Reversing device for in-situ steering of vehicle driven by single engine

A technology of reversing device and in-situ steering, which is applied in the directions of transmission, mechanical control, transmission control, etc., can solve the problems of complex control process of steering mechanism, large space occupied by power system, and reduced complexity, and achieve reversing. The process is easy to operate, the structure is simple and compact, and the effect of reducing the space size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

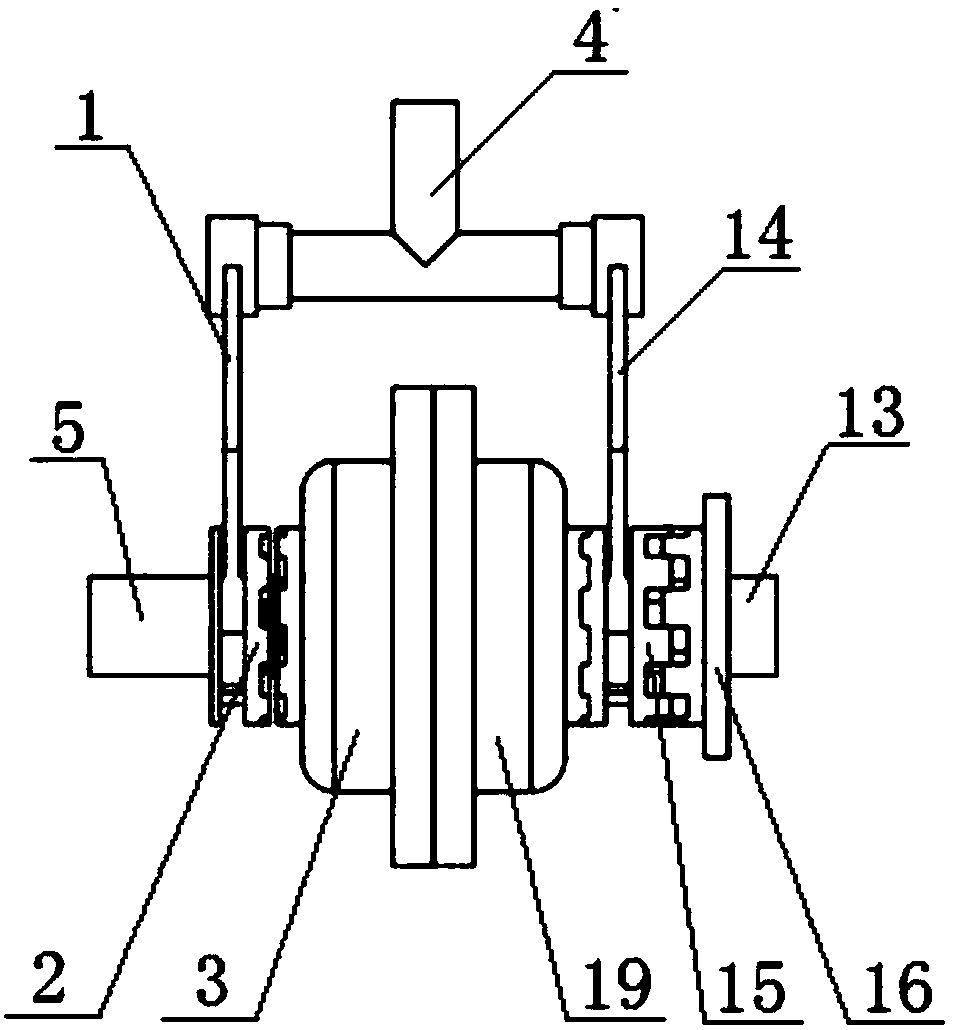

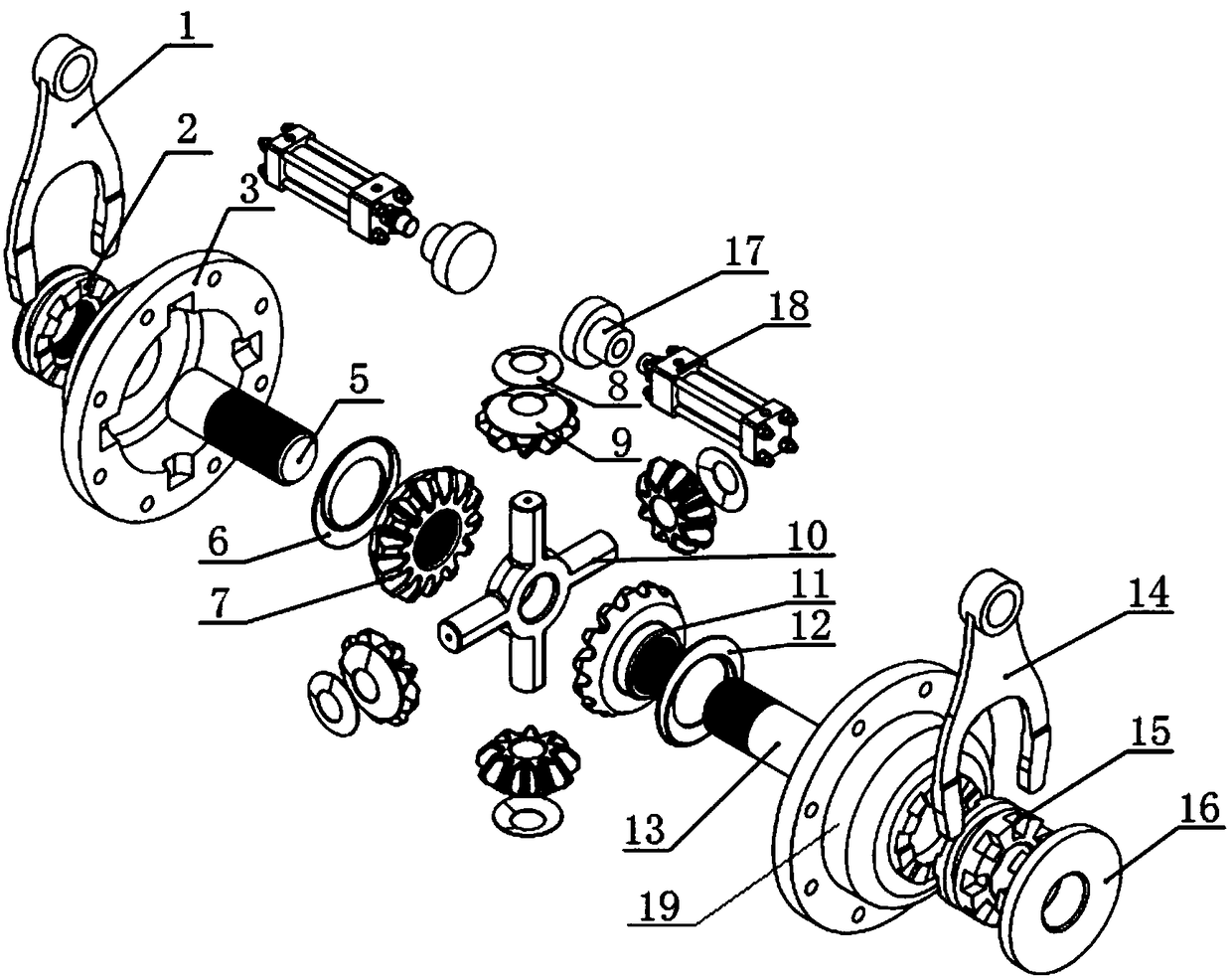

[0041] The first embodiment discloses a reversing device for in-situ steering of a single-engine drive vehicle. The reversing device is installed between the input shaft 5 and the output shaft 13 to realize the Rotating in the same direction or in the opposite direction, the reversing device is composed of a planetary gear train transmission mechanism, a reversing actuator and a reversing operating mechanism.

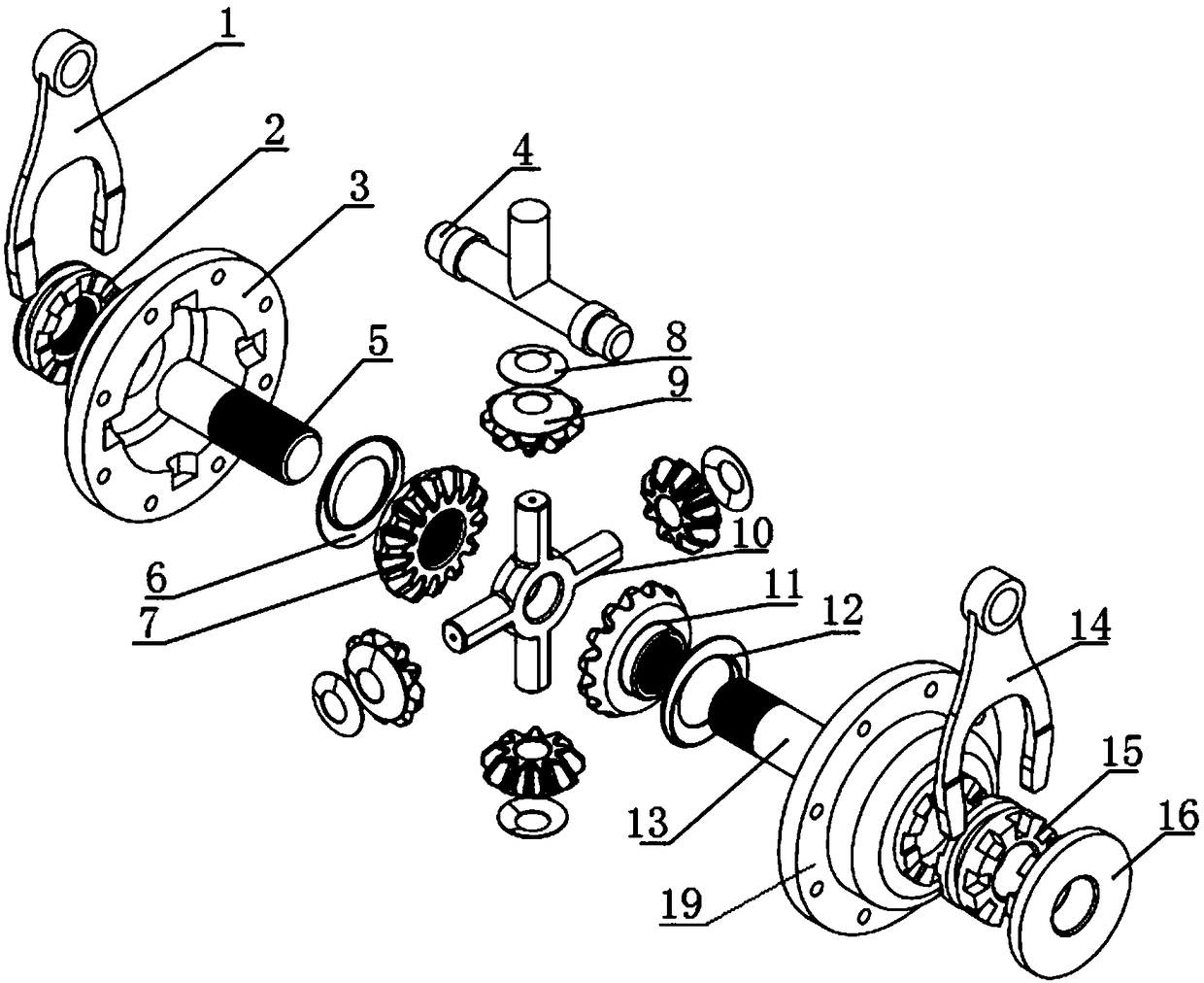

[0042] Such as figure 1 and Figure 5 As shown, the planetary gear train transmission mechanism is composed of an input gear 7, an input gear spacer 6, a cross shaft 10, a planetary gear 9, a planetary gear spacer 8, an output gear 11 and an output gear spacer 12; the input gear 7. Both the output gear 11 and the planetary gear 9 are bevel gears; the input gear 7 and the input shaft 5 are splined to transmit torque, and the input gear gasket 6 is set on the input shaft 5 on the outside of the input gear 7, so The output gear 11 is connected with the output shaft 13 th...

Embodiment 2

[0054] The second embodiment discloses a reversing device for in-situ steering of a single-engine-driven vehicle. The reversing device is installed between the input shaft 5 and the output shaft 13 to realize the Rotating in the same direction or in the opposite direction, the reversing device is composed of a planetary gear train transmission mechanism, a reversing actuator and a reversing operating mechanism.

[0055] Such as Figure 8As shown, the planetary gear train transmission mechanism is composed of an input gear 7, a planetary gear, a tray 20, a planetary gear shaft and an output gear 11; the input gear 7, the output gear 11 and the planetary gear are all cylindrical gears; the input The gear 7 is fixedly connected to the end of the input shaft 5 and transmits torque, and the output gear 11 is fixedly connected to the end of the output shaft 13 and transmits torque; the axes of the input gear 7 and the output gear 11 are on the same straight line; the planetary gears...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com