Plastic molding die charging crane

A technology for plastic molding and loading and unloading machines, applied in the field of injection molding machinery, can solve the problems of inaccurate placement of cranes, labor-intensive costs, and low safety factor, and achieve the effects of avoiding personal accidental injuries, high work efficiency, and high returns.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

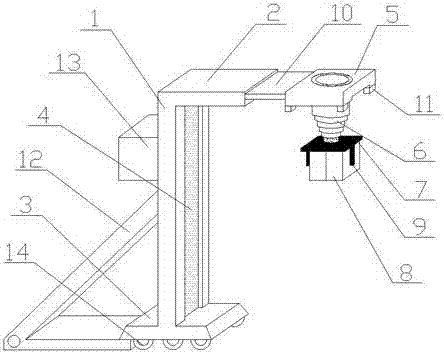

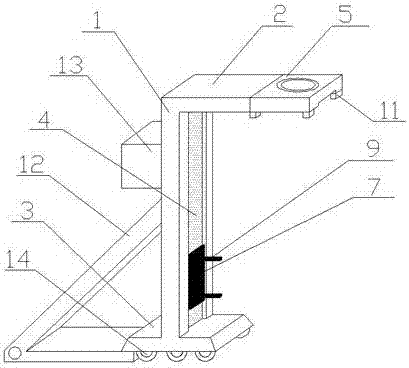

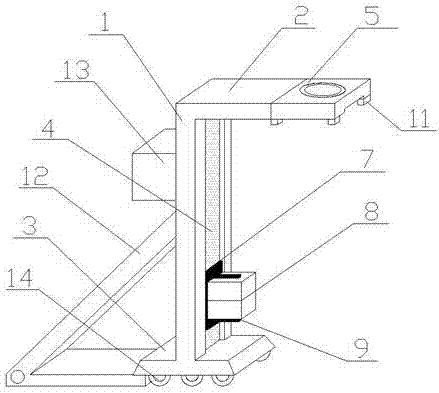

[0026] The present invention will be further elaborated and illustrated below in conjunction with the accompanying drawings and specific embodiments.

[0027] As shown in the figure, a plastic molding mold loading and unloading machine includes a vertical frame 1, a horizontal frame 2, a base 3, a magnetic disk 7, a loading and unloading device 5 and a control device 13, and the vertical frame 1 and the horizontal frame 2 are vertical connected, and provided with a coherent magnetic conveying trough 4, the base 3 is placed under the vertical frame 1, the loading and unloading device 5 is connected to the horizontal frame 2, and a magnetic telescopic head 6 is provided in the middle, and the magnetic disk 7 can be Embedded in the magnetic conveying groove 4 and move along the magnetic conveying groove 4, and when moving to the magnetic telescopic head 6, it is closely magnetically attracted to the bottom of the telescopic head 6, the magnetic disk 7 is loaded with a plastic mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com