Hydraulic oil circuit for reversing control of automatic transmission

A technology of automatic transmission and hydraulic oil circuit, which is applied in the direction of transmission control, toothed components, belt/chain/gear, etc., can solve the problems of poor driving experience of the driver and shorten the life of the transmission, and achieve improved working conditions, Shorten the development cycle and design reasonable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

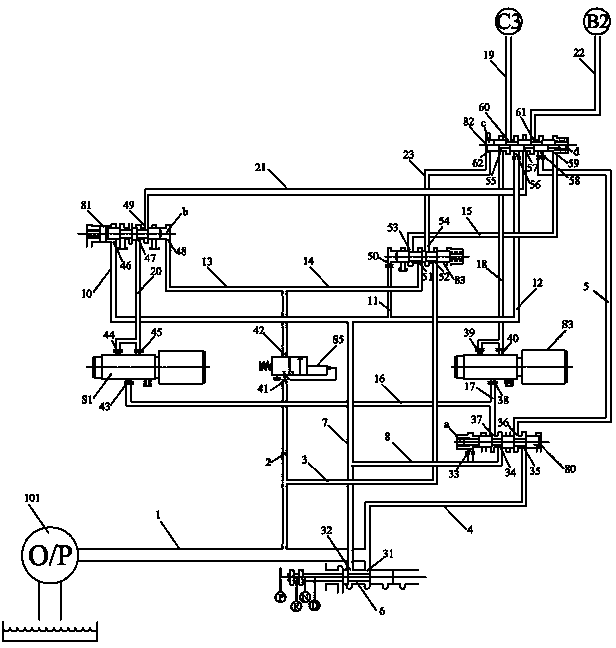

[0009] combine figure 1 To illustrate, the present invention includes an oil pump 101, a first shift actuator C3, a second shift actuator B2 and a manual valve 6, and it also includes a first solenoid valve S1, a second solenoid valve S3, a switch solenoid valve S5, D gear / R gear logic valve 80, low reverse gear logic valve 81, C3-B2 pressure switch valve 82 and shift switch valve 83,

[0010] The oil outlet of the oil pump 101 is provided with an oil passage 1, and the oil outlet of the oil passage 1 is respectively connected with the oil inlet of the oil passage 2, the oil inlet of the oil passage 4 and the inlet 31 of the manual valve 6,

[0011] Wherein, the oil outlet of the oil passage 2 communicates with the oil inlet of the oil passage 3 and the inlet 41 of the switch solenoid valve S5 respectively, and the oil outlet of the oil passage 3 communicates with the inlet 52 of the shift switch valve 83, The outlet 54 communicates with the oil chamber c oil port 62 of the C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com