Cantilever type automatic aligning oil-unloading crane tube

An automatic alignment and cantilever technology, applied in special distribution devices, packaging, distribution devices, etc., can solve the problems of incompatibility between cans and canning points, high labor intensity, and many safety accidents, and achieve airtight packaging. The effect of truck operation, avoiding pollution, and precise tank loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

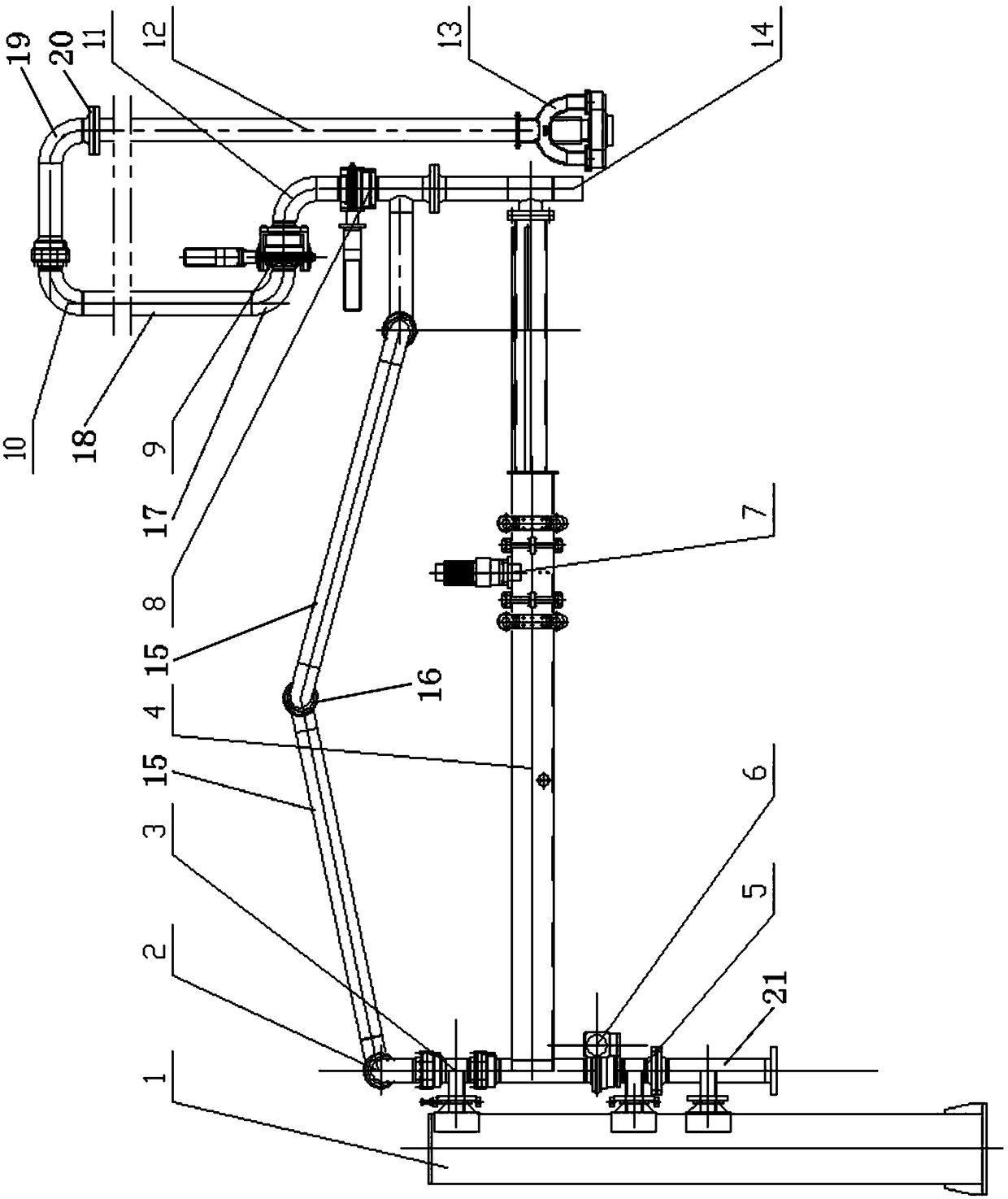

[0011] A cantilever type automatic alignment oil unloading crane pipe, such as figure 1 As shown, the column 1 is vertically fixed on the trestle, and the first connecting pipe 21 erected on the column 1 is fixed, and the first horizontal rotation driving mechanism 6 is installed on the first connecting pipe 21. 6 is installed with the second connecting pipe 3, the upper nozzle of the first connecting pipe 21 and the lower nozzle of the second connecting pipe 3 communicate through the first interface 5 fixed and sealed, the second connecting pipe 3 is driven by the first horizontal rotation drive mechanism 6 is driven to rotate horizontally around the vertical axis in the direction of its own length, and the hinged pipe group consists of two or more than two joints at both ends and the third connecting pipe 15 which is arranged in the same direction to be sequentially hinged and sealed. Any two adjacent third connecting pipes 15 in the hinged pipe group revolve around the axis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com