Patents

Literature

35 results about "Reverse execution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

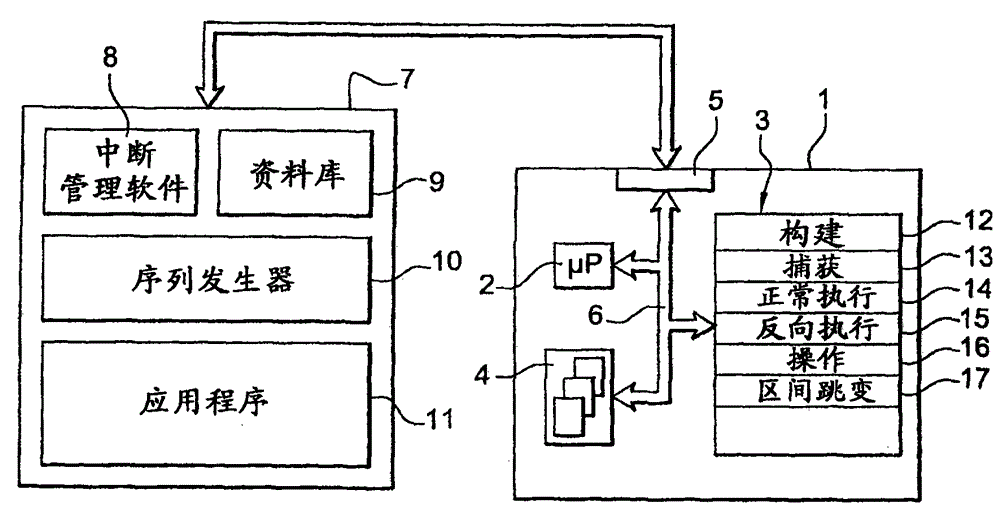

Automated software support system with backwards program execution and debugging

InactiveUS20080244325A1Software testing/debuggingMultiple digital computer combinationsSupporting systemSoftware bug

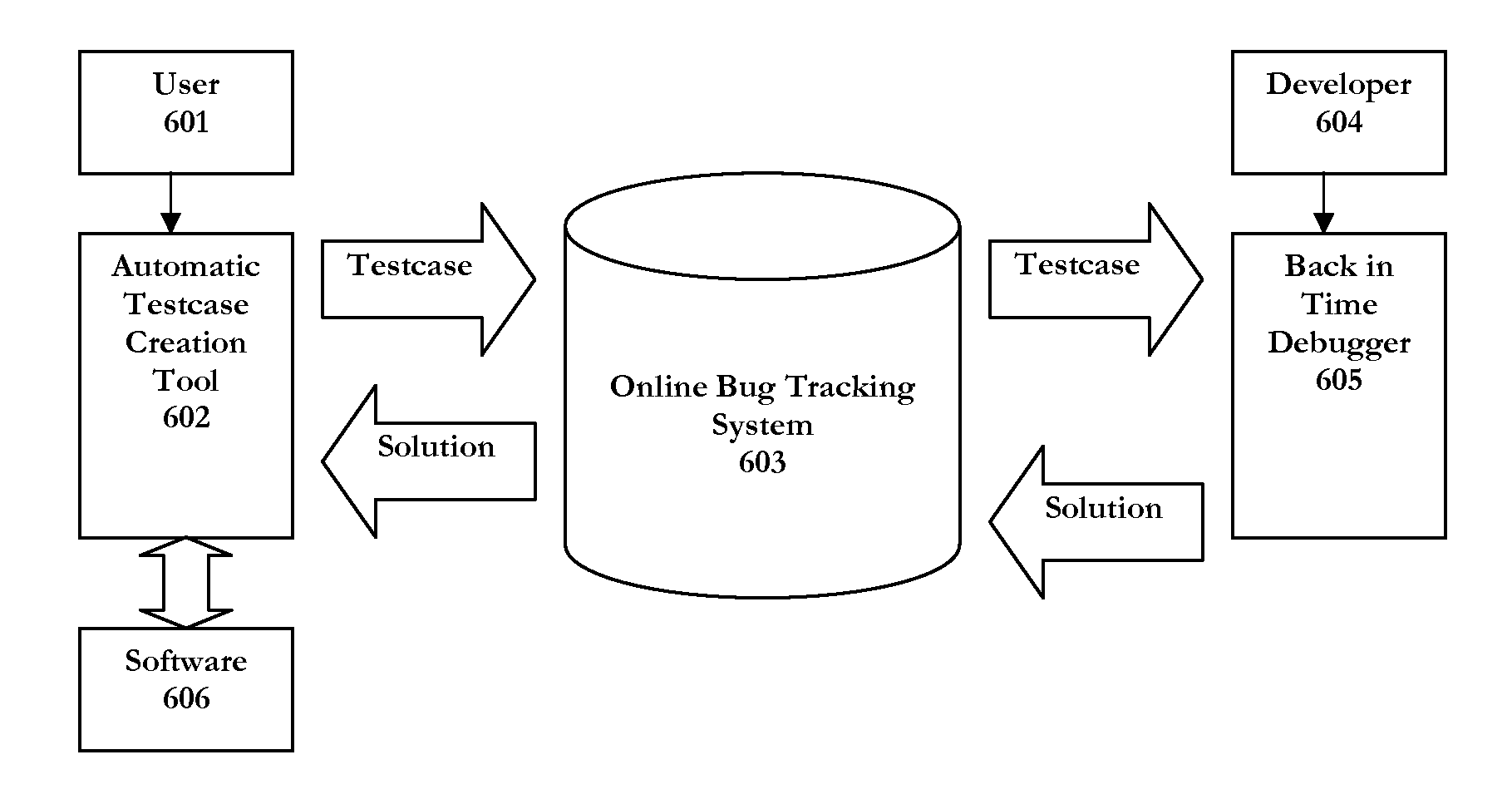

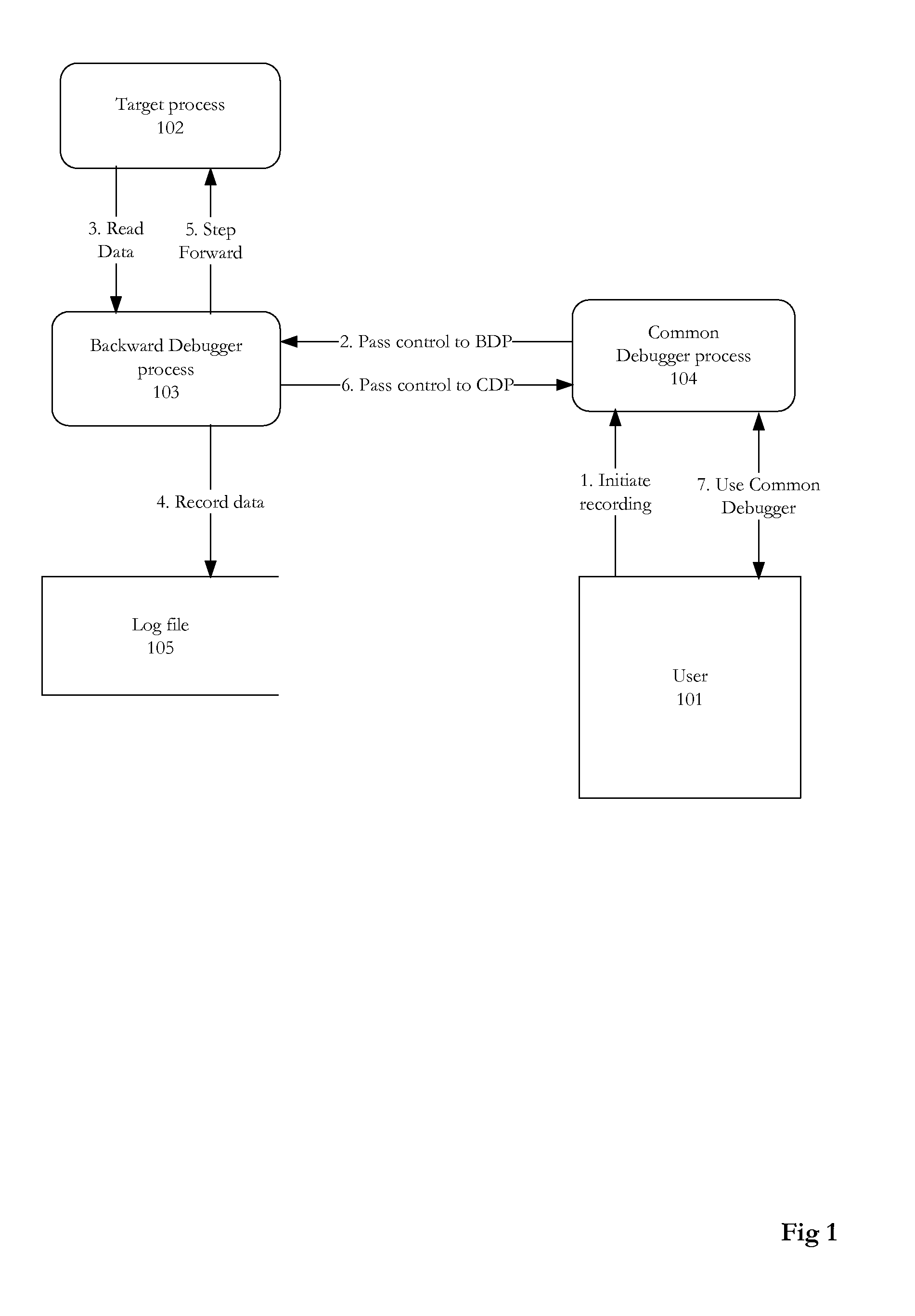

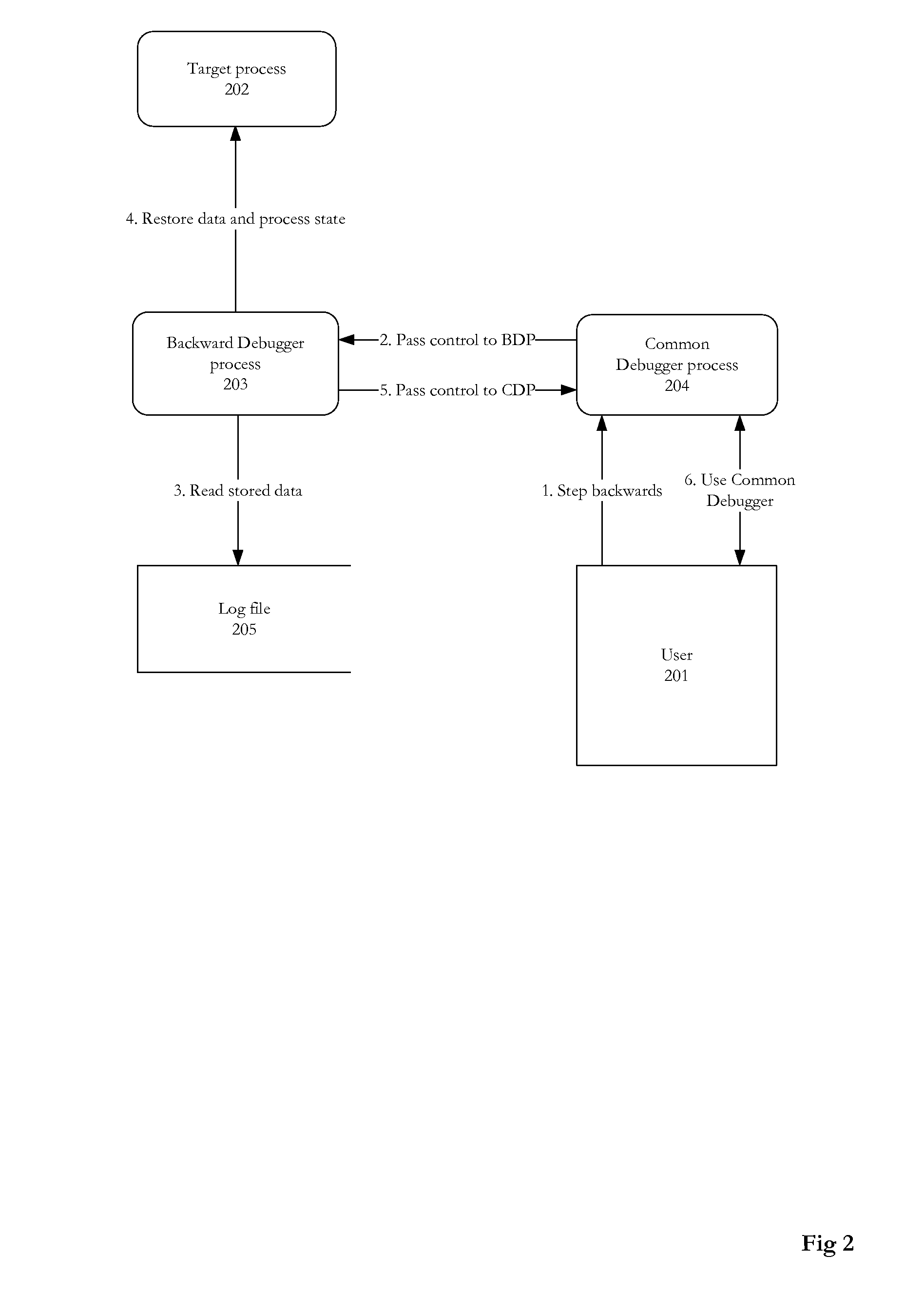

The invention describes an automated software support system comprising automated bug filing and test case creation component to checkpoint a client process initial state and record the client process initial state changes while the client process undergoes sequence of states which need to be analyzed, such as software bug, deliver the recordings to a development node, where the problem can be debugged without reproducing the client process environment by using the recorded state to recreate initial state of the client program and by using the recorded log to simulate the client program execution forwards and backwards.

Owner:TYULENEV MIKHAIL

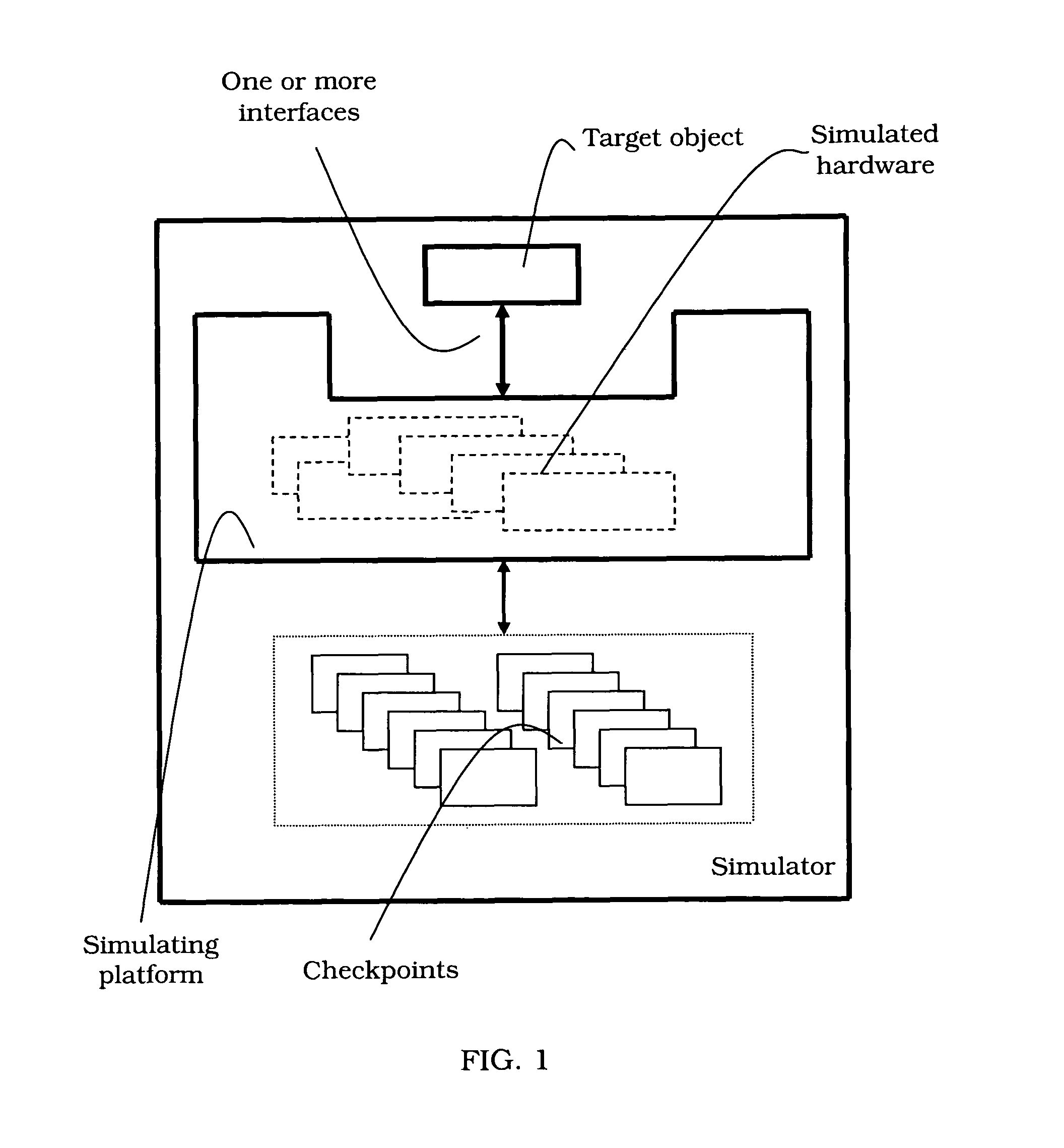

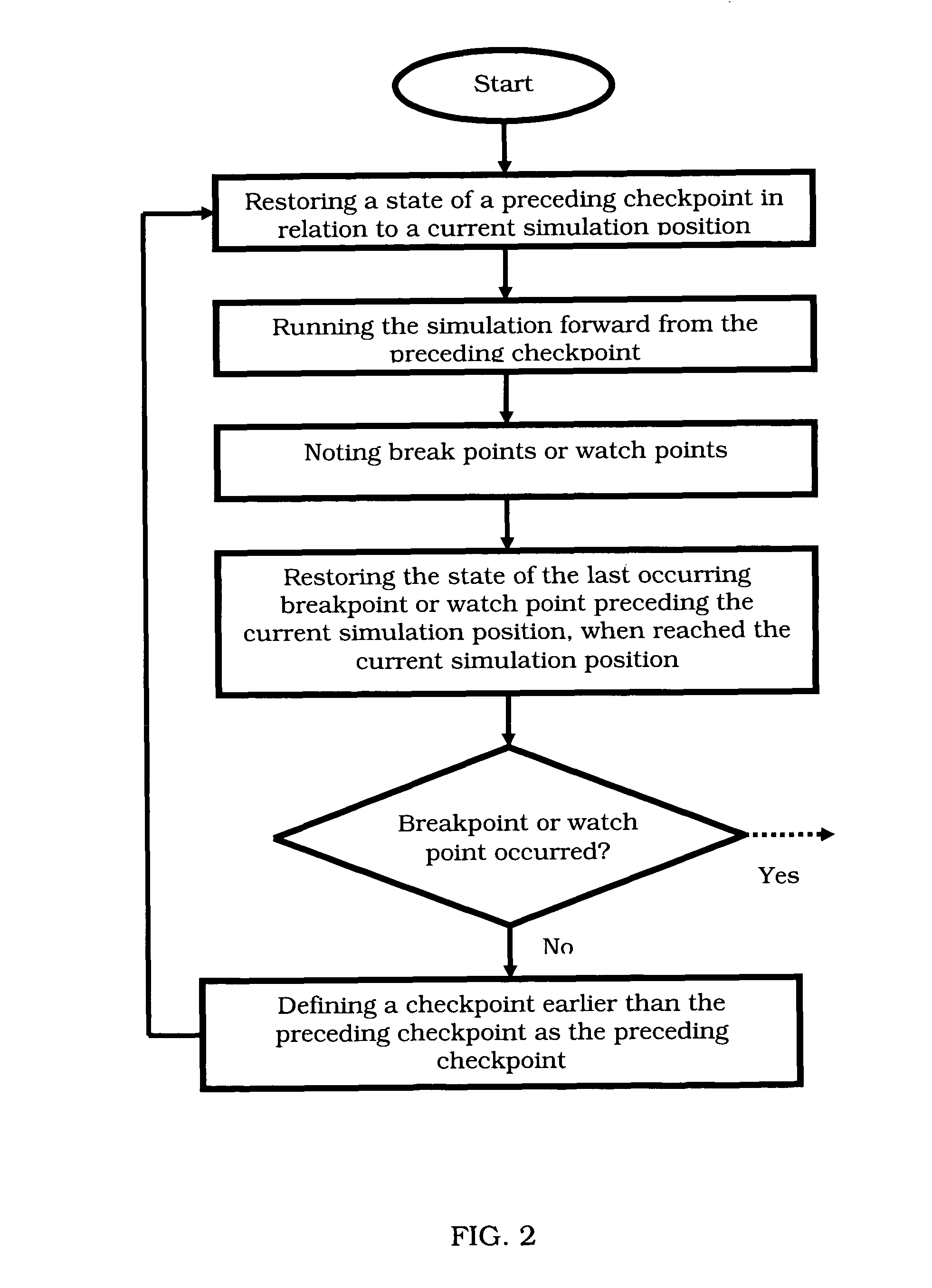

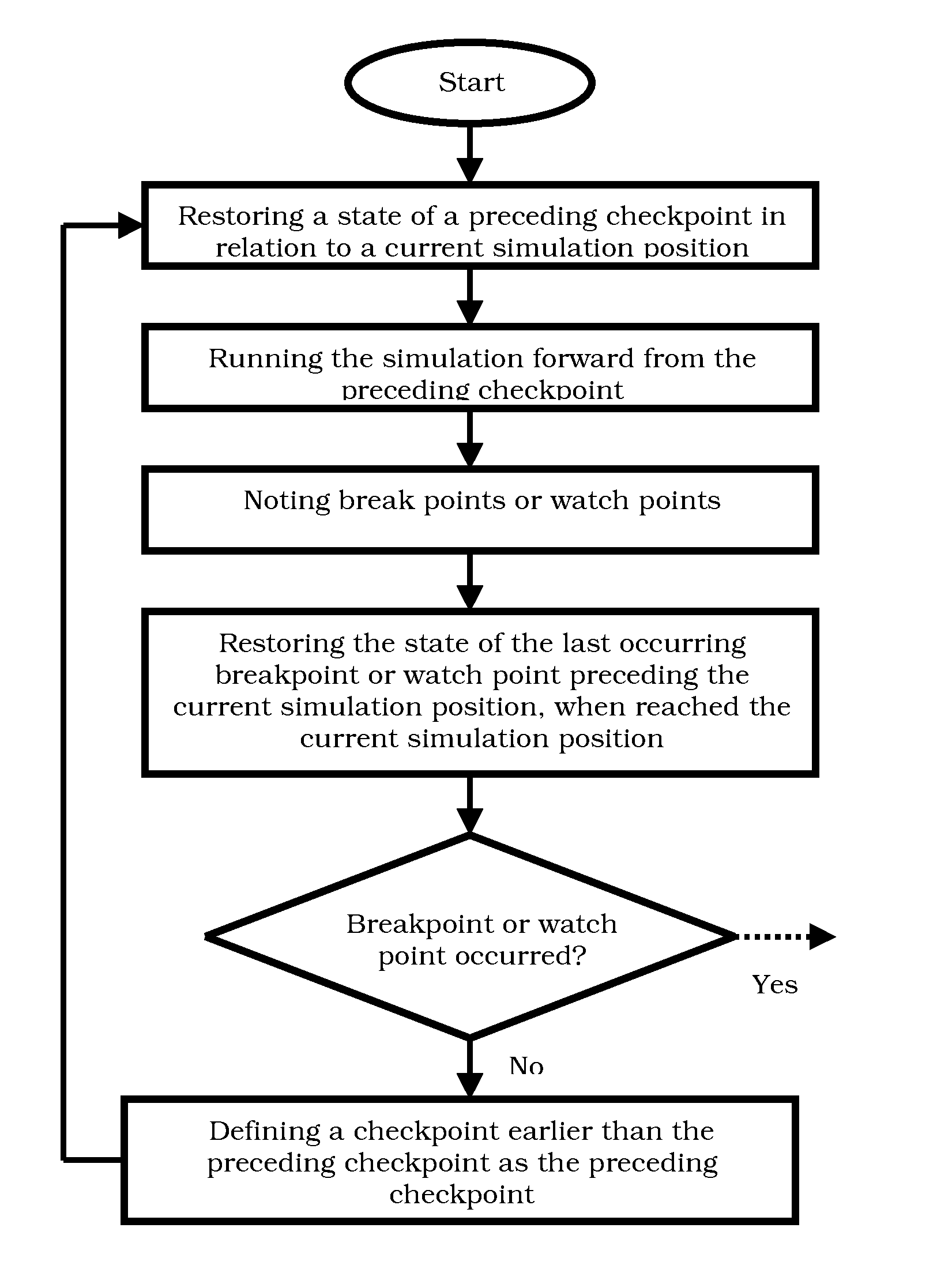

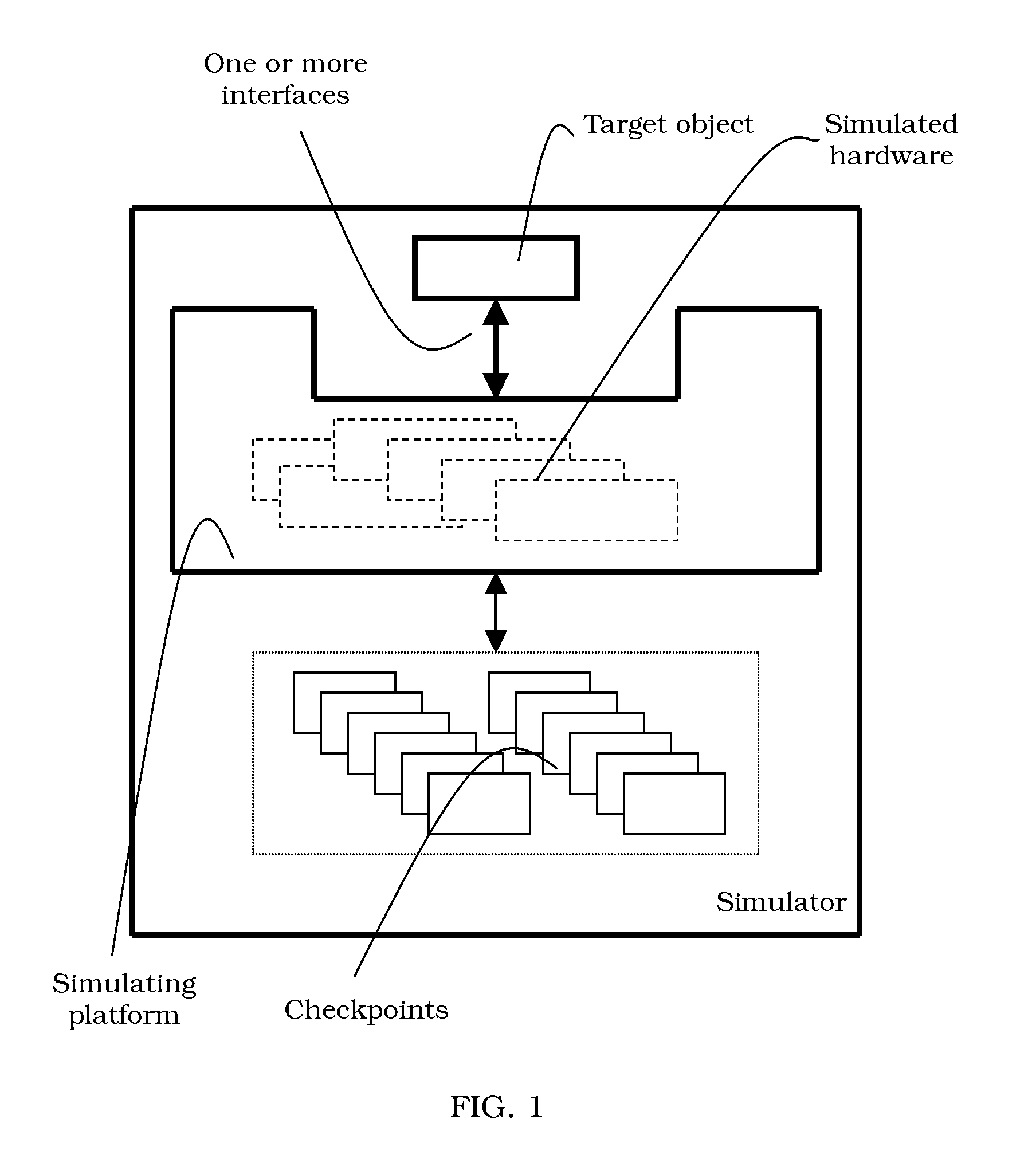

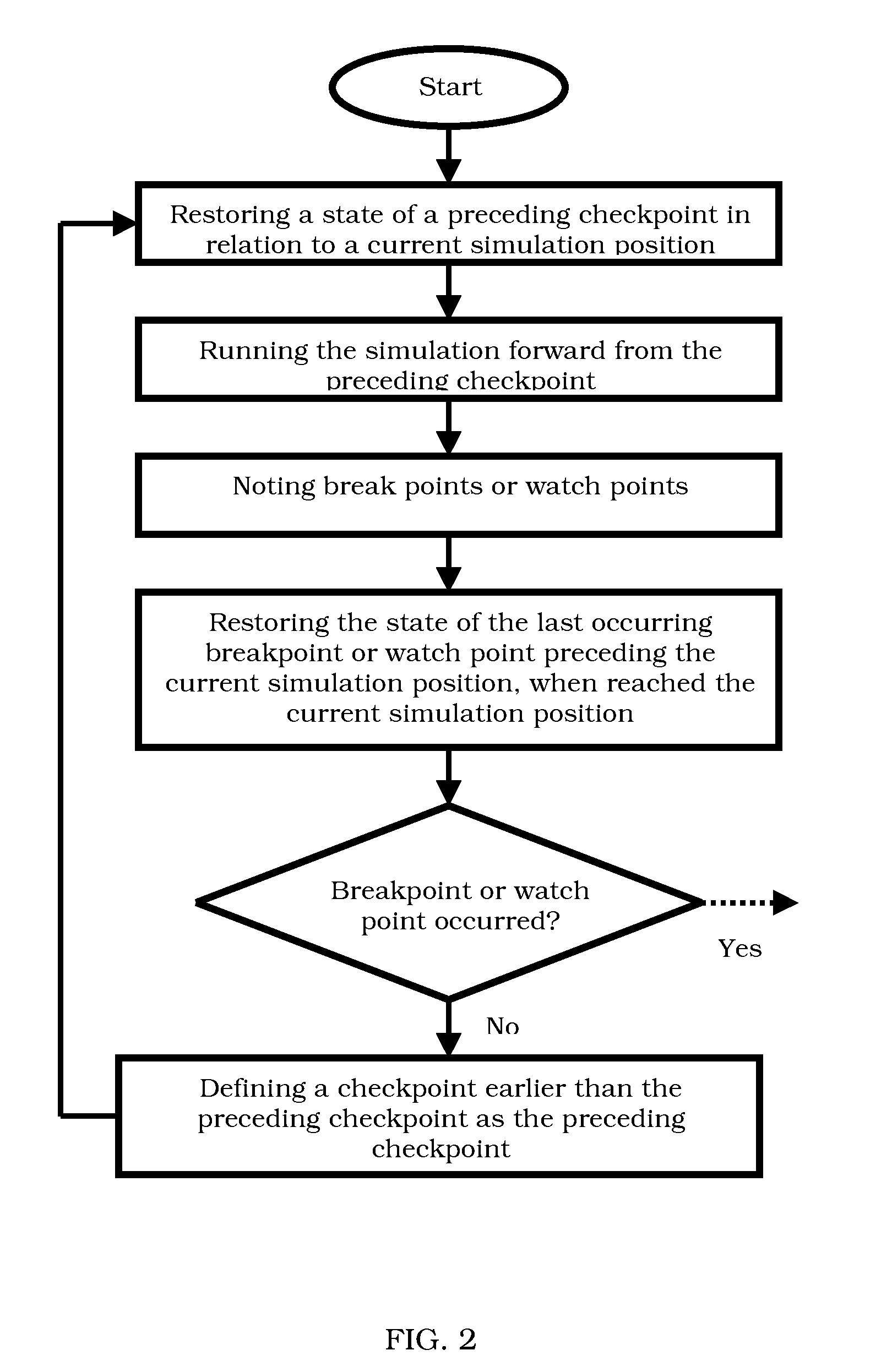

Devices, methods and computer program products for reverse execution of a simulation

InactiveUS7849450B1Error detection/correctionSpecific program execution arrangementsReverse executionObservation point

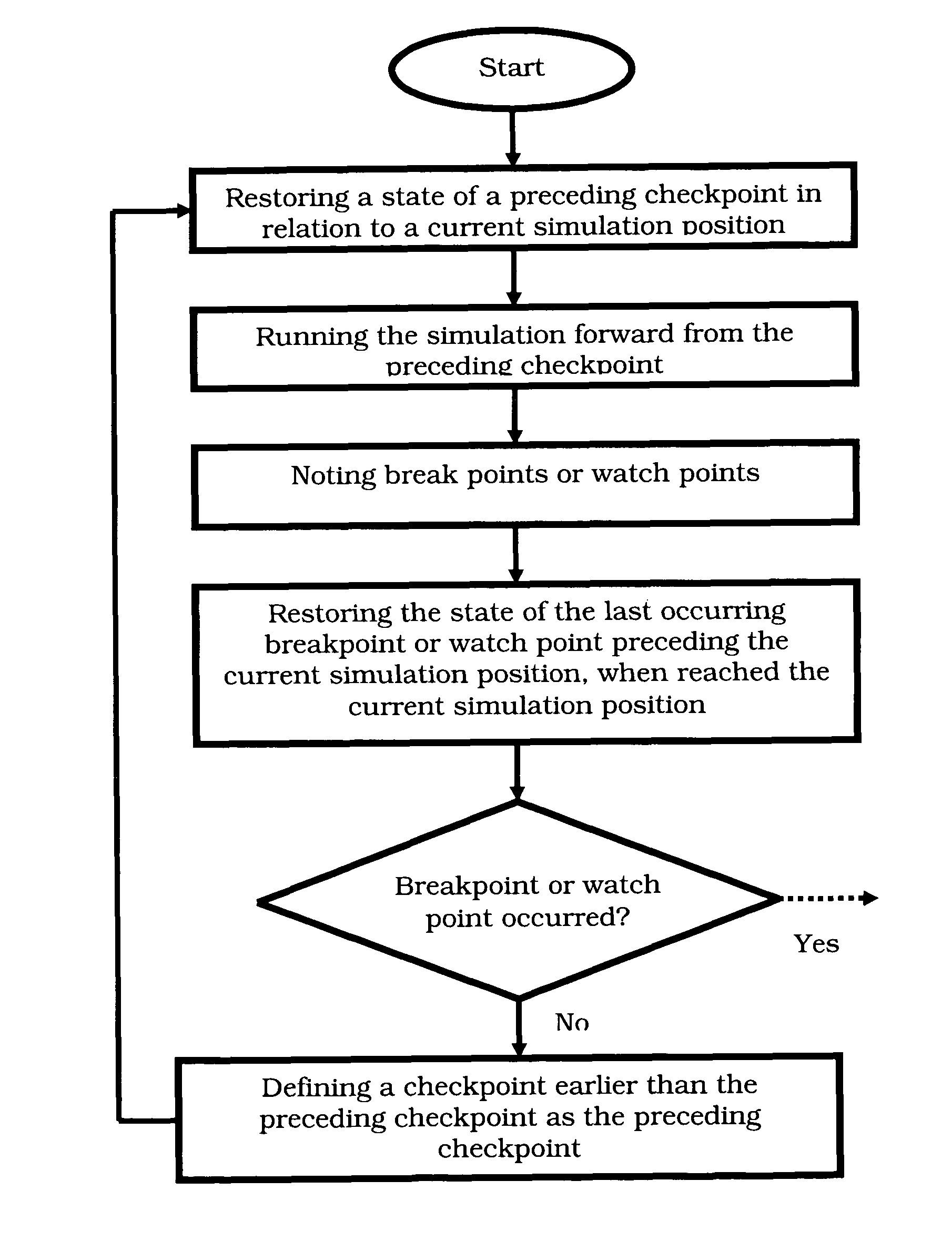

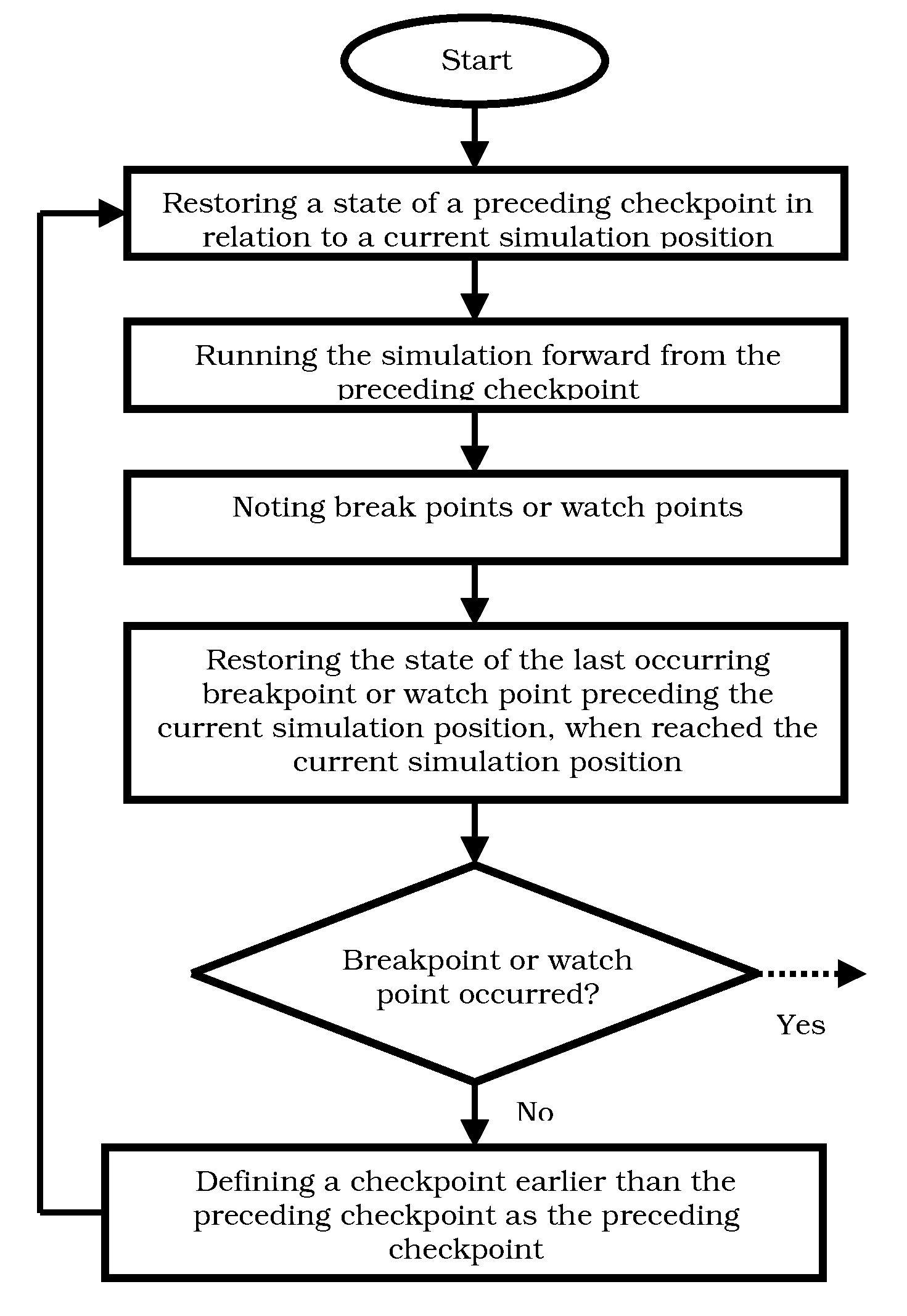

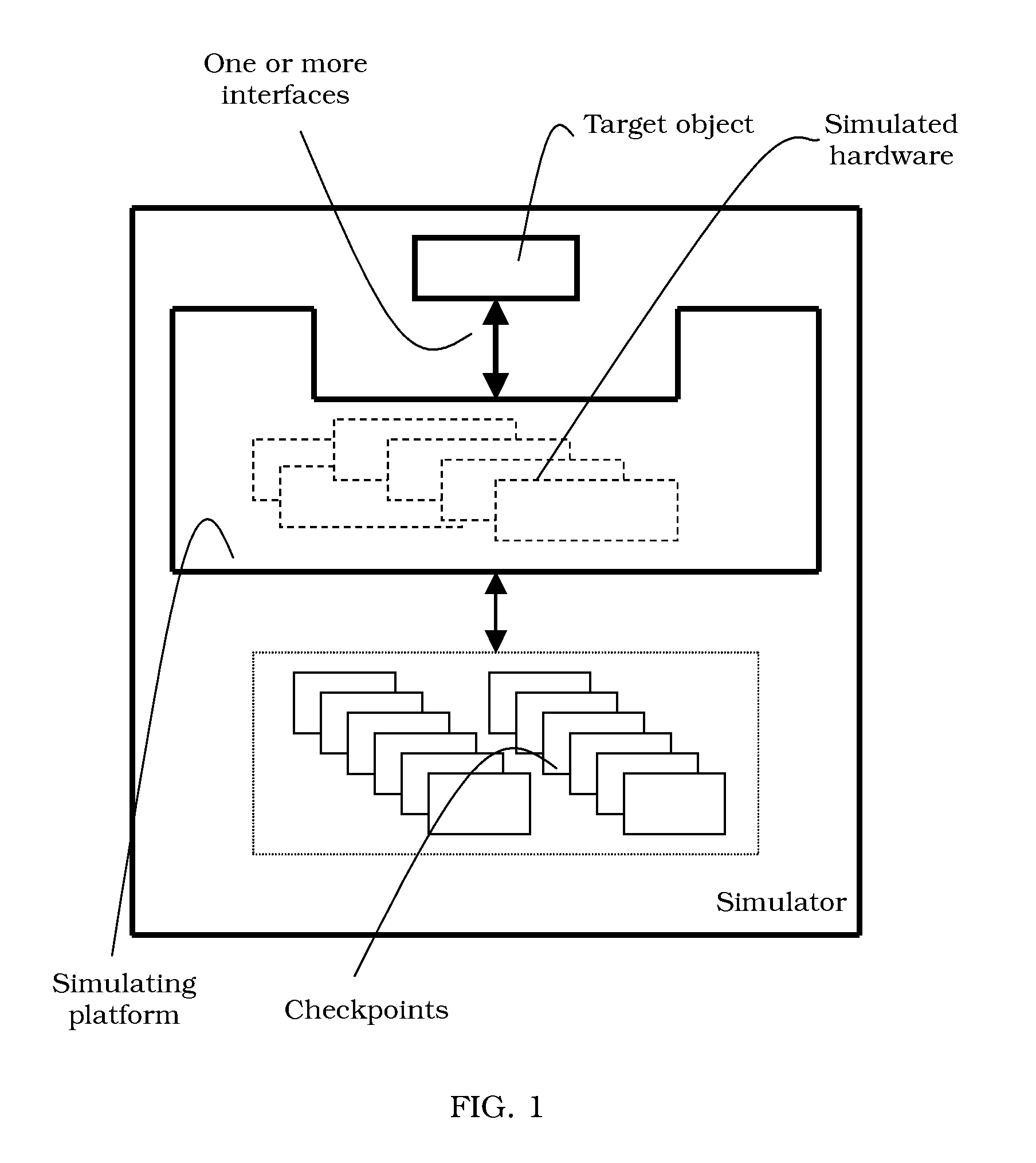

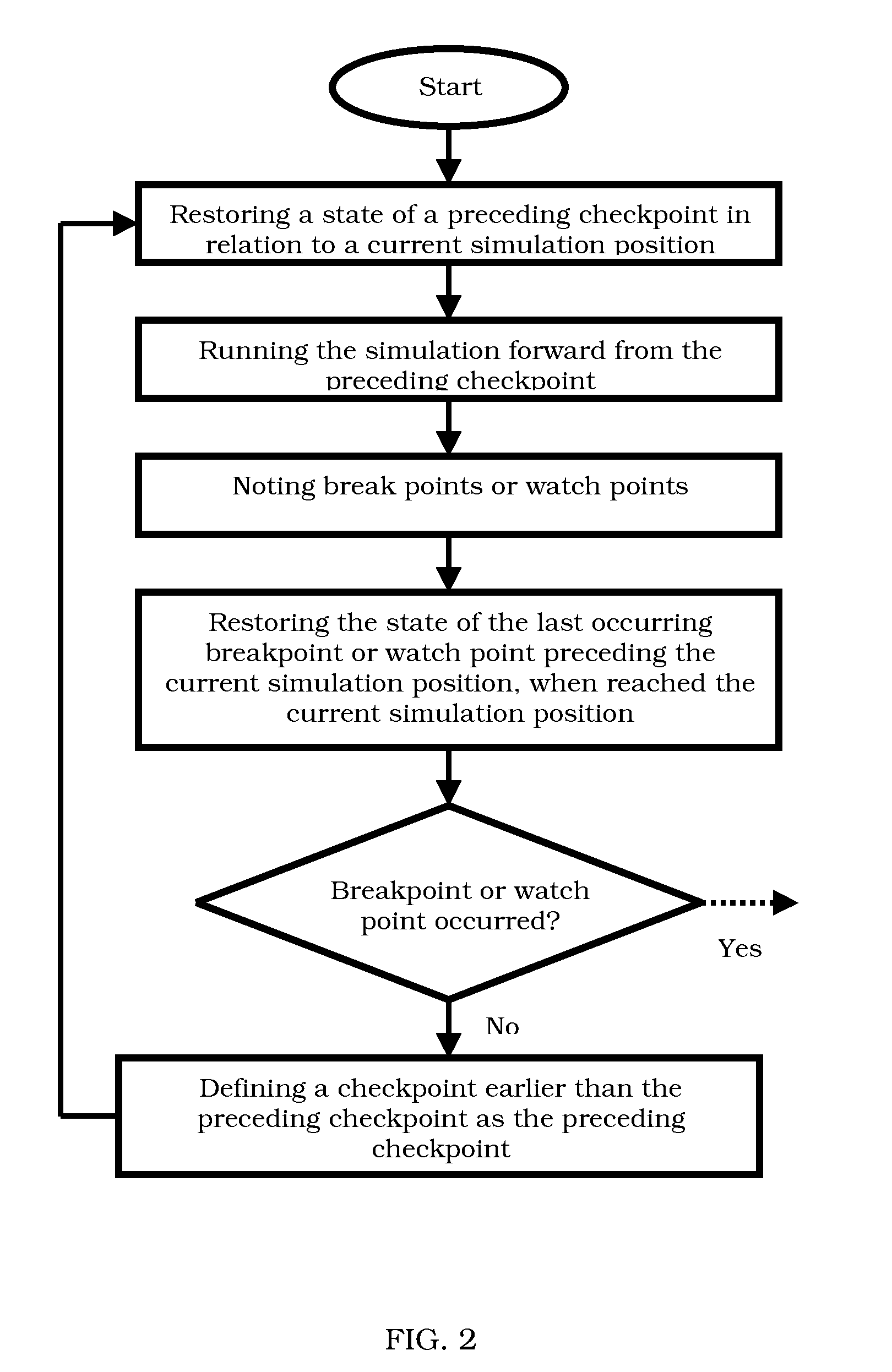

Devices, methods, and software program products for reverse execution of a simulation and / or tracing a value are provided. A state of a preceding checkpoint may be restored and a simulation may be run forward. Break points or watch points may be noted and the state of the last occurring breakpoint or watch point preceding the current simulation position may be restored. If no breakpoint or watch point occurred, an earlier checkpoint may be loaded and the previous steps may be repeated.

Owner:INTEL CORP

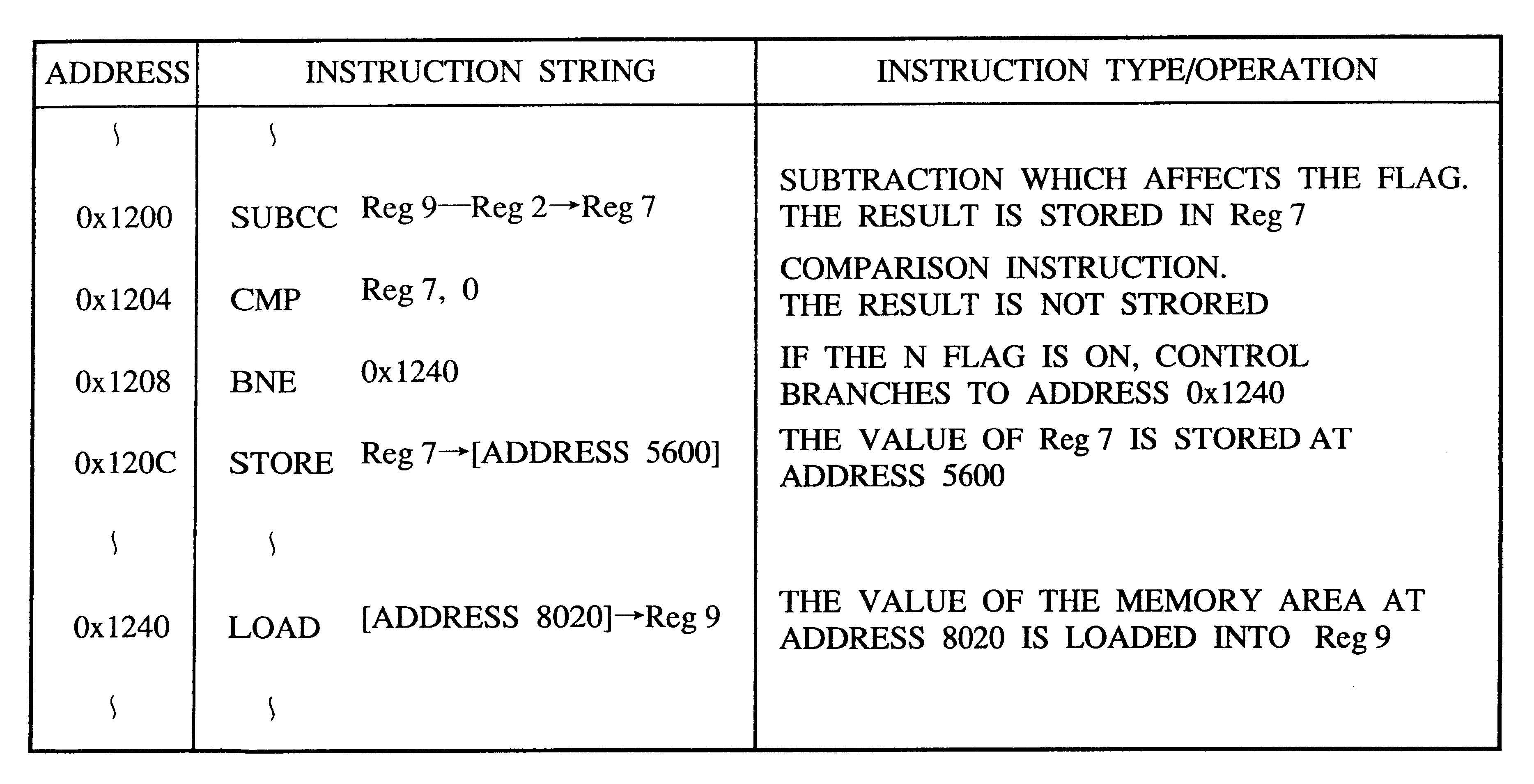

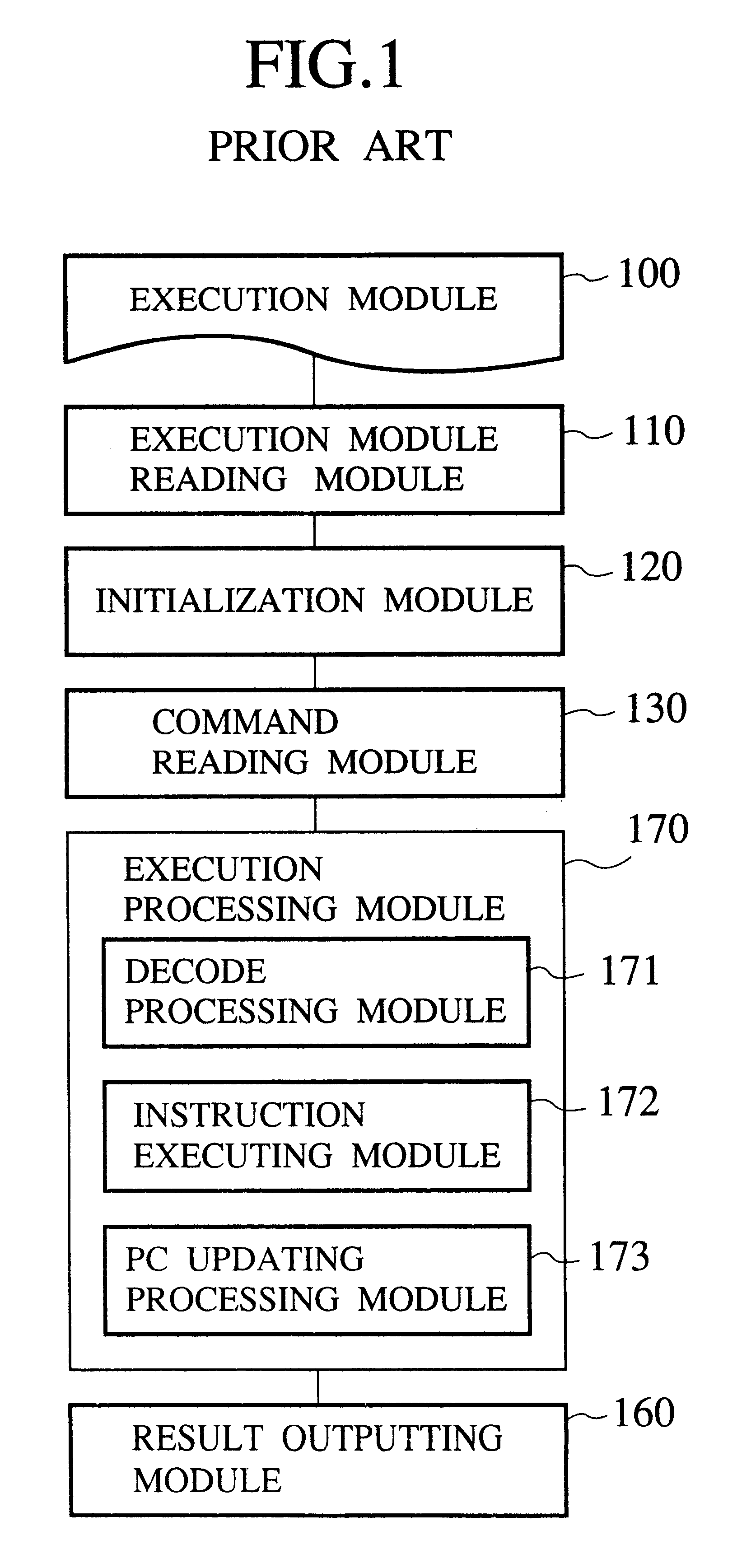

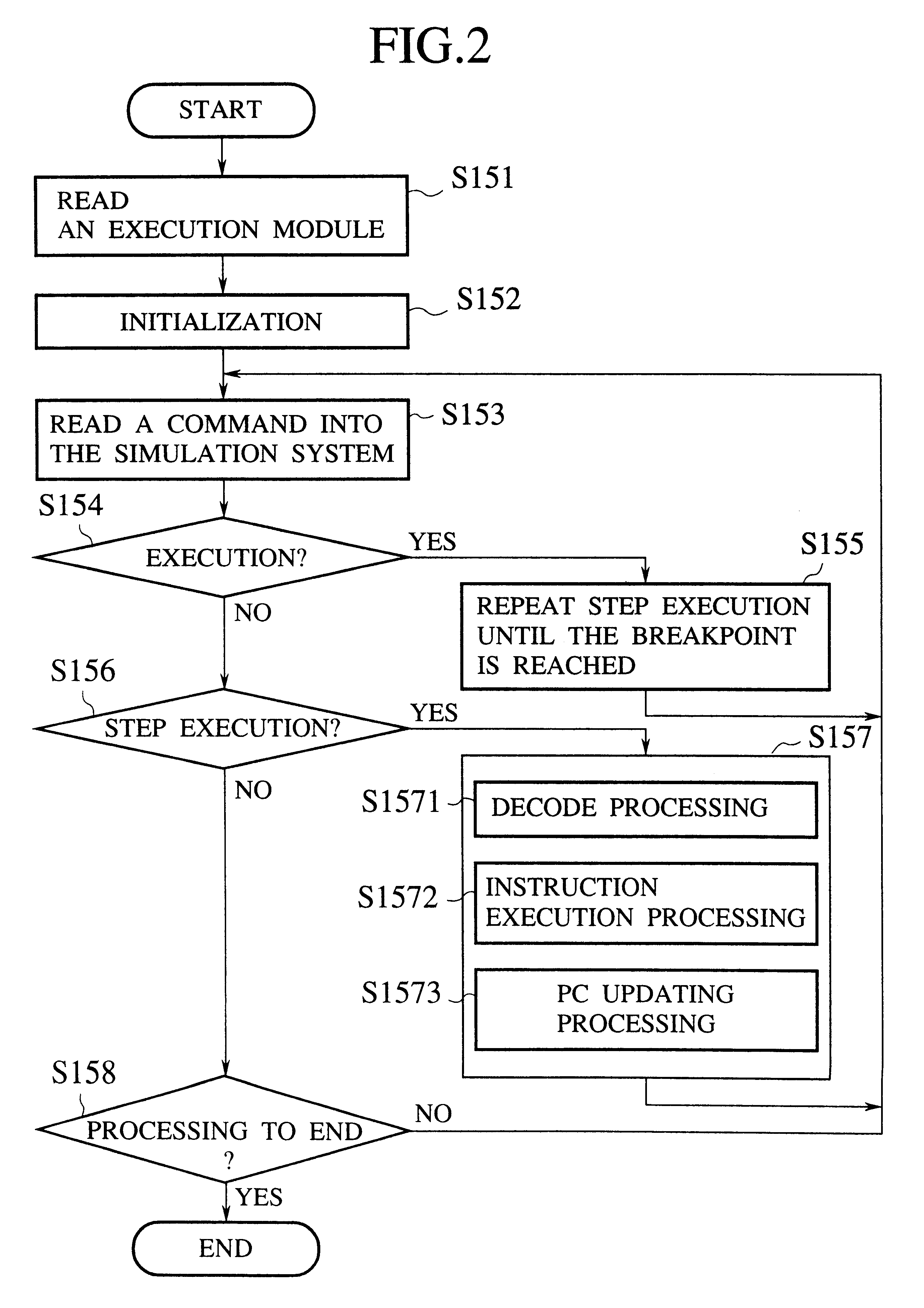

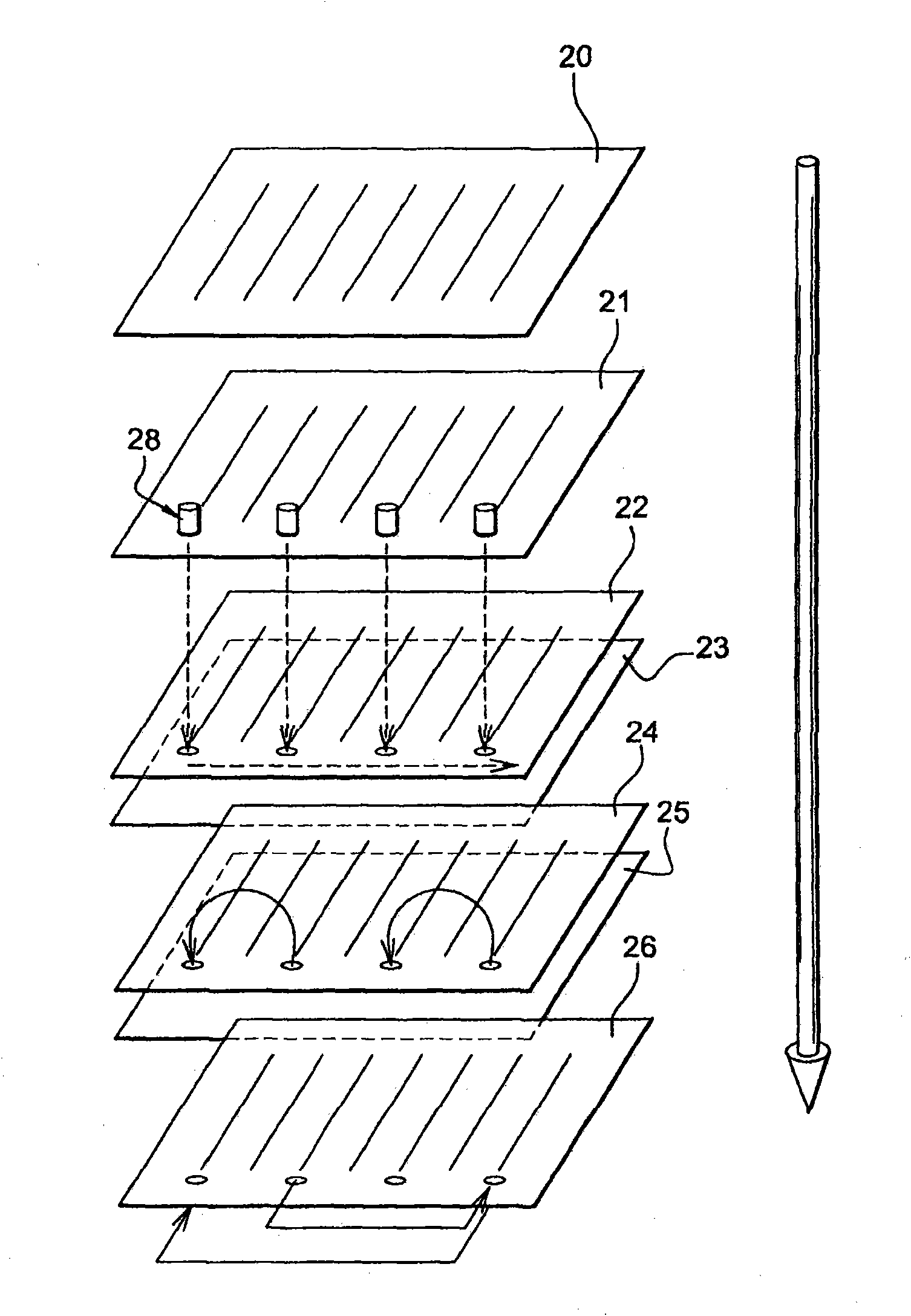

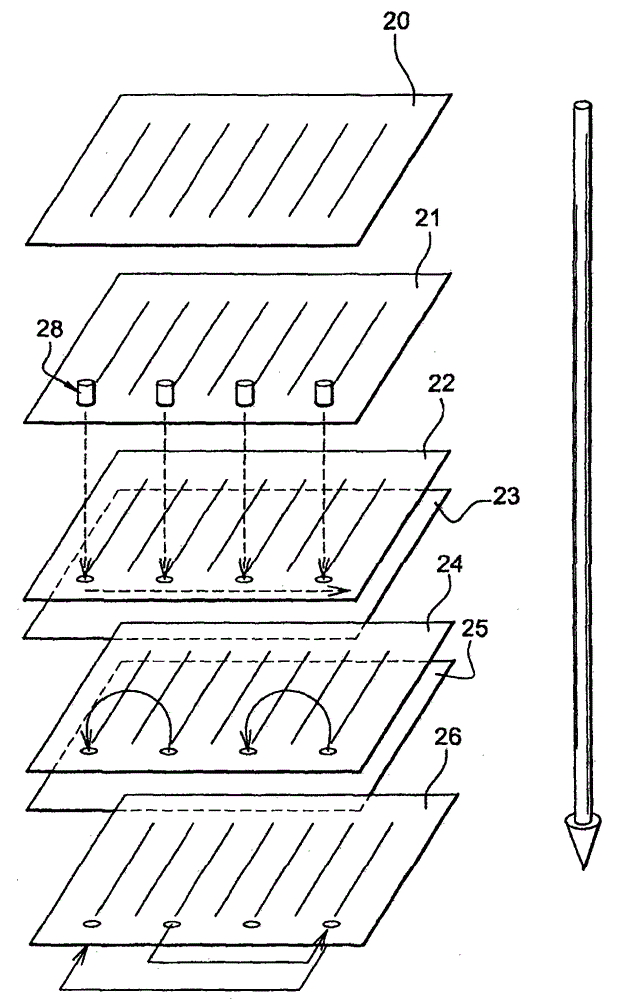

Simulation system, simulation evaluation system, simulation method, and computer-readable memory containing a simulation program, having less trace information for reverse execution

InactiveUS6240544B1Software testing/debuggingSpecific program execution arrangementsReverse executionEvaluation system

An execution processing module, while executing an execution module, stores an instruction type, and selectively stores a register value, a flag value, a branch source address, or a memory area value that may be updated by instruction execution according to the instruction type for use as trace data when a command read by a command reading module is a forward command. An UNDO execution processing module performs restoration processing using the trace data according to the instruction type when the command read by the command reading module is a backward command.

Owner:KK TOSHIBA

Devices, methods and computer program products for reverse execution of a simulation

InactiveUS8276127B2Error detection/correctionSpecific program execution arrangementsReverse executionObservation point

Devices, methods, and software program products for reverse execution of a simulation and / or tracing a value are provided. A state of a preceding checkpoint may be restored and a simulation may be run forward. Break points or watch points may be noted and the state of the last occurring breakpoint or watch point preceding the current simulation position may be restored. If no breakpoint or watch point occurred, an earlier checkpoint may be loaded and the previous steps may be repeated.

Owner:INTEL CORP

Devices, Methods And Computer Program Products For Reverse Execution Of A Simulation

InactiveUS20110061043A1Error detection/correctionSpecific program execution arrangementsReverse executionParallel computing

Devices, methods, and software program products for reverse execution of a simulation and / or tracing a value are provided. A state of a preceding checkpoint may be restored and a simulation may be run forward. Break points or watch points may be noted and the state of the last occurring breakpoint or watch point preceding the current simulation position may be restored. If no breakpoint or watch point occurred, an earlier checkpoint may be loaded and the previous steps may be repeated.

Owner:INTEL CORP

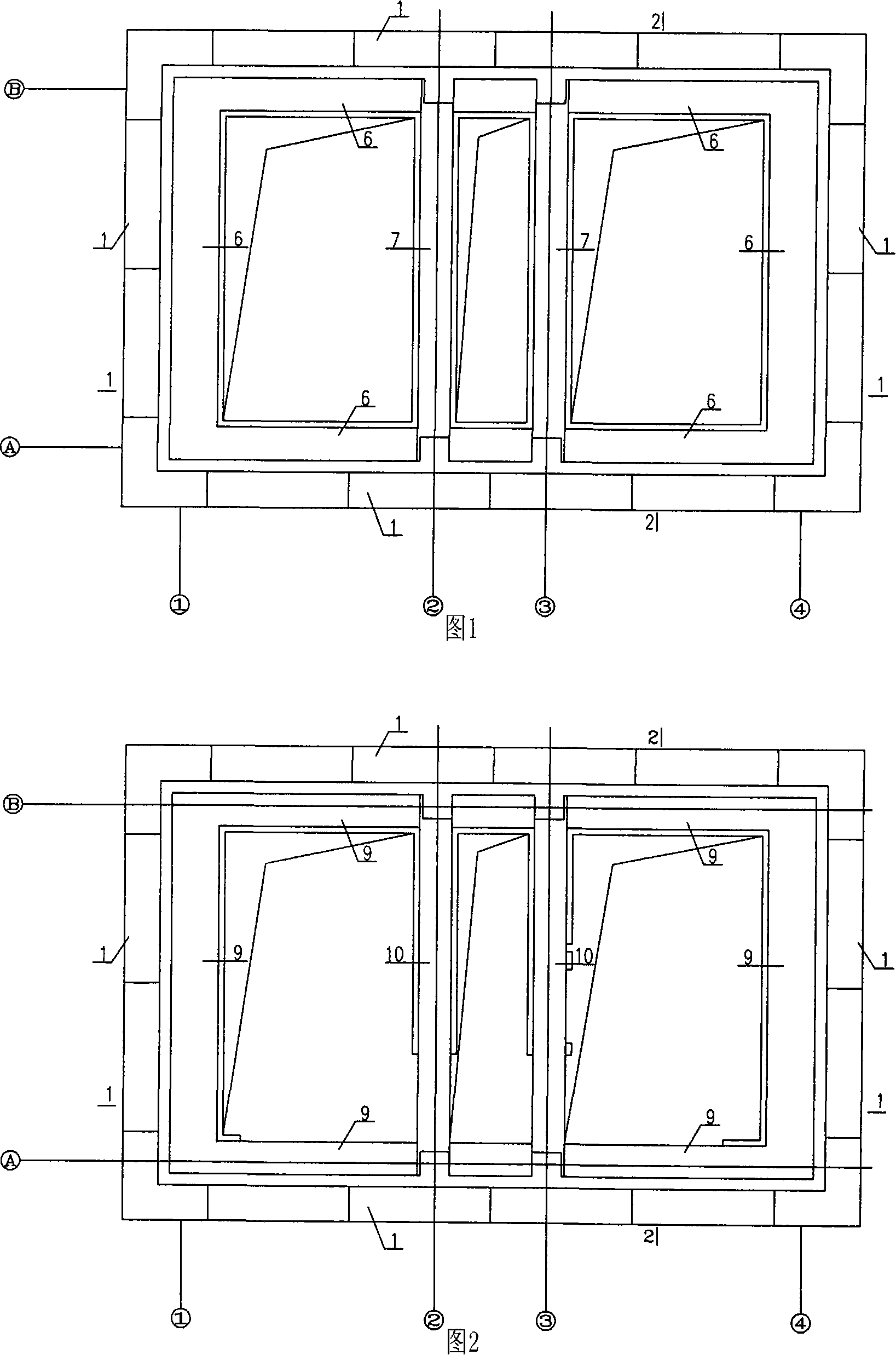

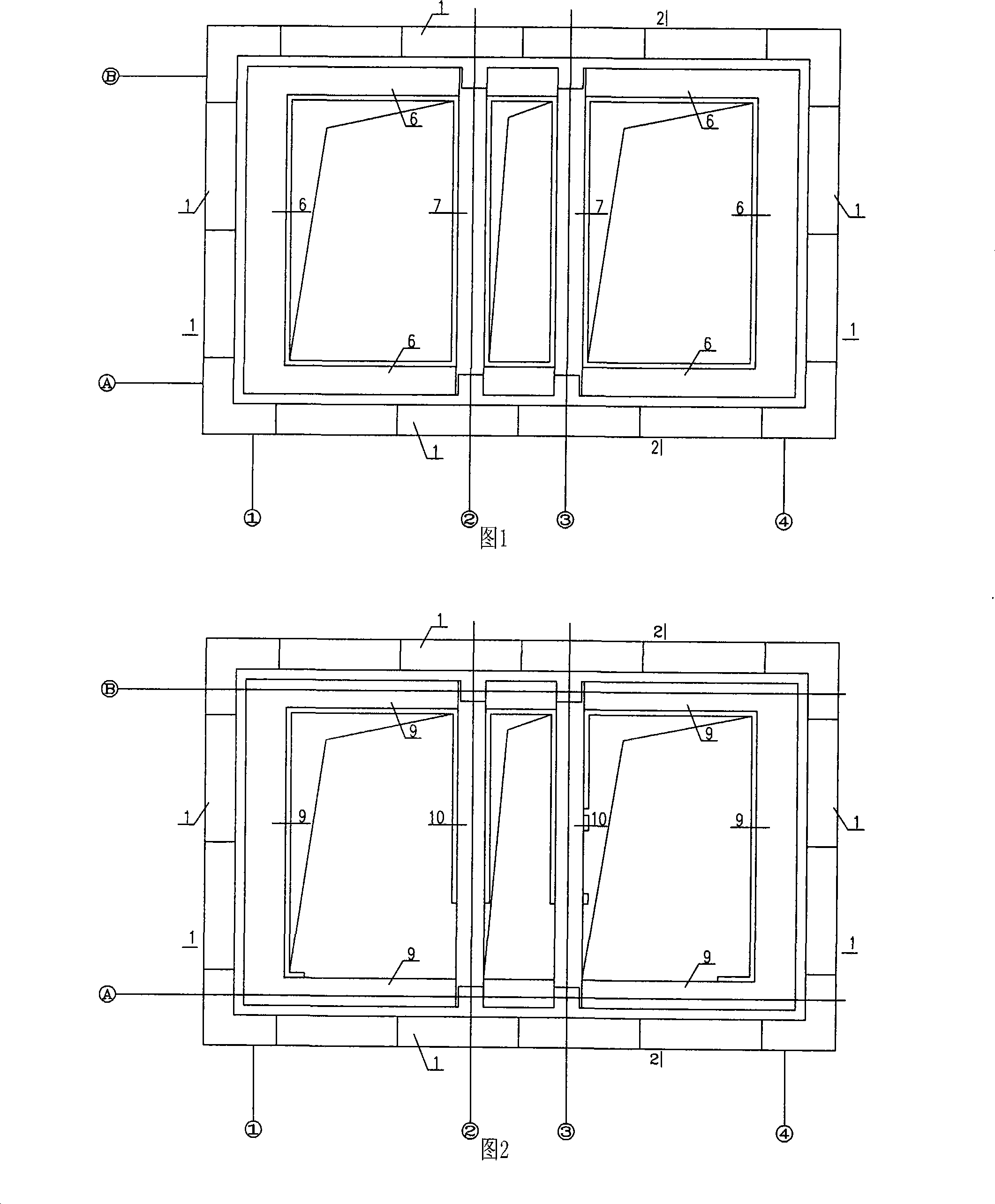

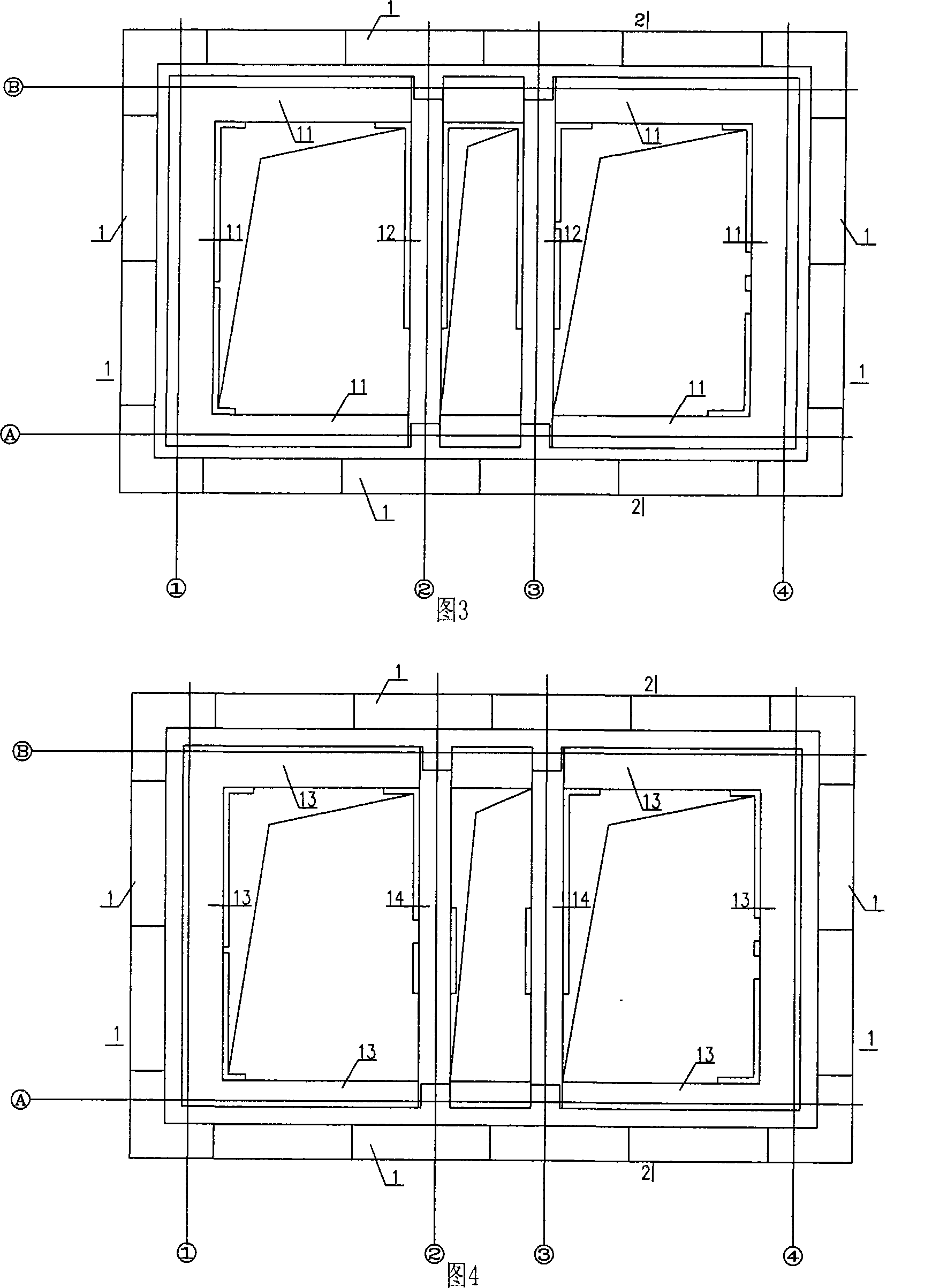

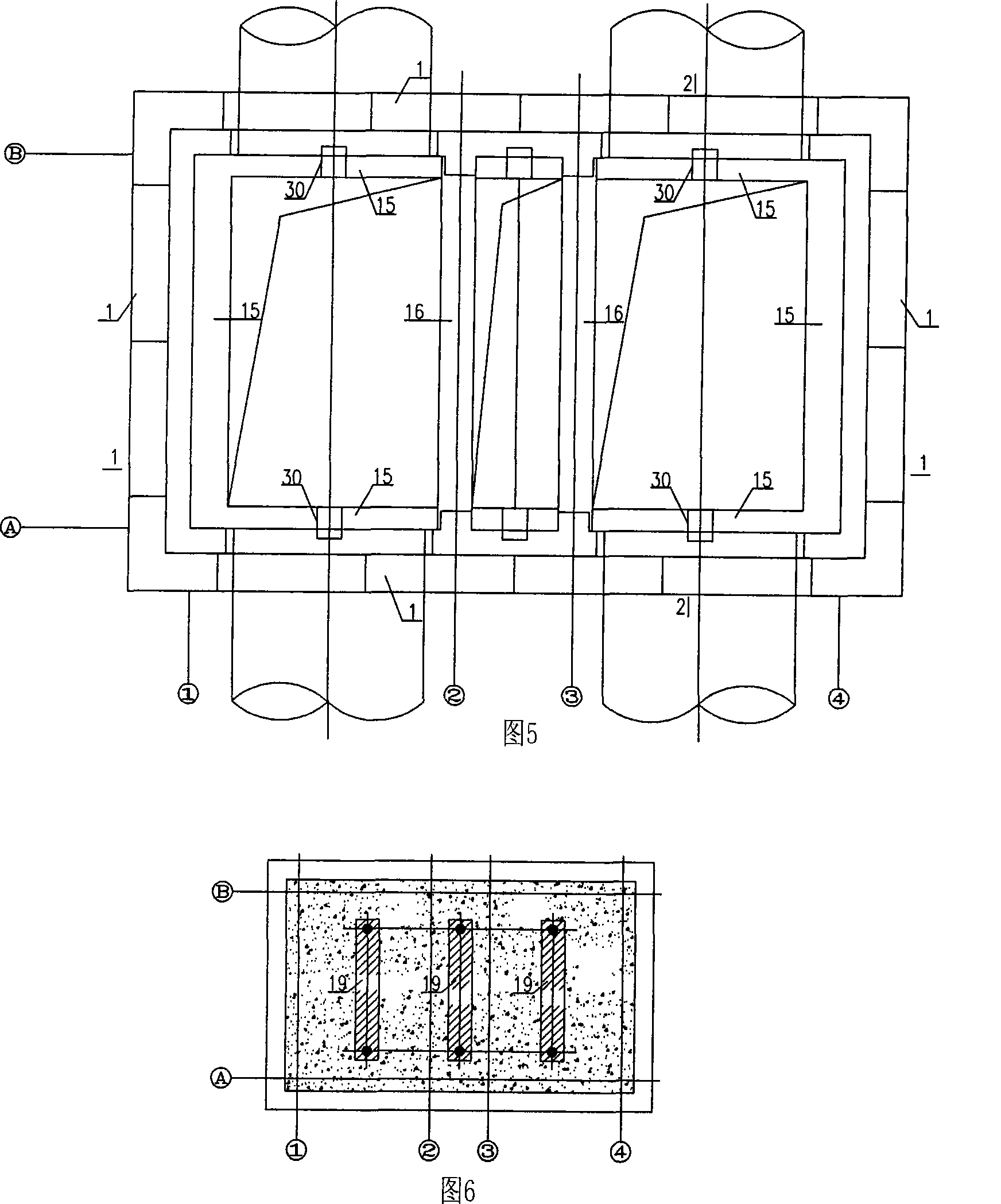

Setting arrangement for high artesian area ultra-deep foundation pit

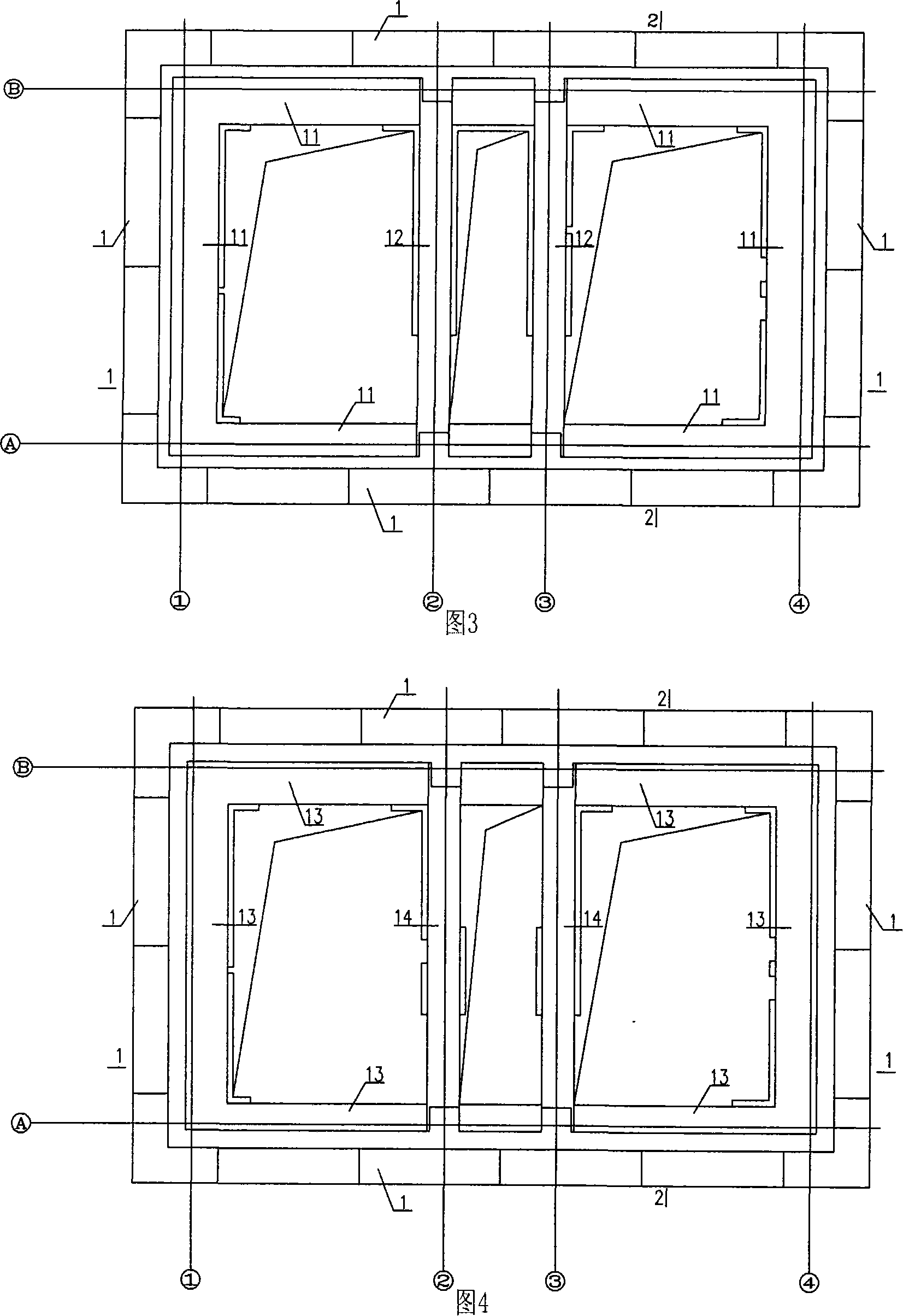

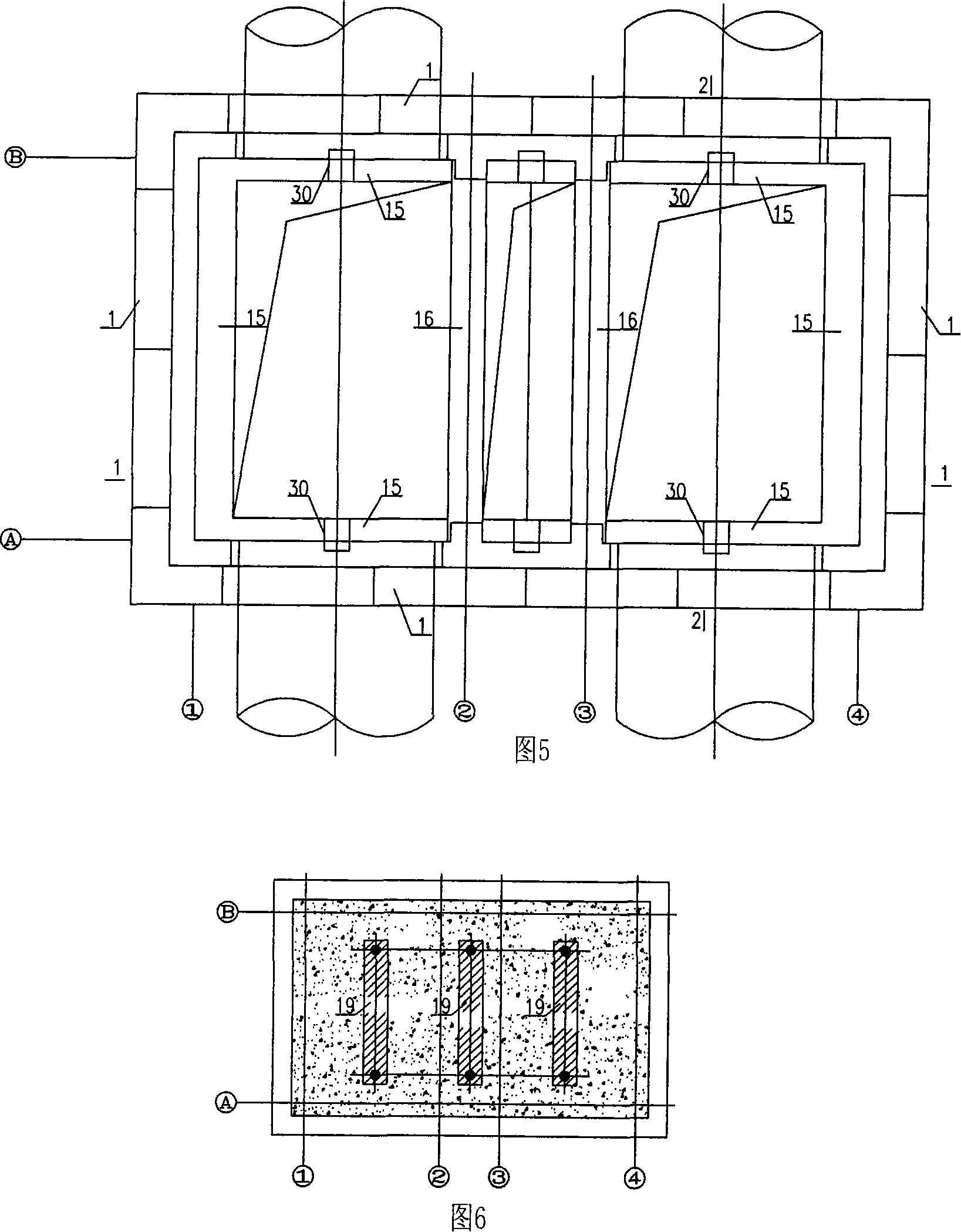

The invention relates to track traffic and tunnel categories, in specific to an arrangement structure of superdeep foundation pits in high pressure water areas; the structure adopts underground continuous walls (or drilling piles, drill biting piles and corresponding waterproof curtains) as enclosure structure, and inner supports (steel supports or concrete supports ) as support structures; during the course of foundation pit excavation, perform reverse execution on surrounding purlins, supports and side walls; through placing precast concrete beams or steel beams in seal concrete, the invention solves shortcomings in prior arts; the invention mainly has the following advantages: On one hand, the invention can avoid the diffuculty in penetration in execution of enclosure structure (in particular to waterproof curtains) when confined aquifers are rather thick and deep; on the other hand, the invention can also avoid all kinds of difficulties in pressure drop of pressure water. Therefore, the invention can save construction cost and lower construction risk at the same time of well protecting surrounding environments.

Owner:SHANGHAI TUNNEL ENGINEERING RAILWAY TRANSPORTATION DESIGN INSTITUTE

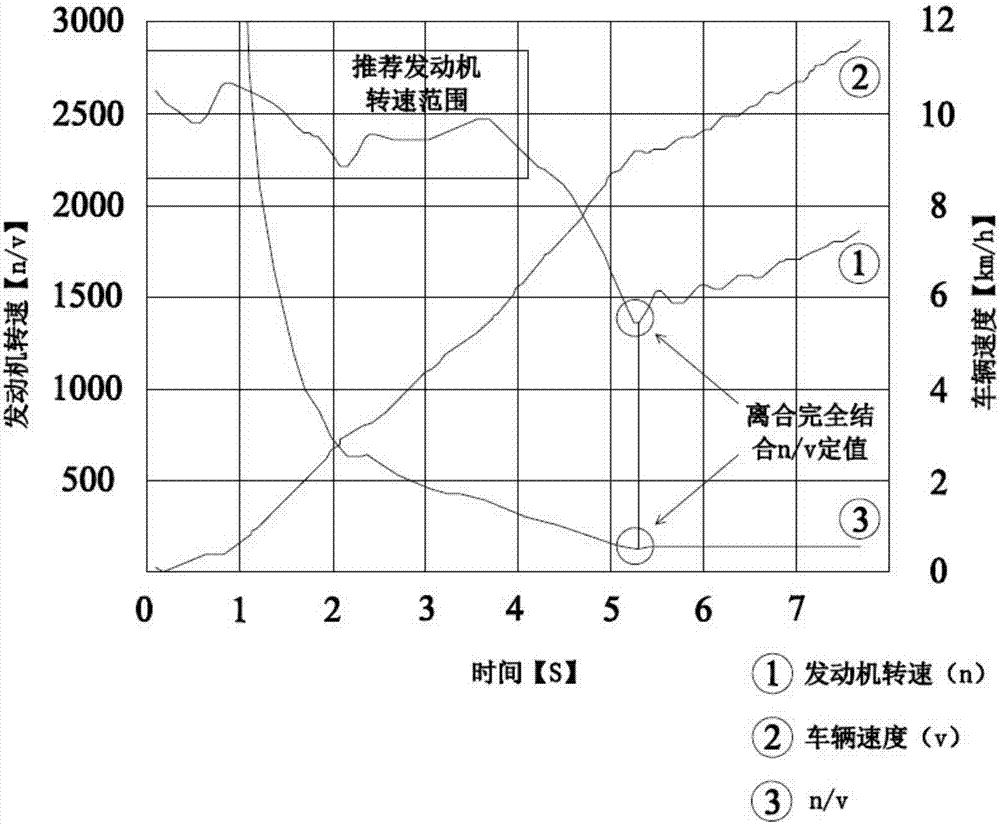

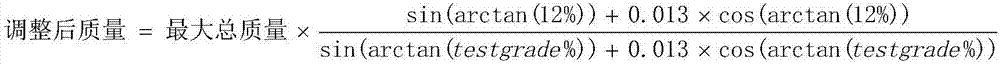

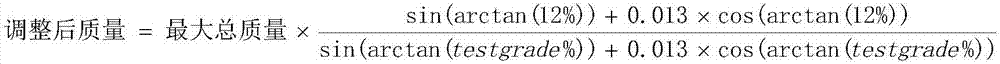

Evaluation method for evaluating hill-start performance of vehicle

The invention discloses an evaluation method for evaluating the hill-start performance of a vehicle and belongs to the technical field of vehicles. The method comprises the following steps of 1, parking a vehicle on a ramp at the gradient of n% when the vehicle is in the maximum total mass state, and keeping the parking state of the vehicle; 2, driving the vehicle to carry out the hill starting process by a driver, and keeping the parking state of the vehicle after the hill starting process of the vehicle is carried over a certain distance; 3, repeating the step 2, and carrying out hill starting processes for at least two times; 4, judging the state completion condition of each hill starting process; 5, evaluating and judging whether bad phenomena occur during the hill starting process of the vehicle or not, wherein the bad phenomena are composed of abnormal sound, abnormal smell, engine stall, wheel trackslip, reverse execution and the like. Therefore, the hill-start performance of the vehicle can be evaluated. Based on the evaluation method for evaluating the hill-start performance of the vehicle, the problem that no related evaluation method is available for evaluating the hill-start performances of vehicles in the prior art can be solved. As a result, the design personnel and users can evaluate the hill-start performances of vehicles.

Owner:NANJING NAVECO AUTOMOBILE CO LTD

Intelligent pillow

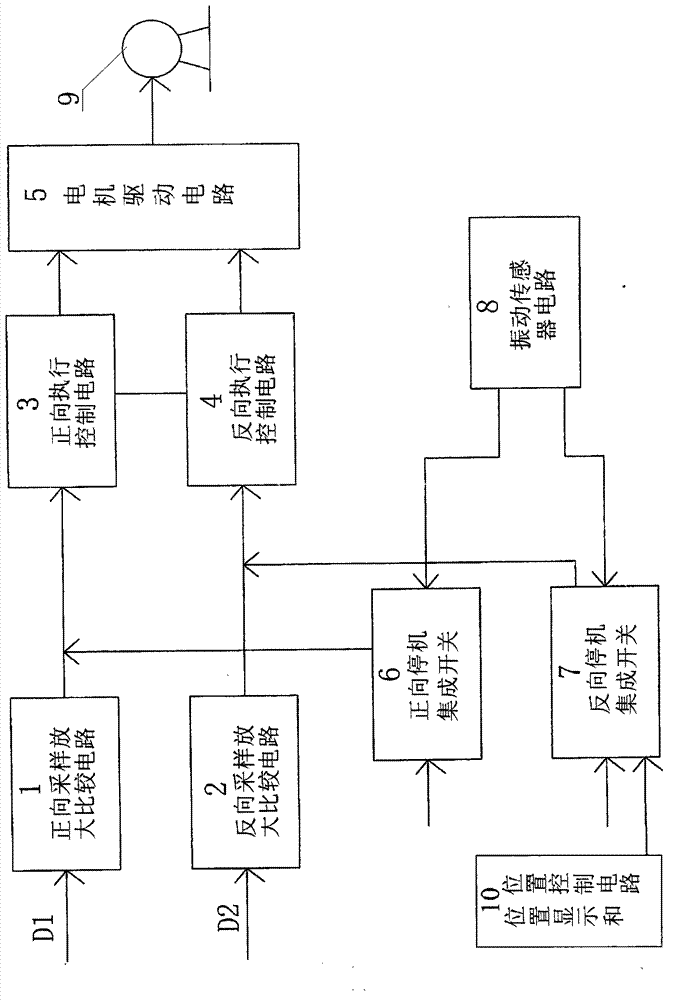

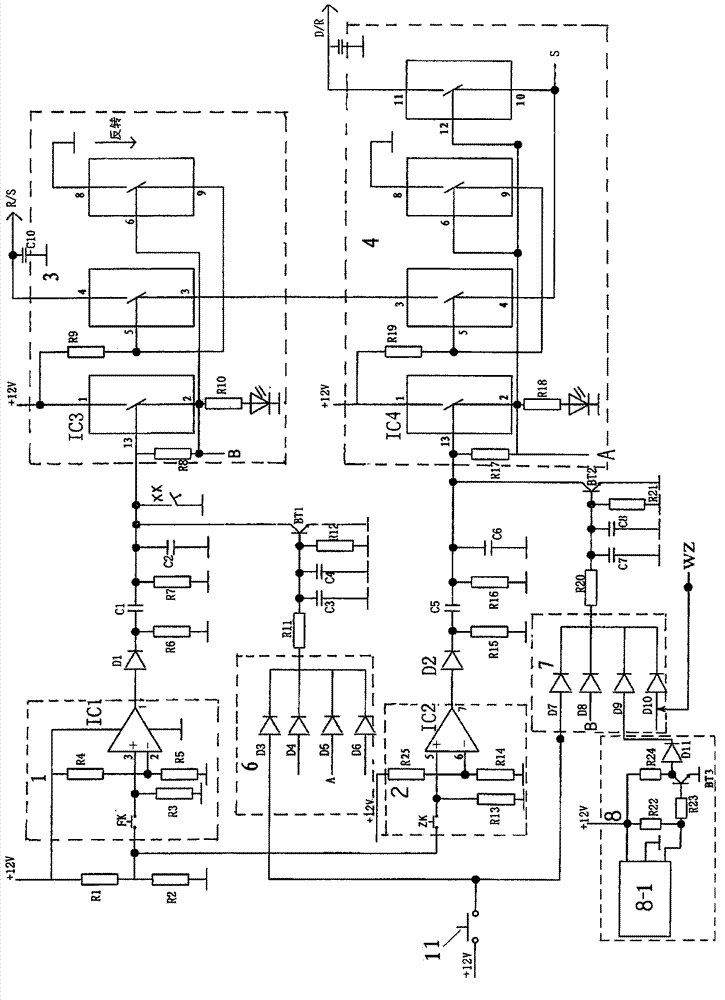

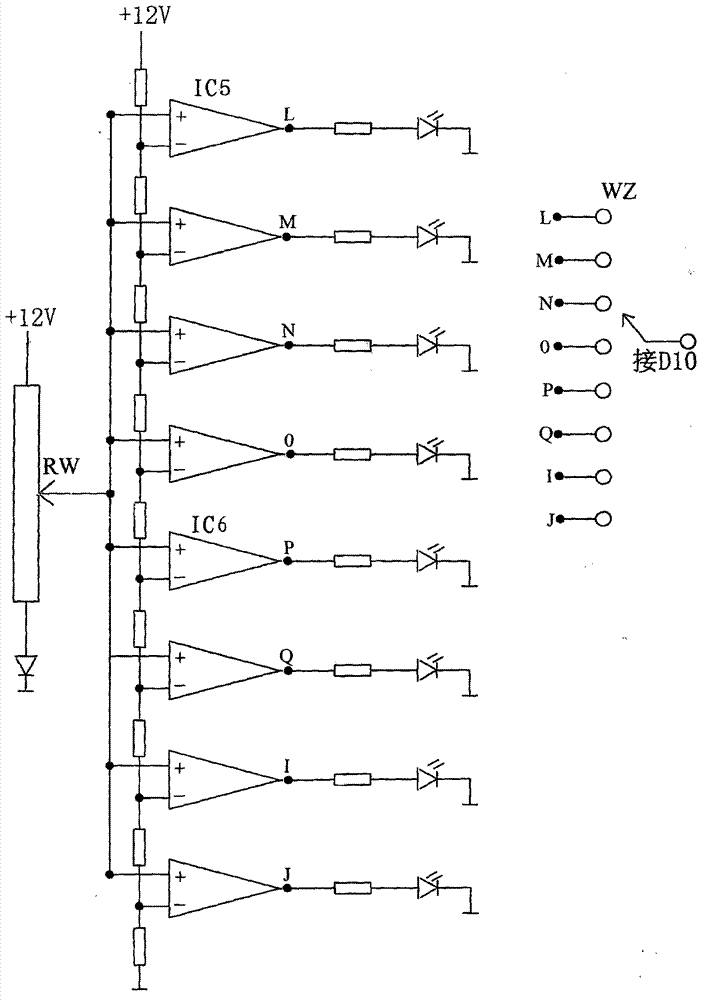

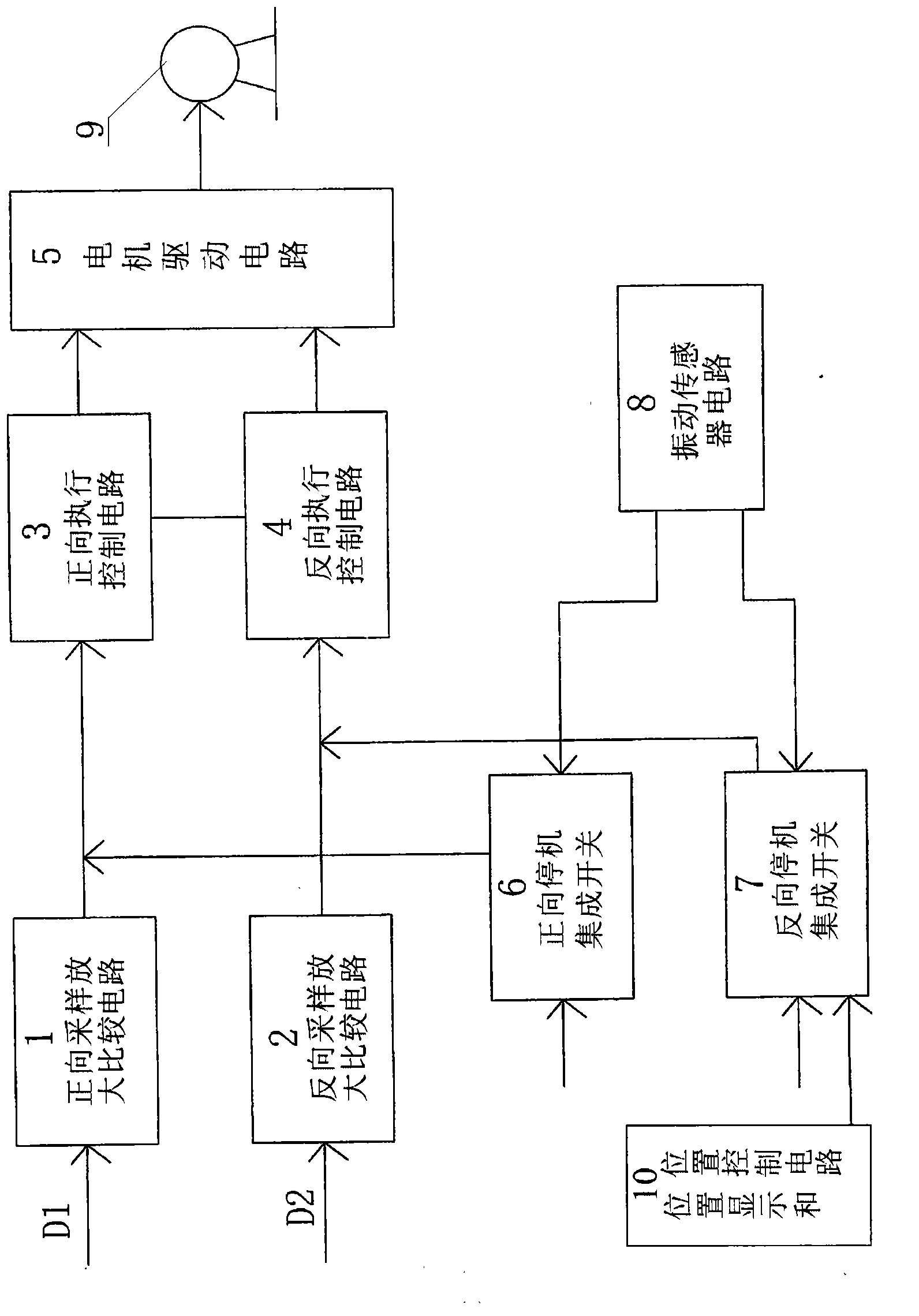

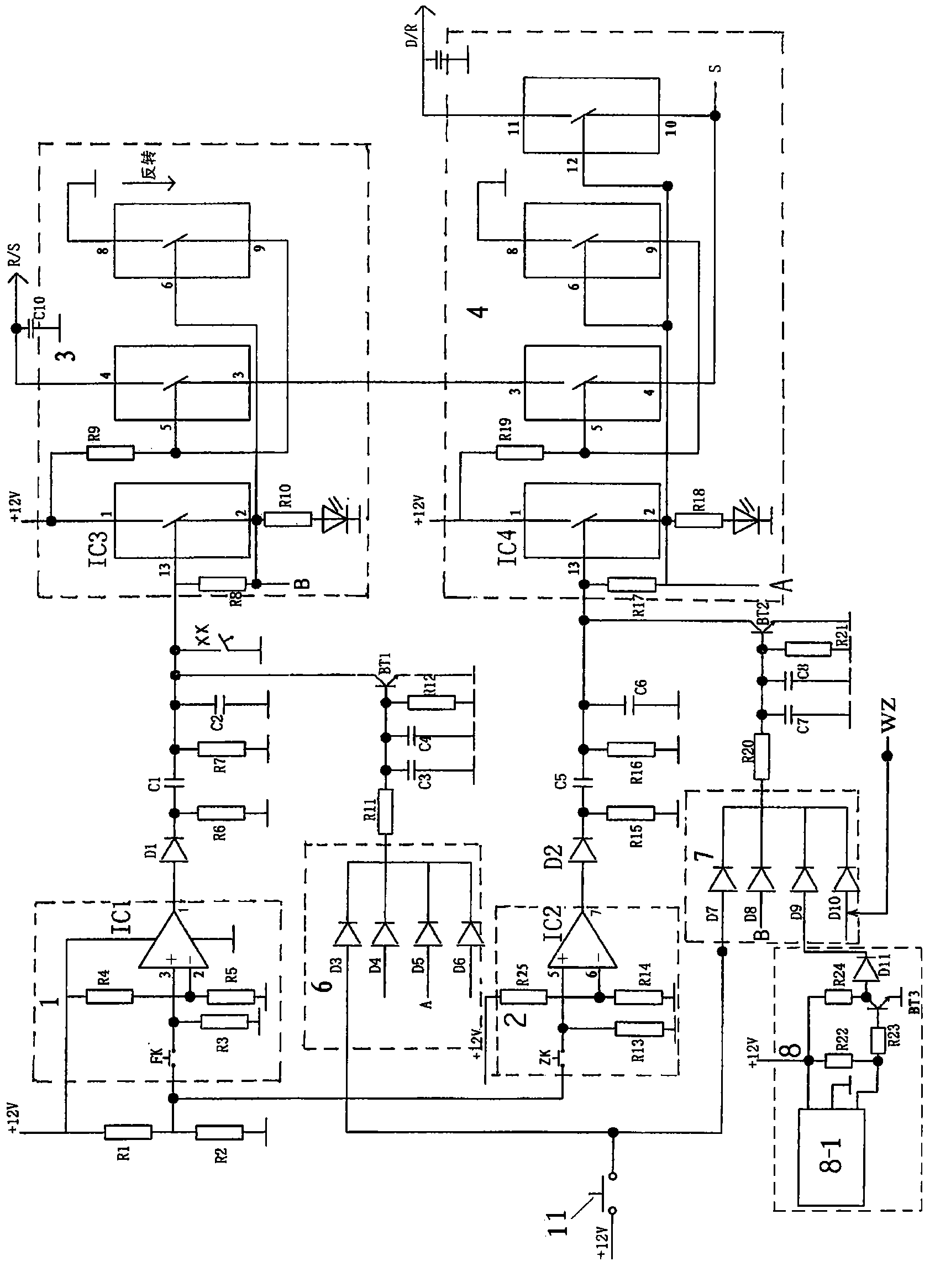

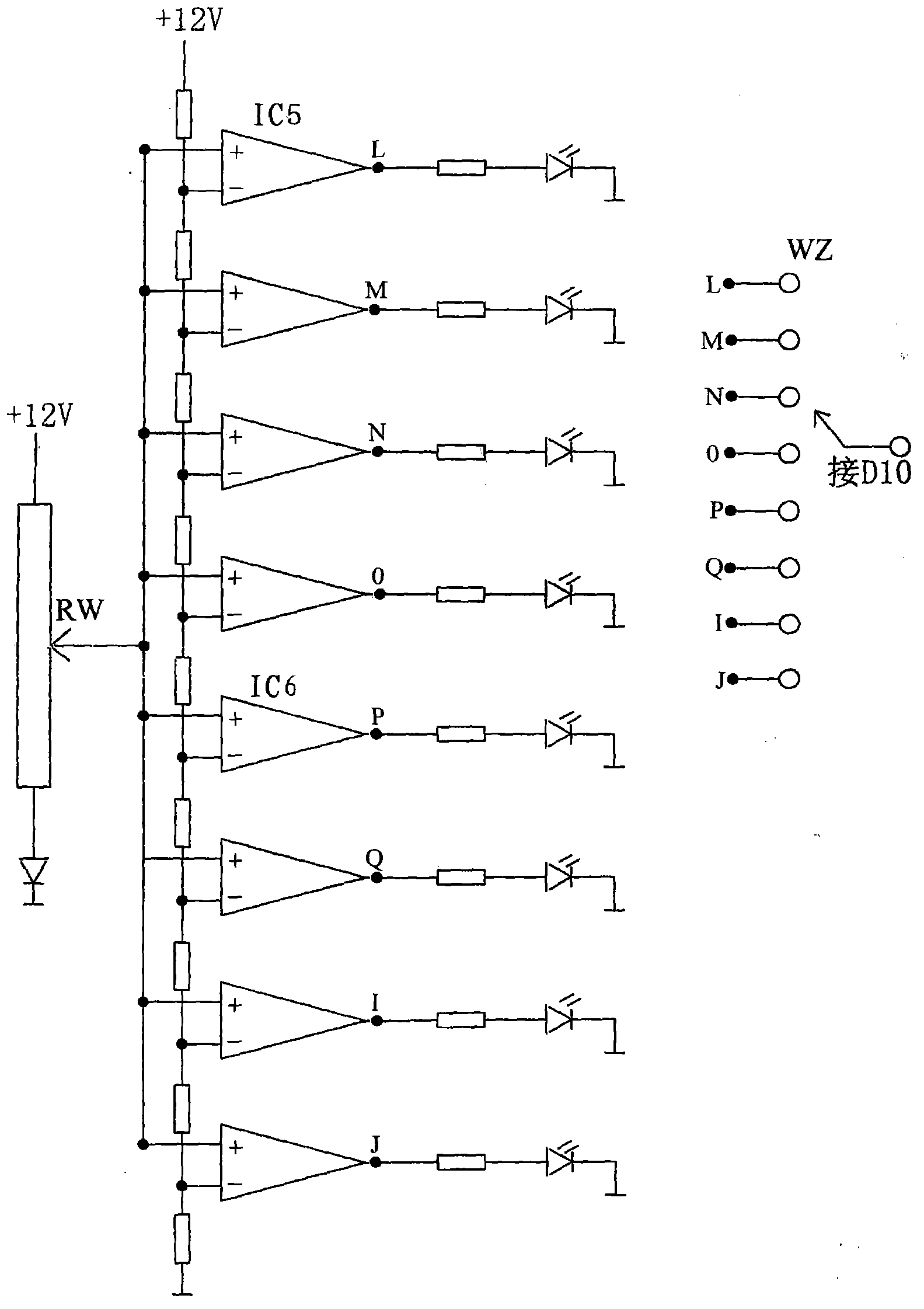

The invention relates to an intelligent pillow which comprises an electric control device and a mechanical structure portion (a pillow support). The electric control device can adjust the height of the pillow automatically according to sleeping positions of a human body. The electric control device is composed of a forward sampling amplitude comparison circuit, a reverse sampling amplitude comparison circuit, a forward execution control circuit, a reverse execution control circuit, a motor driving circuit, a forward shut-down integrated switch, a reverse shut-down integrated switch, a vibration sensor circuit, a motor, and a position display and control circuit. A lifting plate is arranged at the middle position inside a casing of a pillow support structure, a pillow supporting plate is arranged on the lower portion of the casing, the motor is arranged on the lateral side inside the casing, and the motor is connected with a rotating rod through a coupler and a gearbox. A bevel gear is fixedly arranged at a terminal of the rotating rod and matched with a bevel gear wheel arranged at the bottom of the casing. The intelligent pillow can adjust the height of the pillow automatically along with the sleeping positions of the human body, can nurse the necks of people in sleep, and enables the necks to keep a normal physiological curvature. Therefore, comfortableness and quality of sleeping are improved, and a cervical disease and a spinal disease are prevented.

Owner:冯燮

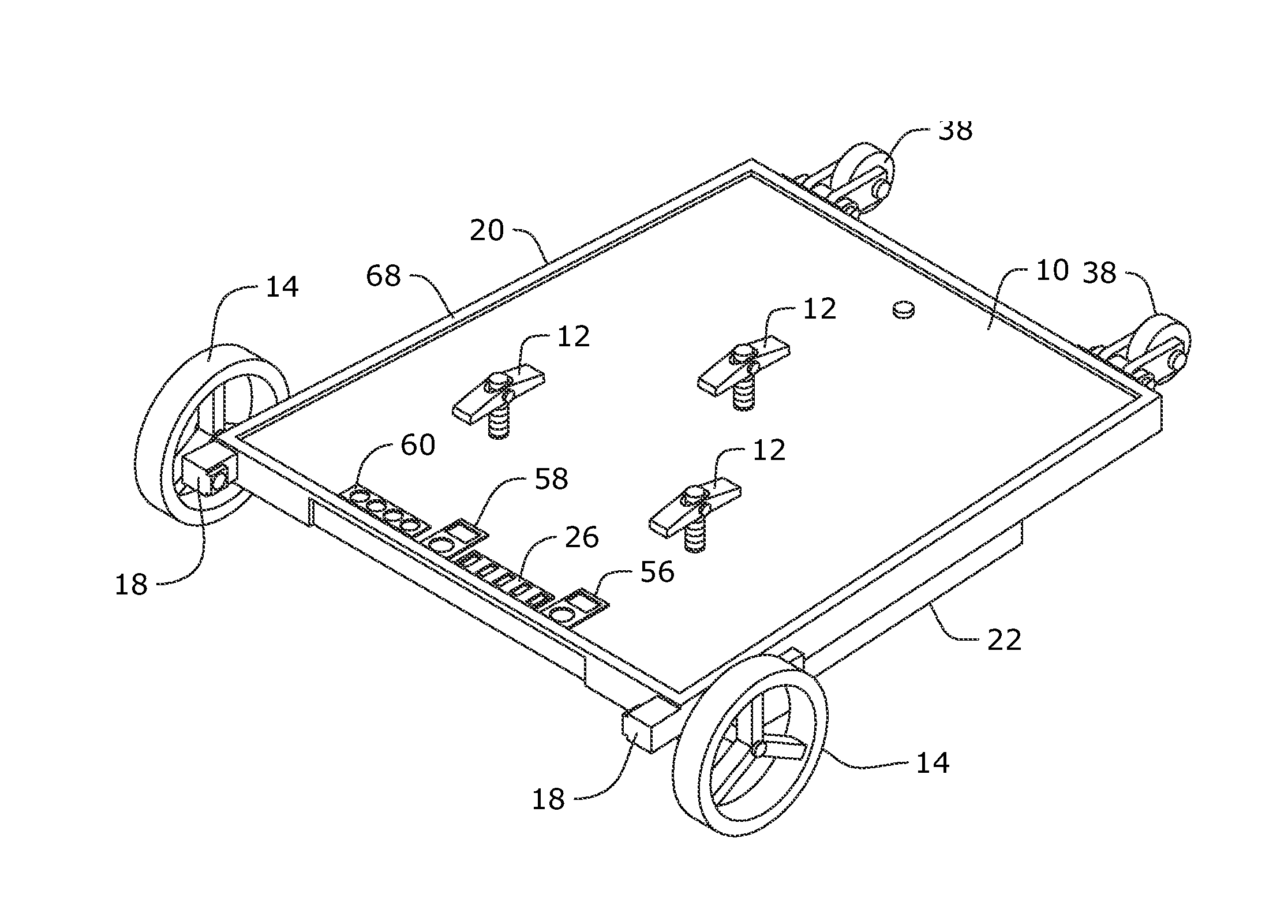

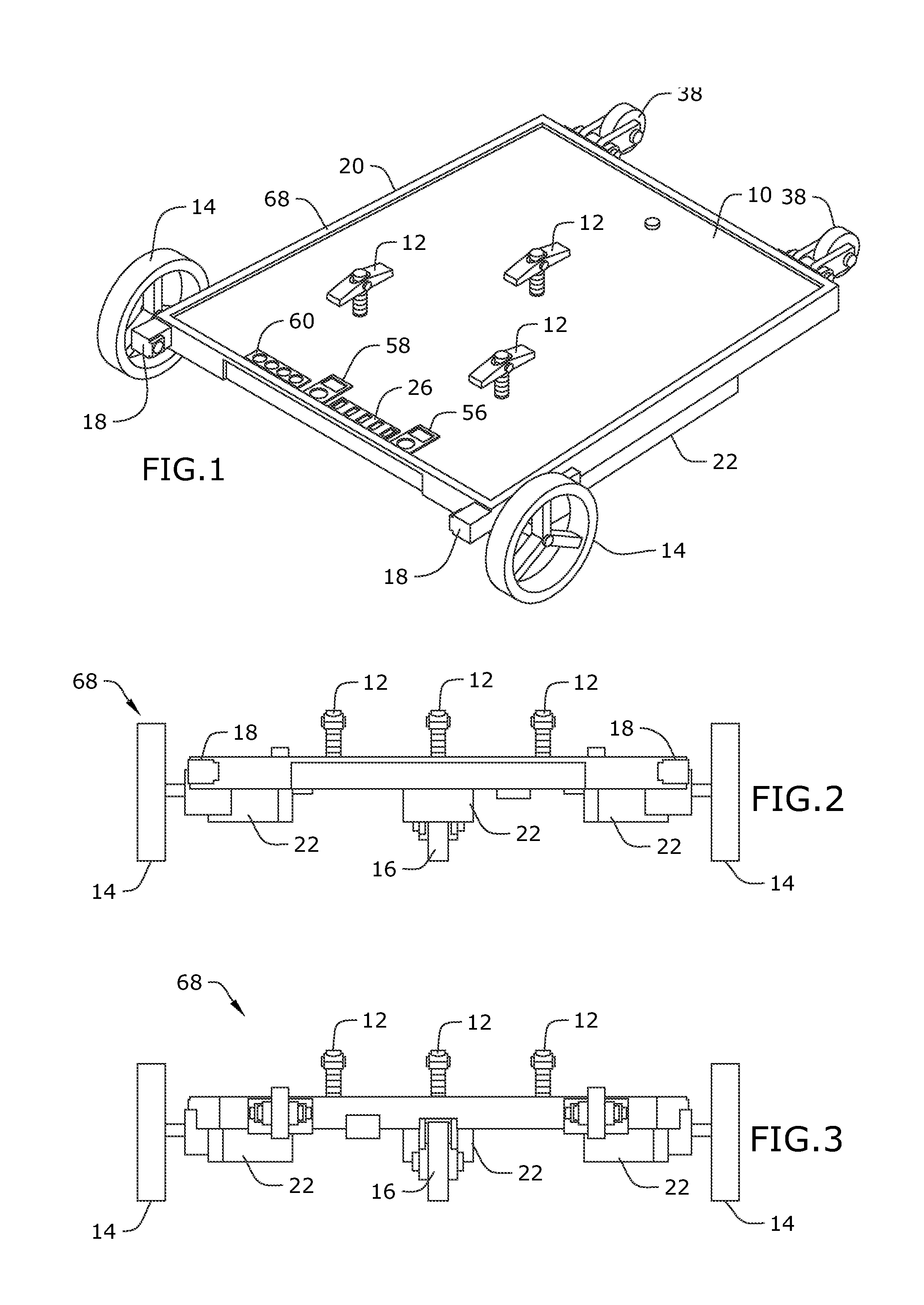

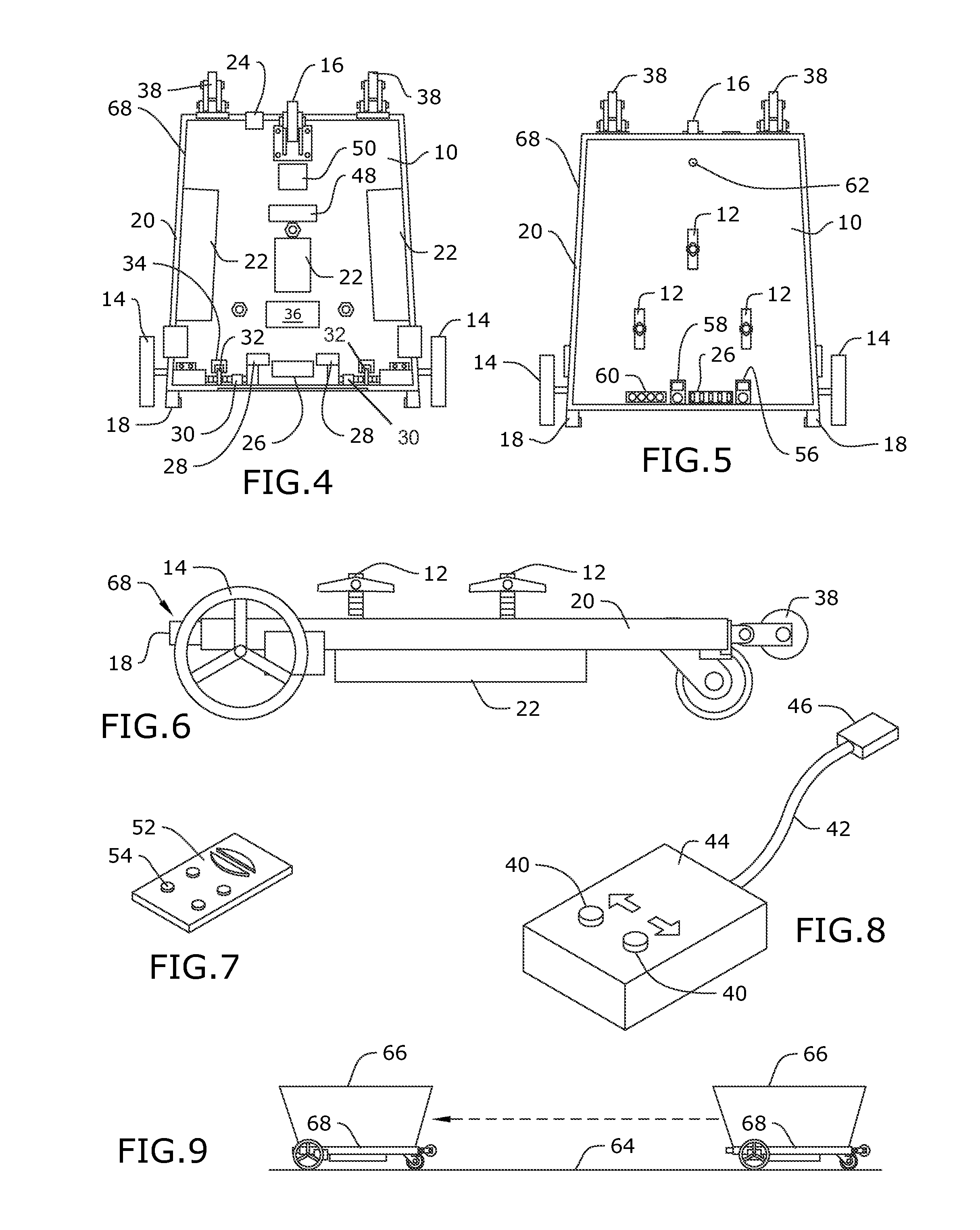

Robot dolly

InactiveUS20160041557A1Navigational calculation instrumentsDistance measurementElectricityDrive wheel

A powered carrier adaptable to traverse varied programmable routes is provided. The powered carrier has a carrier platform with two independently-motorized drive wheels and a castor wheel for tripod support of the platform along a surface. Each drive wheel is coupled to a rotational sensor adapted to electronically store their respective rotational properties so as to retrievably store a plurality of programmable routes the powered carrier traverses from points A to points B. The power sources, the motors, the rotational sensors and other electronic components disposed on the powered carrier are electronically connected to a control circuitry adapted to execute a plurality of modes of operation, including modes incorporating the storage, execution and reverse-execution of the plurality of programmable routes, as well as an override mode.

Owner:TROUT KARL PATRICK

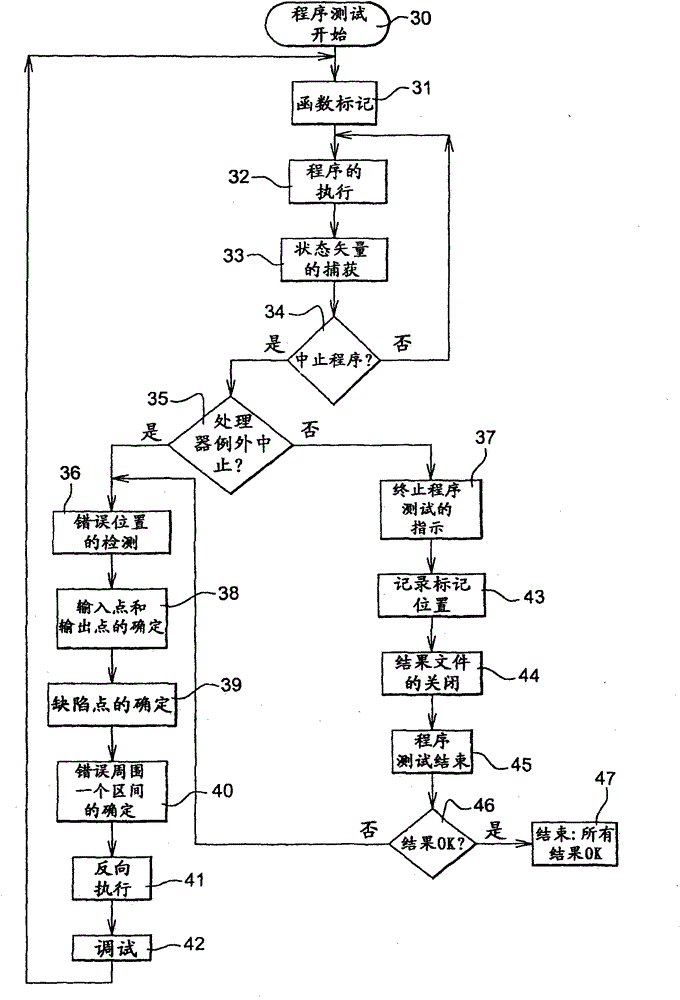

Method for debugging operational software of a system onboard an aircraft and device for implementing the same

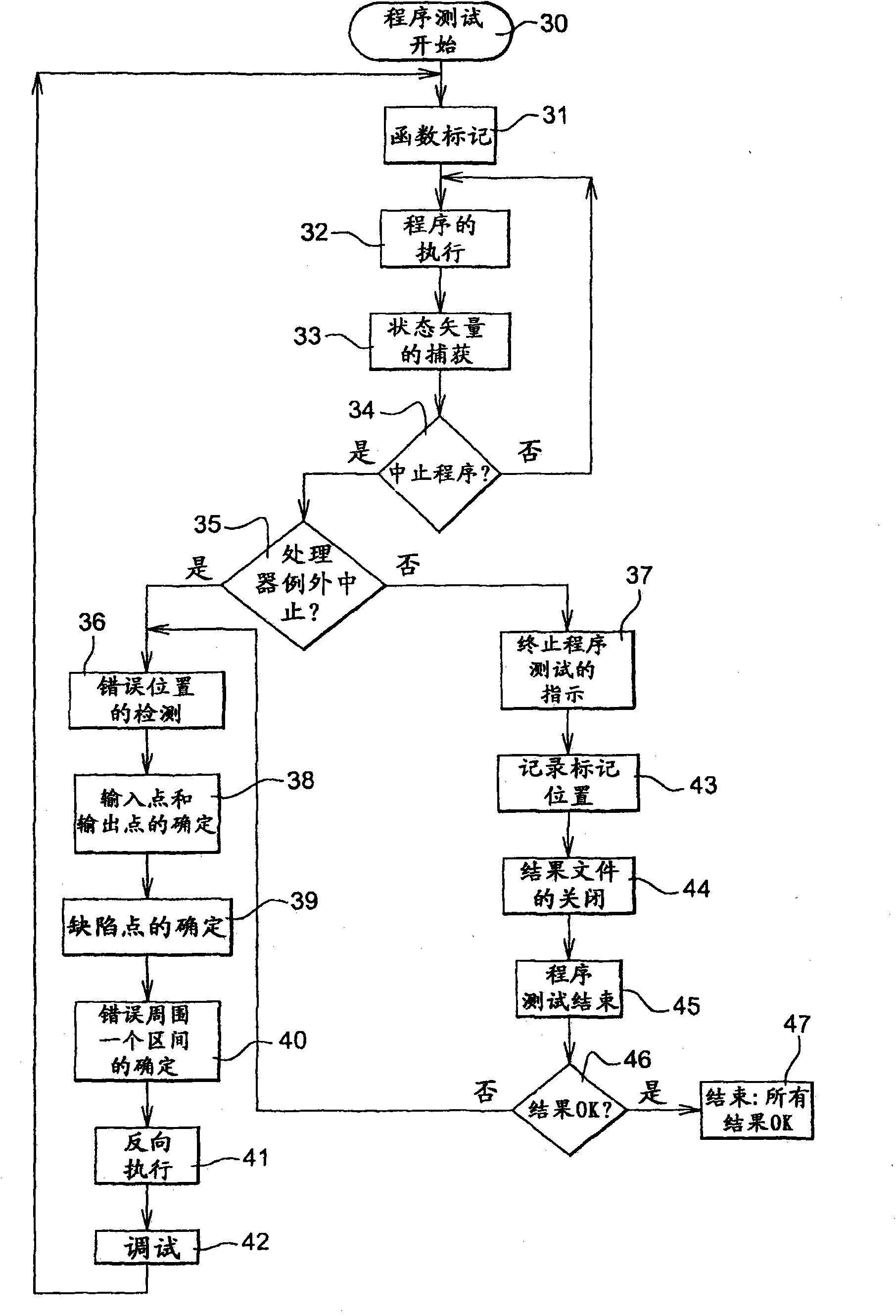

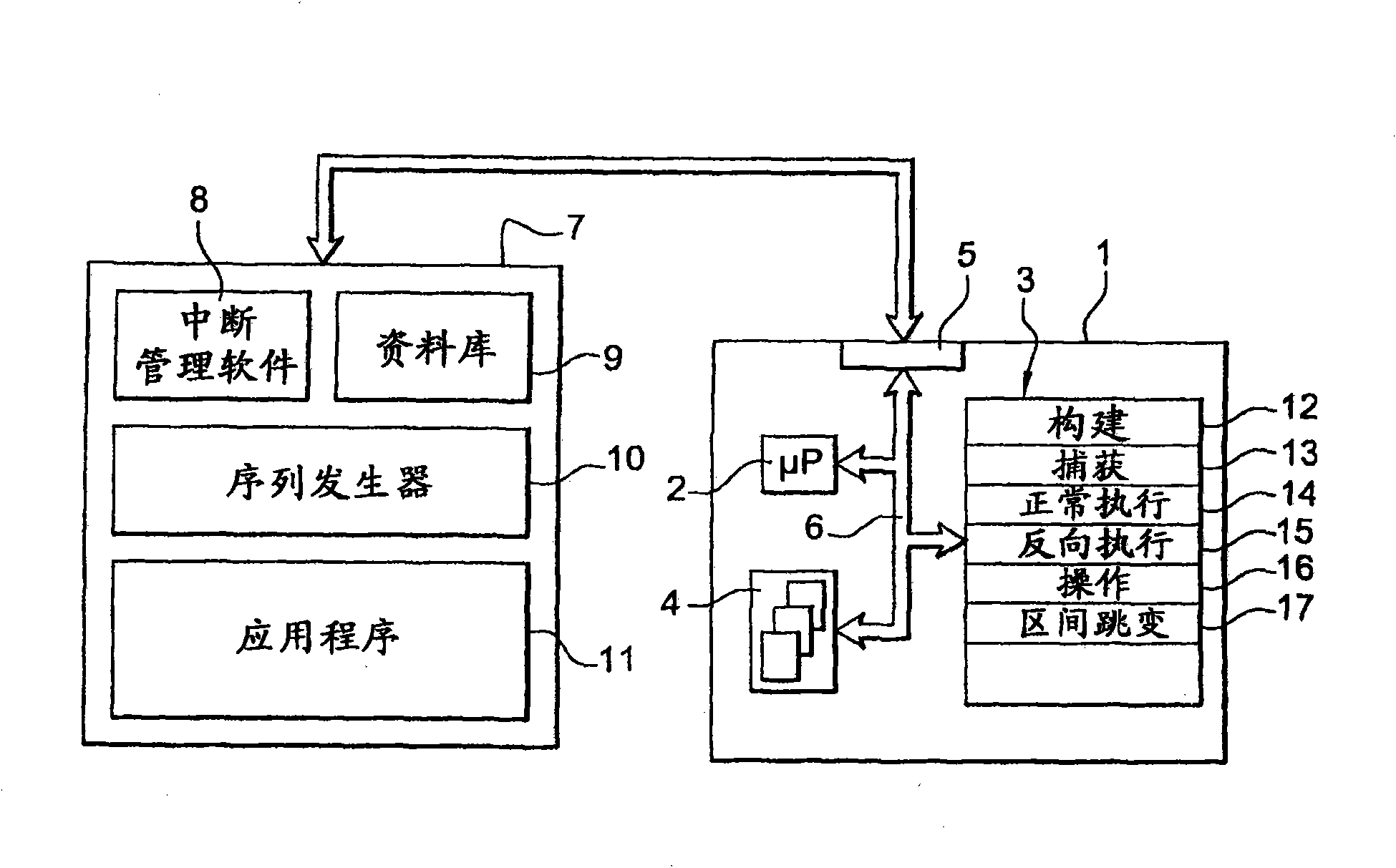

The invention relates to a method for debugging the program of operational software of an onboard system, characterised in that it comprises the following steps: a) flagging (31) the program by positioning flags along an execution path for dividing said execution path into adjacent functional intervals; b) normal execution (32) of the program; c) acquiring (33) an execution condition of the program by flag condition vectors; d) when an error is detected, searching (36) a faulty functional interval based on the flag condition vectors, reverse execution (41) of the program in said faulty functional interval, and determination and correction of the error (42).

Owner:AIRBUS OPERATIONS (SAS)

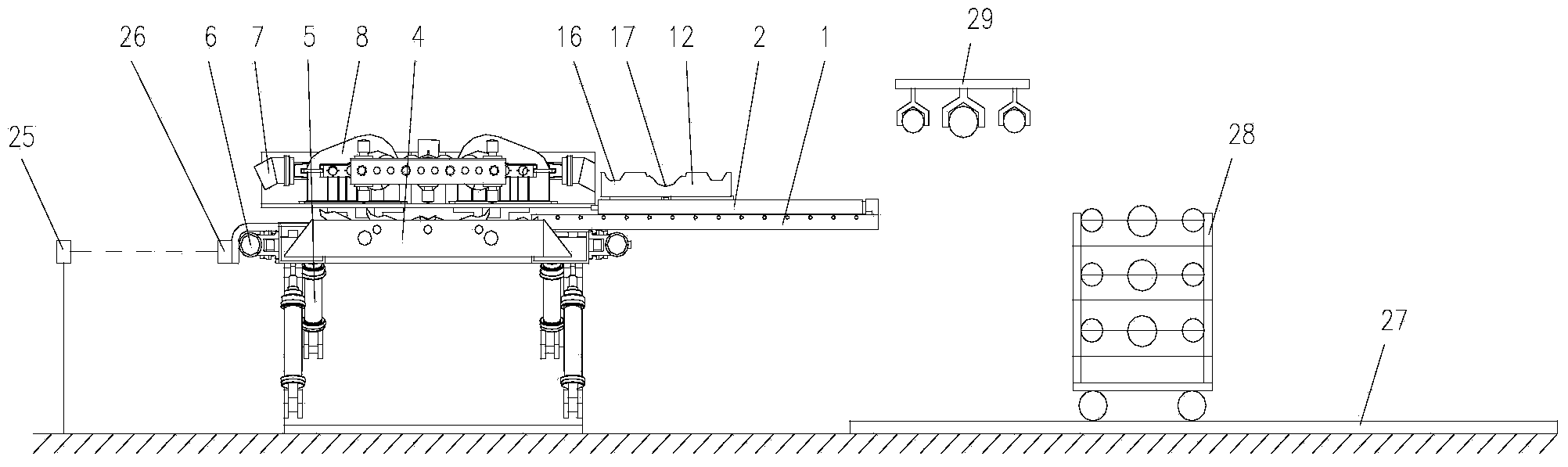

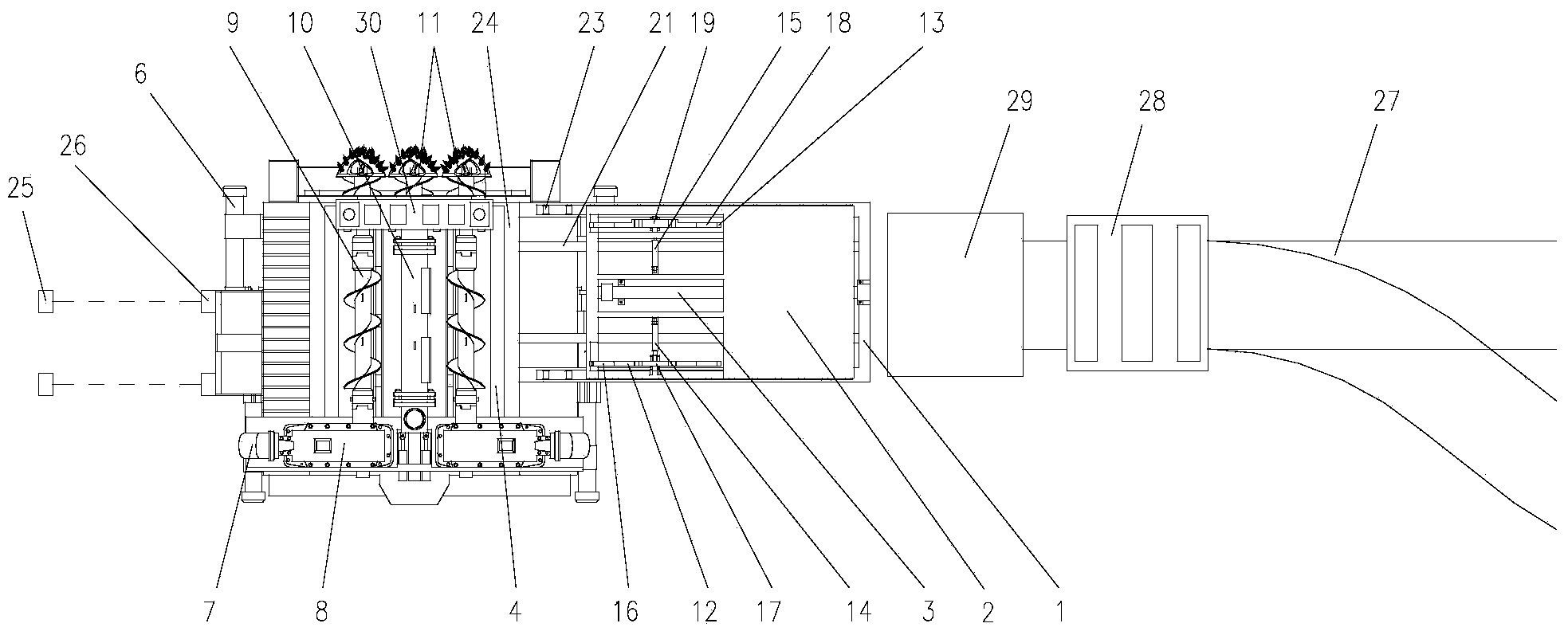

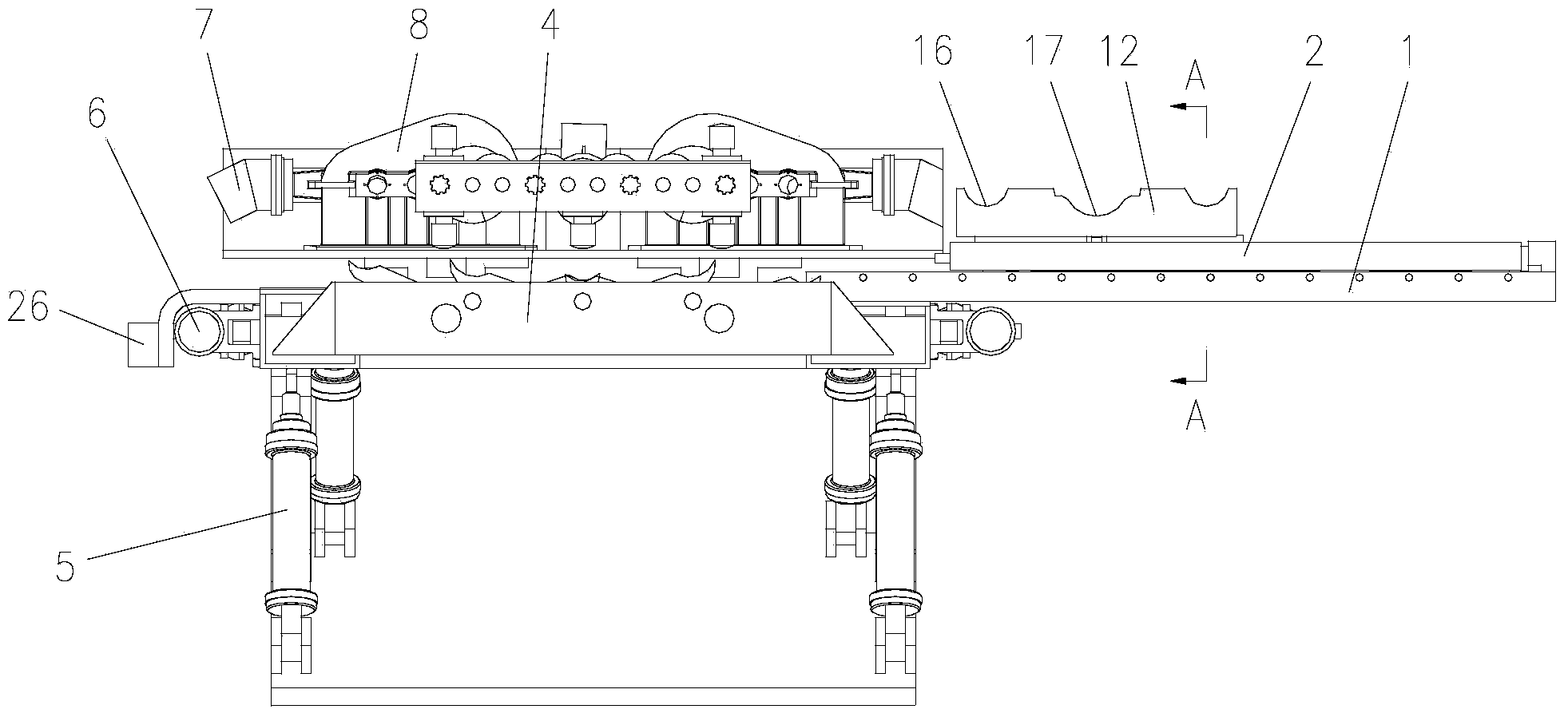

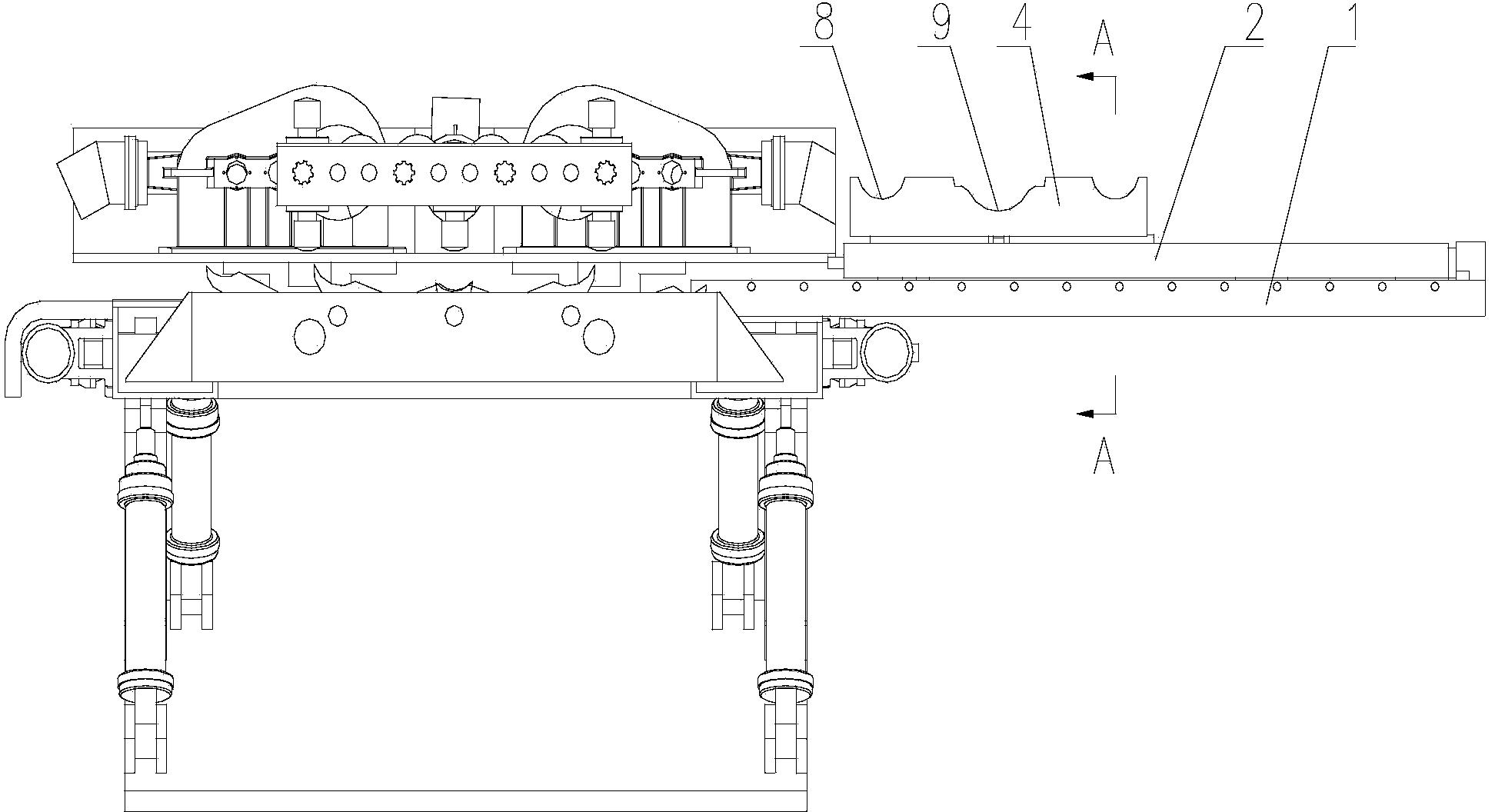

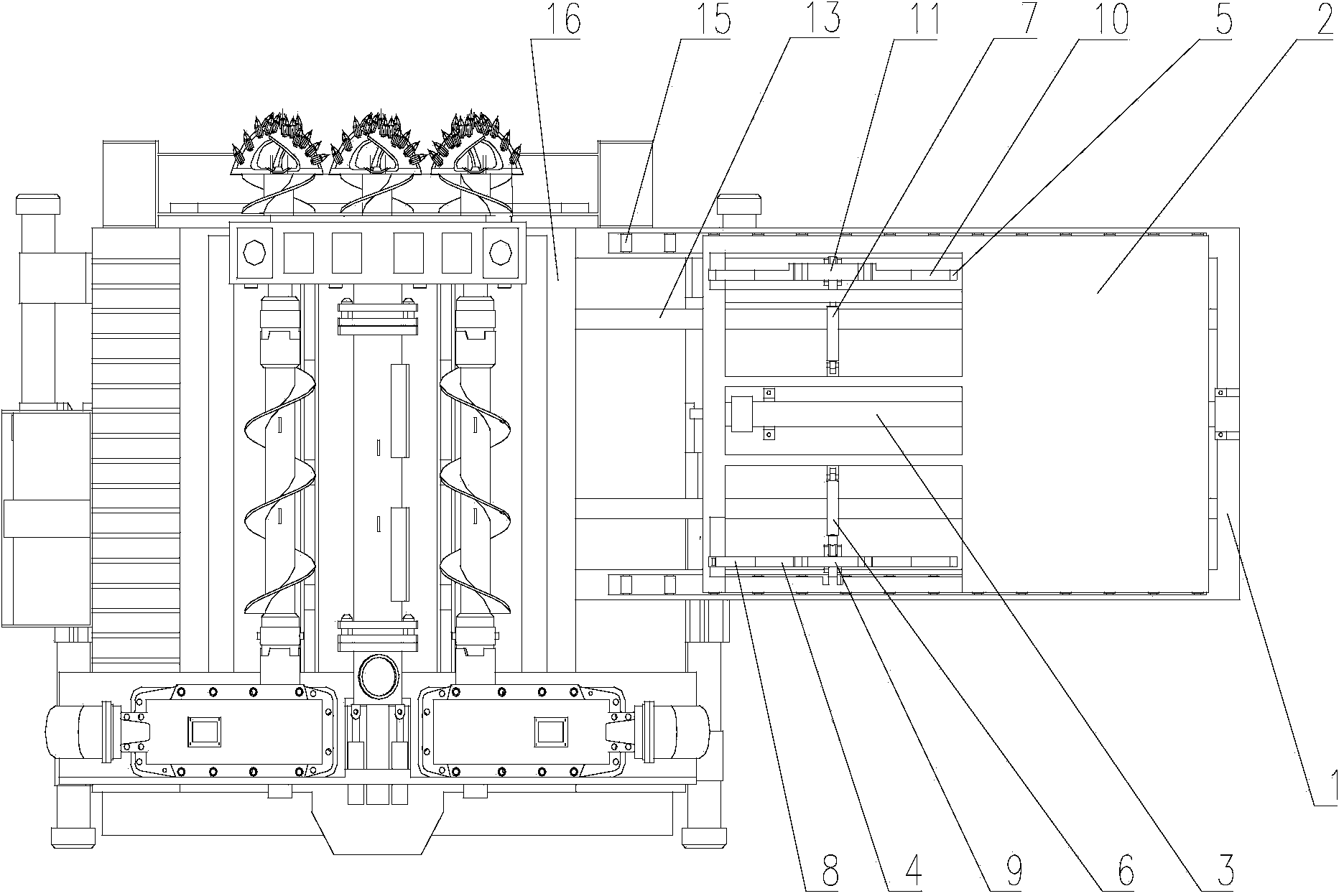

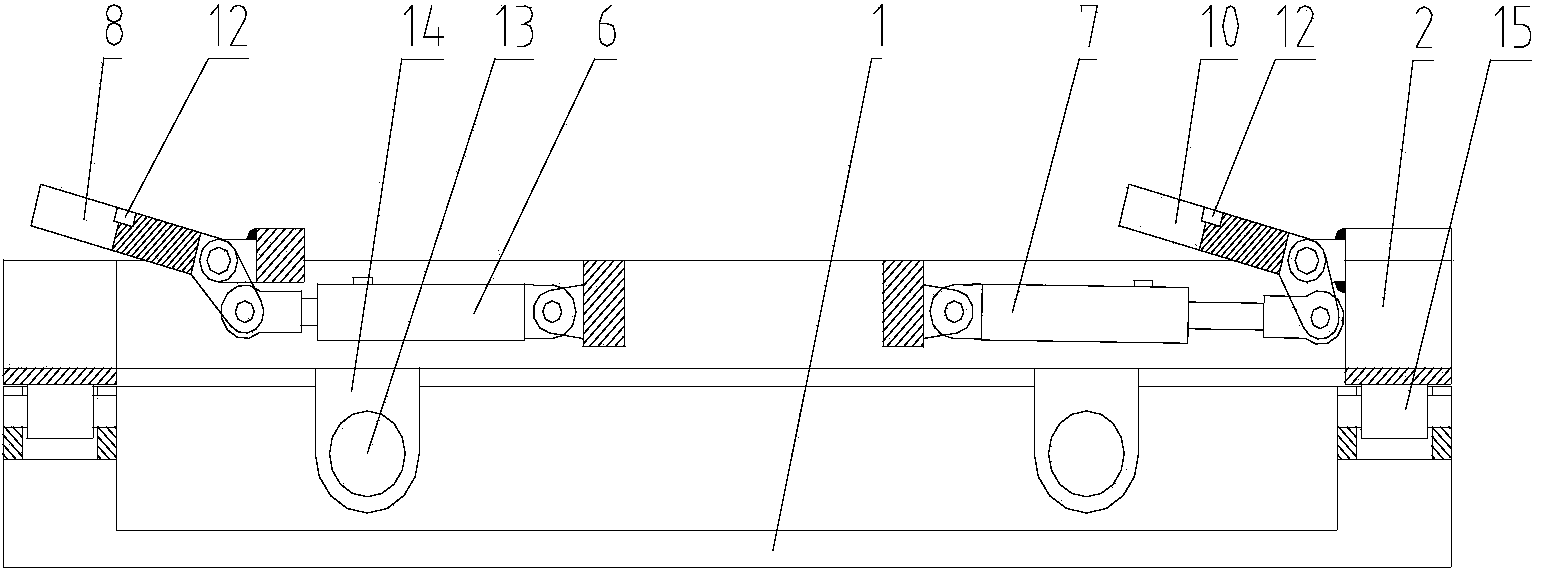

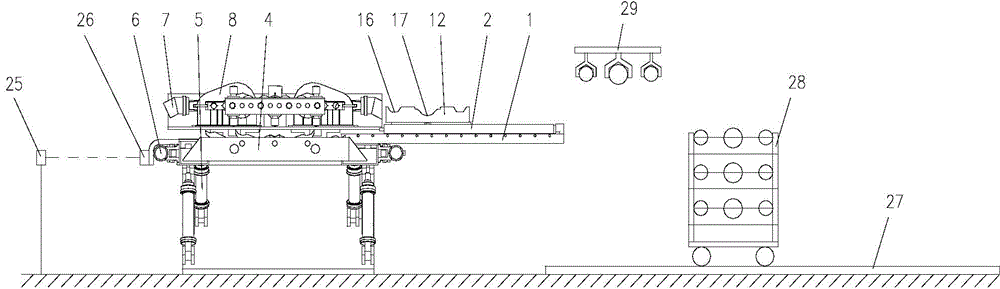

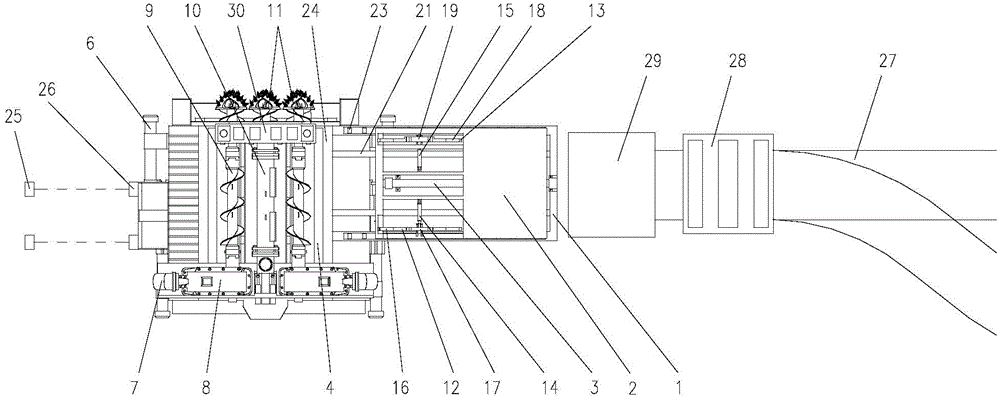

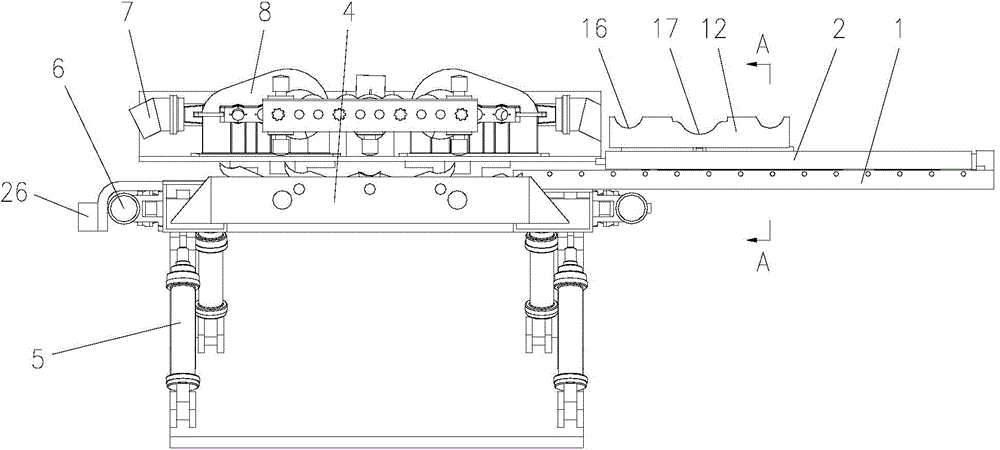

Coal mining system capable of automatically assembling and disassembling drill rod groups

ActiveCN103541731APrecise loading and unloadingPrecise positioningSlitting machinesSingle degree of freedomReverse execution

The invention discloses a coal mining system capable of automatically assembling and disassembling drill rod groups. The coal mining system comprises a twist drill type coal cutter and an automatic drill rod group assembling and disassembling platform, wherein the automatic drill rod group assembling and disassembling platform comprises a bottom plate, a sliding table, a side slip driving device and a drill rod group positioning component; the bottom plate is fixedly arranged on a main engine frame of the twist drill type coal cutter; the sliding table is connected to the bottom plate in a sliding mode with a single degree of freedom and is driven to slide in a reciprocating mode through the side slip driving device; the drill rod group positioning component is arranged on the sliding table; after a drill rod group is positioned on the automatic drill rod group assembling and disassembling platform, the drill rod group can be conveyed between a main engine spindle of the twist drill type coal cutter and a connected drill rod group, and a main engine is controlled to push, so that the assembly of the drill rod group can be finished; the sliding table can return to be in an original position after the drill rod group is assembled, and then a next drill rod group is mounted. The drill rod group can be disassembled through reverse execution, the labor intensity of workers can be reduced, and the drill rod groups can be accurately positioned, so that the process of assembling and disassembling drill rods is smooth, the time consumption is saved, and the coal mining efficiency is improved.

Owner:CHONGQING UNIV

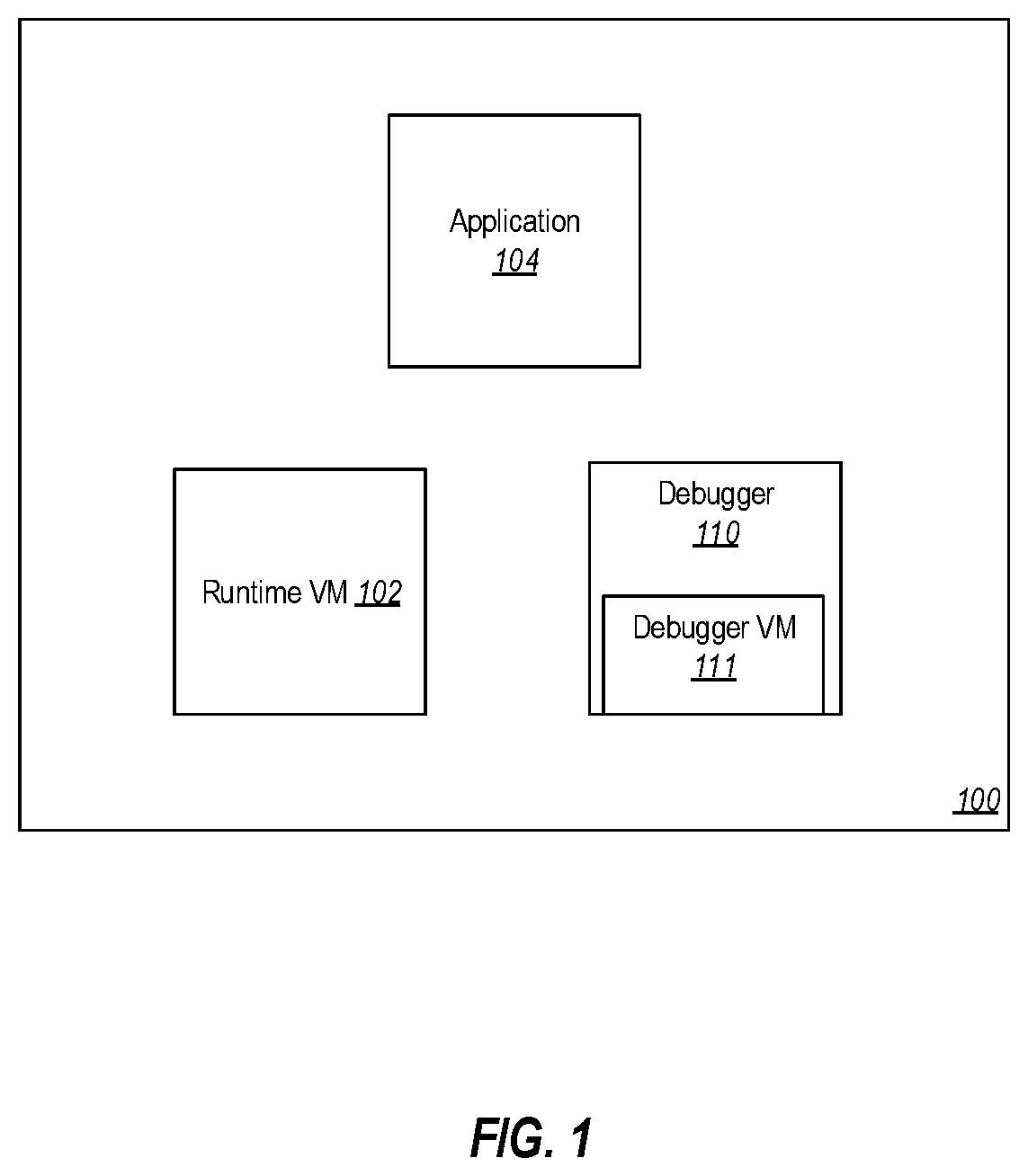

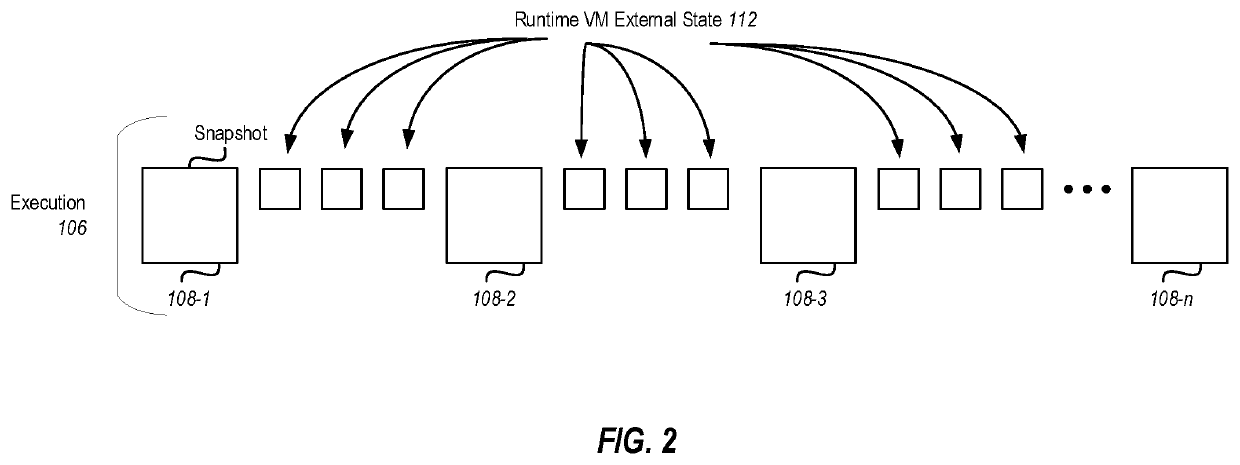

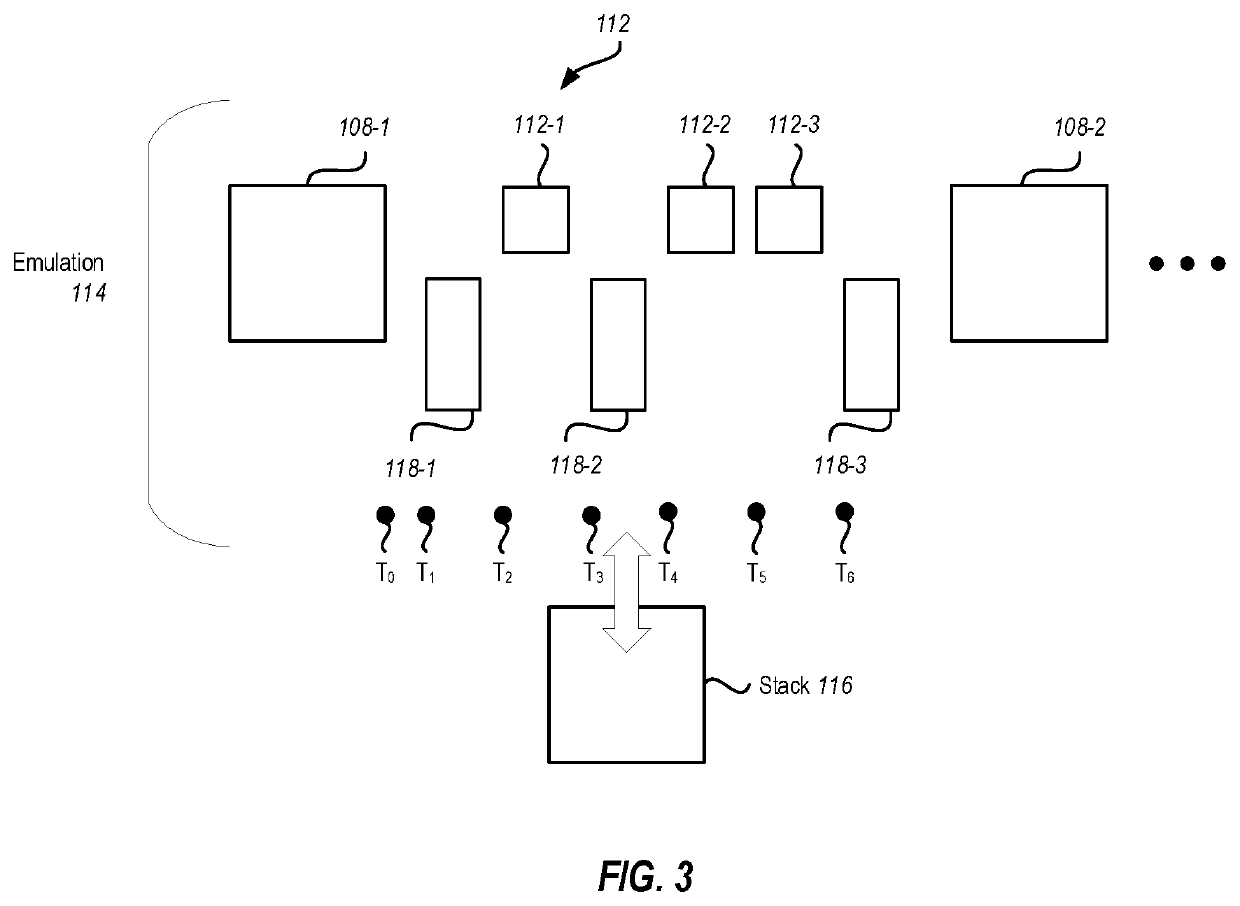

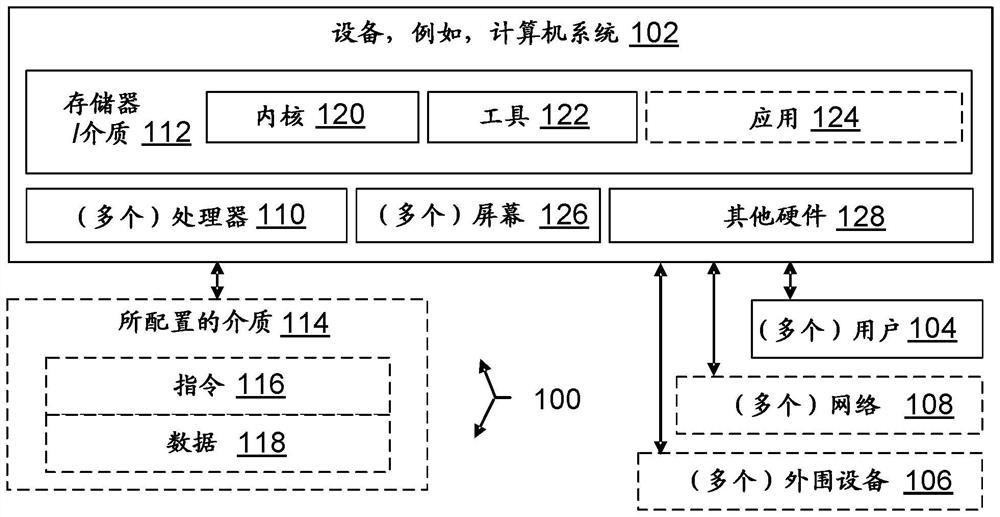

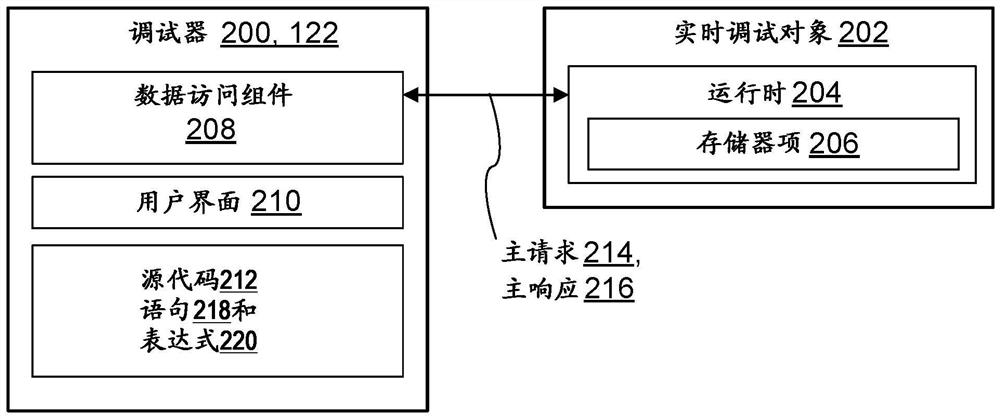

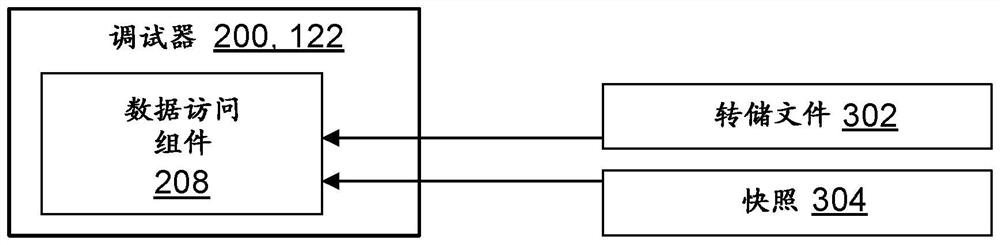

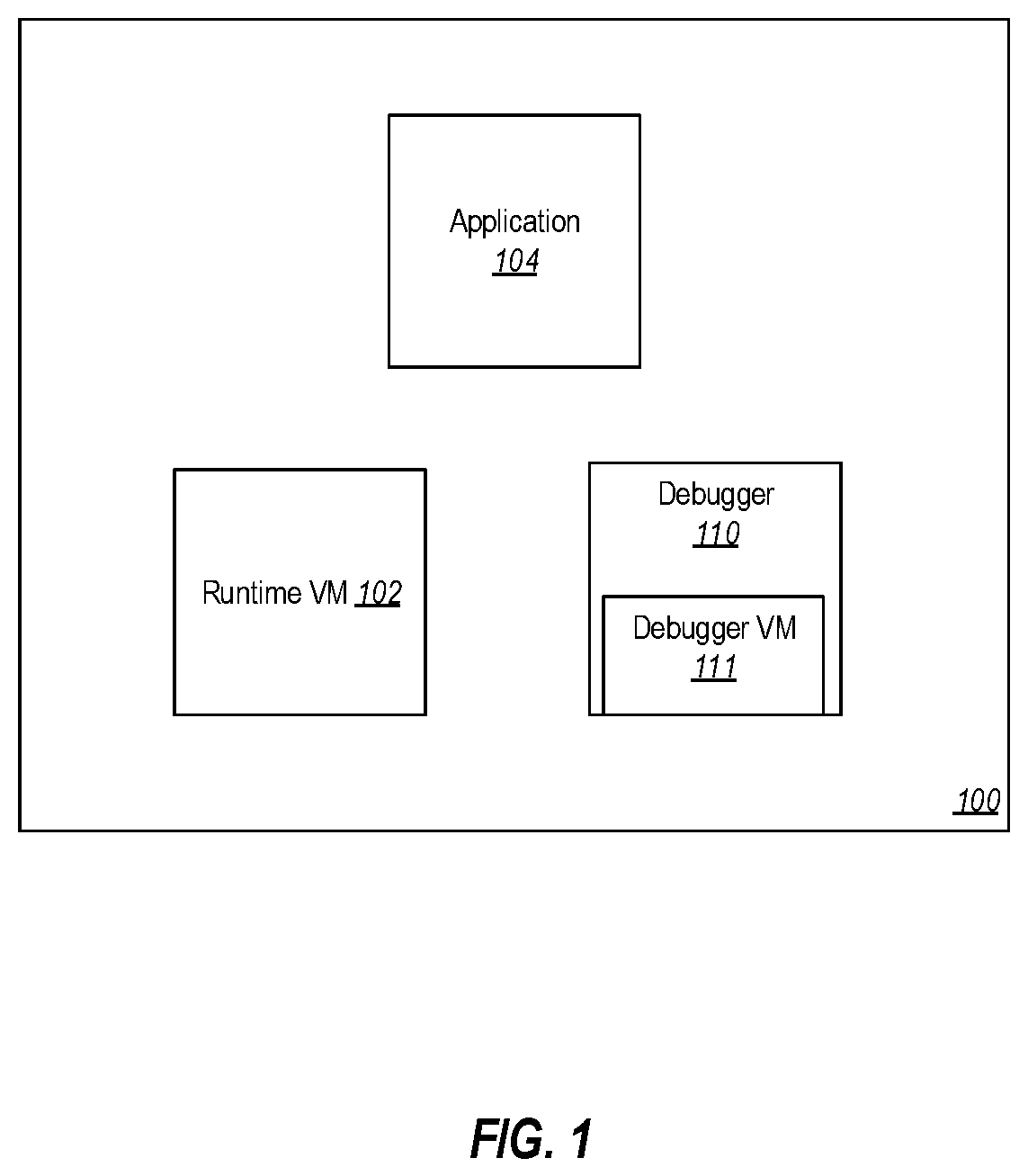

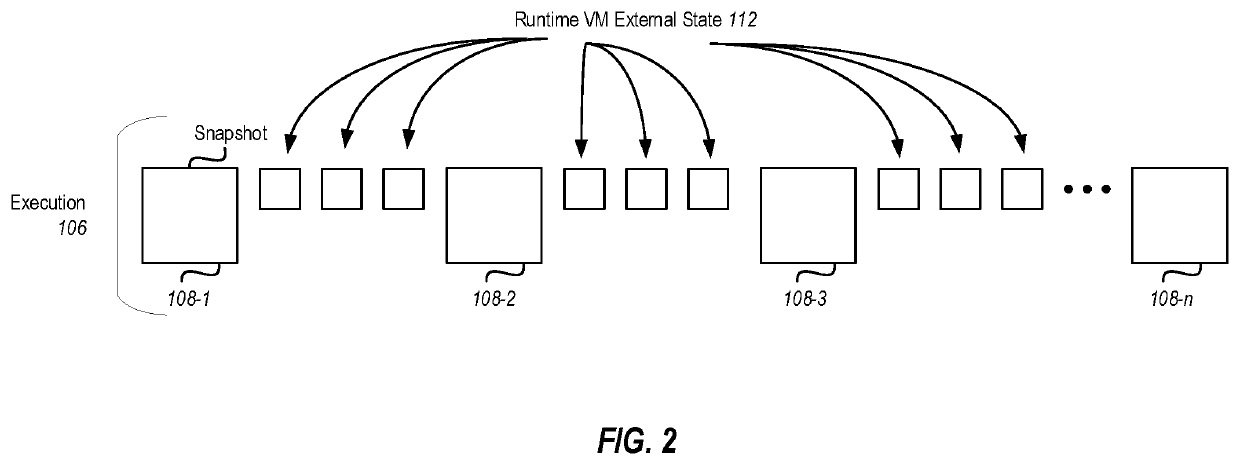

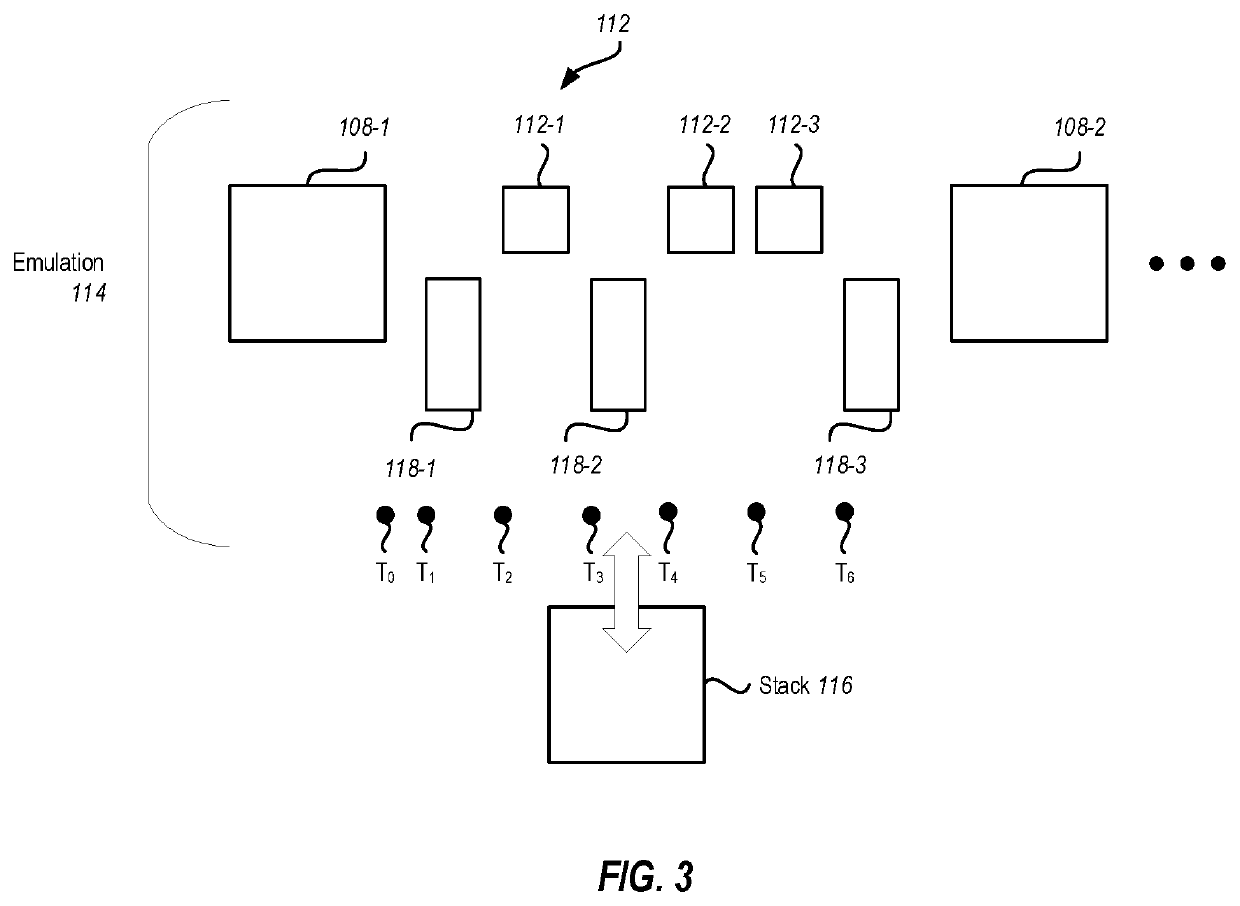

Reversible debugging in a runtime environment

ActiveUS20200310946A1Well formedSoftware testing/debuggingDesign optimisation/simulationReverse executionApplication procedure

Performing reverse execution debugging of an application. The method includes identifying a snapshot of application state for an application in an application framework. The method further includes emulating execution of the application, using bytecode, in a forward direction from the snapshot to an end point, causing generation of historical execution state at various points along the emulation of the application. The method further includes collecting the historical execution state. The method further includes using the collected historical execution state, emulating reverse execution of the application by substituting collected historical execution state, when needed, to restore previous state needed as a result of emulation of reverse execution of the application.

Owner:MICROSOFT TECH LICENSING LLC

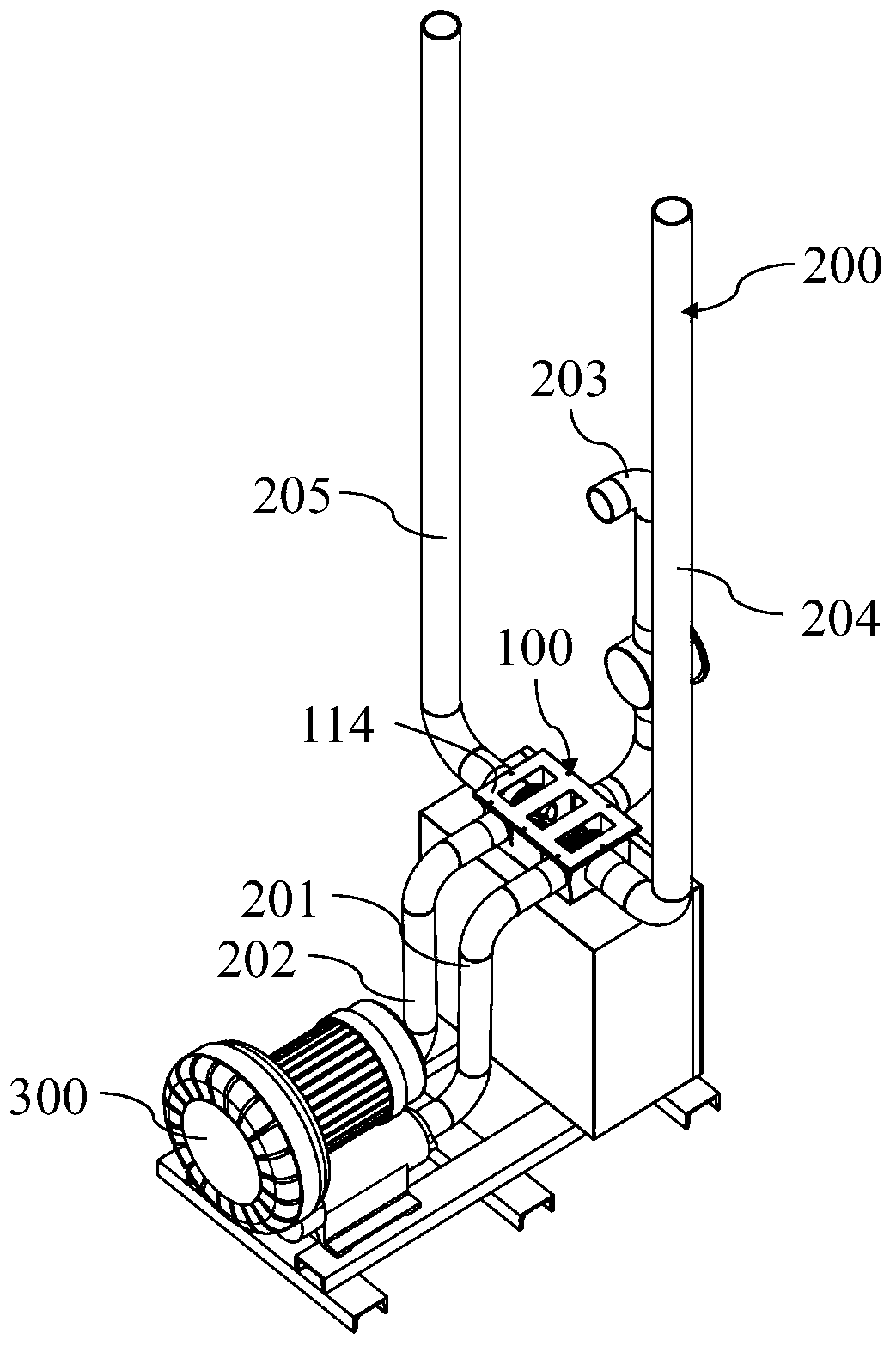

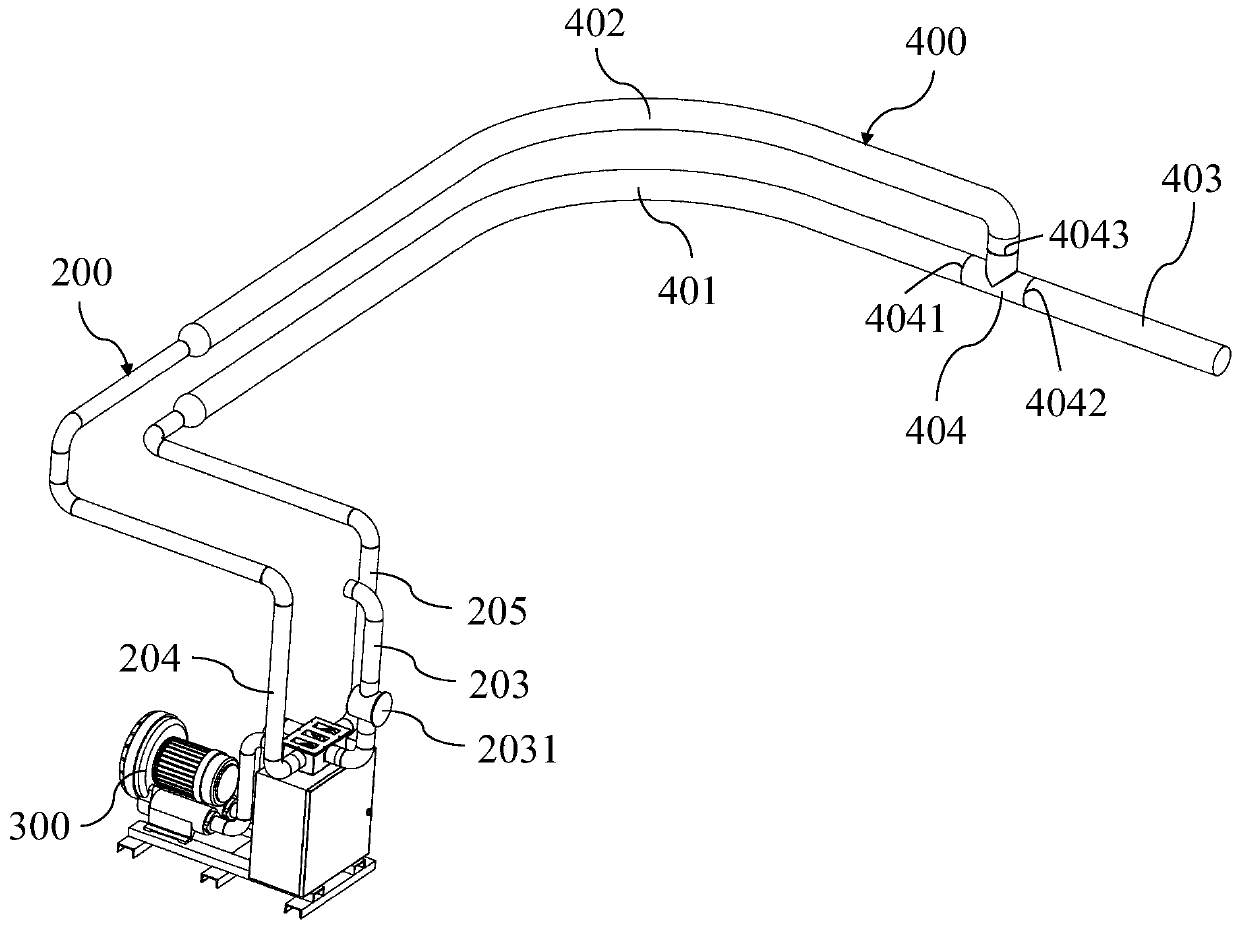

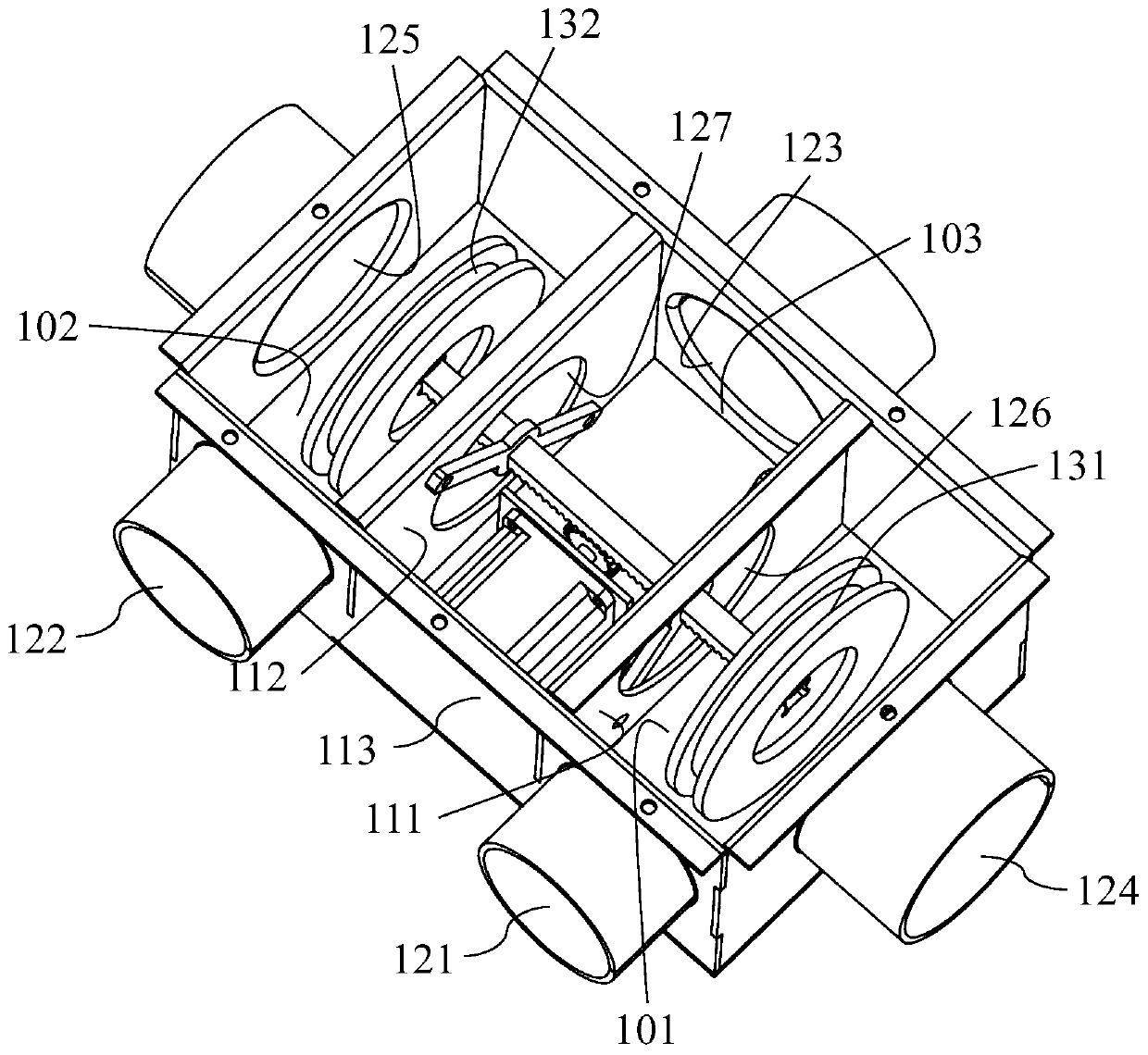

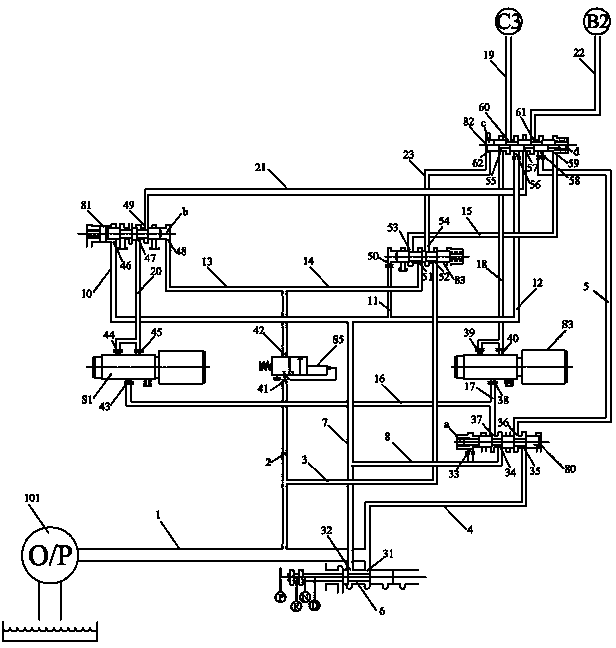

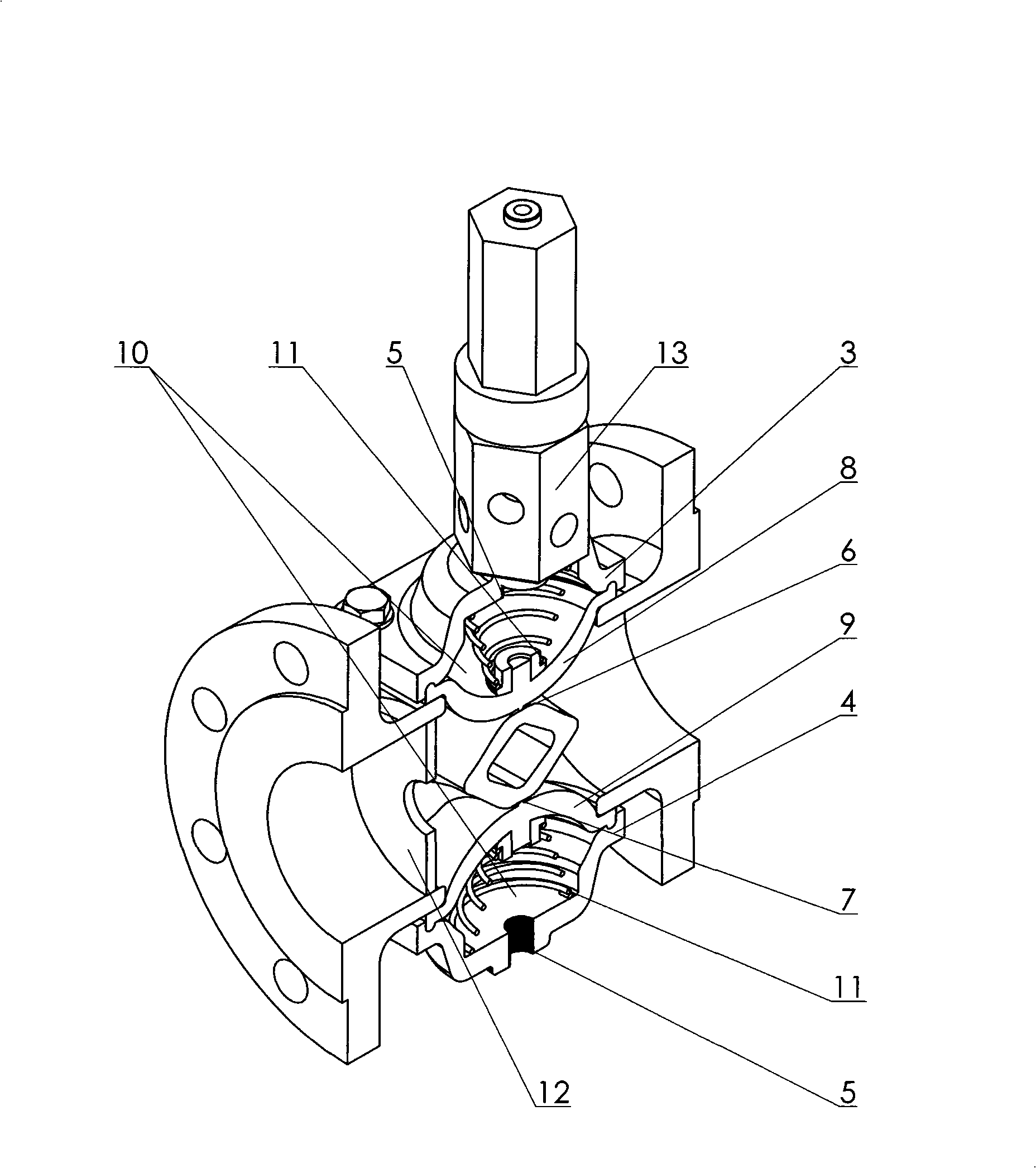

Reversing mechanism of pneumatic conveying system, and pneumatic conveying system

PendingCN109867144ARealize two-way transmissionEasy to inhaleBulk conveyorsReverse executionPositive pressure

The invention provides a reversing mechanism of a pneumatic conveying system, and the pneumatic conveying system. An inner cavity of a shell of the reversing mechanism is divided into three cavities through a first partition board (111) and a second partition board (112), the first partition board (111) is provided with a first inner cavity opening (126), and the second partition board (112) is provided with a second inner cavity opening (127); the outer wall of the shell is provided with an air outlet (121), an air inlet (122), a ventilation opening (123), an air suction port (124) and an airblowing port (125); the reversing mechanism (100) further comprises a reversing execution assembly capable of blocking the air suction port (124) and the second inner cavity opening (127) at the sametime, so that a material conveying pipeline (400) can obtain positive pressure; and meanwhile, the reversing execution assembly can block the air blowing port (125) and the first inner cavity opening(126) at the same time, so that the material conveying pipeline (400) obtains negative pressure. According to the reversing mechanism, the flowing direction of airflow in the reversing mechanism is adjusted as needed, so that bidirectional conveying of materials is achieved.

Owner:上海速地工业科技有限公司

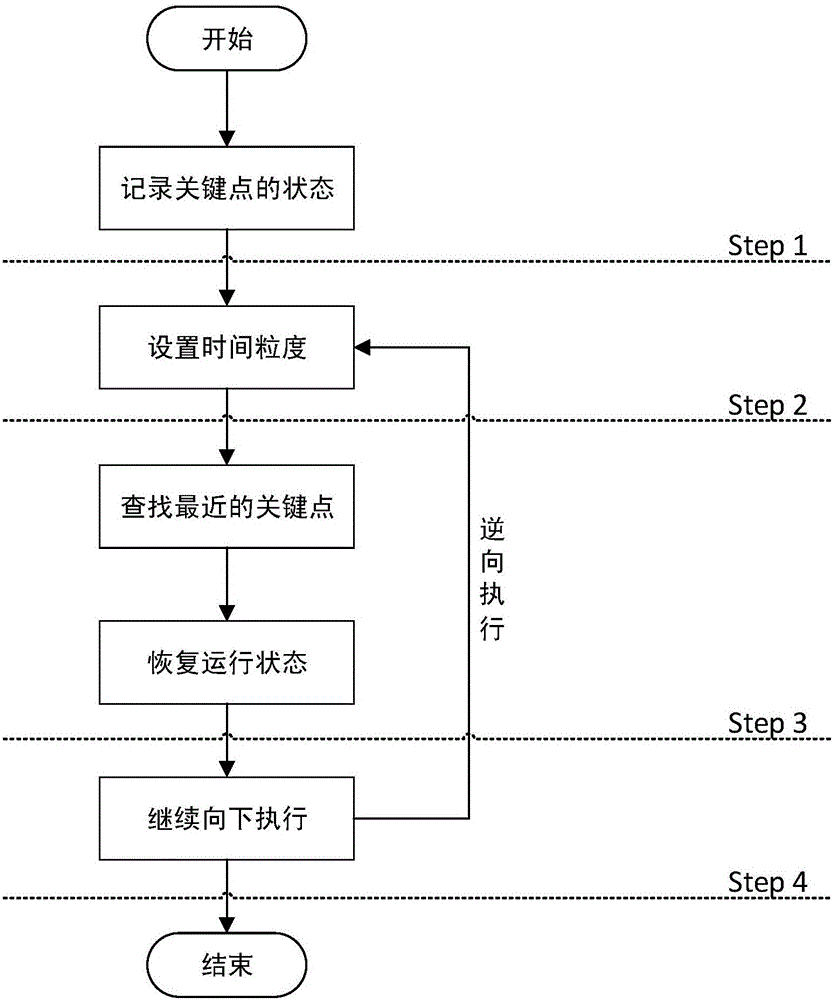

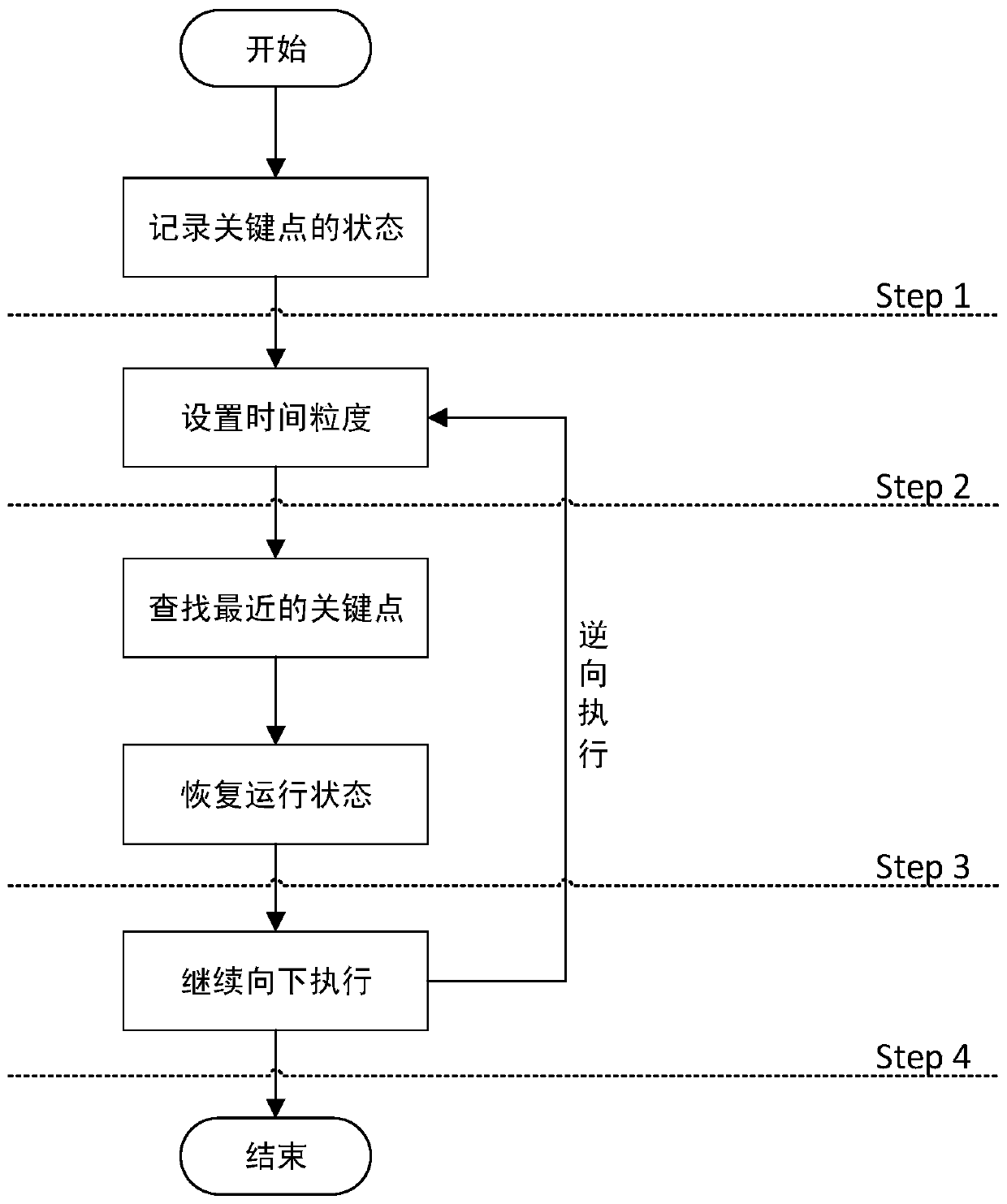

Method for realizing positive and reverse execution of instruction set simulator

ActiveCN106557352AShorten the timeSave energySoftware testing/debuggingSoftware simulation/interpretation/emulationStart timeGranularity

The invention discloses a method for realizing positive and reverse execution of instruction set simulator. The method comprises the steps of firstly executing software by using the instruction set simulator to obtain processor running states, register states, memory states and peripheral states of the instruction set simulator corresponding to multiple key recording time points; then obtaining an external execution instruction; obtaining a starting time point of needed reverse execution if the reverse execution is needed in a positive execution process; and finally calculating a key recording time point by using time granularity or an ending time point of the needed reverse execution, and recovering the processor running state, the resister state, the memory state and the peripheral state of the instruction set simulator at the key recording point, and performing the positive execution until reaching the ending time point of the needed reverse execution so as to finish positive and reverse execution of the instruction set simulator.

Owner:北京轩宇信息技术有限公司

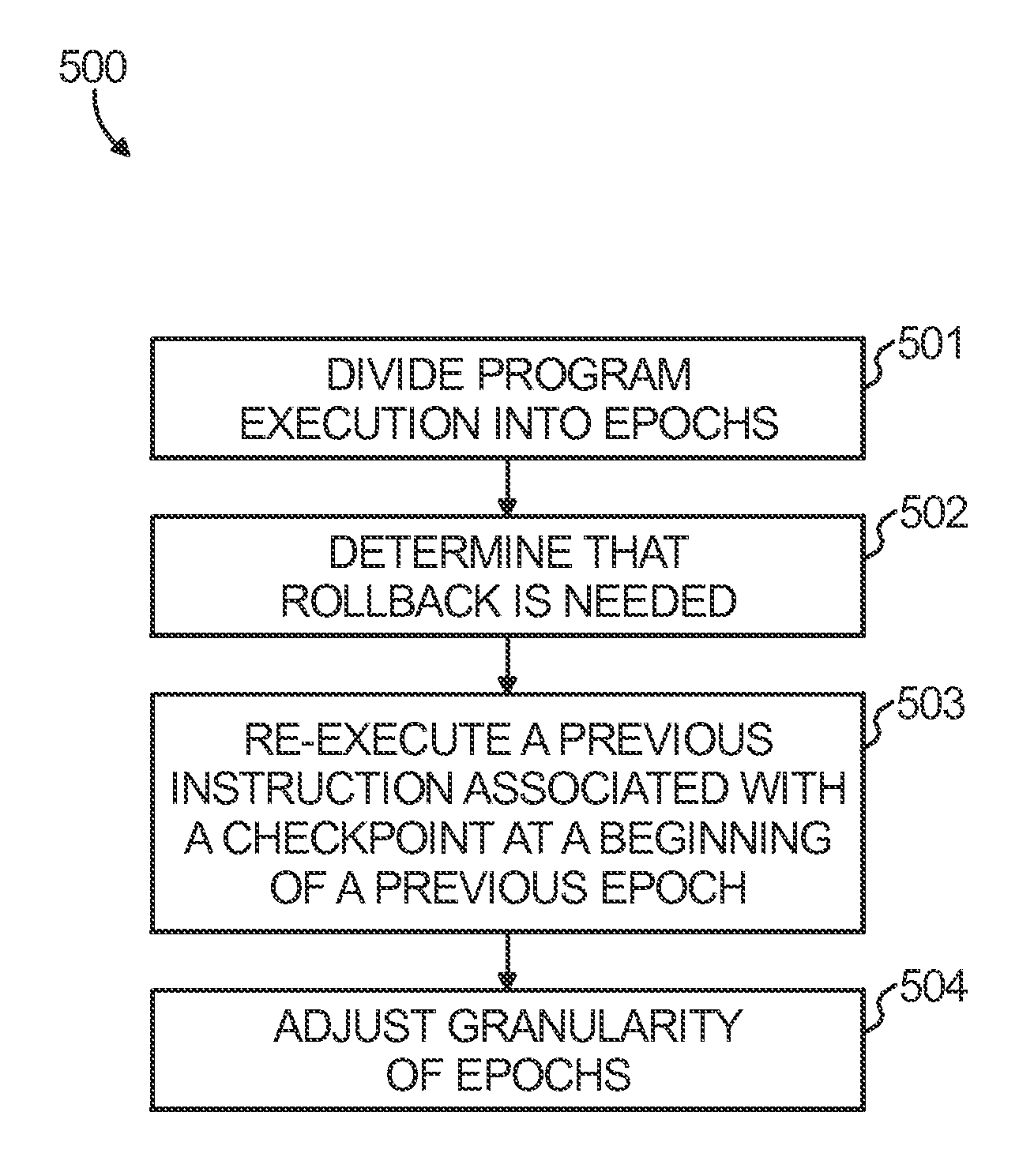

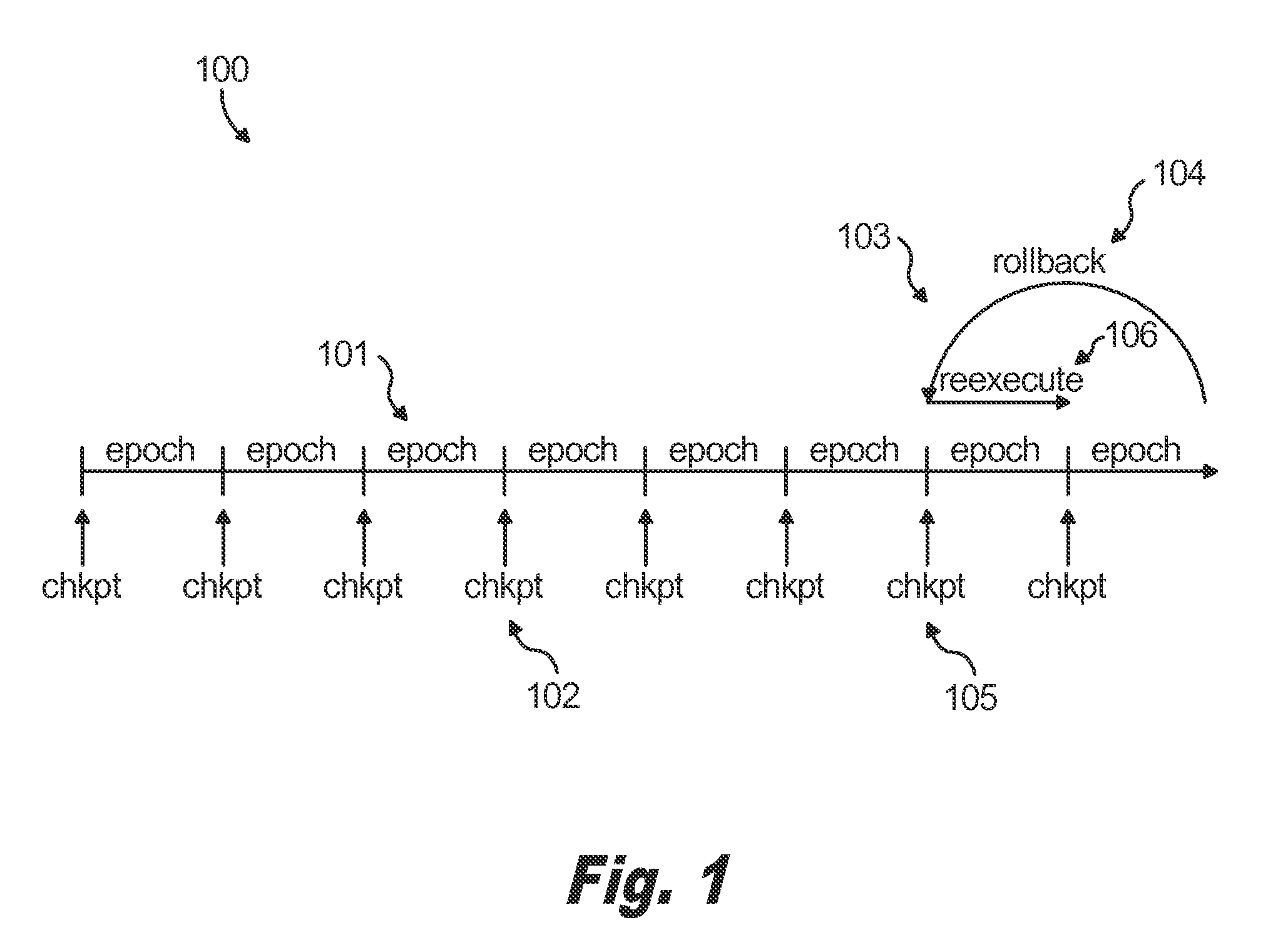

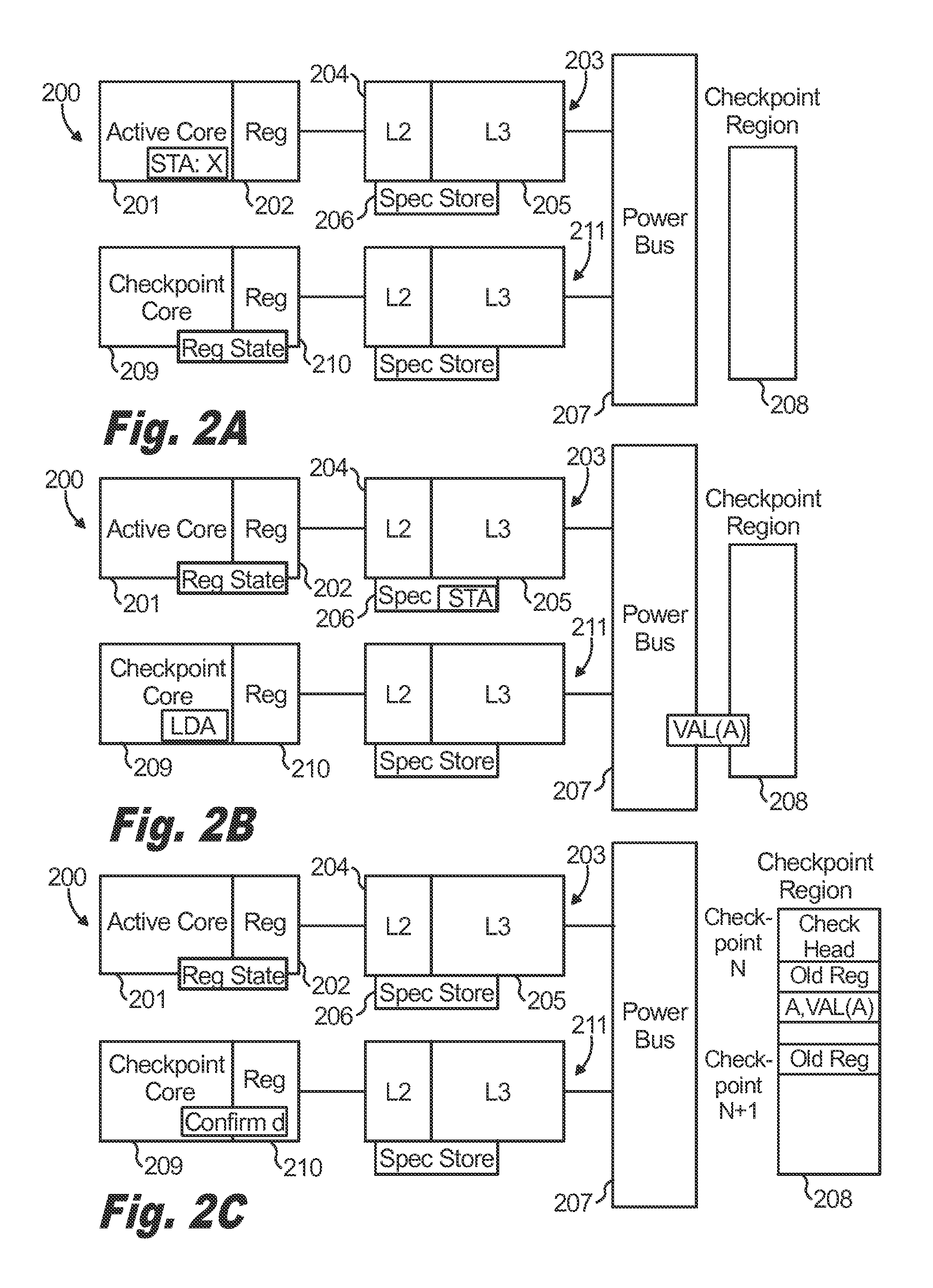

Transactions for checkpointing and reverse execution

A method of backstepping through a program execution includes dividing the program execution into a plurality of epochs, wherein the program execution is performed by an active core, determining, during a subsequent epoch of the plurality of epochs, that a rollback is to be performed, performing the rollback including re-executing a previous epoch of the plurality of epochs, wherein the previous epoch includes one or more instructions of the program execution stored by a checkpointing core, and adjusting a granularity of the plurality of epochs according to a frequency of the rollback.

Owner:INT BUSINESS MASCH CORP

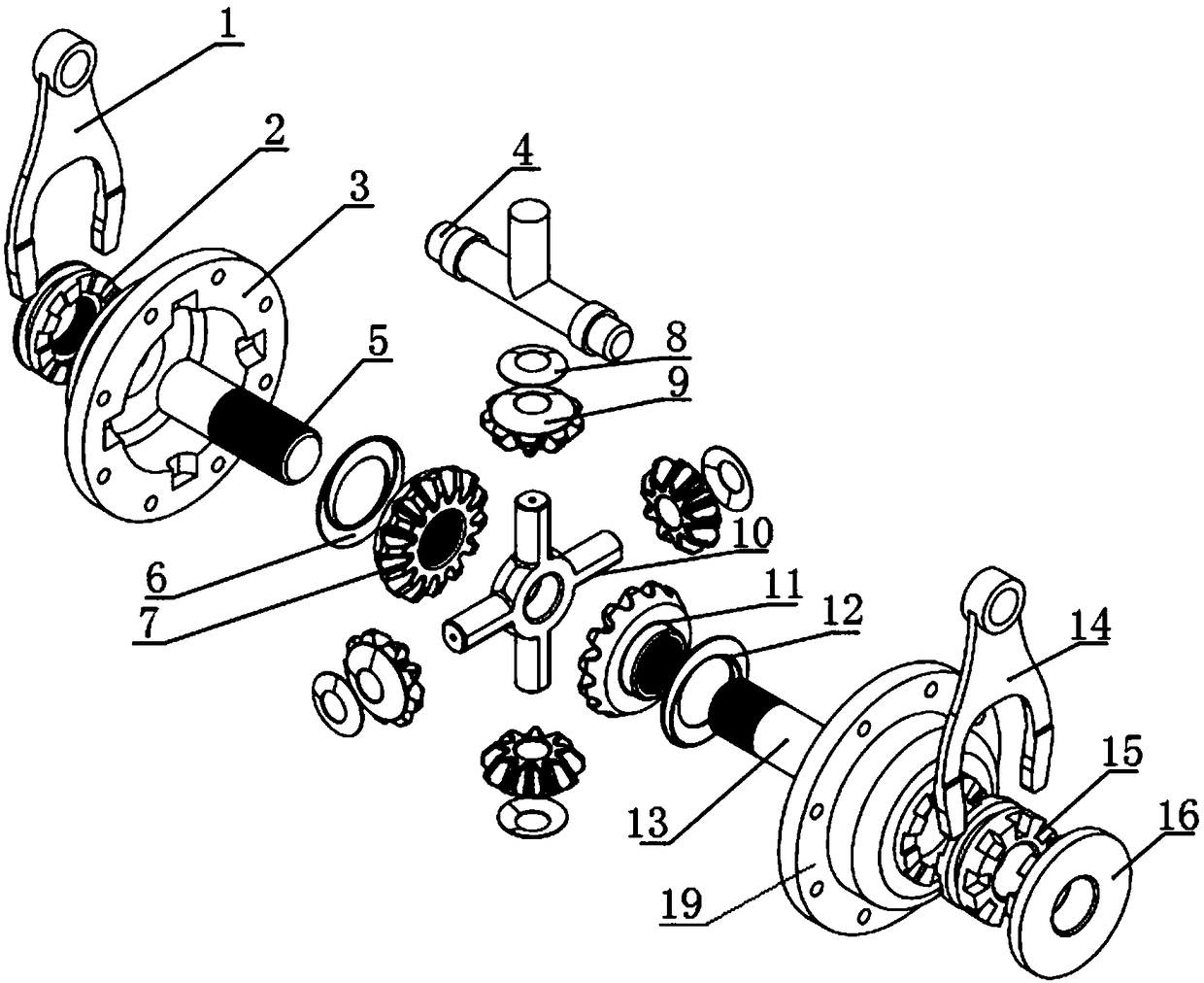

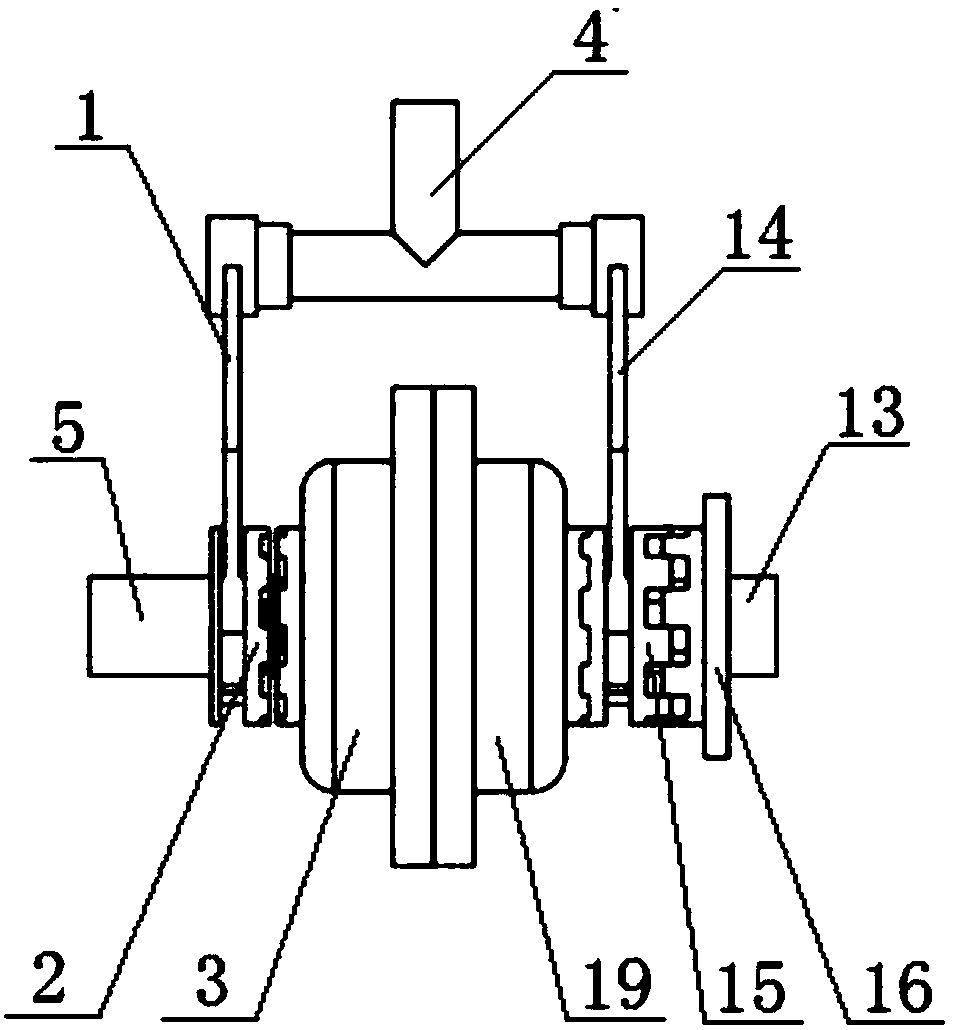

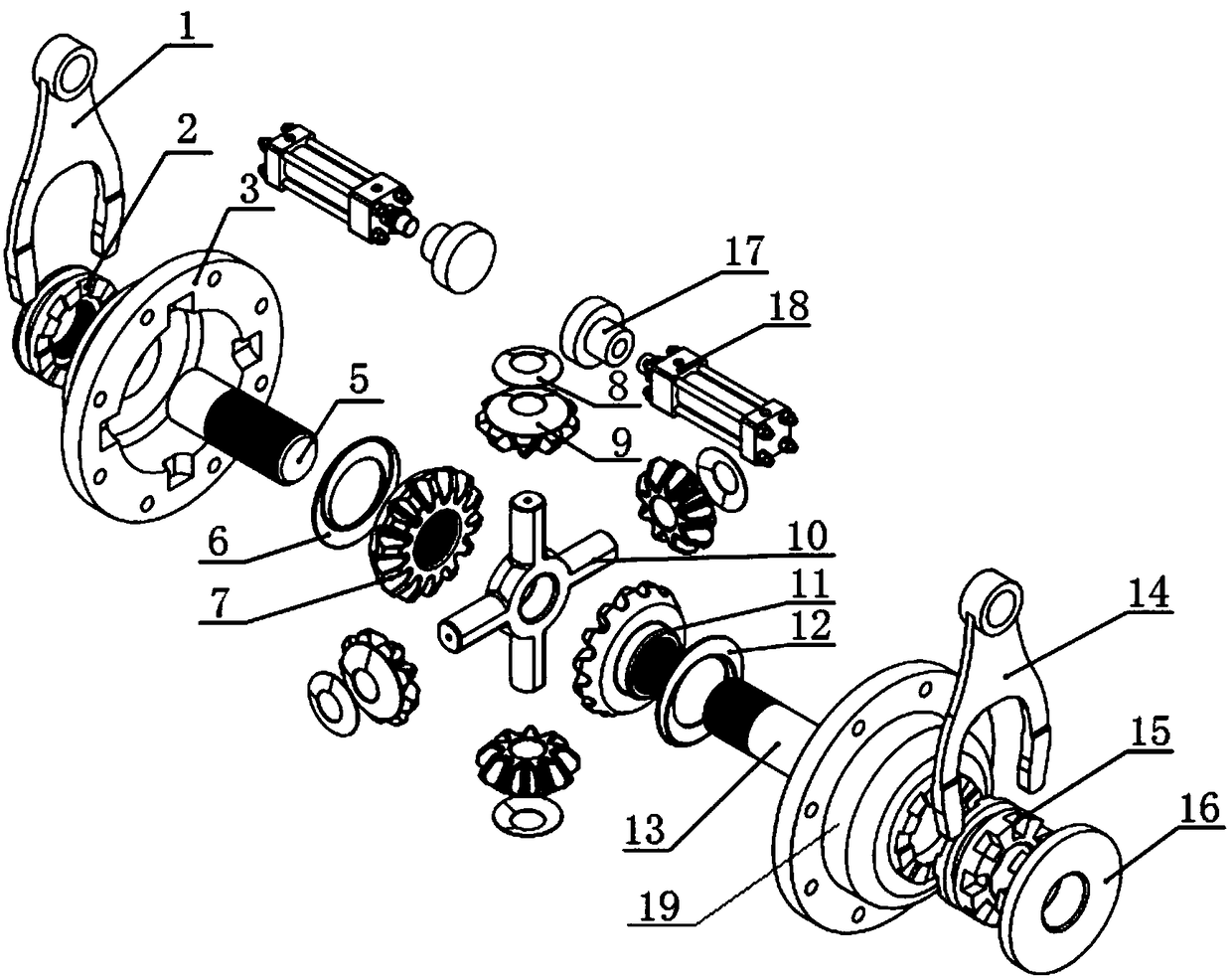

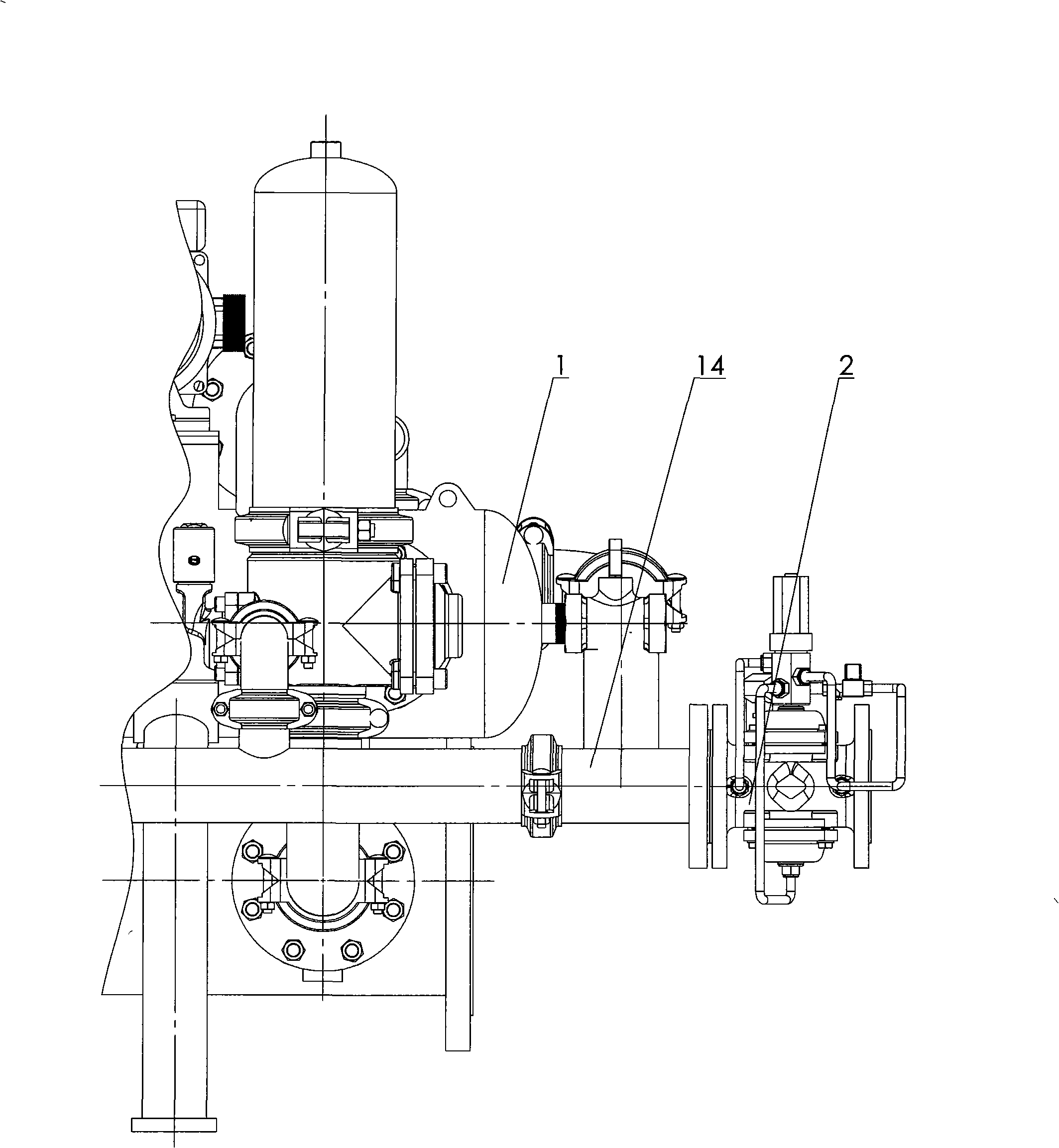

Reversing device for in-situ steering of vehicle driven by single engine

PendingCN108412986AReliable transmissionThe transmission is compactControlled membersToothed gearingsReverse executionEngineering

The invention provides a reversing device for in-situ steering of a vehicle driven by a single engine. The reversing device is characterized by being arranged between an input shaft and an output shaft so that the input shaft and the output shaft can rotate in the same direction or the reverse direction, and composed of a planetary gear train transmission mechanism, a reversing execution mechanismand a reversing operation mechanism, wherein the planetary gear train transmission mechanism is located in the middle of the reversing execution mechanism, and power is transmitted through autorotation or revolution of planetary gears; and in the reversing operation mechanism, a shifting fork is used for shifting movable connectors of the reversing execution mechanism to slide in the axial direction so that the movable connectors can mesh with or be separated from gear teeth on the end surfaces of corresponding reverser shells, and therefore power can be transmitted in the same direction or in the reverse direction in the planetary gear train transmission mechanism. According to the reversing device, the structure is simple and compact, the occupied space is small, and the function of in-situ steering of the vehicle driven by the single engine can be effectively realized.

Owner:JILIN UNIV

Automatic loading and unloading platform for drill rod group

ActiveCN103541671ASmooth loading and unloadingRealize loading and unloadingDrilling rodsDrilling casingsSingle degree of freedomReverse execution

The invention discloses an automatic loading and unloading platform for a drill rod group. The automatic loading and unloading platform comprises a bottom plate, a sliding table, a side sliding driving device and a drill rod group positioning component, the sliding table is slidably connected to the bottom plate by single degree of freedom and is driven by the side sliding driving device to slide in a reciprocating manner, the drill rod group positioning component is mounted on the sliding table, drill rods and air ducts are combined to form the drill rod group which can be conveyed to the space between a spindle of a spiral drill type coal mining machine and a connected drill rod group through the sliding table after the drill rod group is placed and positioned on the automatic loading and unloading platform for the drill rod group, a main engine is controlled to advance, so that the drill rod group can be connected, the sliding table can return to an original position after connection, a next drill rod group is mounted, the drill rod group can be detached by the aid of reverse execution, manual loading and unloading can be replaced, the labor intensity of workers is reduced, the drill rod group can be accurately positioned, the drill rods are successfully loaded and unloaded, time consumption is reduced, and the mining efficiency of coal beds is improved.

Owner:CHONGQING UNIV

Execution control with cross-level trace mapping

Described technologies aid execution control during replays of traced program behavior. Cross-level mapping correlates source code, an intermediate representation, and native instructions in a trace.The trace includes a record of native code instructions which were executed by a runtime-managed program. The trace does not include any executing instance of the runtime. Breakpoints are set to aligntrace locations with source code expressions or statements, and to skip over garbage collection and other code unlikely to interest a developer. A live debugging environment is adapted to support trace-based reverse execution. An execution controller in a debugger or other tool may utilize breakpoint ranges, cross-level mappings, backward step-out support, and other items to control a replay execution of the trace. Aspects of familiar compilers or familiar runtimes may be re-purposed for innovative execution control which replays previously generated native code, as opposed to their established purpose of generating native code.

Owner:MICROSOFT TECH LICENSING LLC

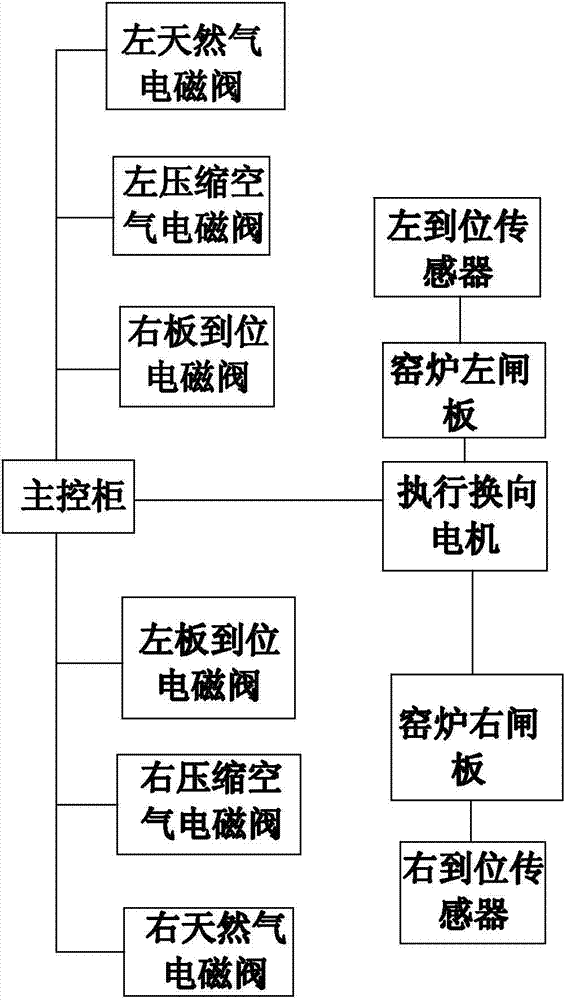

Automatic reversing device of fuel gas kiln

InactiveCN104743770AIncrease chain protectionEliminate potential safety hazardsGlass furnace apparatusReverse executionEngineering

The invention belongs to the field of glass production equipment accessory, and in particular relates to an automatic reversing device of a fuel gas kiln. The automatic reversing device comprises a master control cabinet, wherein the master control cabinet is provided with a time relay and a PLC controller, the PLC controller is externally connected with three paths of signal lines, the first path of signal line is connected with a left natural gas electromagnetic valve, a left compressed air electromagnetic valve and a right board in-place electromagnetic valve, the second path of signal line is connected with a right natural gas electromagnetic valve, a right compressed air electromagnetic valve and a left board in-place electromagnetic valve, the third path of signal line is connected with a reversing execution motor, two sides of the reversing execution motor are respectively connected with a left gate and a right gate of the kiln, the left gate and the right gate of the kiln are respectively and correspondingly provided with a left in-place sensor and a right in-place sensor, the left in-place sensor and the right in-place sensor are respectively connected with a left board in-place electromagnetic valve and a right board in-place electromagnetic valve. The in-place information of each of the left gate and the right gate can be judged through the left in-place sensor and the right in-place sensor; the reversing can be immediately stopped if one action is not in place or the operation is abnormal in the reversing process, the potential safety hazard is eliminated, and the work is stable and reliable.

Owner:SHANDONG PHARMA GLASS

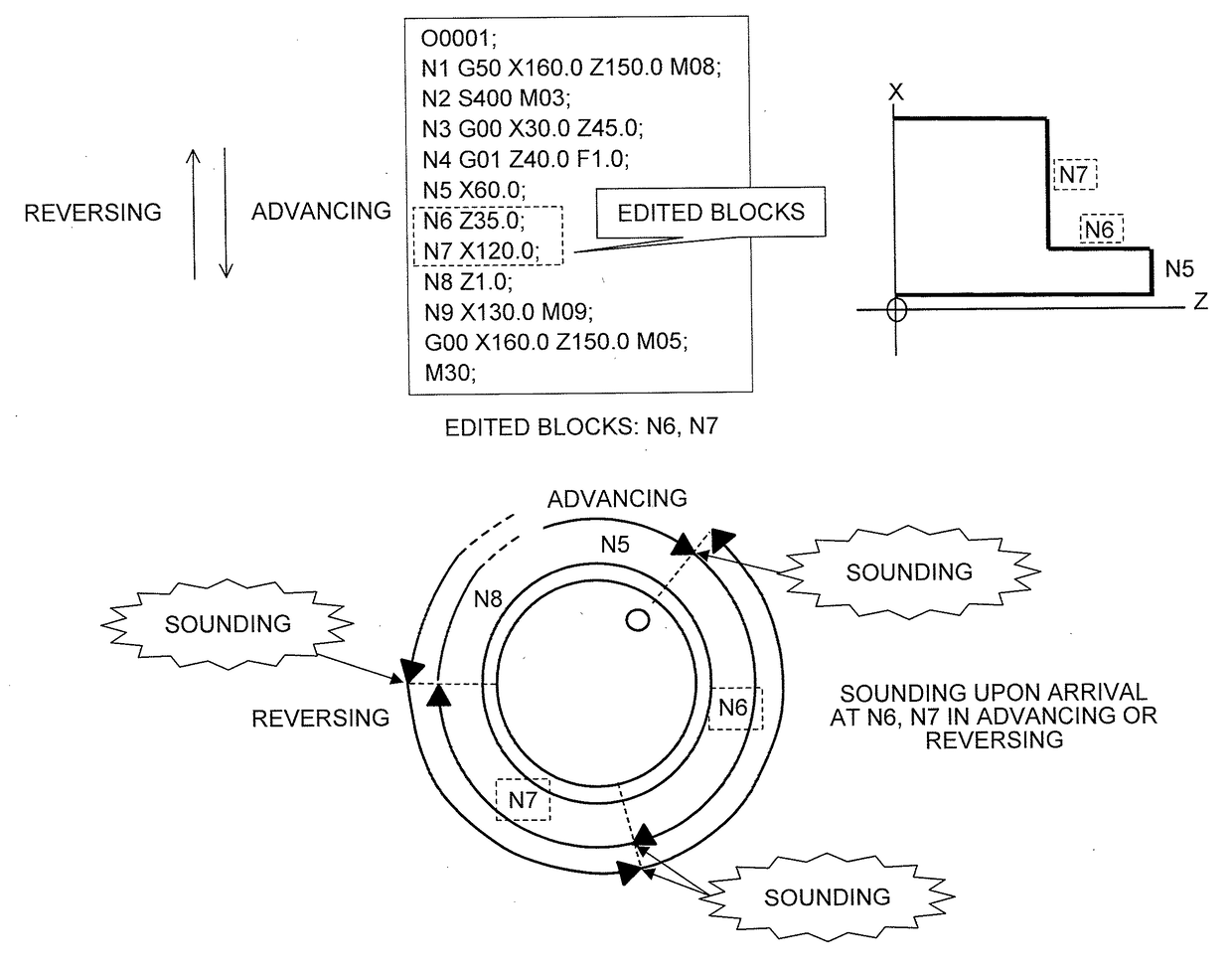

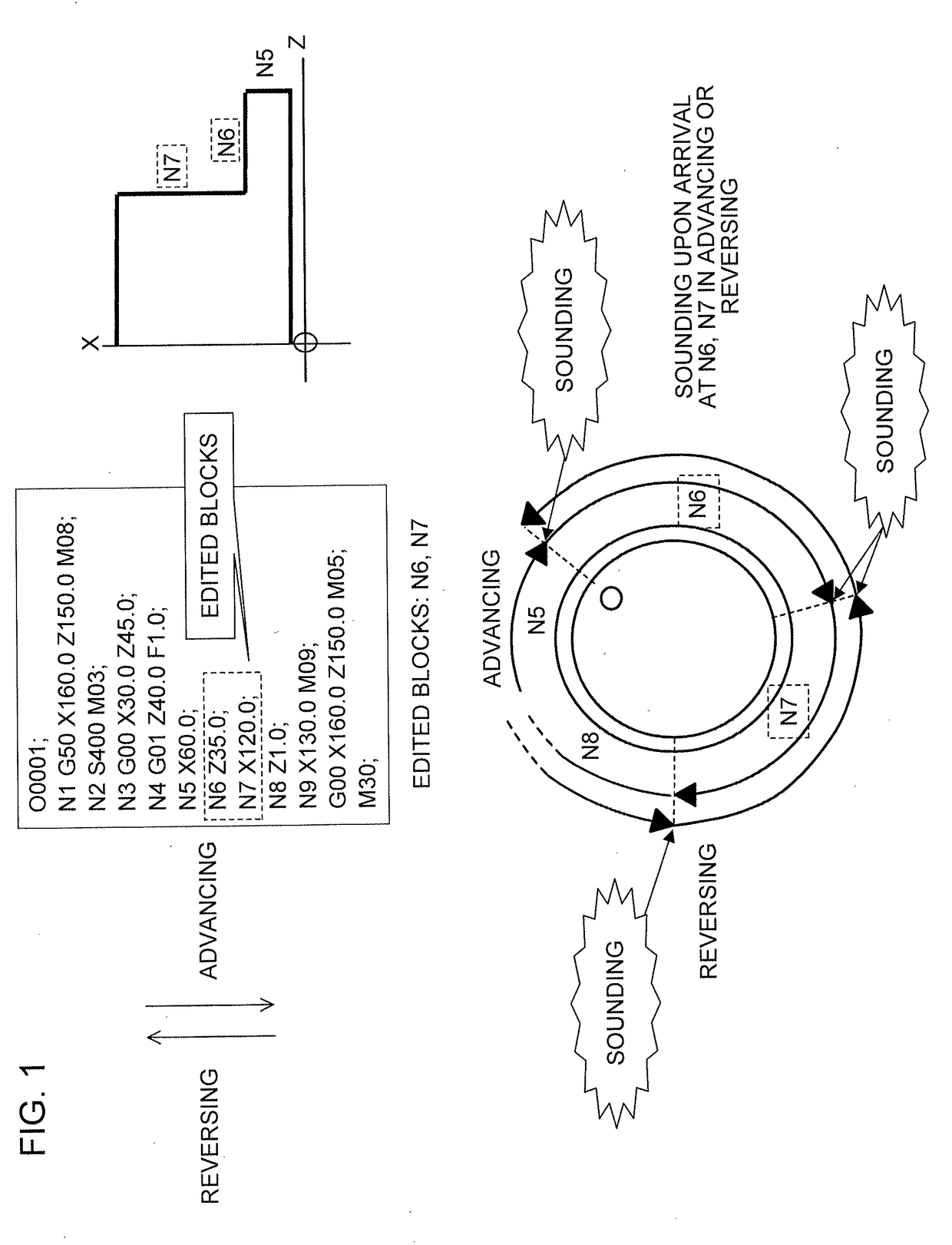

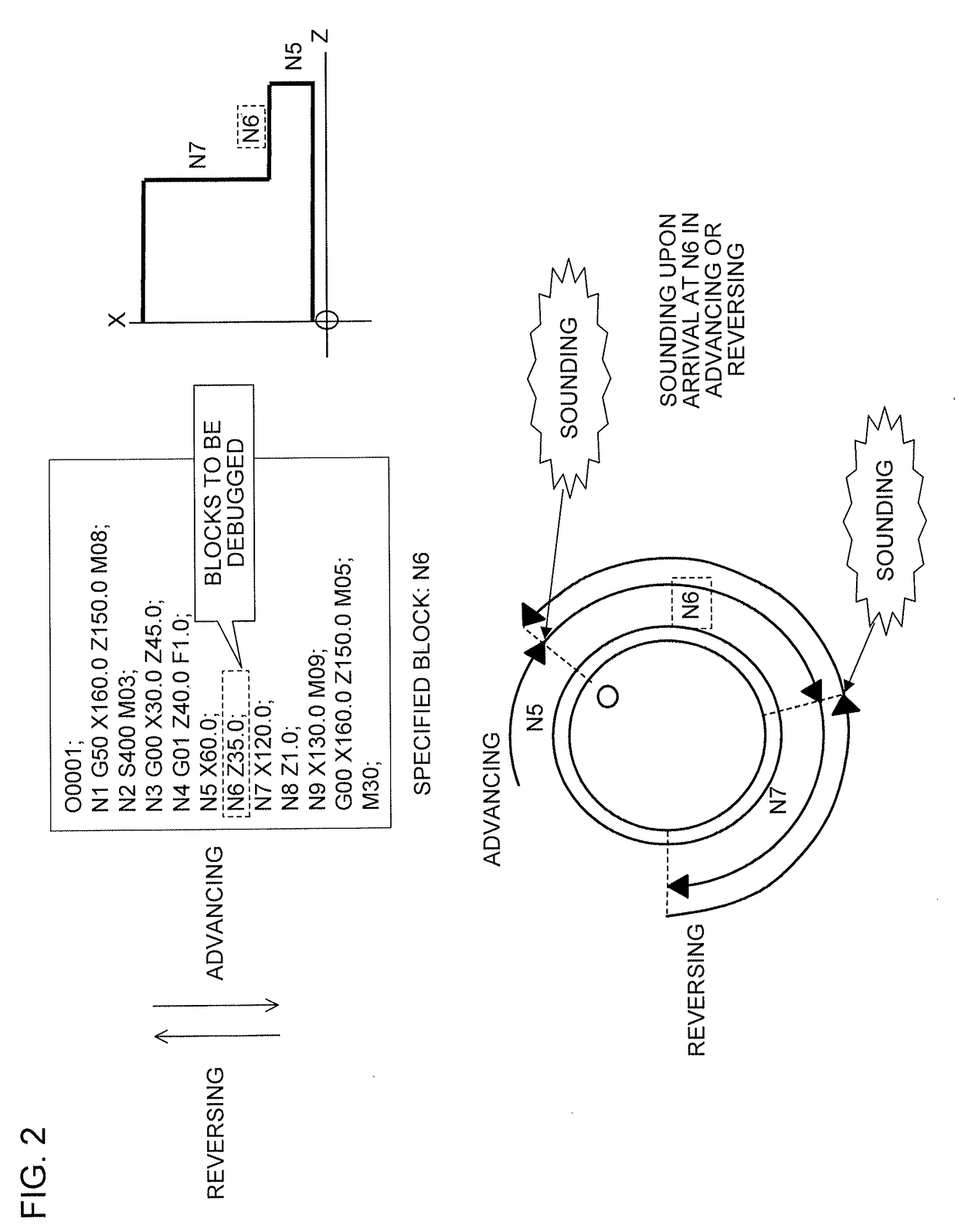

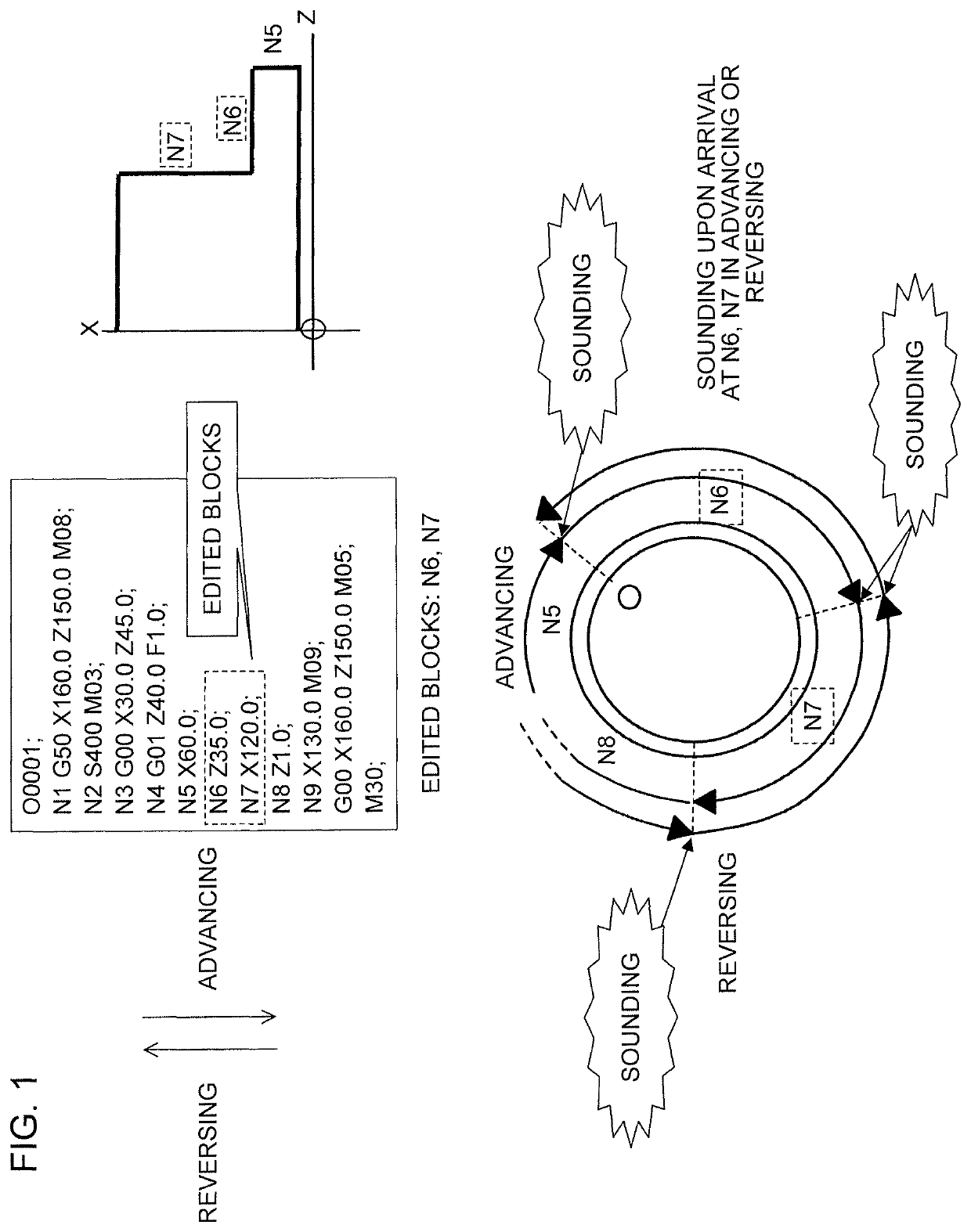

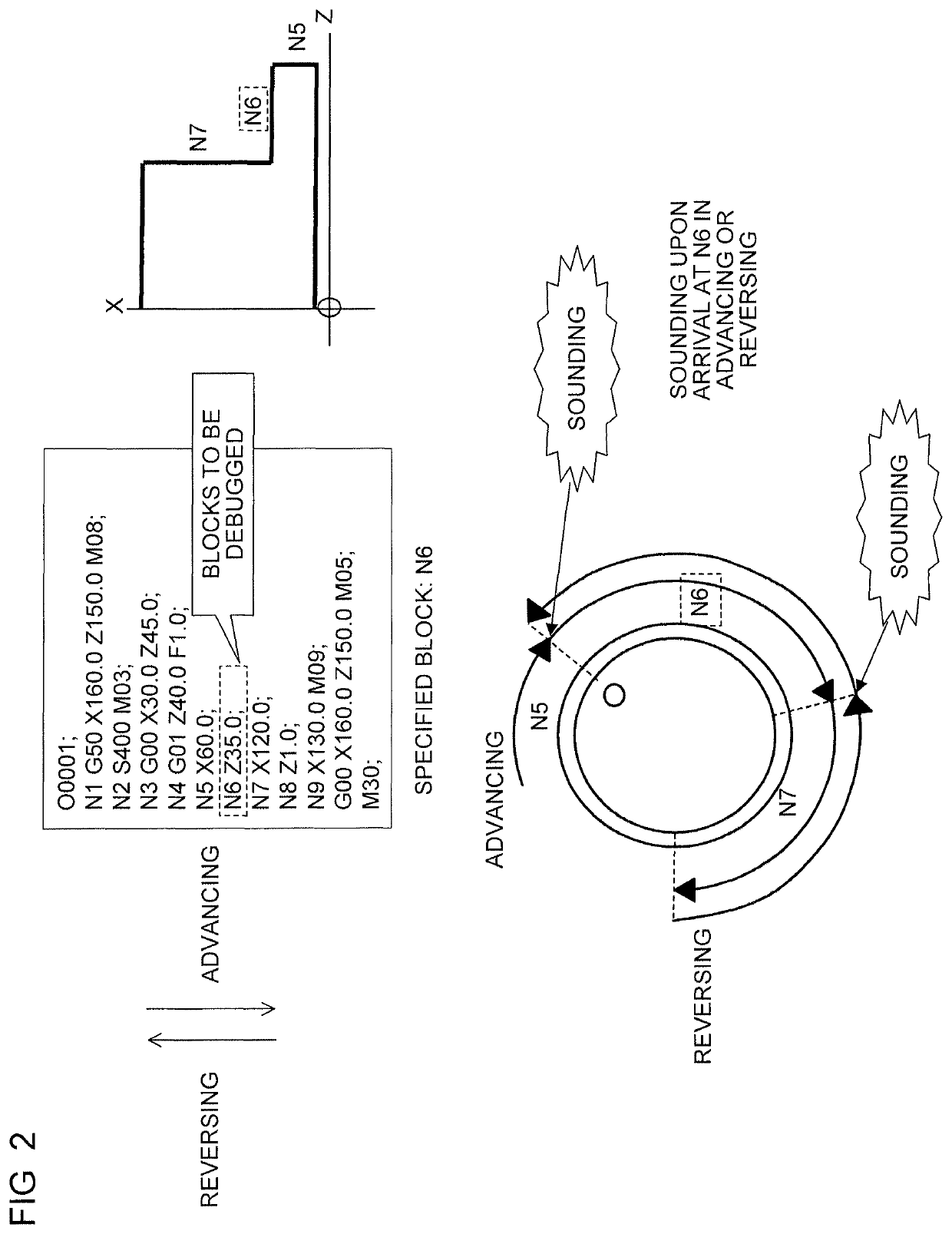

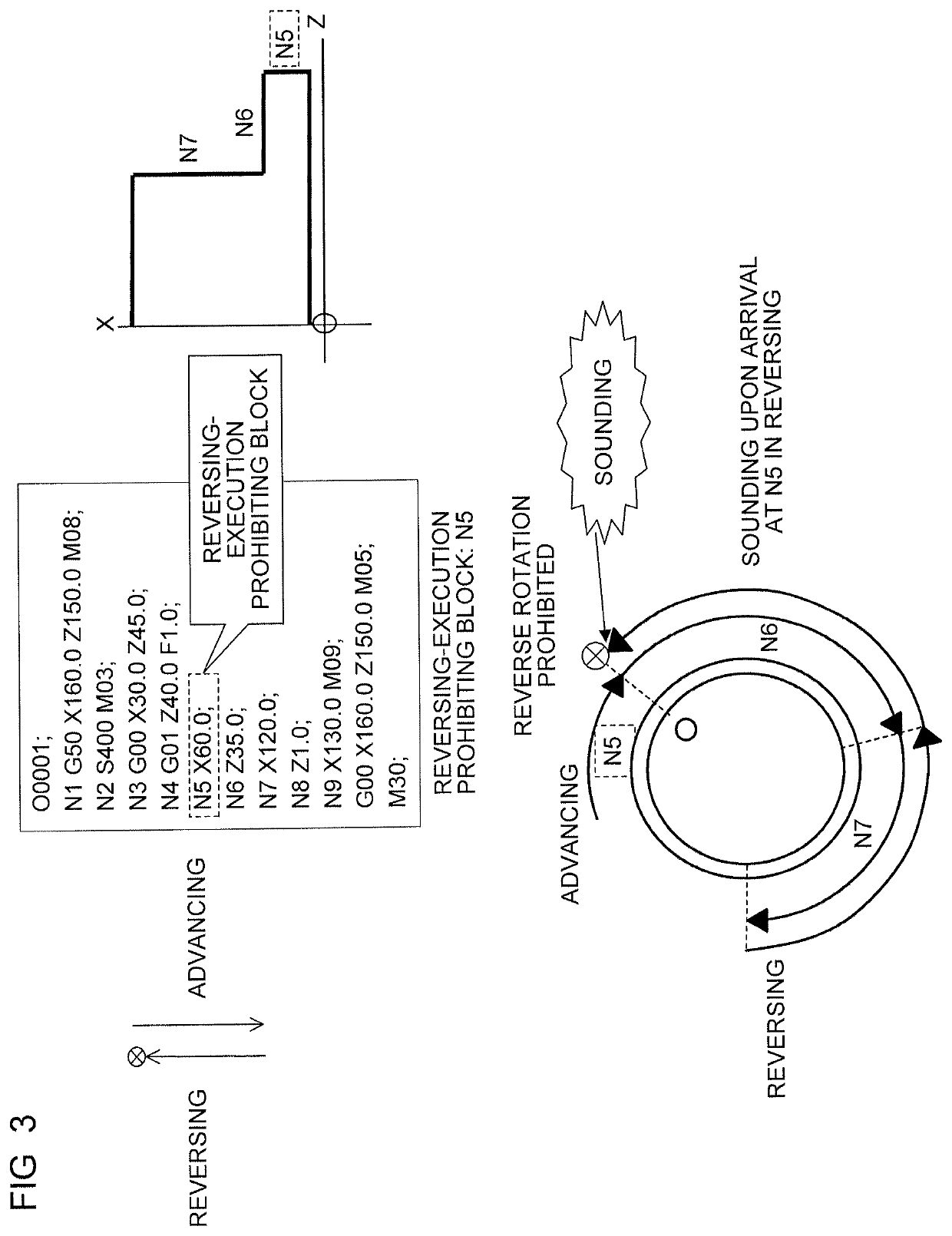

Numerical controller including means for checking execution status of program

ActiveUS20170185079A1Efficient executionReduce necessityProgramme controlElectric testing/monitoringInstruction unitReverse execution

A numerical controller that controls a machine based on a program includes a manual program execution instruction unit that gives instructions for advancing and reversing execution of the program in a manual manner, a program manual execution unit that sequentially executes the program, and a block information notification unit that identifies a block in the program the execution of which is about to be started, based on execution status of the program reported from the program manual execution unit, and that makes notification in accordance with an attribute of the identified block.

Owner:FANUC CORP

Hydraulic oil circuit for reversing control of automatic transmission

ActiveCN104358862AImprove working conditionsExtend your lifeGearing controlDriver/operatorAutomatic transmission

The invention discloses a hydraulic oil circuit for reversing control of an automatic transmission, belongs to the technical field of automotive transmissions, and solves the technical problems of obvious impact feel, short transmission life, high maintenance and repair costs and poor driving feel of a driver in a shifting process due to over-high oil pressure in a control oil circuit during reversing of an existing automatic transmission automobile. The hydraulic oil circuit is characterized in that the operations of adjusting the pressure and switching the oil circuit are carried out through solenoid valves, and the input main oil pressure is reduced and output to reversing execution elements. The hydraulic oil circuit is simple in structure and reasonable in design; the oil circuit is switched and the main oil pressure is adjusted to be relatively low under the control of the solenoid valves; the oil pressure is controlled to be within a relatively low range under the reversing working condition in a specific situation, and the performance is stable; the use of complicated control programs is avoided and the reversing execution elements need to be improved, so that the part development cost and the control program matching and calibration cost are reduced, the product development cycle is shortened, the product life is prolonged, and the use, maintenance and repair costs are lowered.

Owner:HARBIN DONGAN AUTOMOTIVE ENGINE MFG CO LTD

Reversible debugging in a runtime environment

ActiveUS11113182B2Software testing/debuggingDesign optimisation/simulationReverse executionApplication procedure

Owner:MICROSOFT TECH LICENSING LLC

Method for debugging operating software of aircraft onboard system and equipment for implementing the method

The invention relates to a method for debugging a program of running software of an airborne system, which is characterized in that it comprises the following steps: a) setting up marks (31) for the program by arranging marks along the execution path, so as to divide the execution path into Adjacent function intervals; b) execute (32) the program normally; c) capture (33) the program execution state through the flag state vector; d) when an error is detected: search (36) the defective one according to the flag state vector A function interval, reverse execution (41) of the program in the defective function interval; determining and correcting (42) the error.

Owner:AIRBUS OPERATIONS (SAS)

Coal mining system capable of automatically assembling and disassembling drill rod groups

ActiveCN103541731BPrecise loading and unloadingPrecise positioningSlitting machinesReverse executionSingle degree of freedom

The invention discloses a coal mining system capable of automatically assembling and disassembling drill rod groups. The coal mining system comprises a twist drill type coal cutter and an automatic drill rod group assembling and disassembling platform, wherein the automatic drill rod group assembling and disassembling platform comprises a bottom plate, a sliding table, a side slip driving device and a drill rod group positioning component; the bottom plate is fixedly arranged on a main engine frame of the twist drill type coal cutter; the sliding table is connected to the bottom plate in a sliding mode with a single degree of freedom and is driven to slide in a reciprocating mode through the side slip driving device; the drill rod group positioning component is arranged on the sliding table; after a drill rod group is positioned on the automatic drill rod group assembling and disassembling platform, the drill rod group can be conveyed between a main engine spindle of the twist drill type coal cutter and a connected drill rod group, and a main engine is controlled to push, so that the assembly of the drill rod group can be finished; the sliding table can return to be in an original position after the drill rod group is assembled, and then a next drill rod group is mounted. The drill rod group can be disassembled through reverse execution, the labor intensity of workers can be reduced, and the drill rod groups can be accurately positioned, so that the process of assembling and disassembling drill rods is smooth, the time consumption is saved, and the coal mining efficiency is improved.

Owner:CHONGQING UNIV

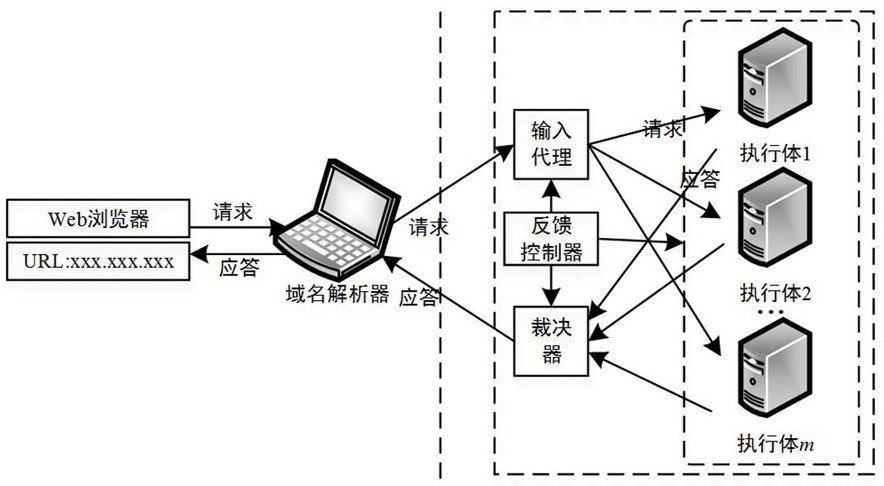

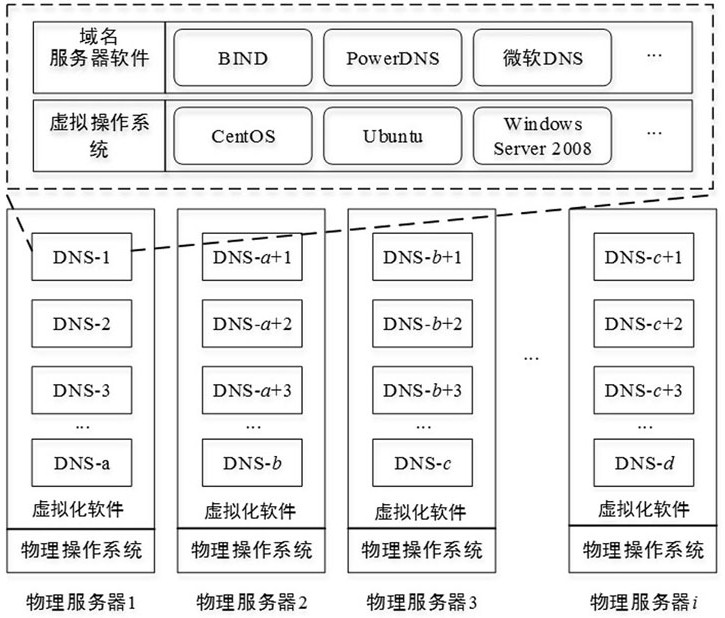

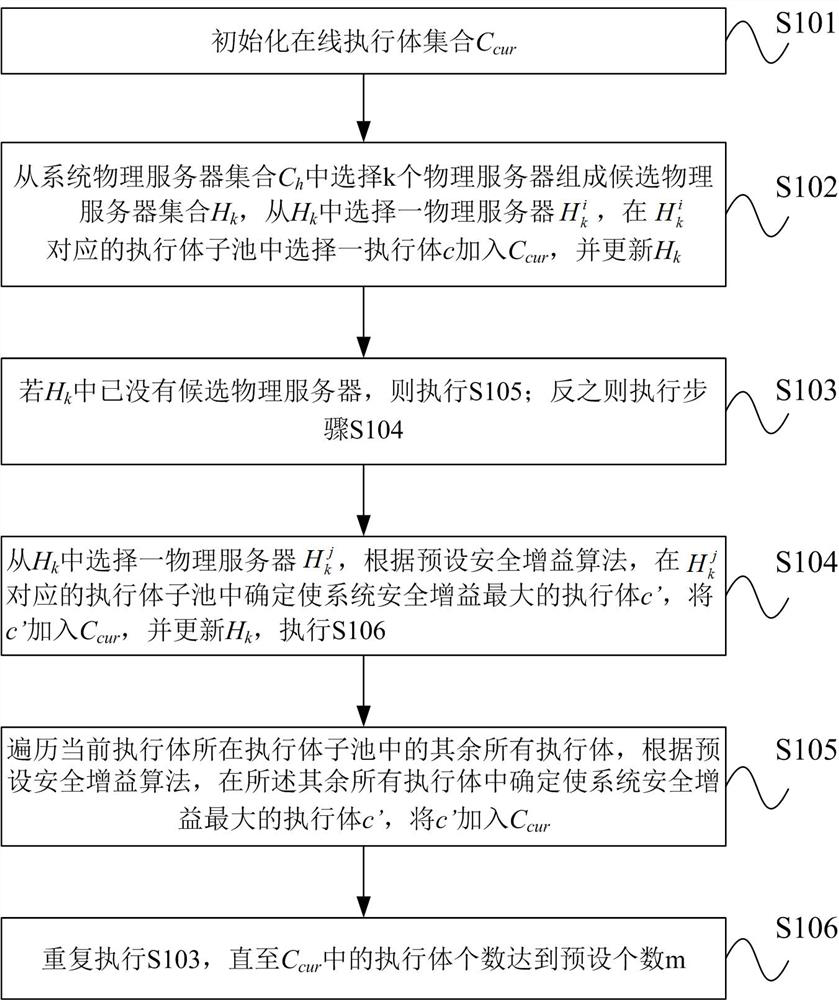

A dns dynamic scheduling method based on mimetic domain name server

ActiveCN108900654BPrevent the threat of failureMaximize safety gainTransmissionDomain nameReverse execution

The present invention provides a kind of DNS dynamic scheduling method based on mimetic domain name server, comprising: step 1.1, initializing C cur ; Step 1.2, from C h Select k physical servers to form candidate set H k , from H k Select executive c in the sub-pool of executives to join C cur ; Step 1.3, if H k If there is no candidate physical server, go to step 1.5; otherwise go to step 1.4; step 1.4, from H k According to the preset security gain algorithm, determine the executor c’ that maximizes the system security gain in the executor sub-pool, and add C cur , execute step 1.6; step 1.5, traverse all other execution bodies in the execution body sub-pool where the current execution body is located, and determine the execution body c' that maximizes the system security gain among all the remaining execution bodies according to the preset security gain algorithm , join C cur ; Step 1.6, repeat step 1.3 until C cur The number of executive bodies reaches m. The invention selects the online execution body based on the security gain, so as to maximize the system security gain.

Owner:PLA STRATEGIC SUPPORT FORCE INFORMATION ENG UNIV PLA SSF IEU

Intelligent pillow

The invention relates to an intelligent pillow which comprises an electric control device and a mechanical structure portion (a pillow support). The electric control device can adjust the height of the pillow automatically according to sleeping positions of a human body. The electric control device is composed of a forward sampling amplitude comparison circuit, a reverse sampling amplitude comparison circuit, a forward execution control circuit, a reverse execution control circuit, a motor driving circuit, a forward shut-down integrated switch, a reverse shut-down integrated switch, a vibration sensor circuit, a motor, and a position display and control circuit. A lifting plate is arranged at the middle position inside a casing of a pillow support structure, a pillow supporting plate is arranged on the lower portion of the casing, the motor is arranged on the lateral side inside the casing, and the motor is connected with a rotating rod through a coupler and a gearbox. A bevel gear is fixedly arranged at a terminal of the rotating rod and matched with a bevel gear wheel arranged at the bottom of the casing. The intelligent pillow can adjust the height of the pillow automatically along with the sleeping positions of the human body, can nurse the necks of people in sleep, and enables the necks to keep a normal physiological curvature. Therefore, comfortableness and quality of sleeping are improved, and a cervical disease and a spinal disease are prevented.

Owner:冯燮

Numerical controller including means for checking execution status of program

ActiveUS10732616B2Efficient operation checkEfficient executionProgramme controlSafety arrangmentsProgramming languageInstruction unit

A numerical controller that controls a machine based on a program includes a manual program execution instruction unit that gives instructions for advancing and reversing execution of the program in a manual manner, a program manual execution unit that sequentially executes the program, and a block information notification unit that identifies a block in the program the execution of which is about to be started, based on execution status of the program reported from the program manual execution unit, and that makes notification in accordance with an attribute of the identified block.

Owner:FANUC LTD

Pressure-holding type pressure balancing sewer valve

InactiveCN101270823AHigh pressure levelDiaphragm valvesOperating means/releasing devices for valvesReverse executionEngineering

An equilibrated sewer valve of continuous pressure type belongs to the design and manufacture technical field of a laminated filter. The invention comprises a pilot valve, a valve body, a valve cover, a diaphragm and a restriction orifice. An upper valve cover and a lower valve cover are respectively arranged on and under the valve body. The upper valve cover is provided with one pilot valve. An upper valve seat and a lower valve seat are respectively arranged in the valve body. An upper diaphragm and a lower diaphragm are respectively arranged between the upper and the lower valve seats and the upper and the lower valve covers. The restriction orifice is arranged at the entrance of the valve. The equilibrated sewer valve of continuous pressure type is mounted on the blow-off pipeline of the laminated filter. The blow-off pressure different between the filter and the atmosphere is resolved into the pressure difference of the filter and the blow-off pipe and the pressure difference of the blow-off pipe and the atmosphere in order to reduce the pressure difference at the two ends of the reversing execution diaphragm of the filtering unit of the laminated filter and improve the pressure range of use of the laminated filter.

Owner:王克涛

Setting arrangement for high artesian area ultra-deep foundation pit

The invention relates to the track traffic and tunnel category, in specific to an arrangement structure of superdeep foundation pits in high pressure water areas, which adopts underground continuous walls (or drilling piles, drill biting piles and corresponding waterproof curtains) as enclosure structure, and inner supports (steel supports or concrete supports ) as support structures; during the course of foundation pit excavation, performing reverse execution on surrounding purlins, supports and side walls; placing precast concrete beams or steel beams in seal concrete, so as to solve shortcomings of the prior art. The invention mainly has the advantages that: on the one hand, the invention can avoid the difficulty in penetration in execution of enclosure structure (in particular to waterproof curtains) when confined aquifers are rather thick and deep; on the other hand, the invention can also avoid all kinds of difficulties in pressure drop of pressure water. Therefore, the invention can save construction cost and lower construction risk as well as protect surrounding environments.

Owner:SHANGHAI TUNNEL ENGINEERING RAILWAY TRANSPORTATION DESIGN INSTITUTE

A method for realizing forward and reverse bidirectional execution of an instruction set simulator

ActiveCN106557352BShorten the timeSave energySoftware testing/debuggingSoftware simulation/interpretation/emulationStart timeReverse execution

The invention discloses a method for realizing positive and reverse execution of instruction set simulator. The method comprises the steps of firstly executing software by using the instruction set simulator to obtain processor running states, register states, memory states and peripheral states of the instruction set simulator corresponding to multiple key recording time points; then obtaining an external execution instruction; obtaining a starting time point of needed reverse execution if the reverse execution is needed in a positive execution process; and finally calculating a key recording time point by using time granularity or an ending time point of the needed reverse execution, and recovering the processor running state, the resister state, the memory state and the peripheral state of the instruction set simulator at the key recording point, and performing the positive execution until reaching the ending time point of the needed reverse execution so as to finish positive and reverse execution of the instruction set simulator.

Owner:北京轩宇信息技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com