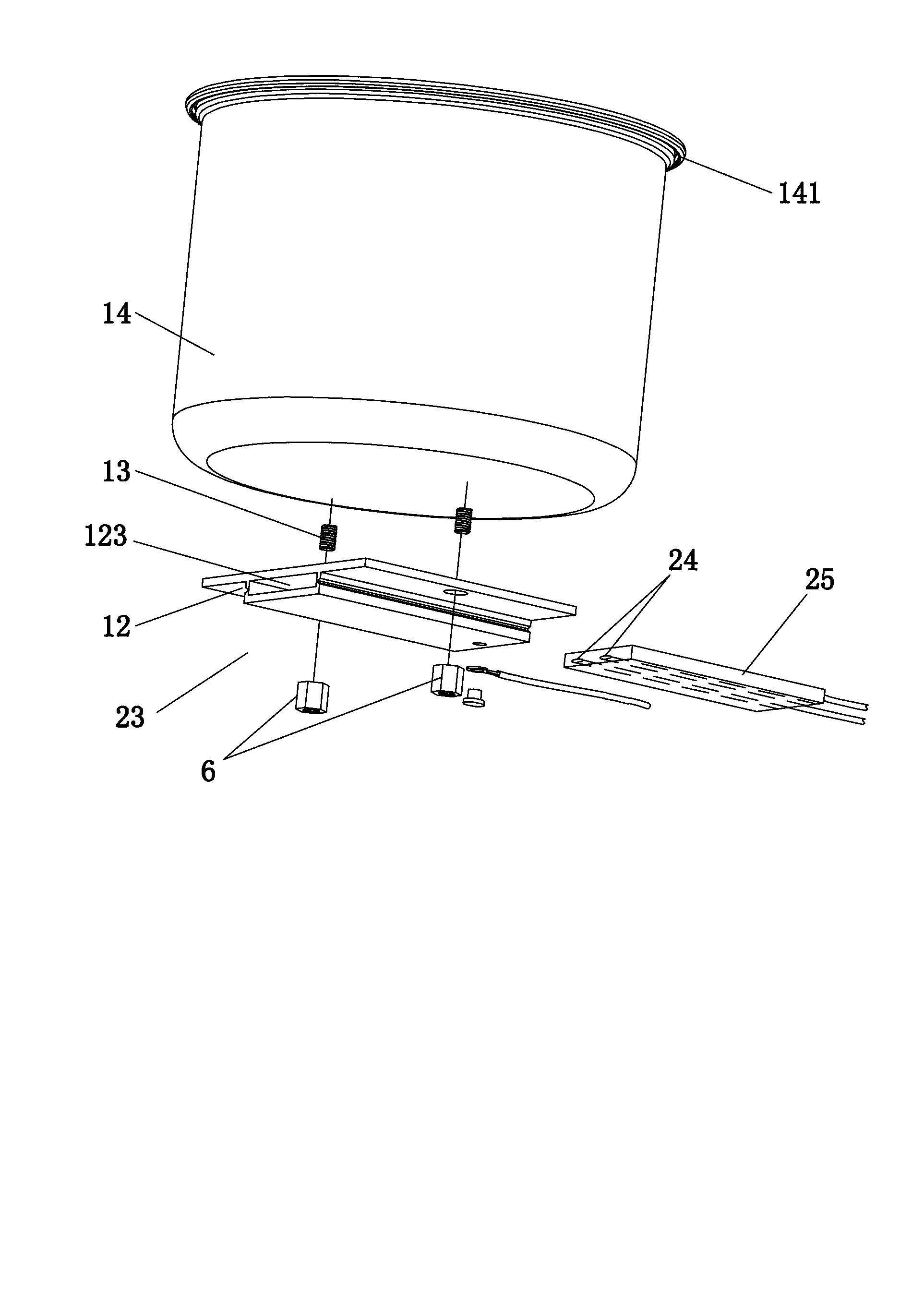

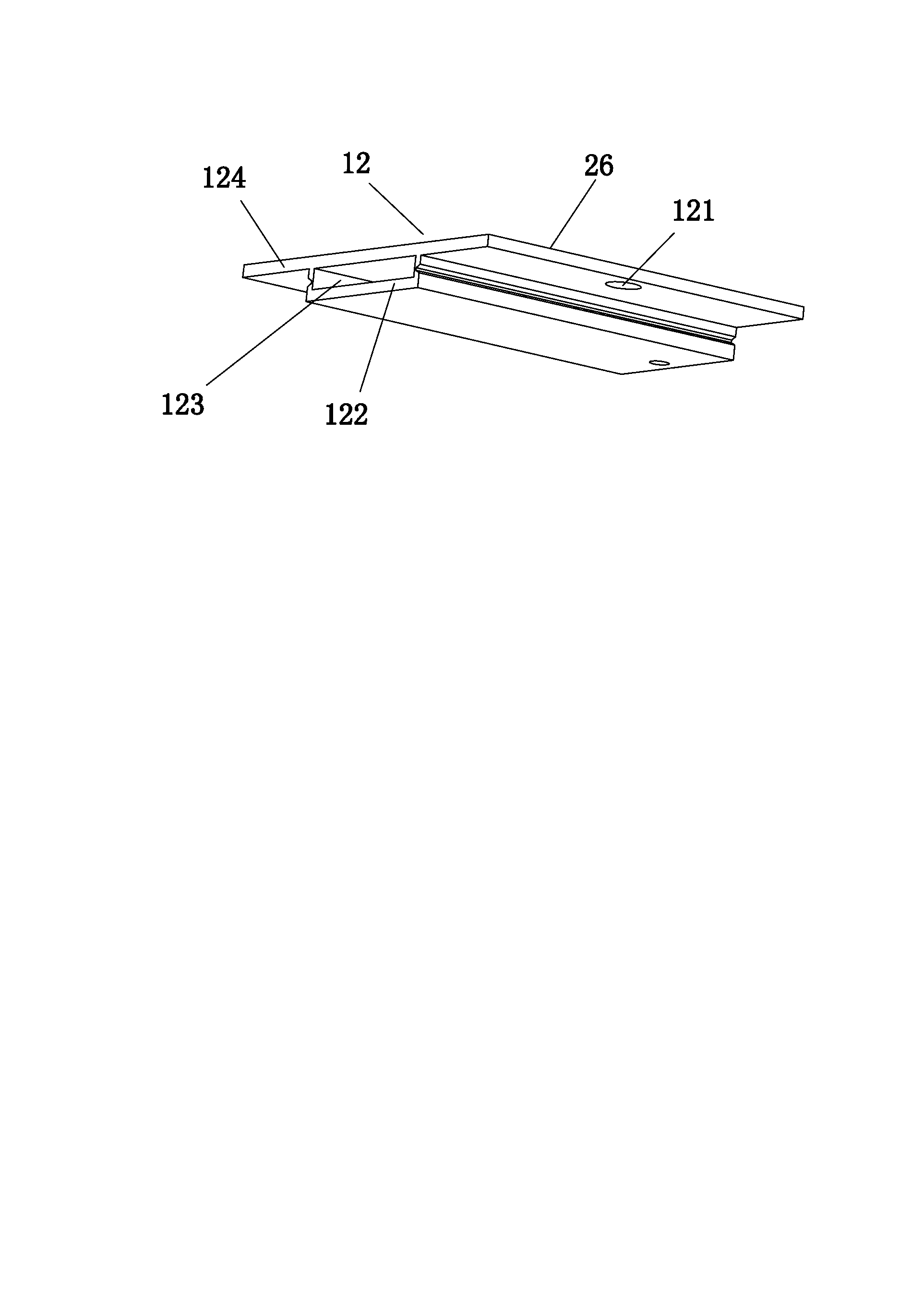

[0028] Such as Figure 1 to Figure 6 As shown, the heating body installation structure of the energy-saving miniature electric rice cooker includes an outer pot 22, an inner container 14, a cover body and an electric heating body 23, the inner container 14 is arranged in the outer pot 22, and the electric heating body 23 includes a heat conducting plate 12, The electric heating body 24 and the insulating and heat-conducting layer 25 are provided with a compacting cavity 123 on the heat-conducting plate 12, and the insulating and heat-conducting layer 25 wraps the electric heating body 24, and they are compressed together in the pressing cavity 123 of the heat-conducting plate 12, and the heat-conducting plate 12 is provided with a heat conduction surface 26, at least two studs 13 extend from the bottom of the liner 14, and the heat conduction plate 12 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com