Large-caliber pneumatic multi-way eccentric butterfly valve

An eccentric butterfly valve, large-diameter technology, used in multi-way valves, valve details, valve devices, etc., can solve the problems of large valve stem rotation resistance, slippage, difficulty in meeting sealing and valve disc movement, etc., to improve operational flexibility, Simple operation and improved bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

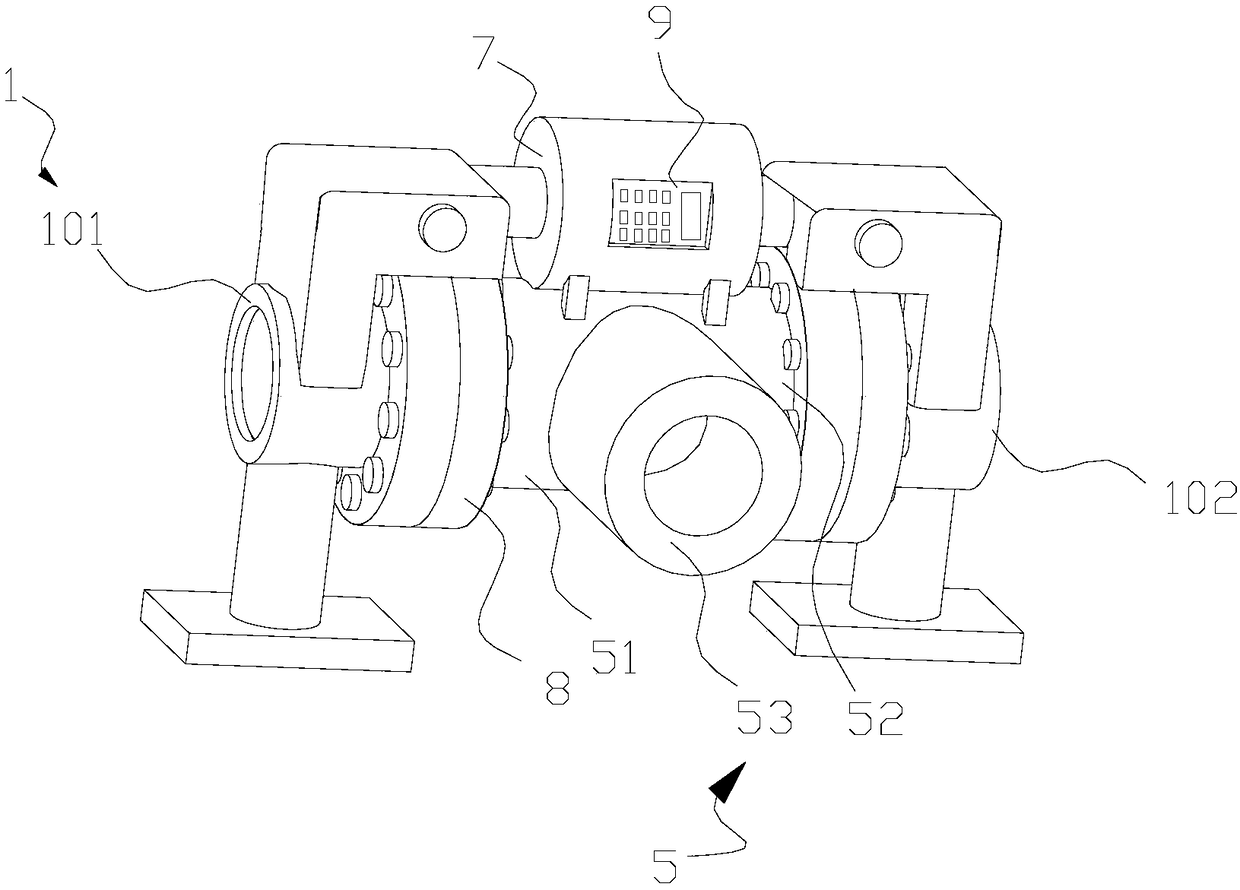

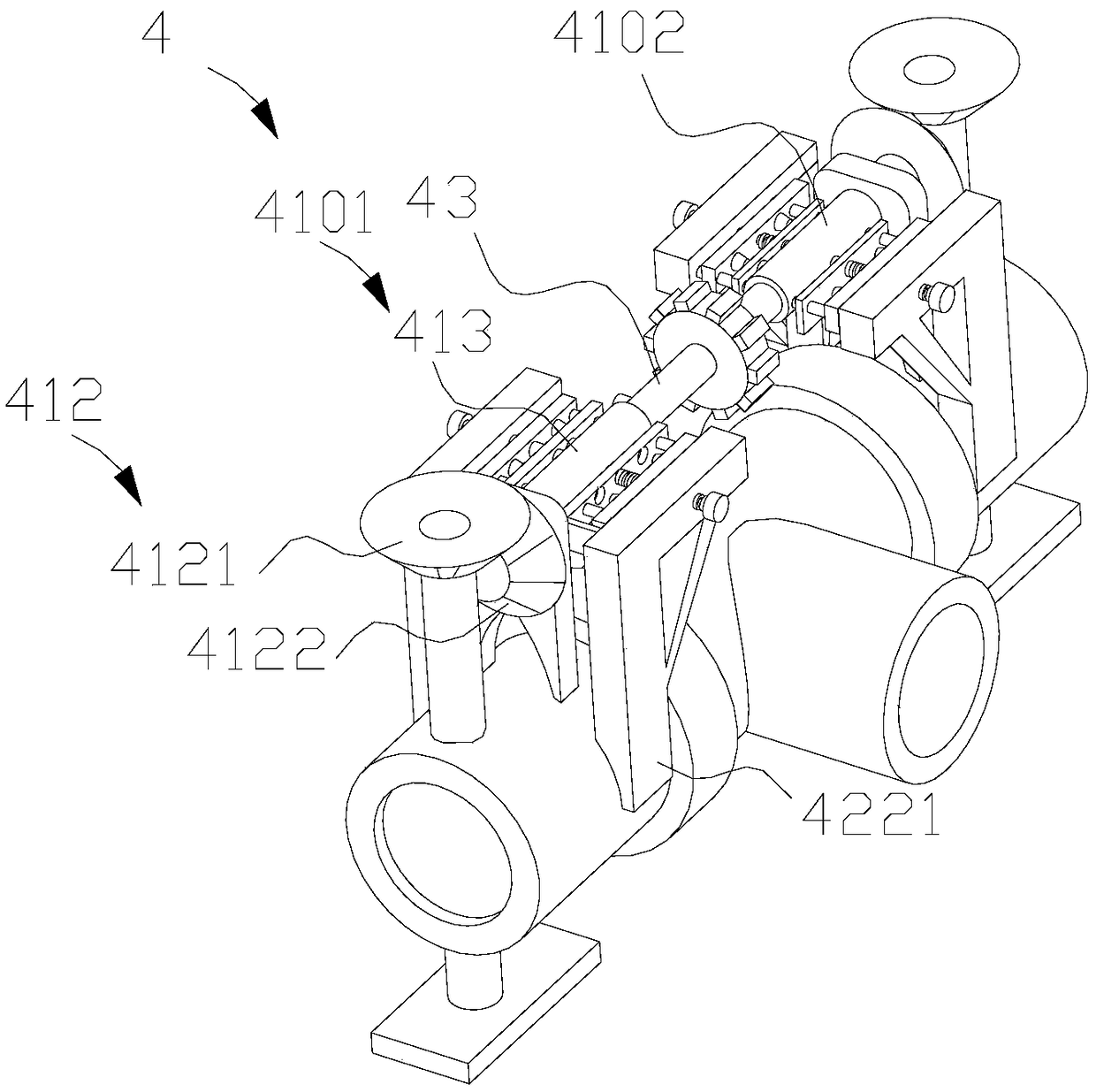

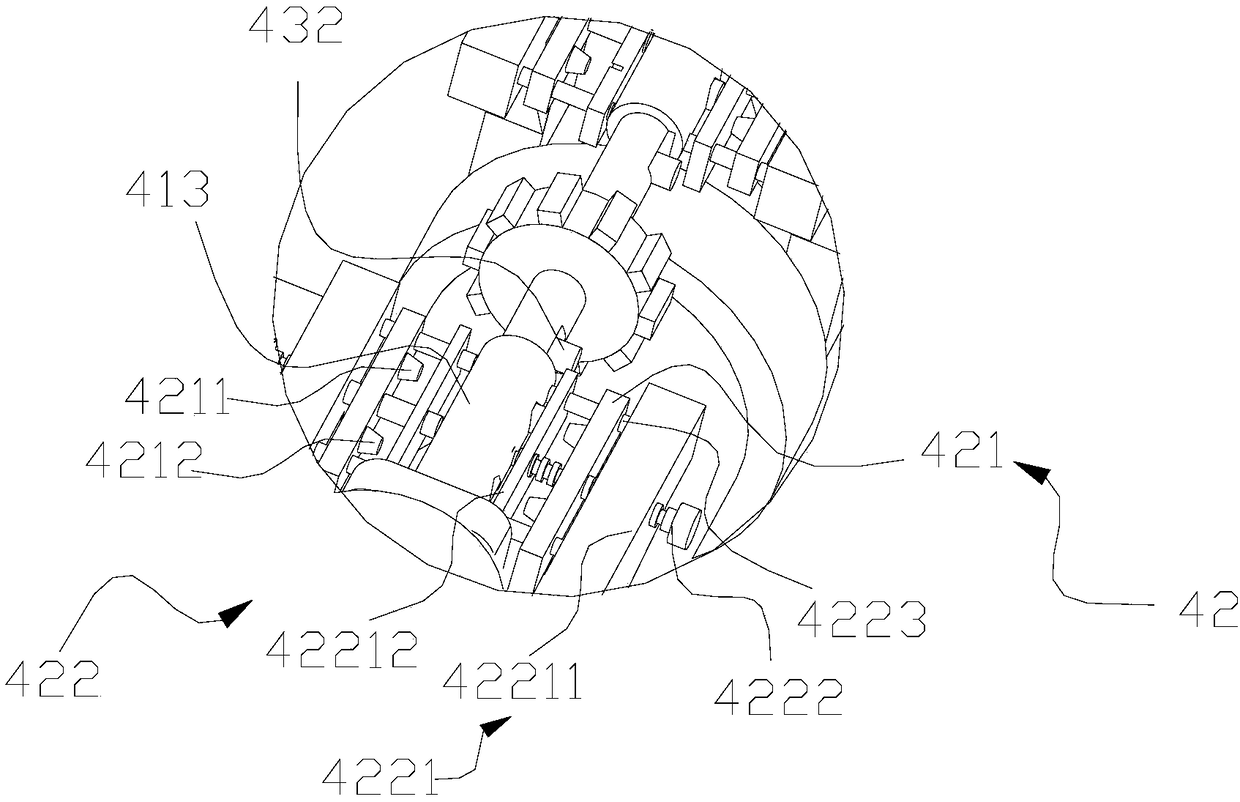

[0042] Such as figure 1 , 2 , 7, this embodiment discloses a large-diameter pneumatic multi-way eccentric butterfly valve, including a butterfly valve body 1, a pneumatic device, a tee pipe 5, and a sliding connection transmission device 4. Such as Figure 7 , 8 As shown, the butterfly valve body 1 includes a valve body 11, a valve stem 12, a valve seat, and a valve disc 14. The valve stem 12 runs through the valve body 11, and the valve disc 14 is installed on the valve stem 12 and is limited in the cavity of the valve body 11. , The valve seat is fitted on the inner wall of the valve body 11 . A butterfly valve body 1 is respectively connected to two horizontally connected ports in the three-way pipe 5 , which are referred to as the first butterfly valve body 101 and the second butterfly valve body 102 in this embodiment. Such as Figure 3-5 As shown, the sliding connection transmission device 4 includes a fixed transmission assembly 41, a push-type positioning device 4...

Embodiment 2

[0049] Such as figure 2 , 3 , 4, the difference between this embodiment and the above-mentioned embodiments is that the pushing device 422 includes a bracket 4221, a guide rail 4222, and a screw rod 4223, the bracket 4221 is installed on the valve body 11, and the bracket 4221 includes a first support rod 42211, a second The support rod 42212, the first support rod 42211, and the second support rod 42212 are parallel to each other, and the second support rod 42212 is close to the fixed guide rotating cylinder 413, and the first support rod 42211 is away from the fixed guide rotating cylinder 413, on the second support rod 42212 A first through hole (not shown in the figure) and a second through hole (not shown in the figure) corresponding to the first through hole 4131101 and the second through hole 4131102 are provided. The guide rail 4222 and the screw rod 4223 are connected in parallel between the first support rod 42211 and the second support rod 42212, wherein one end o...

Embodiment 3

[0053] Such as figure 1 , 2 , 3, the difference between this embodiment and the above-mentioned embodiments is that the pushing device 422 includes a bracket 4221 and a push cylinder (not shown in the figure), the bracket 4221 is installed on the valve body 11, and the cylinder end of the push cylinder is connected to the bracket 4221 connection, the piston rod end of the push cylinder is connected with the pressing plate 421, and the piston rod end of the push cylinder is elongated to drive the protrusion to be inserted into the corresponding through hole 41311.

[0054] The push cylinder of the present invention is preferably a servo push cylinder, and the elongation movement of the piston rod end drives the pressing plate 421 close to the fixed guide rotating cylinder 413, thereby realizing that the first protrusion 4211 and the second protrusion 4212 respectively extend into the corresponding first channel. In the hole 4131101 and the second through hole 4131102; the pist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com