Multipurpose mechanical gripper

A mechanical claw and multi-purpose technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of poor working stability and reliability, uncoordinated work of the double oil cylinder structure, large force on the two claws, etc., and achieve improved Stability and reliability, manufacturing cost savings, and strength enhancement effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below with reference to the drawings and specific implementations of the specification. The following front and rear are only for convenience of description. The side of the cylinder rod of the excavator is defined as the front, and the side of the support mechanism of the excavator is defined as the rear. The front and rear settings of the excavator are generally recognized in the industry.

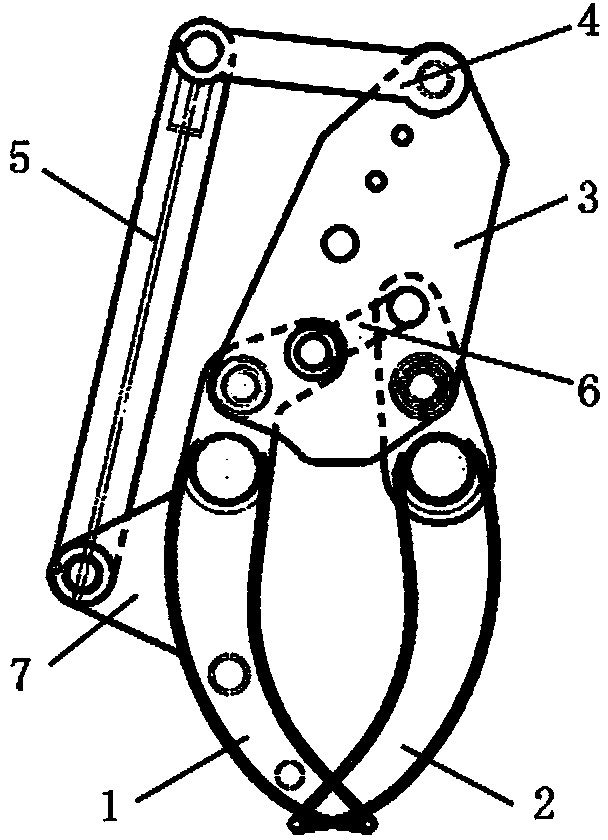

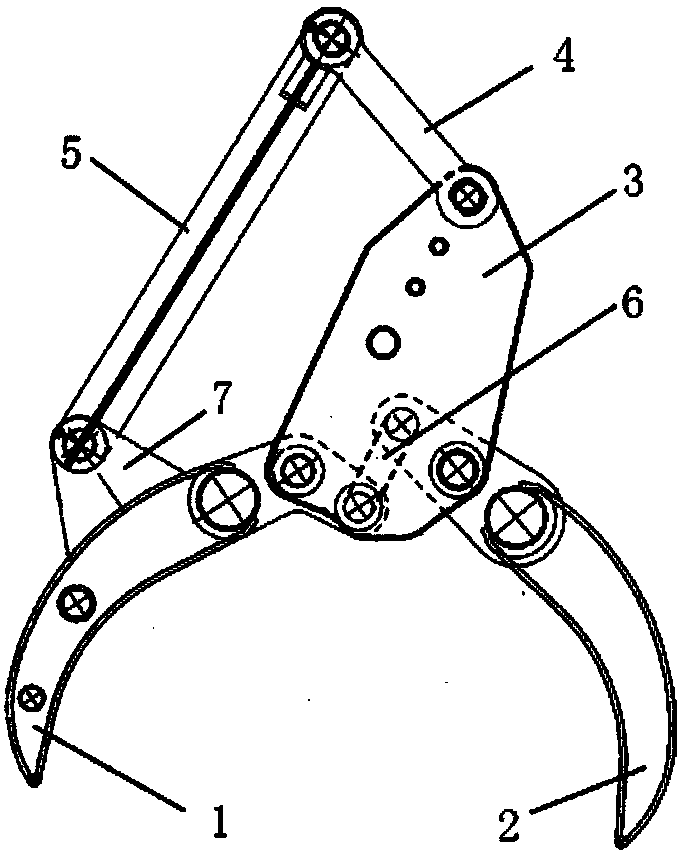

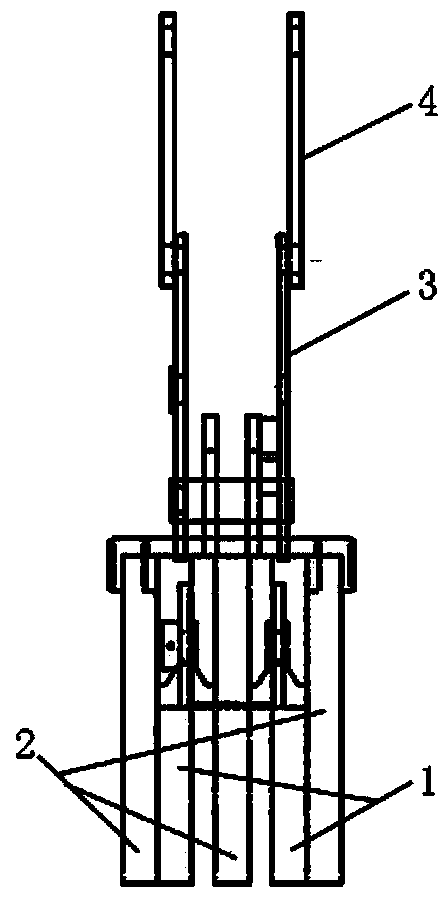

[0014] Such as figure 1 , 2 As shown in Figure 3, a multi-purpose mechanical claw mainly includes a front jaw 1, a rear jaw 2 and a connecting structure. The front jaw 1 and the rear jaw 2 can be opened and closed to claw objects. The opening and closing of the two jaws is completed by the hydraulic or vapor pressure transmission mechanism on the mechanical arm. Such as image 3 As shown, in this embodiment, the front jaw 1 has 2 clamping teeth, the rear jaw 2 has 3 clamping teeth, and the front clamping teeth and the rear clamping te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com