Device and method for improving transverse temperature uniformity of strip steel by transverse magnetic flux induction heating

A technology of transverse magnetic flux and induction heating, applied in the direction of induction heating, induction heating control, coil device, etc., can solve the problems of no control mode provided, temperature uniformity can not meet the requirements of strip continuous annealing process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

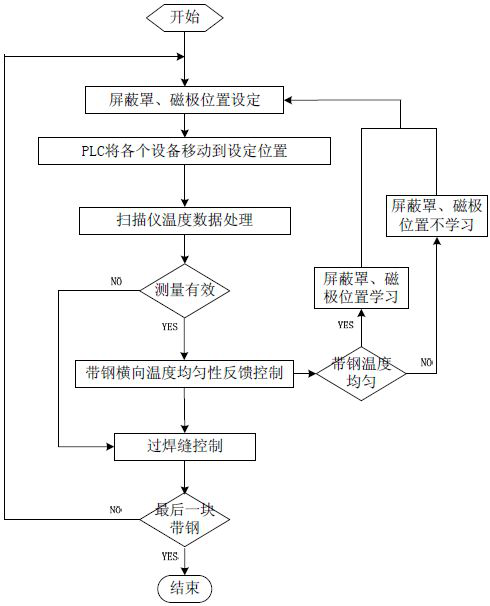

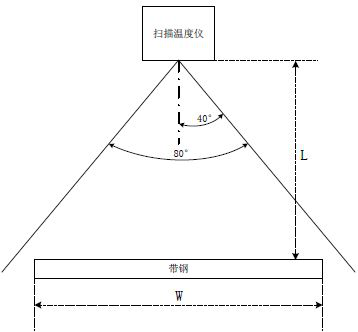

[0075] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

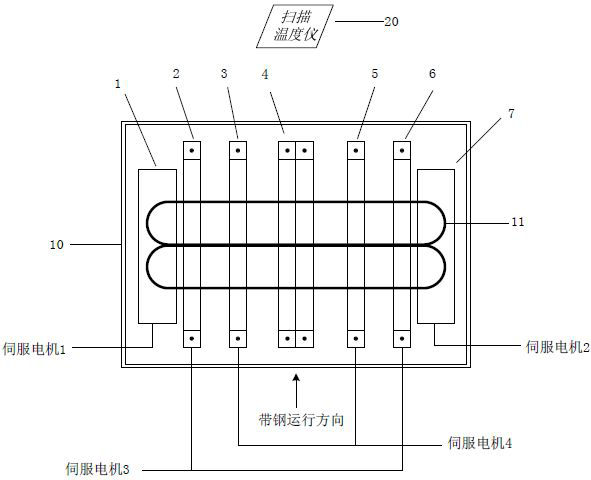

[0076] see figure 1 , a device for improving the transverse temperature uniformity of transverse magnetic flux induction heating strip steel, hereinafter referred to as transverse magnetic equipment, including: a frame, a planar electromagnetic inductor, a shielding cover, and multiple sets of magnetic poles;

[0077] The frame includes an upper frame 10 and a lower frame, and the upper frame 10 and the lower frame are fixed as a whole; the strip steel passes between the upper frame 10 and the lower frame, and the center line of the upper frame, the center line of the lower frame and the running center of the strip steel The lines coincide, the upper frame 10 and the components installed on the upper frame 10 form the front side of the transverse magnetic device, and the lower frame and the components installed on the lower frame form the rever...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com