Electric lifting device

An electric hoisting device and electric technology, applied in cranes and other directions, can solve problems such as hidden safety hazards, inconvenient loading and unloading operations, and difficult telescopic operations, and achieve the effects of saving manpower, improving loading and unloading accuracy and work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

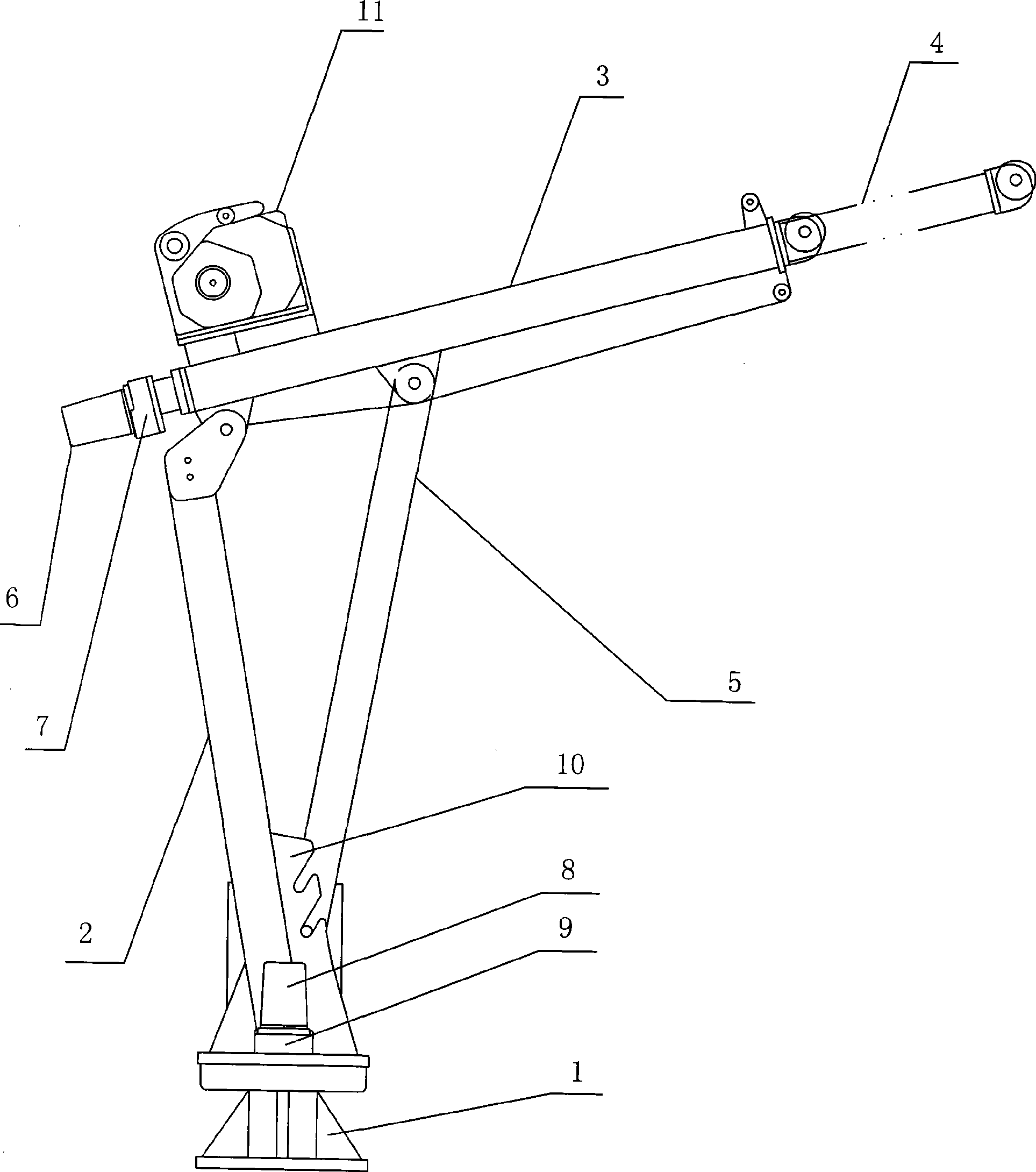

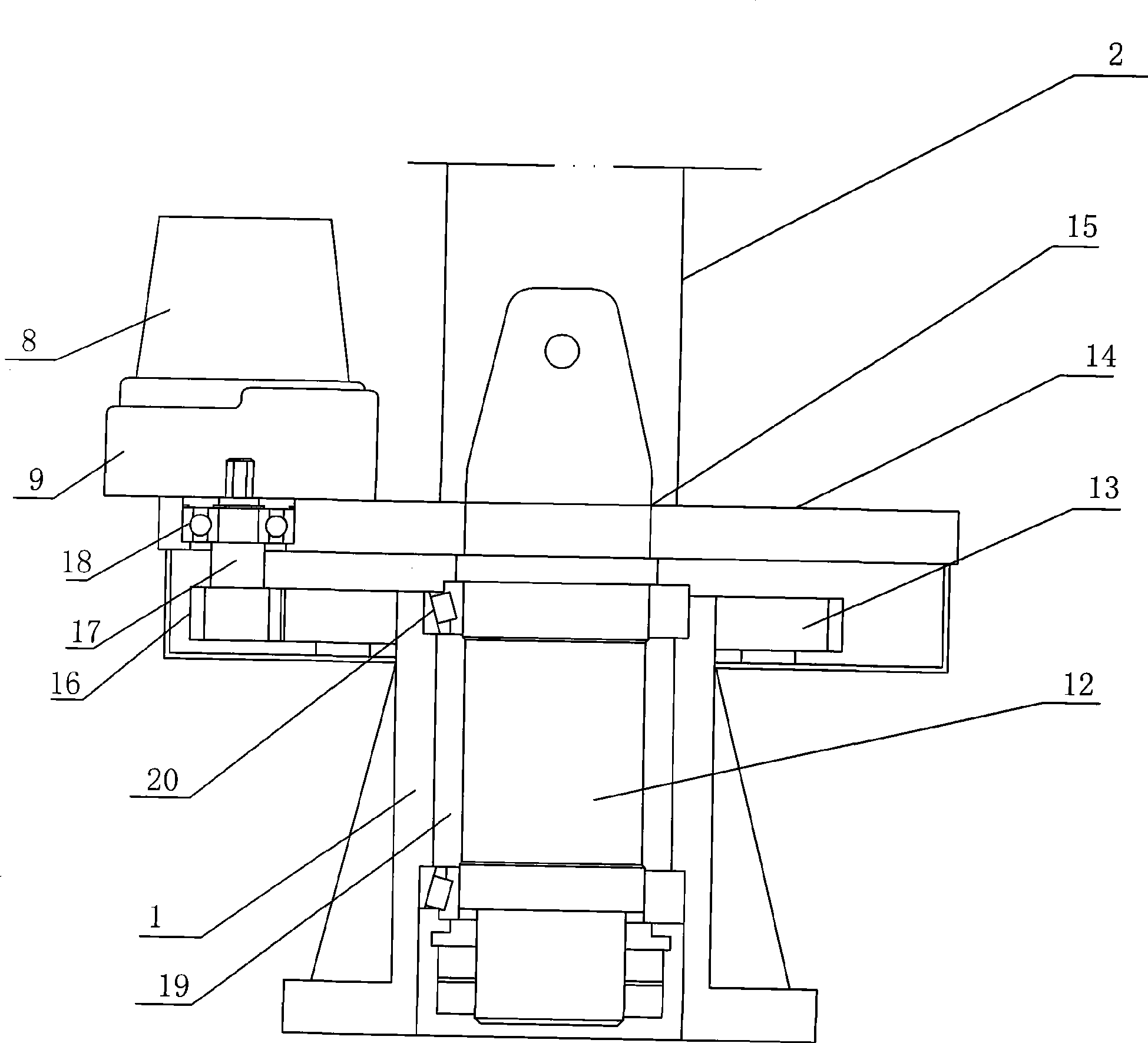

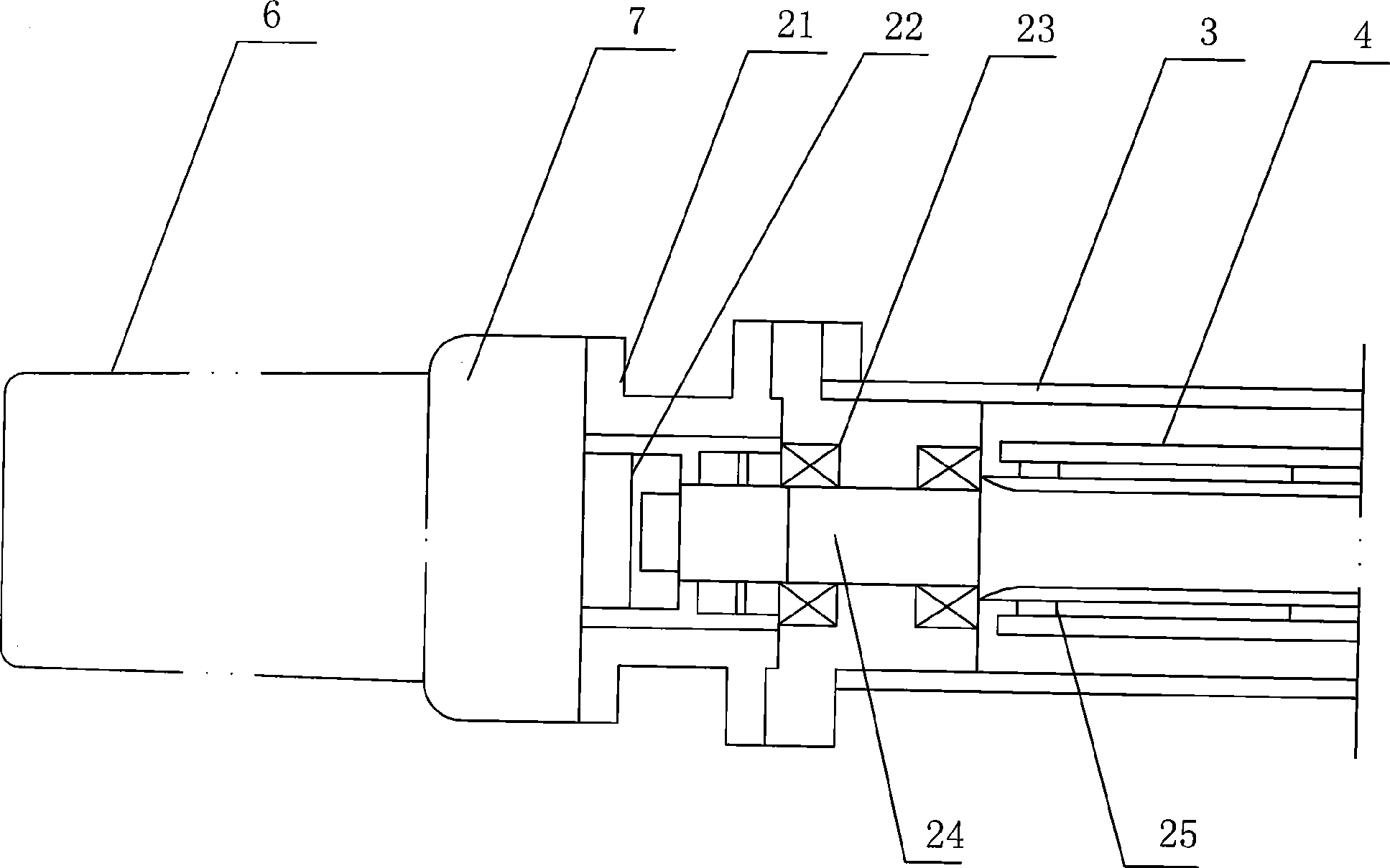

[0019] Such as figure 1 , figure 2 , image 3 , Figure 4 shown.

[0020] The electric lifting device of the present invention includes a base 1, a main arm 2, a cross arm 3, a lifting mechanism 11, a telescopic arm 4, and a rotating main shaft 12. The lifting mechanism 11 is installed on the cross arm 3, and the rotating main shaft 12 The lower part of the base 1 rotates and fits with the central hole I19 of the base 1, and the telescopic arm 4 slides and fits in the cross arm 3. An electric rotating mechanism is arranged between the base 1 and the main arm 2, and the electric rotating mechanism Including drive motor I8, speed reducer I9, drive gear 16, rotating disk 14 and ring gear 13 fixedly connected with the outer wall of center hole I19 of base 1, the output shaft end of said drive motor I8 is connected with speed reducer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com