Forklift truck

A forklift truck and front frame technology, which is applied to motor vehicles, lifting devices, transportation and packaging, etc., can solve the problems of reduced operation quality and work efficiency, short front overhang distance, and reduced cargo stability, so as to improve operation The effect of quality and work efficiency, accurate loading and unloading of goods, and improvement of braking force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

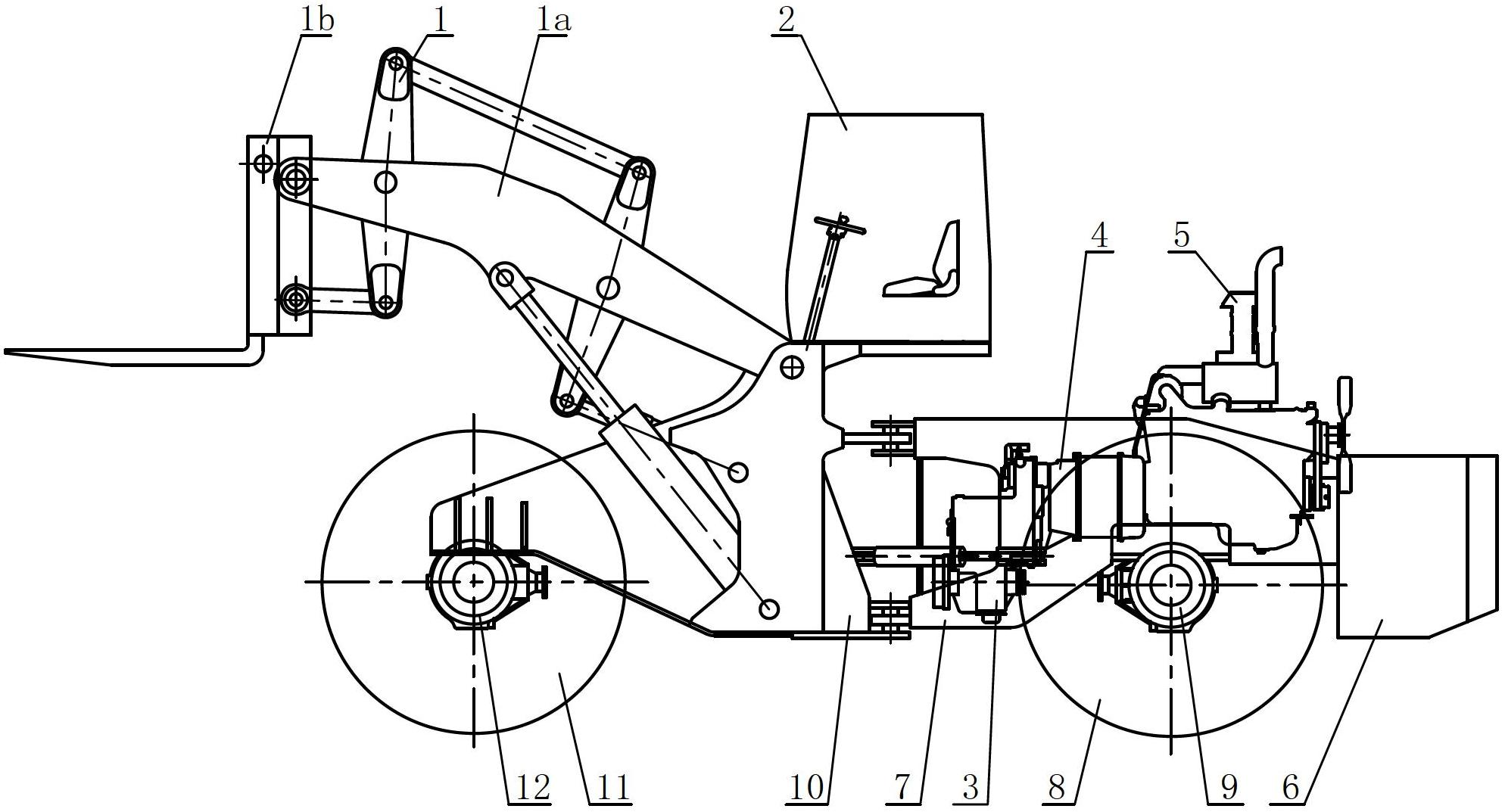

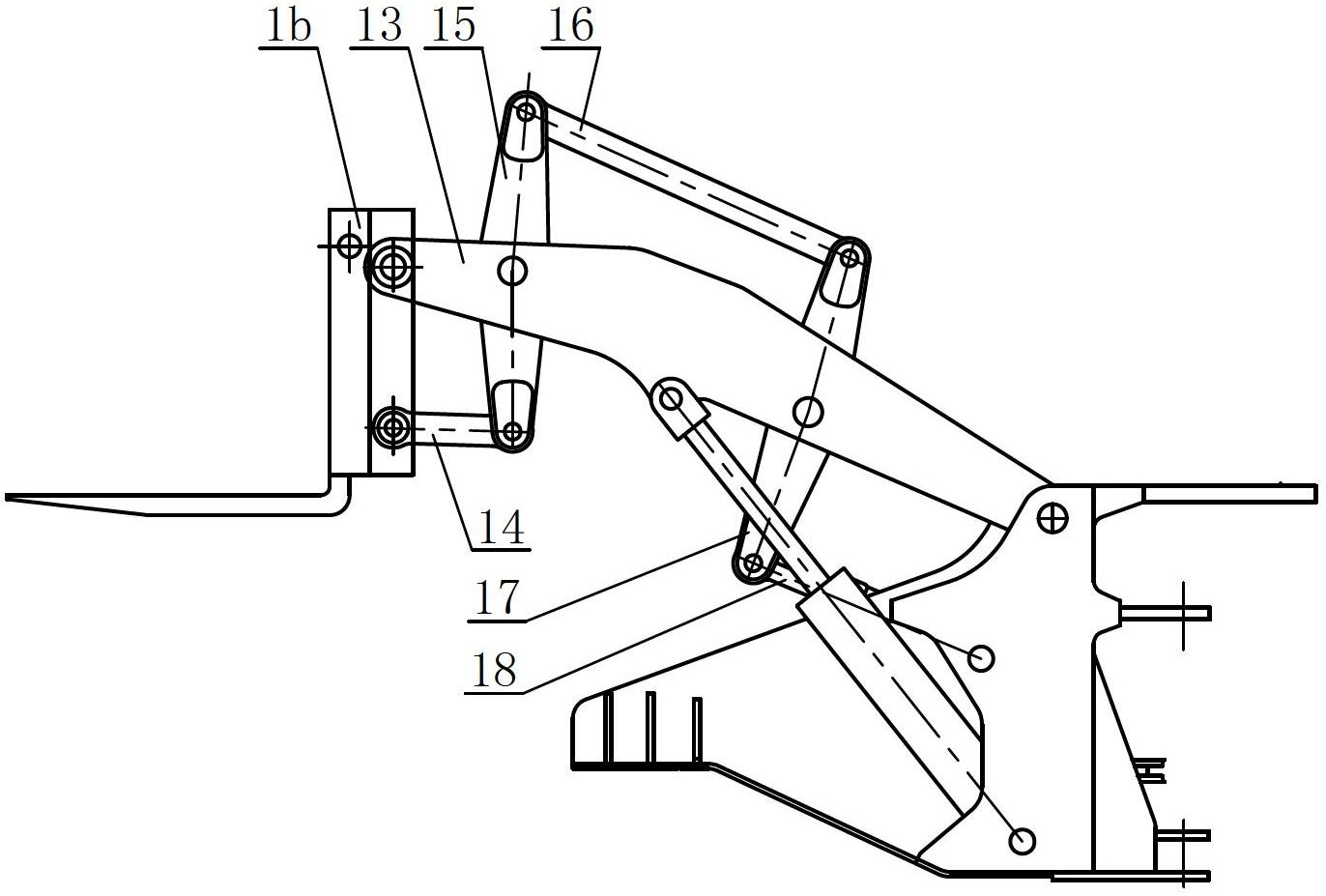

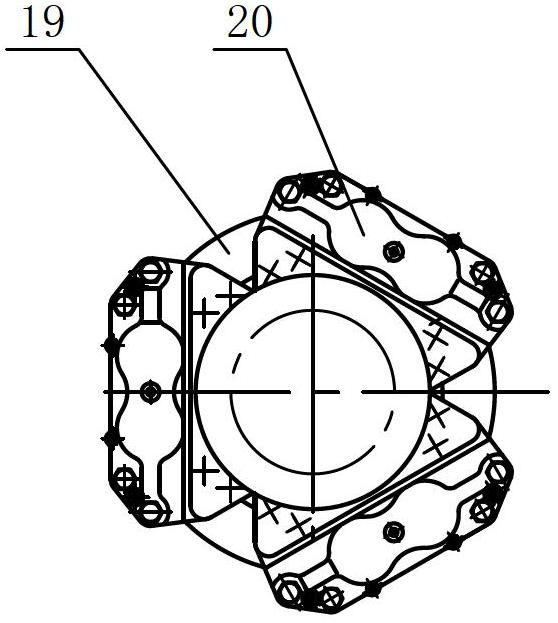

[0020] Such as figure 1 , 2 The shown forklift truck includes a front frame 10, a rear frame 7, a working device 1, a cab 2, an engine 5, a torque converter 4, a gearbox 3, front and rear drive axles 12, 9, and is characterized in that The working device 1 and the cab 2 are installed on the front frame 10, the engine 5, the torque converter 4, the gearbox 3 and the counterweight 6 are installed on the rear frame 7; the lifting mechanism 1a of the working device 1 is eight connecting rods Structure: The braking device is symmetrically installed at both ends of the drive axle, and each braking device is composed of a brake disc 19 and three brake calipers 20, and the three brake calipers 20 are evenly distributed along the circumference of the brake disc 19.

[0021] The working device 1 is installed in front of the front frame 10. The working device 1 is composed of a lifting mechanism 1a and an attachment 1b. The attachment 1b in this embodiment is a fork assembly; one end of...

Embodiment 2

[0028] Such as Figure 4 For the shown forklift truck, its attachment 1b is replaced by a bucket assembly.

[0029] The parts not described in this embodiment are the same as those in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com