Automatic feeding system for cam blank

An automatic feeding and blank technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems that the production error of parts is affected by human error, and the uniformity of workpiece production cannot be well guaranteed, so as to save manpower investment and ensure consistent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

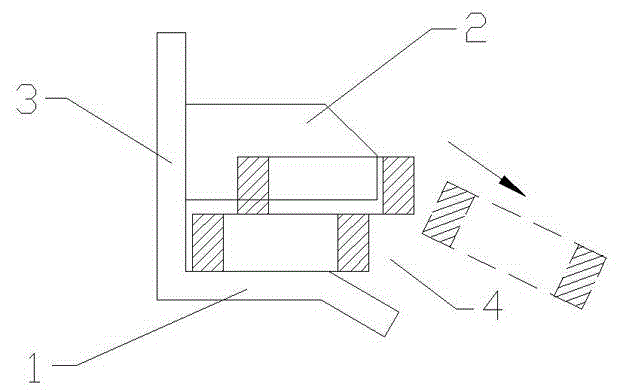

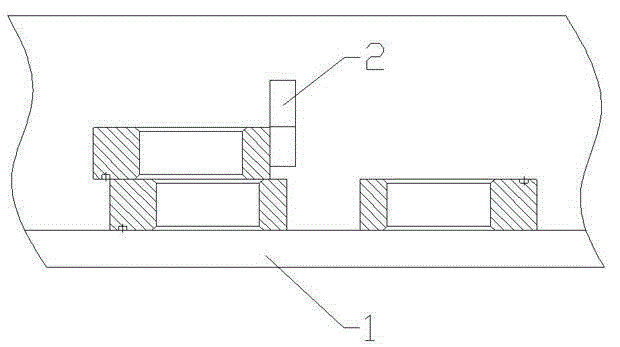

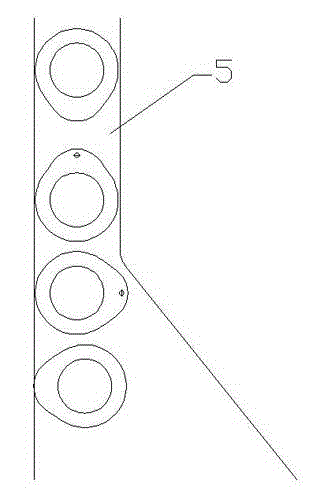

[0027] The present invention provides an automatic feeding system for cam blanks, which includes a feeding channel and a profiled feeding channel. The profiled feeding channel is equipped with an adjusting device, and the discharge end of the feeding channel is connected with the profiled feeding channel. At the feeding end of the forehearth, the conveying direction of the upper forehearth is the same as that of the profiling forehearth, and the upper surface of the upper forehearth and the upper surface of the profiling foreman are in the same plane, so that The cam blank of the upper forehearth can directly enter the profiling forehearth, and the upper forehearth is used to limit the number of cam blanks that enter the profiling forehearth each time to one and the cross-section of the cam blank The direction of the centerline is the same as the conveying direction, the contoured material channel is used to adjust the cam blank conveyed thereon to a vertical state with the vert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com