Hydraulic rapid locking device for oil film bearing

A technology of locking device and oil film bearing, which is applied in the direction of bearing components, shafts and bearings, rigid supports of bearing components, etc., can solve the problems of long overhead crane operation, potential safety hazards, complicated locking and disassembly operations, etc., and achieve Safe operation, accurate loading and unloading, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

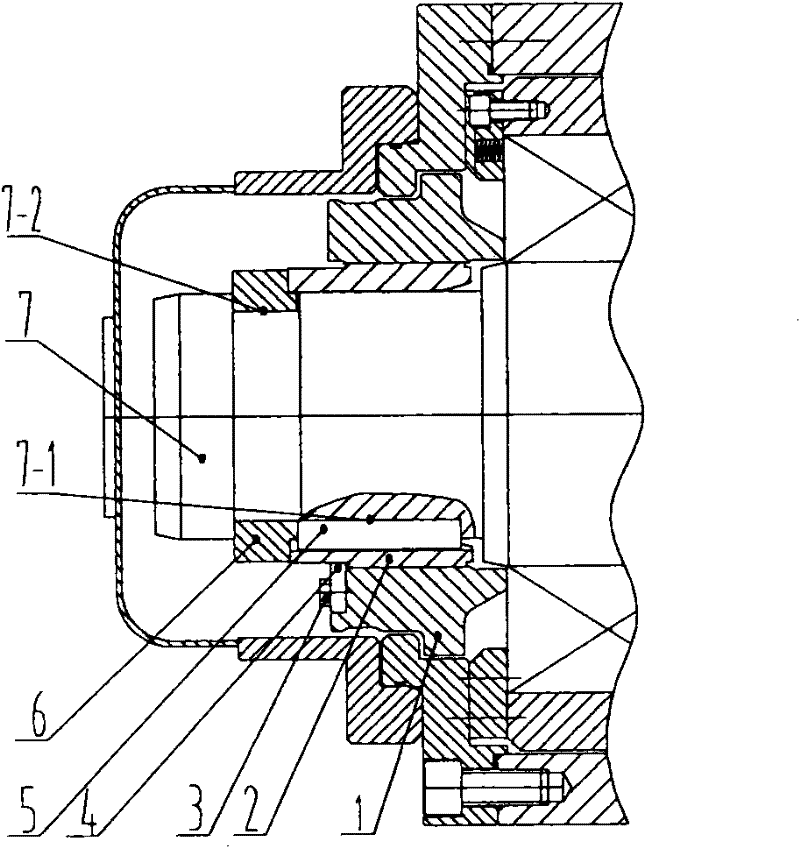

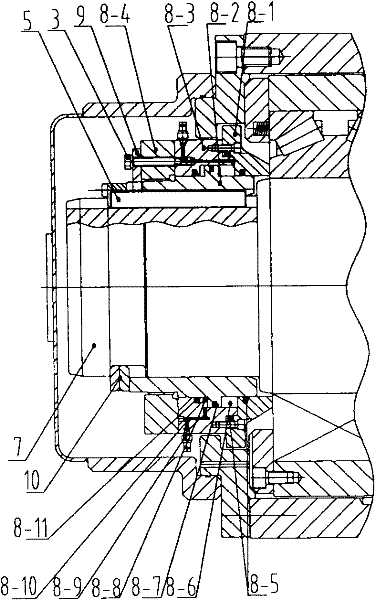

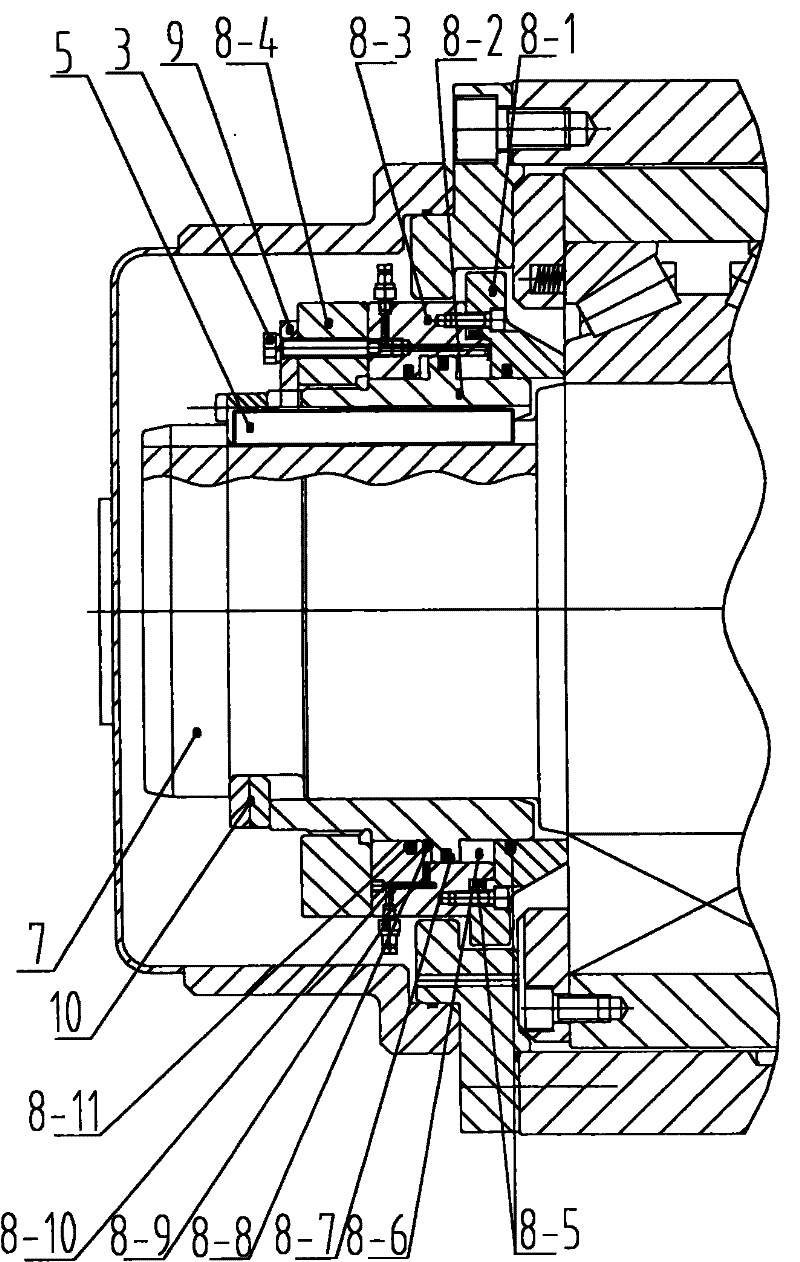

[0010] Such as figure 2 As shown, the oil film bearing hydraulic fast locking device of the present invention is composed of a short hydraulic cylinder, a locking plate 9, a square key 5, a snap ring assembly 10, a fastening bolt 3, etc., and the short hydraulic cylinder includes a cylinder Sleeve 8-1, piston 8-2, cylinder head 8-3, nut 8-4, cylinder liner seal 8-5, piston seal 8-7, cylinder head seal 8-11, quick change joint 8-9; The inner hole of the cylinder liner 8-1 is provided with a double-channel cylinder liner seal 8-5, the inner hole of the cylinder head 8-3 is provided with a single-channel cylinder head seal 8-11, and the oil hole 8-10 connecting the two oil chambers is arranged; the piston 8 -2 The inner hole is provided with a keyway; the cylinder liner 8-1, the piston 8-2, the cylinder head 8-3, the cylinder liner seal 8-5, the piston seal 8-7 and the cylinder head seal 8-11 are assembled together And form two oil chambers, that is, locking oil chamber 8-6, di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com