Pile top supporting walking type moving piling platform

A piling platform, walking technology, applied in sheet pile wall, construction, infrastructure engineering and other directions, can solve the problems of high erection cost, low work efficiency and low positioning accuracy of fixed platform, and achieve good practicability and market application value, The effect of improving construction efficiency and simple mobile operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

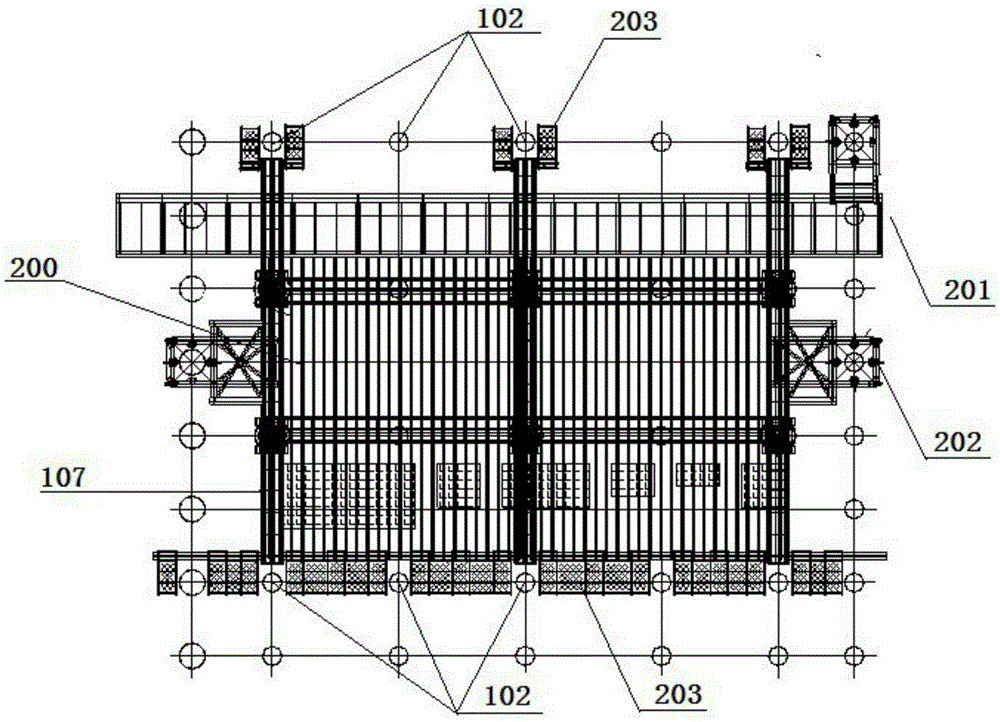

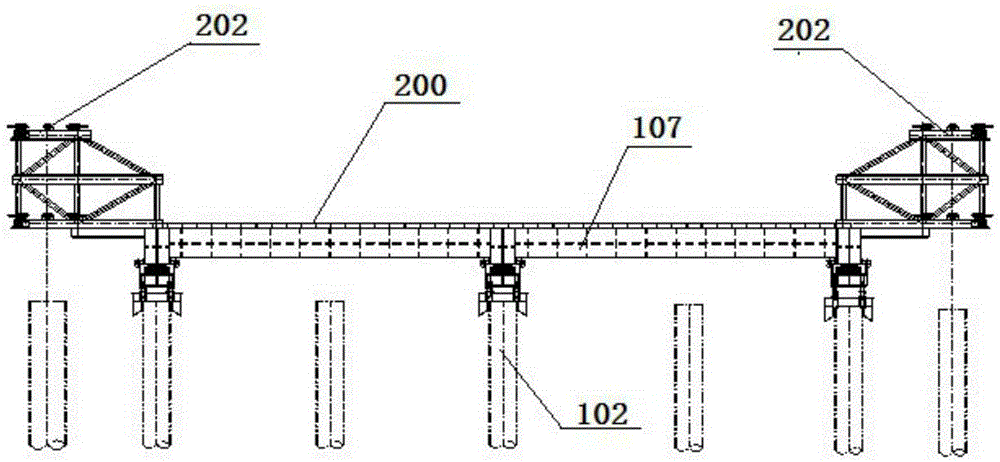

[0035] Such as figure 1 - The pile top support walking type mobile piling platform shown in 4 includes a pile top pushing positioning device fixed on the top of the steel pipe pile 102, a load-bearing platform 107 is fixed on the pile top pushing positioning device, and a working platform is fixed on the load-bearing platform 107. Platform 200, a large bent frame guide frame 201 is fixed on the front part of the operation platform 200, a small bent frame guide frame 202 is respectively fixed on the left and right sides of the load-bearing platform 107, and the front and rear sides of the load-bearing platform 107 are connected with the steel pipe pile 102. An installation platform 203 is fixed at the corresponding position.

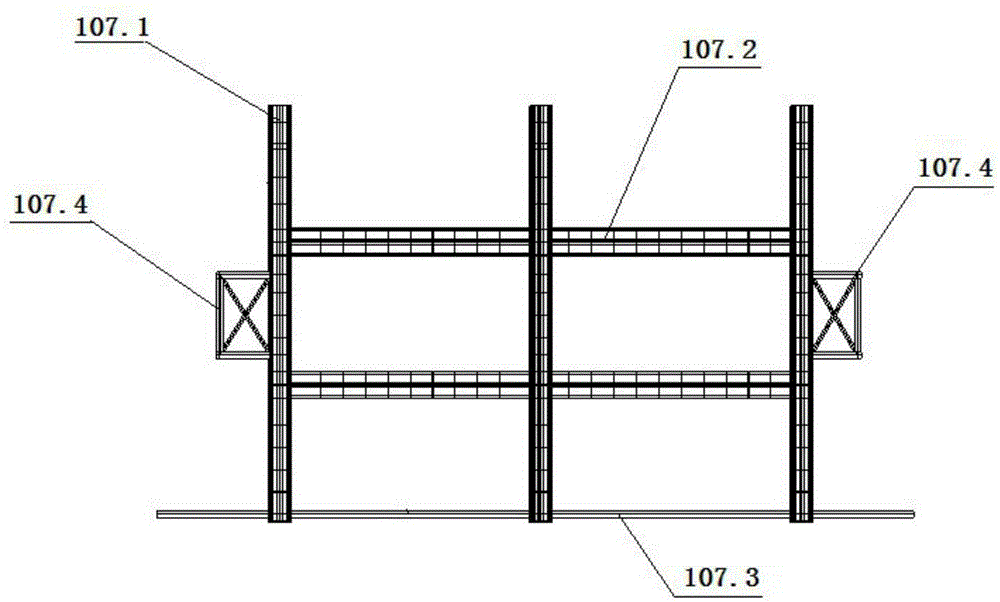

[0036] Such as figure 2 As shown, the load-bearing platform 107 includes a plurality of main longitudinal b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com