Coal mining system capable of automatically assembling and disassembling drill rod groups

A technology for automatic loading and unloading of drill pipes, which is applied to earthwork drilling and slitting machinery, etc. It can solve problems such as harsh working conditions, low recovery efficiency, and small working space for thin and extremely thin coal seam mining, so as to save time and reduce waste. Labor intensity, the effect of improving the efficiency of coal seam mining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

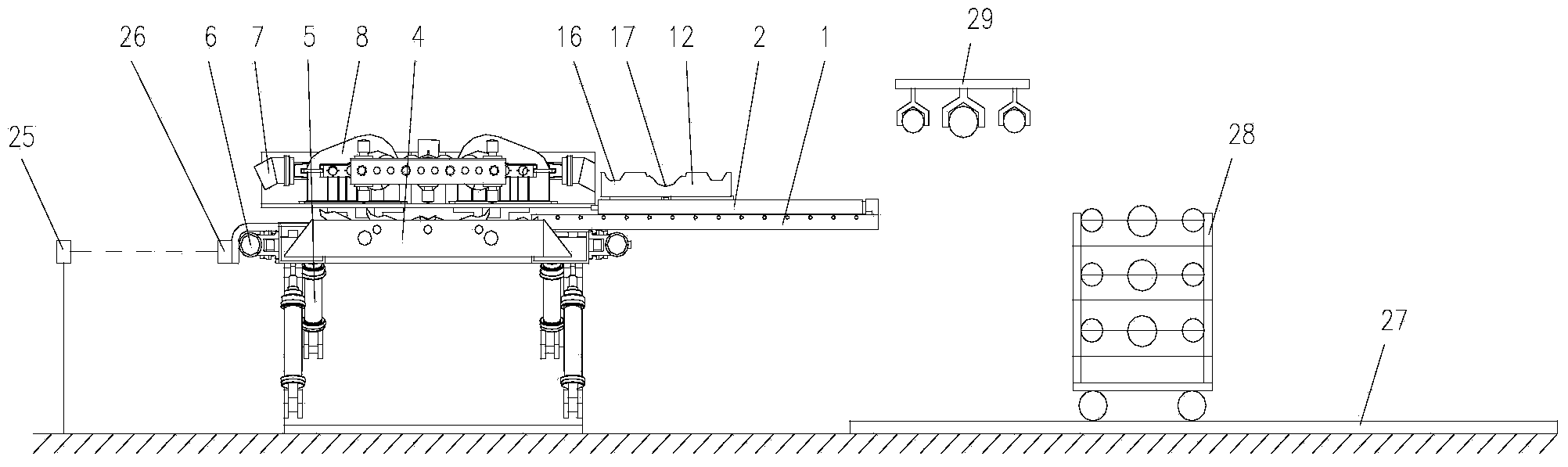

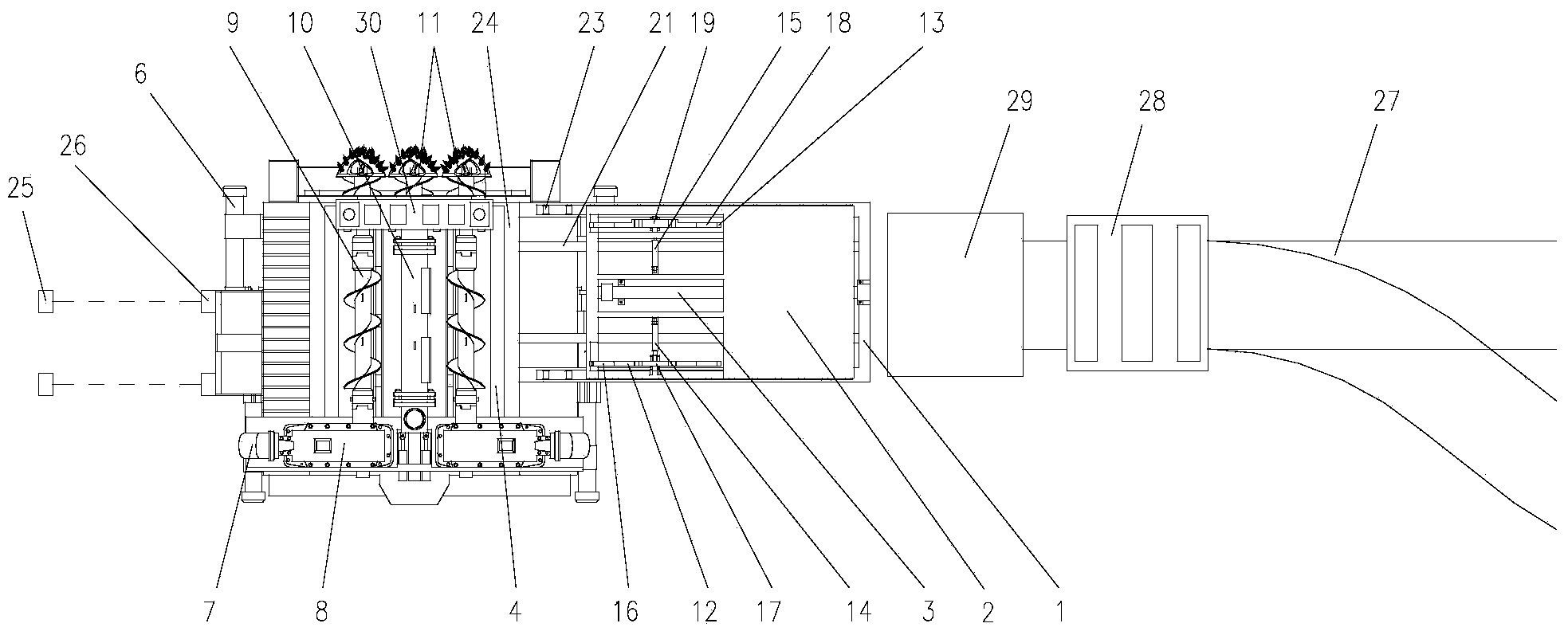

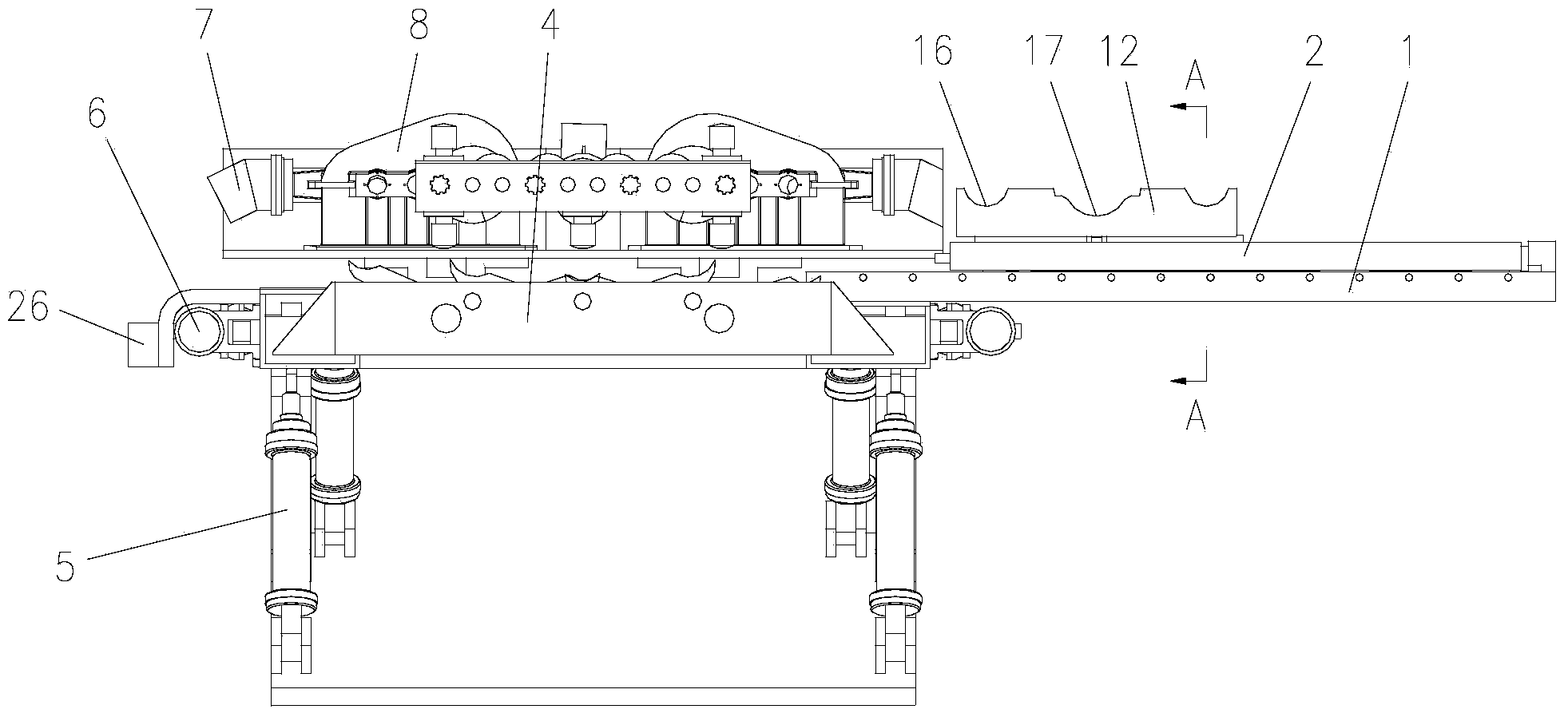

[0022] figure 1 It is a structural schematic diagram of the present invention, figure 2 for figure 1 top view of image 3 It is a schematic diagram of the structure of the automatic loading and unloading platform of the drill string installed on the auger shearer, Figure 4 for image 3 top view of Figure 5 for image 3 A-A sectional view of A-A, as shown in the figure: the coal mining system that can automatically load and unload drill strings in this embodiment includes an auger shearer and an automatic loading and unloading platform for drill strings; the automatic loading and unloading platform for drill strings includes a bottom plate 1 , a slide table 2, a sideslip driving device 3 and a drill string positioning assembly; the base plate 1 is fixedly installed on the main frame 4 of the auger shearer; the slide table 2 is slidably connected to the base plate 1 with a single degree of freedom and The reciprocating slide is driven by the sideslip driving device 3; t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com