Patents

Literature

55results about How to "Realize automatic material distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

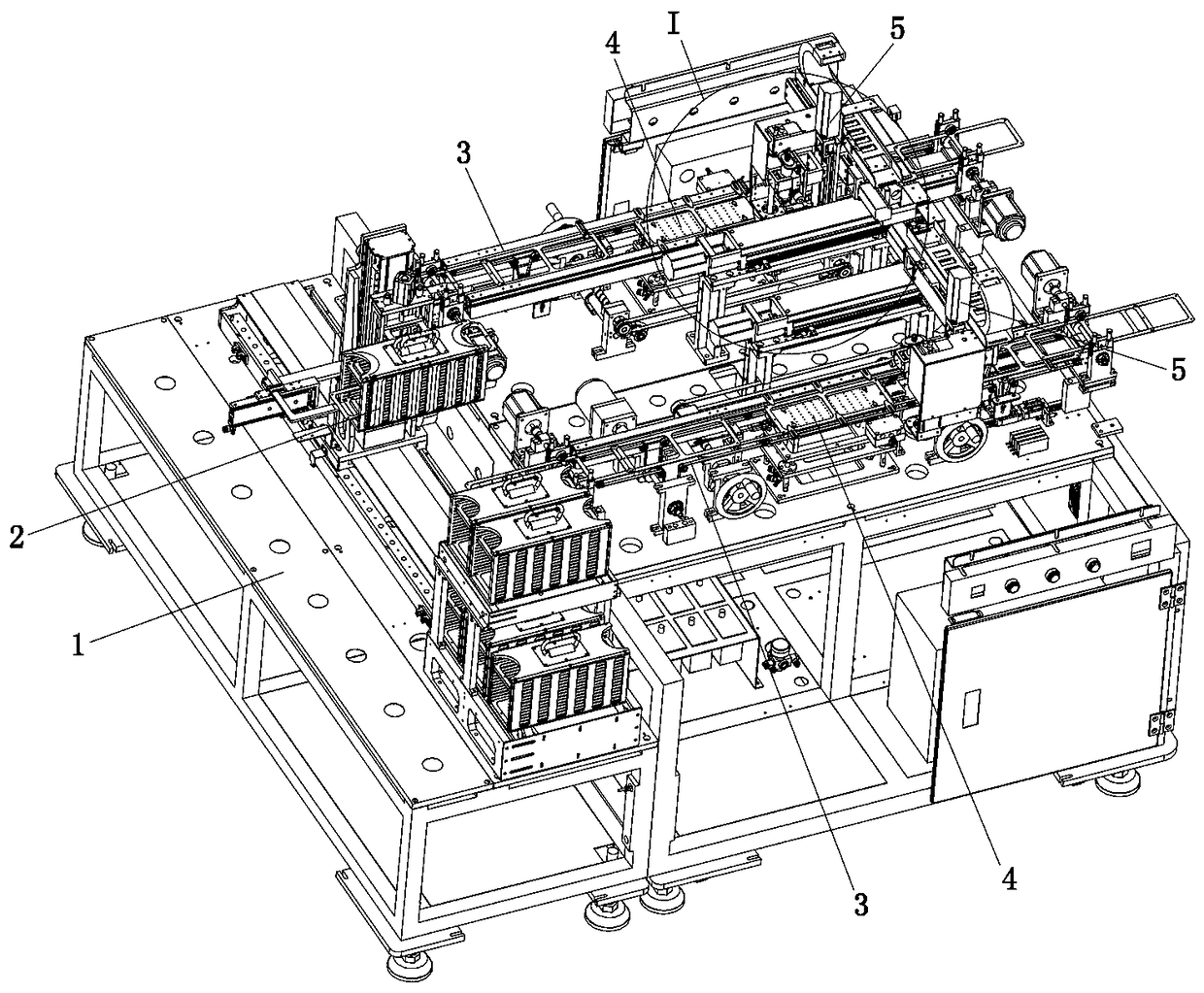

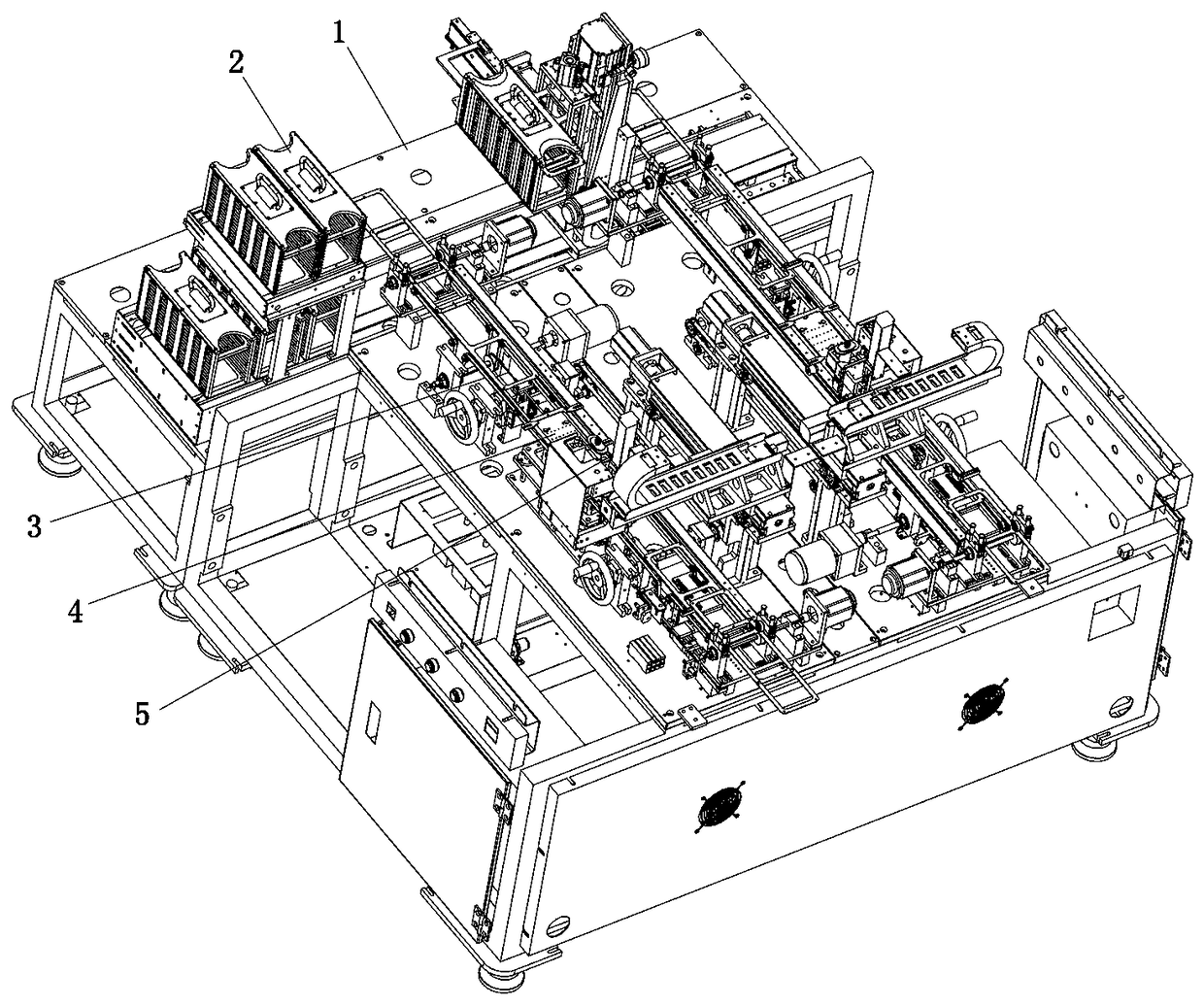

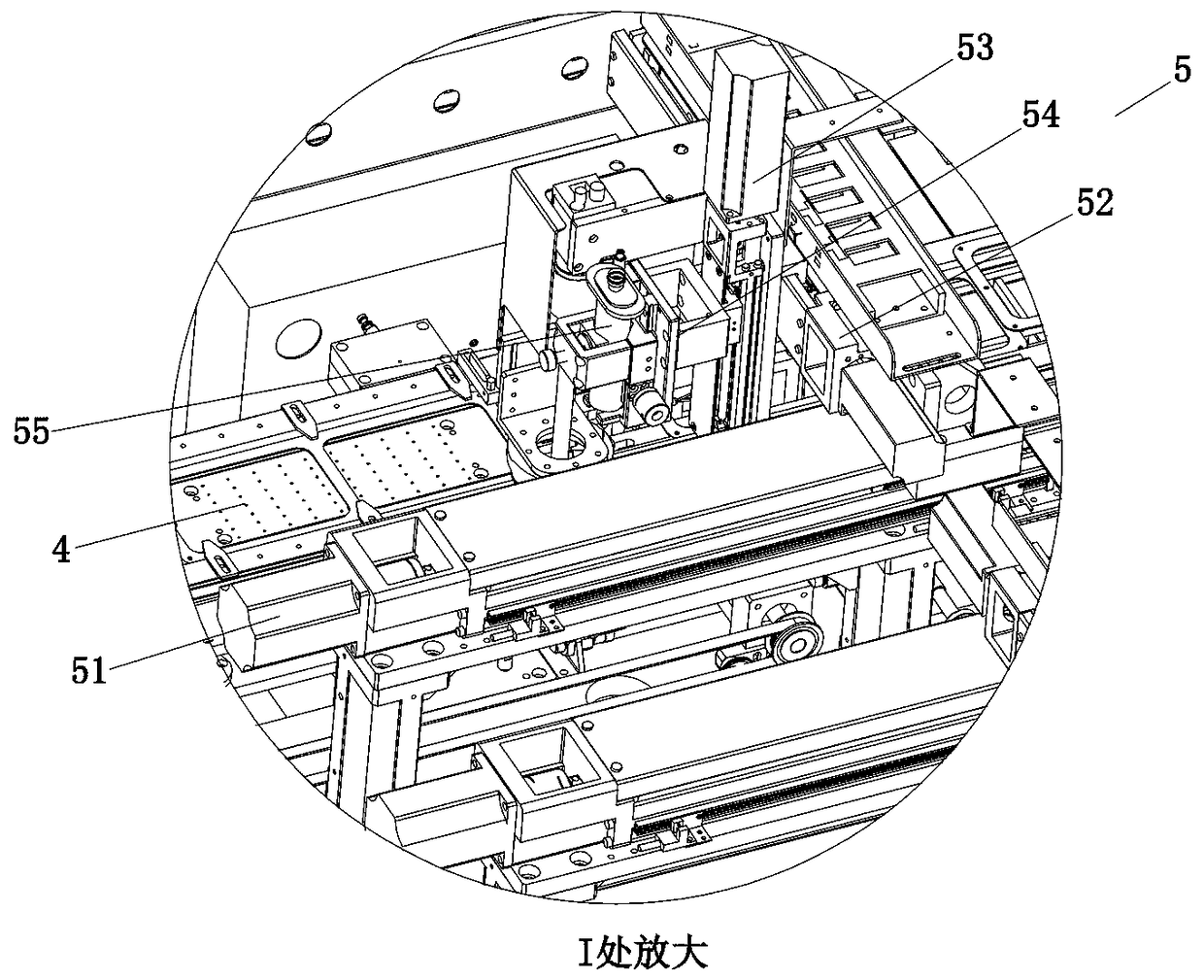

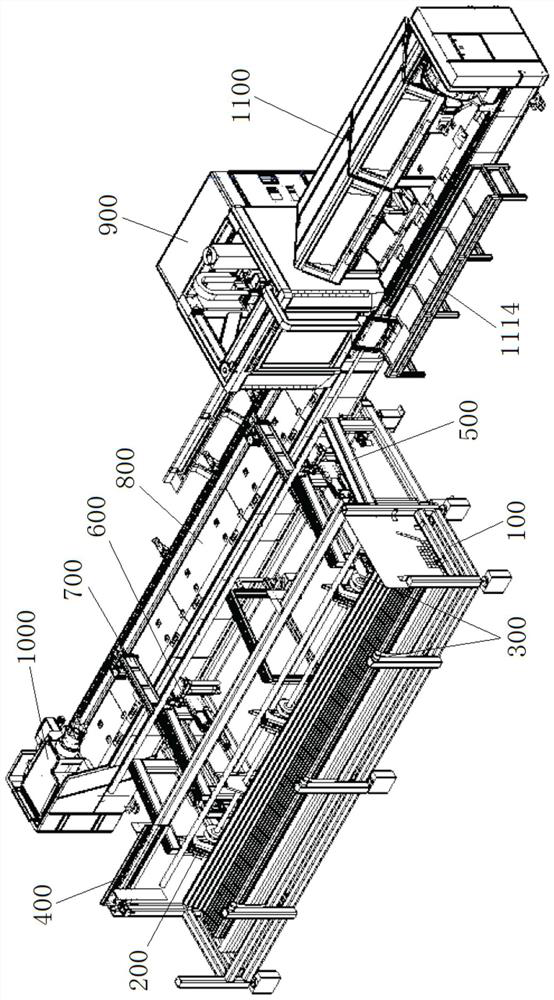

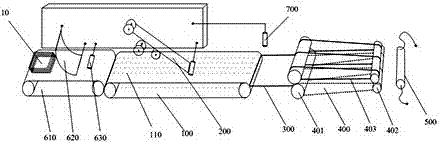

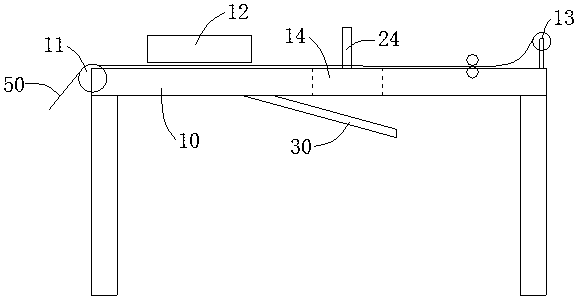

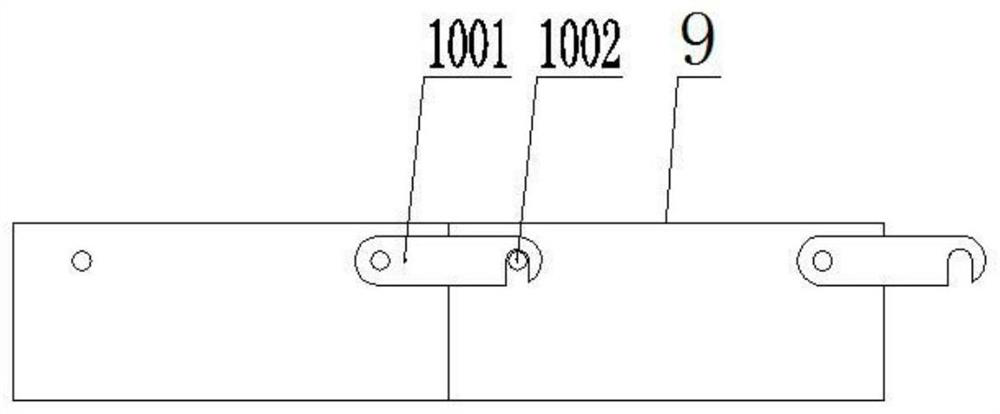

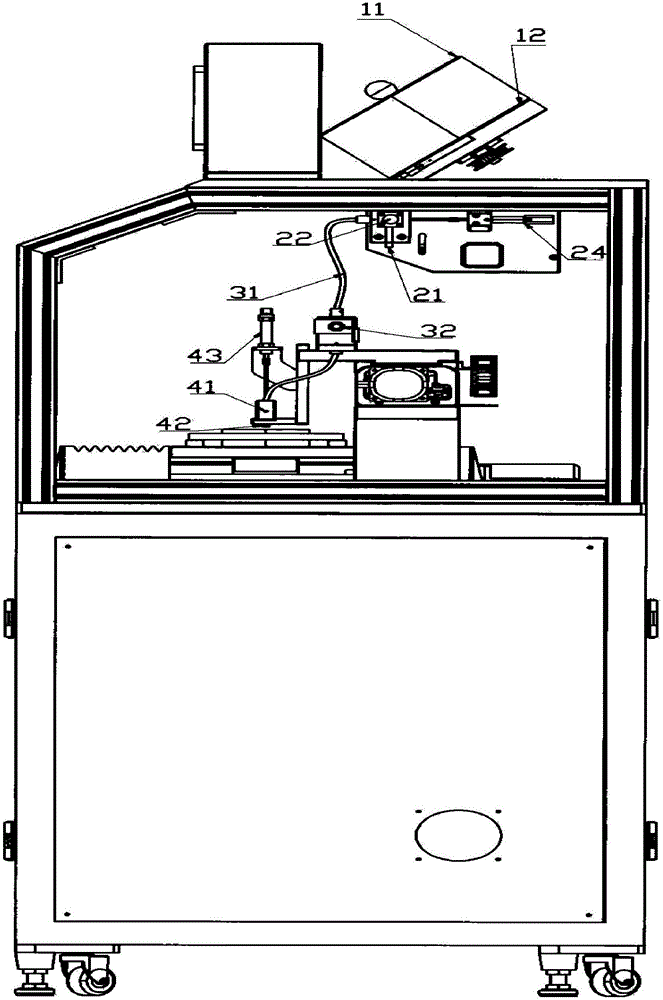

Full-automatic double-track glue dispensing machine and glue dispensing process thereof

PendingCN109482430AAchieve independent transmissionAvoid collisions with each otherLiquid surface applicatorsCoatingsDischarge efficiencyEngineering

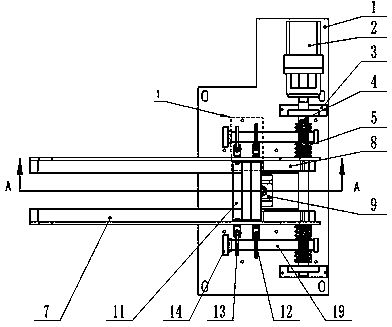

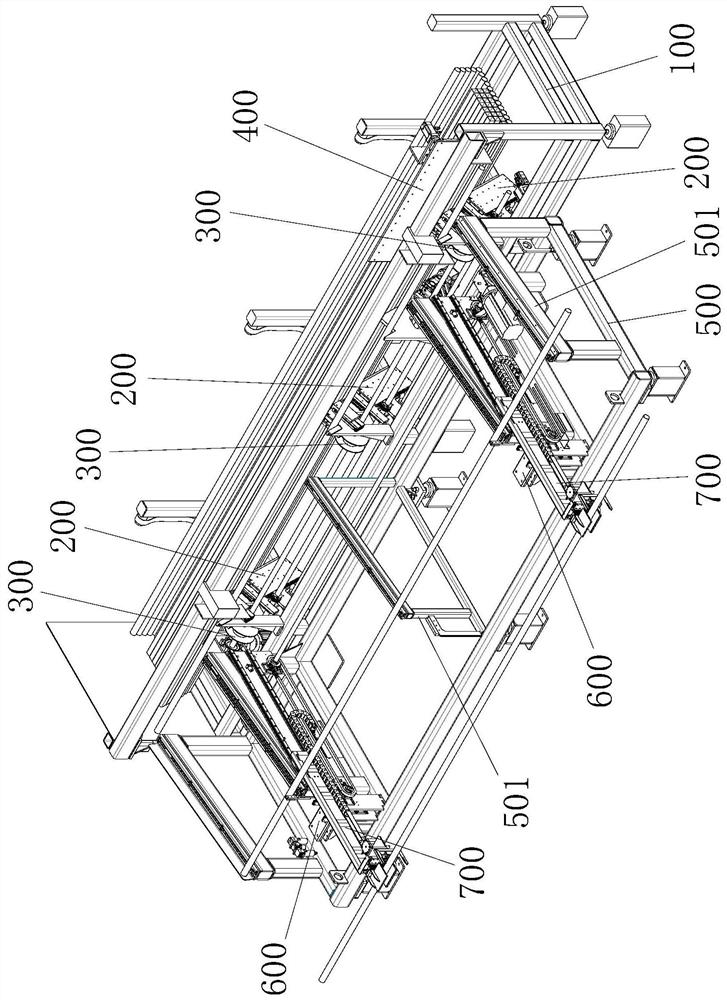

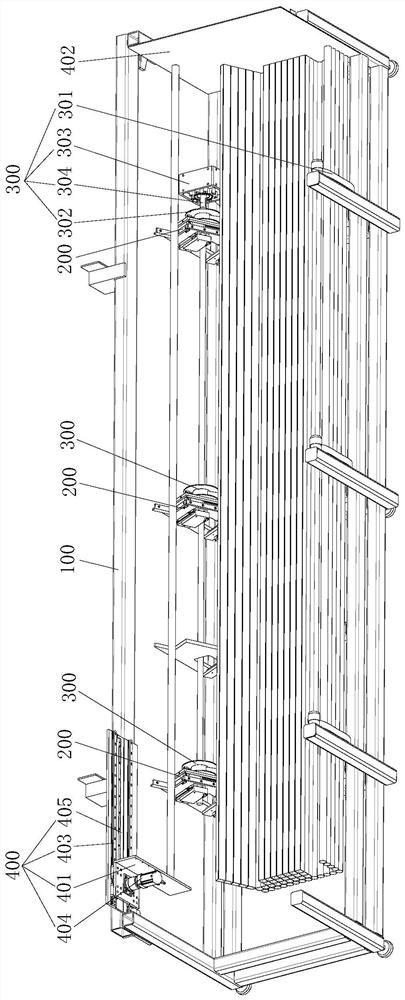

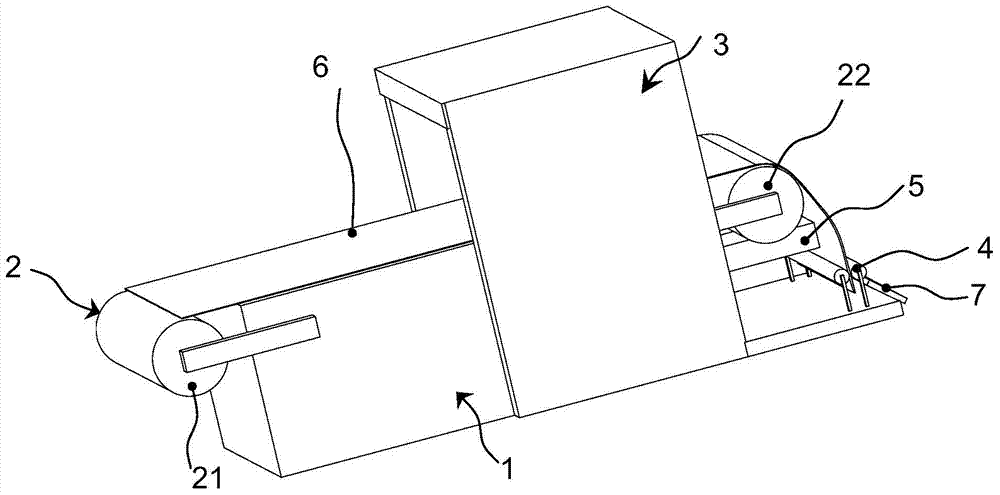

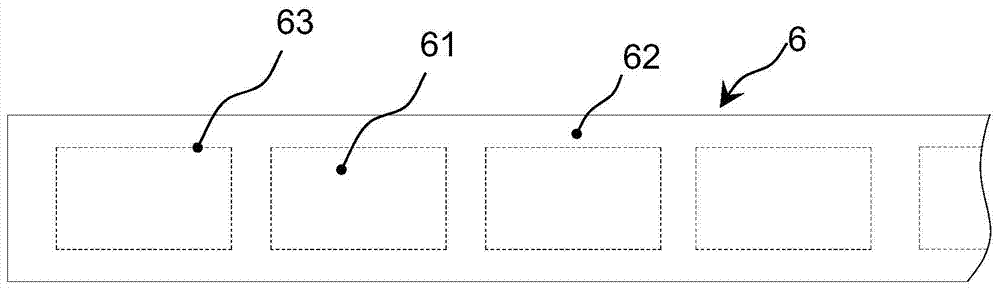

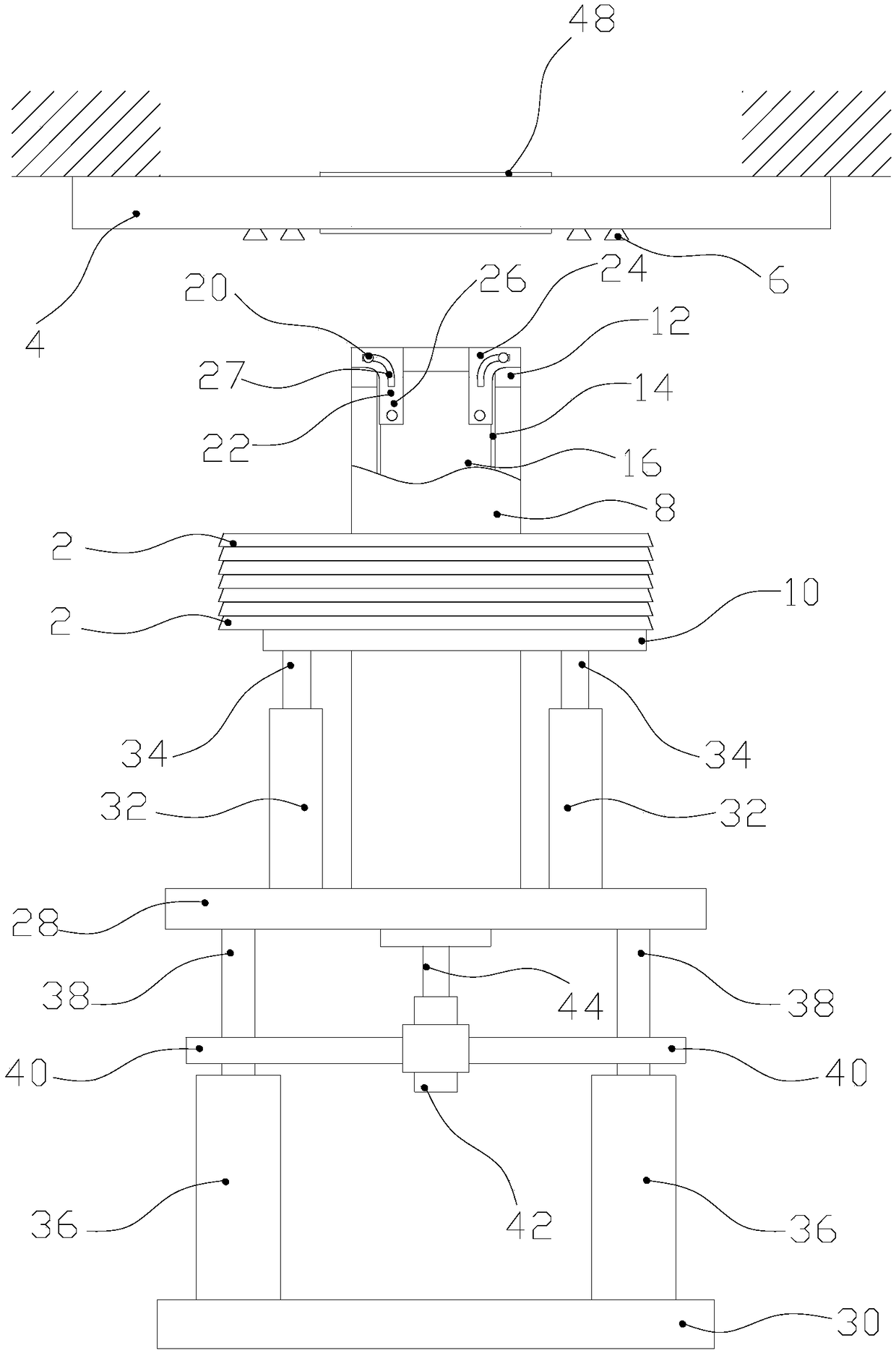

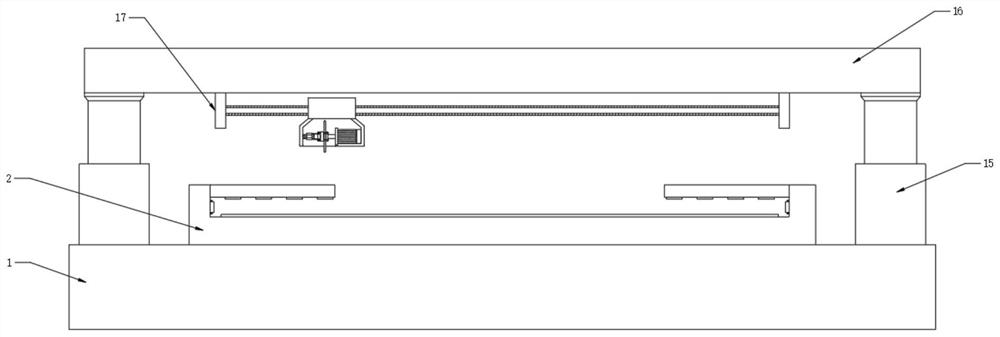

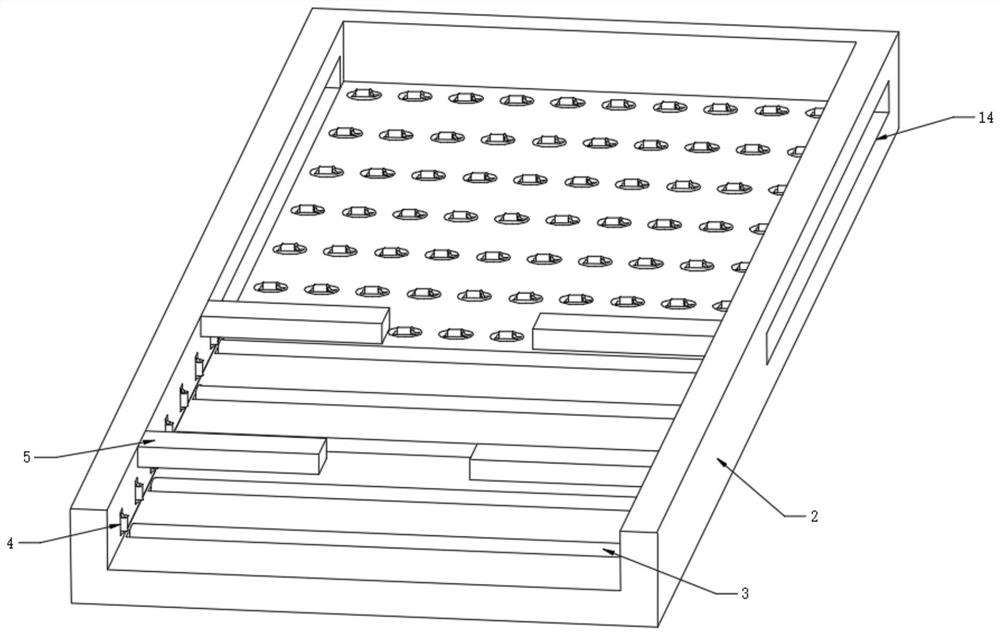

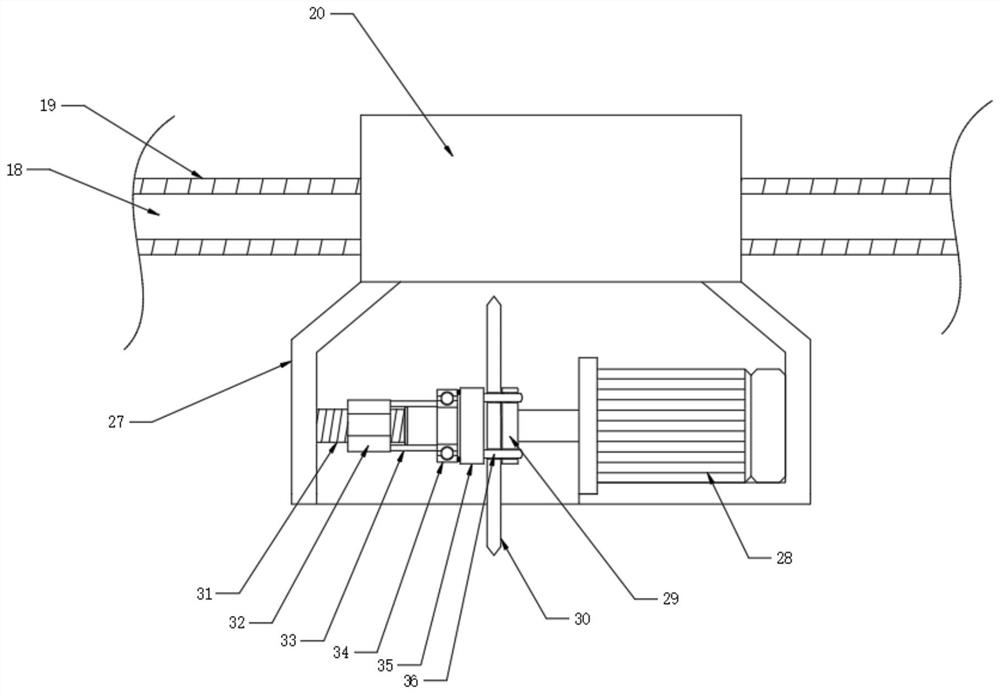

The invention discloses a full-automatic double-track glue dispensing machine and a glue dispensing process thereof. The full-automatic double-track glue dispensing machine comprises a material box feeding mechanism, two conveying tracks, a glue dispensing platform and a glue dispensing assembly. The two conveying tracks are arranged in parallel in the straight line direction in a spaced mode. Thematerial box feeding mechanism is arranged at the ends of the two conveying tracks in the direction perpendicular to the conveying tracks. A material box assembly is arranged on the side portion of the front end of a transfer member. At least two material boxes are placed in the material box assembly. The glue dispensing platform is arranged in the conveying tracks. The glue dispensing assembly is arranged above the glue dispensing platform. Independent conveying of carrier boards is achieved, and the functions of clamping the boxes, distributing materials to the conveying tracks, pushing thecarrier boards to the conveying tracks and the like are simultaneously completed; frictional collision between the adjacent carrier boards is effectively avoided; and through a linear pushing mode, the positional stability of fingerprint modules on the carrier boards is ensured while the feeding and discharging efficiency is improved.

Owner:SHENZHEN NUOFENG OPTOELECTRONICS EQUIP

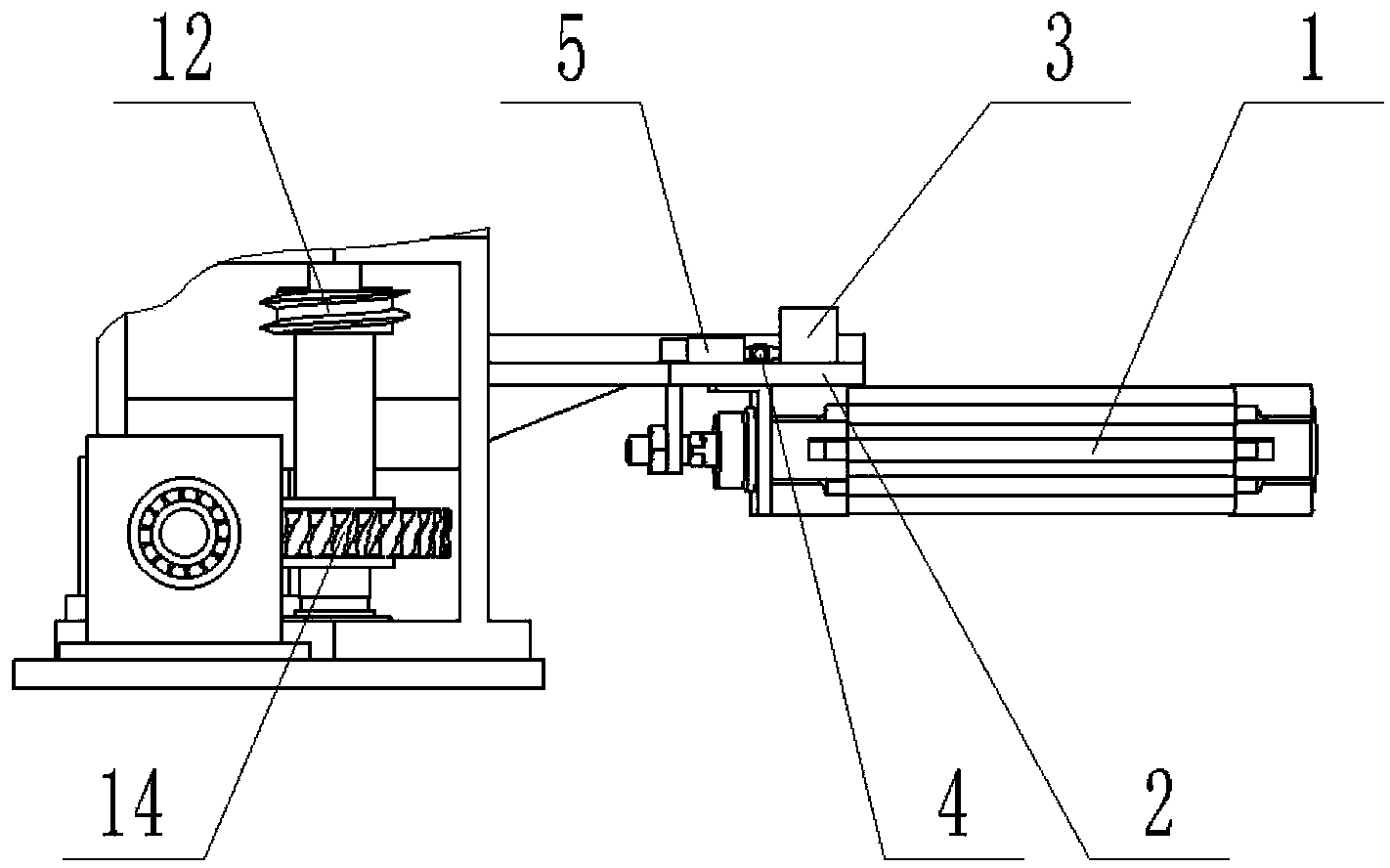

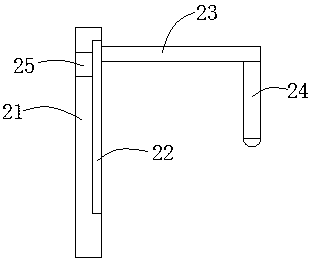

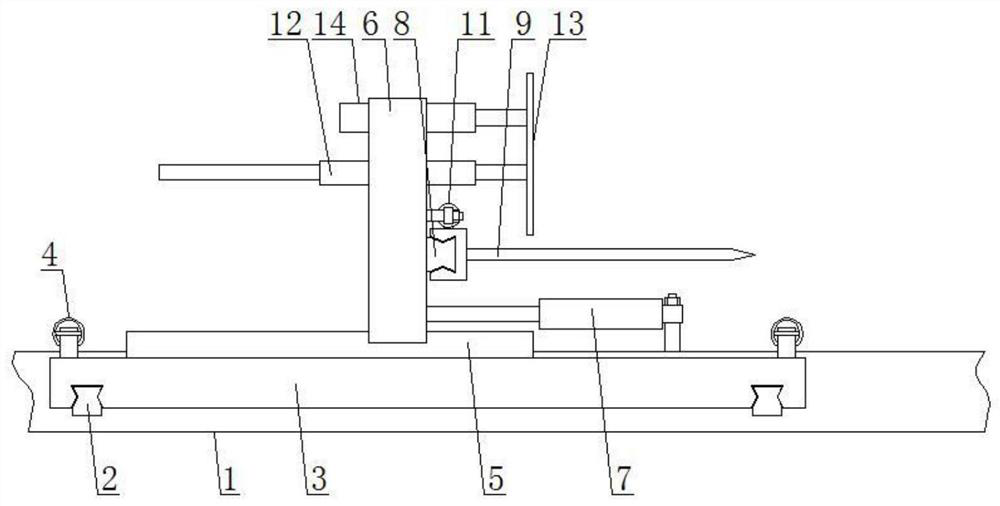

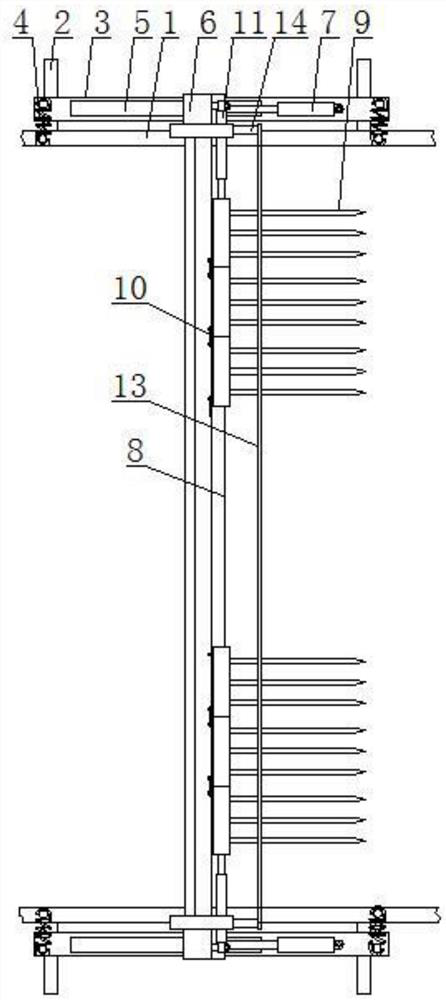

Flexible automatic distribution device for deformed bar materials

ActiveCN103358166AHigh degree of processing automationEasy to operateMetal working apparatusNumerical controlRobot hand

The invention relates to a bar material distribution device, in particular to a flexible automatic distribution device for deformed bar materials. The device comprises a flexible material storage mechanism, a servo distribution mechanism and a pneumatic material pushing mechanism which are used for storing, distributing and pushing the deformed bar materials respectively. Starting from a mechanical-electrical integration design idea, the distribution automation of the deformed bar materials is achieved by a flexible design method according to the characteristics of the deformed bar materials; after the device works with a special mechanical hand and a numerical control special machine, the automatic distributing, feeding and processing of the deformed bar materials can be achieved; the device is simple and reliable to use; the processing automation level of the deformed bar materials is effectively increased; the labor intensity is reduced; the influences caused by human factors are reduced; good cost performance is achieved.

Owner:SUZHOU ZIJINGANG INTELLIGENT MFG EQUIP

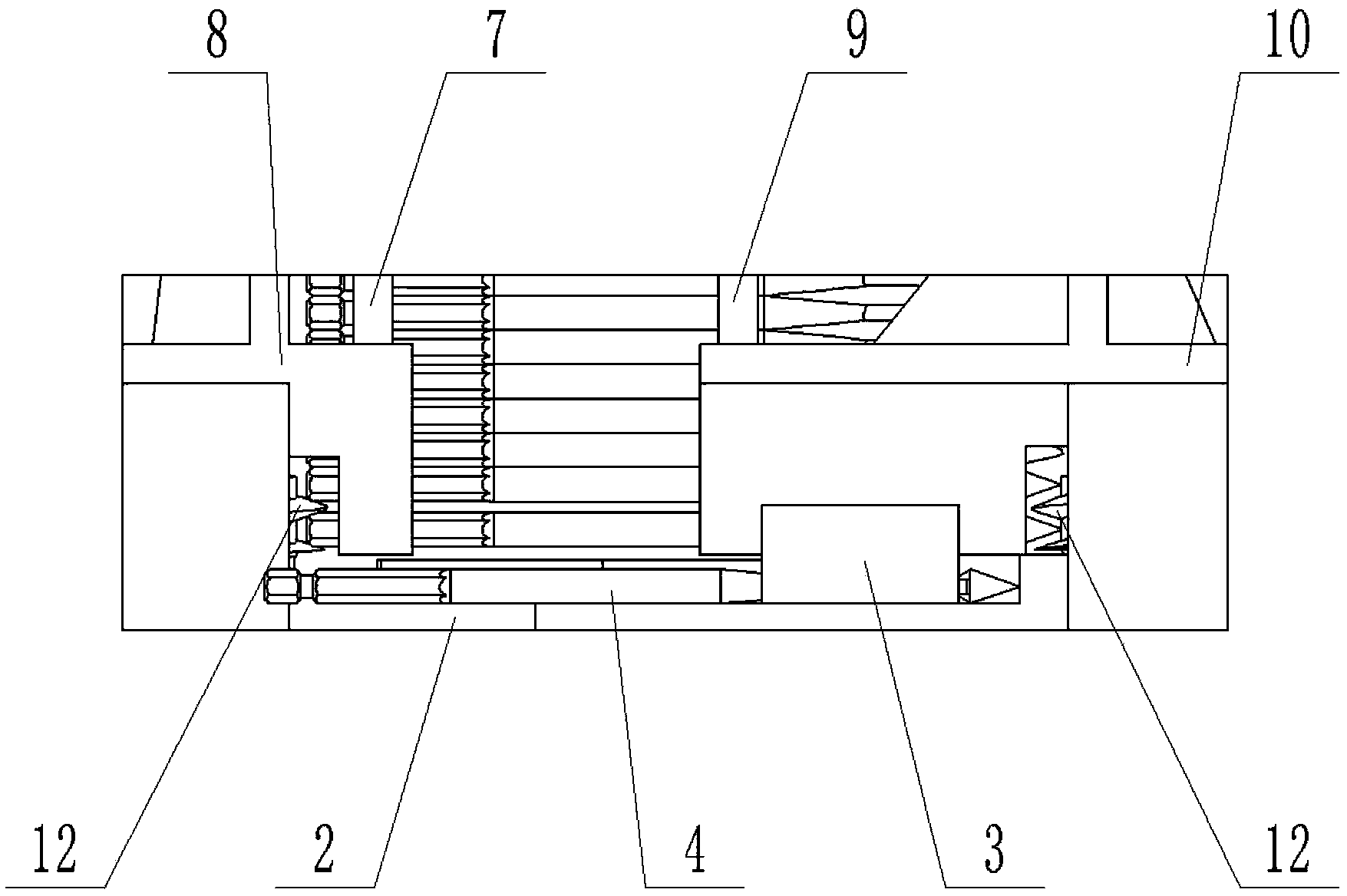

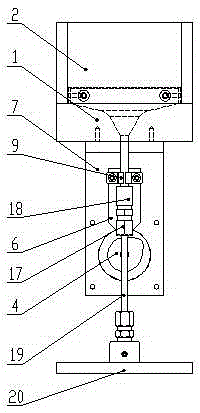

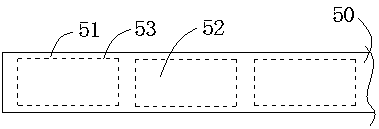

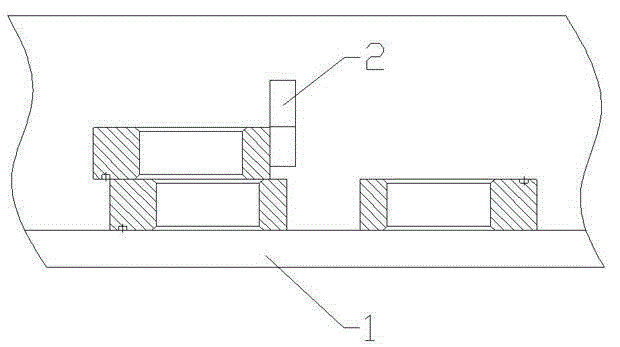

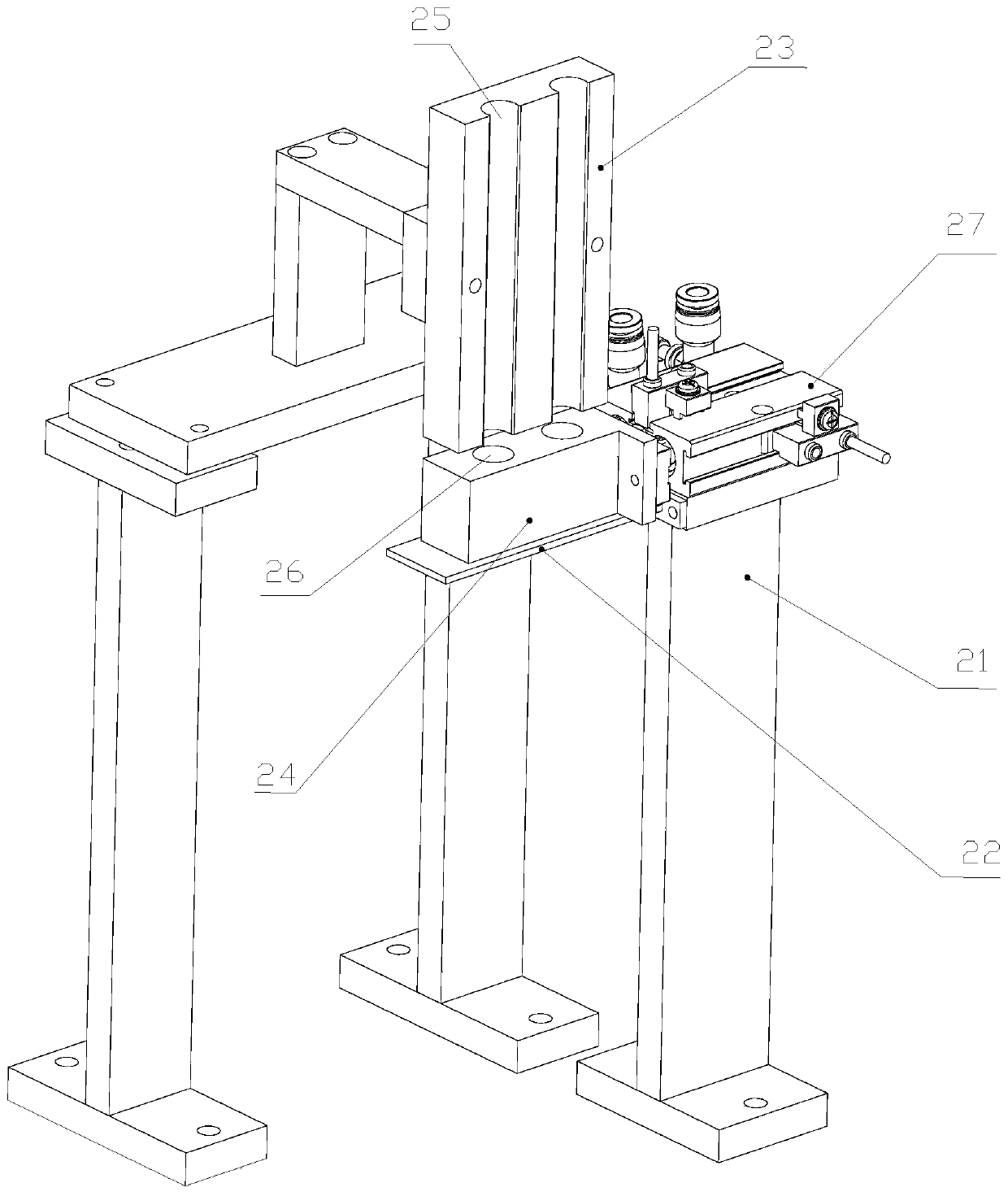

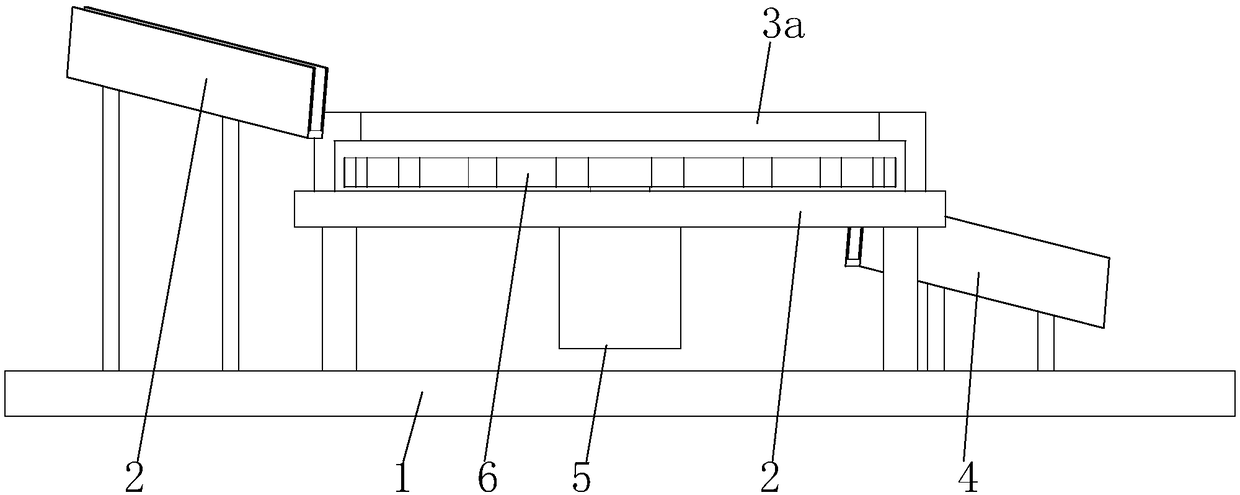

Flexible and automatic distributing device for shaft sleeve workpieces

InactiveCN103878628AOvercome stuckHigh degree of processing automationMetal working apparatusProcess engineeringManipulator

The invention discloses a flexible and automatic distributing device for shaft sleeve workpieces. The device comprises a flexible storage mechanism, a servo distribution mechanism and a pneumatic pushing mechanism arranged under the servo distribution mechanism. The three mechanisms achieve storage, distribution and pushing of the shaft sleeve workpieces respectively. According to characteristics of the shaft sleeve workpieces and by the adoption of a flexible design method, automation of distribution of the shaft sleeve workpieces is achieved, operation is easy, the number of workers is effectively reduced, and recruitment and management difficulty is eased. In specific application, an operator only needs to place a preset number of the shaft sleeve workpieces in the flexible storage mechanism, and other distribution work is finished through the servo distribution mechanism and the pneumatic pushing mechanism automatically. With the combination of a simple manipulator and a numerical control machine tool, automatic distribution, feeding and machining of the shaft sleeve workpieces are achieved, and accordingly influences of human factors are reduced and product quality and production efficiency are improved.

Owner:ZHEJIANG UNIV

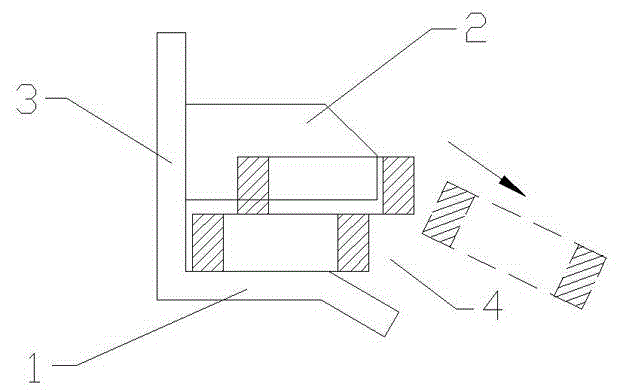

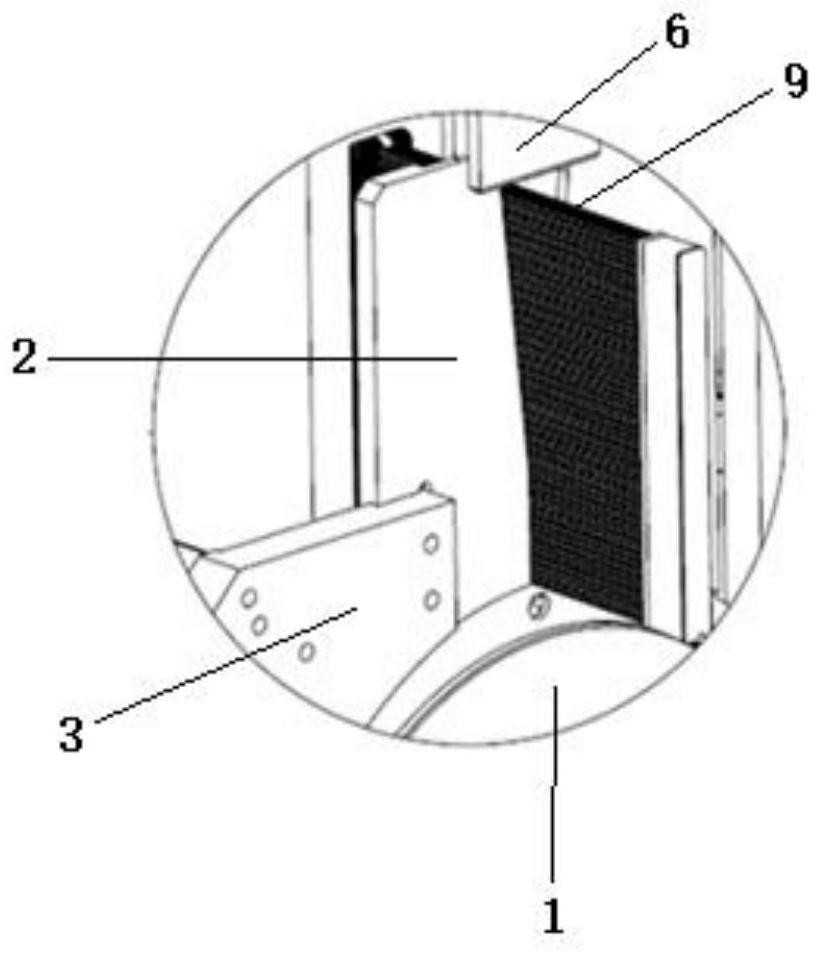

Automatic chip insertion machine

ActiveCN106024980ASolve the entanglementRealize automatic material distributionFinal product manufactureSemiconductor devicesBreakage rateEngineering

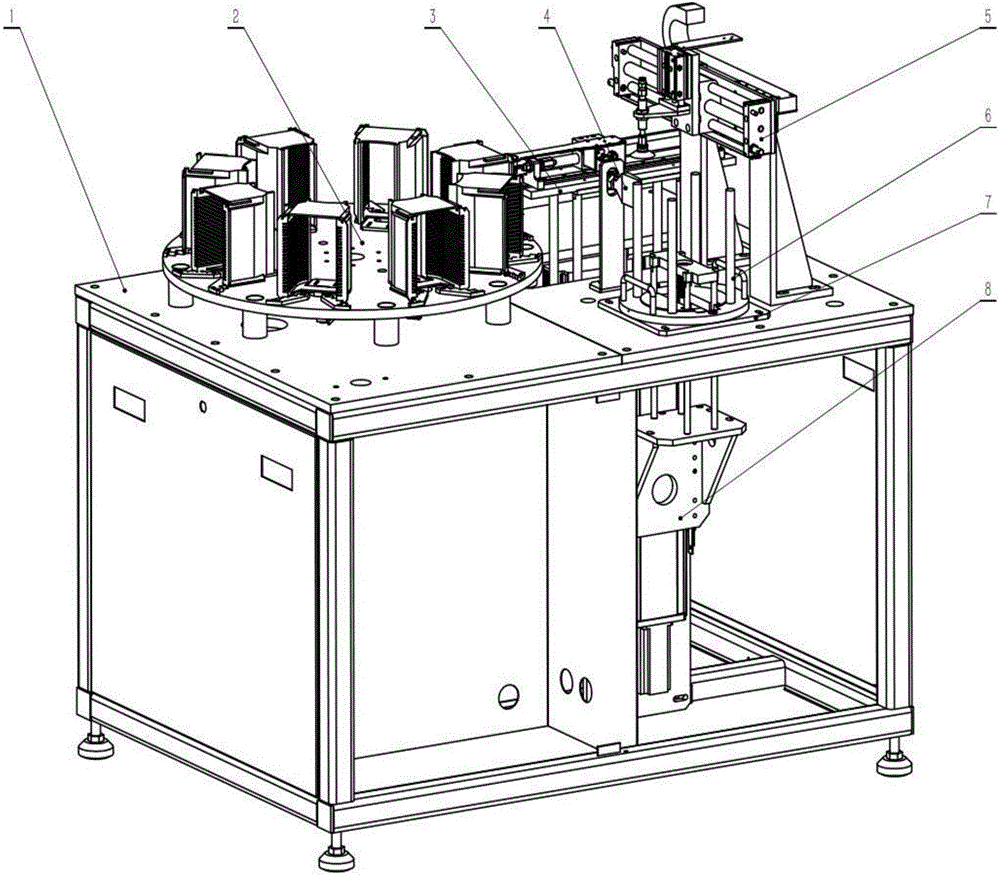

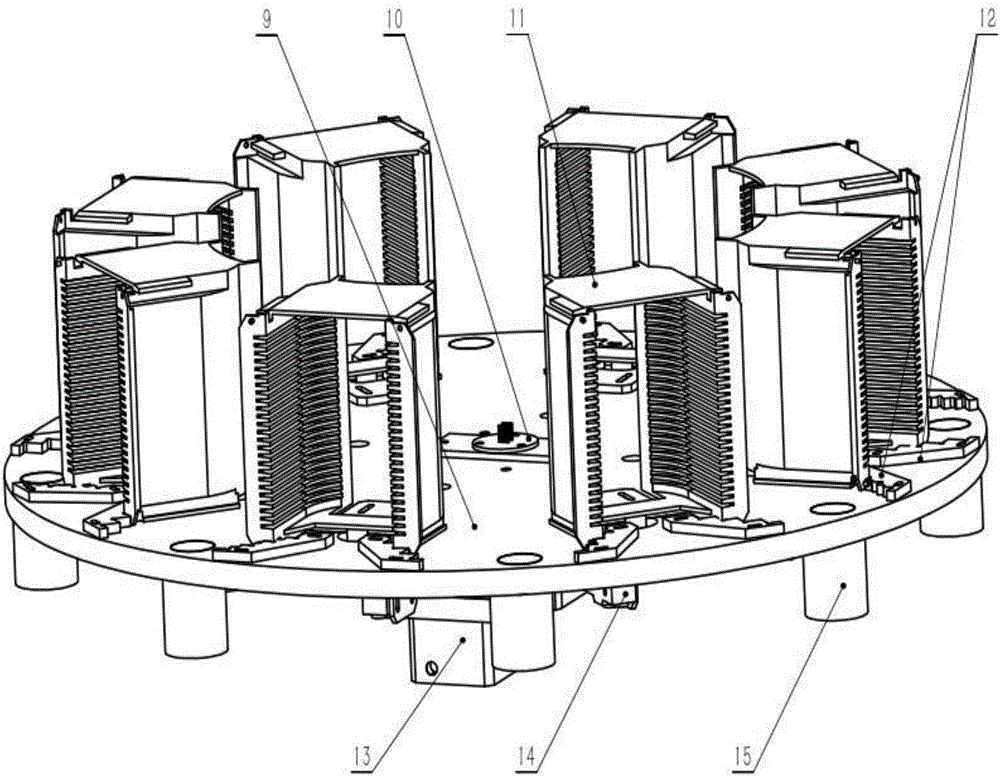

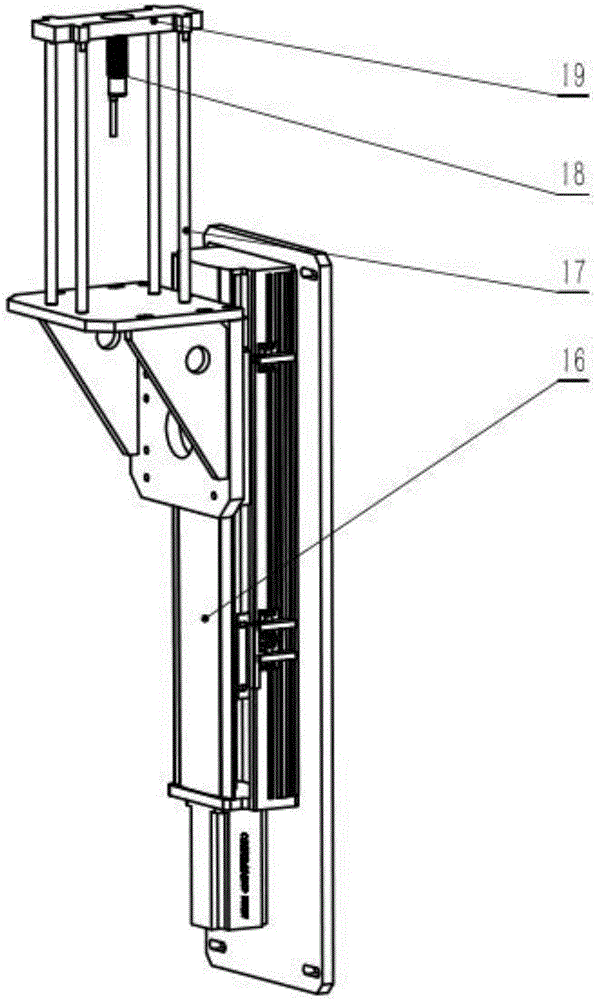

The present invention discloses an automatic chip insertion machine, which comprises a device rack, a basket tool rotating device, a silicon chip lifting device, an air blowing port, a silicon chip box, a fixed bottom plate, a sucking disc reclaiming device, and a silicon chip in-basket device. The basket tool rotating device is arranged on the device rack and comprises a hollow turntable, a conductive slip ring, a rotating disc, a button switch, a micro switch, a bearing box, and a bearing box positioning block. The conductive slip ring is connected with the hollow turntable. The hollow turntable is connected with the rotating disc. The bearing box positioning block is fixed onto the rotating disc through a bolt. The silicon chip lifting device comprises a material-ejection servo sliding table, a material-ejection supporting rod, a material-ejection block and a first detection switch. The material-ejection servo sliding table is connected with the material-ejection supporting rod. The material-ejection supporting rod is connected with the material-ejection block. When the automatic chip insertion machine is put to use, the manual operation of silicon chips is substantially abandoned, so that the manual chip-by-chip operation is avoided. Therefore, not only the breakage rate of silicon chips is reduced, but also the production efficiency is greatly improved.

Owner:ZHEJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

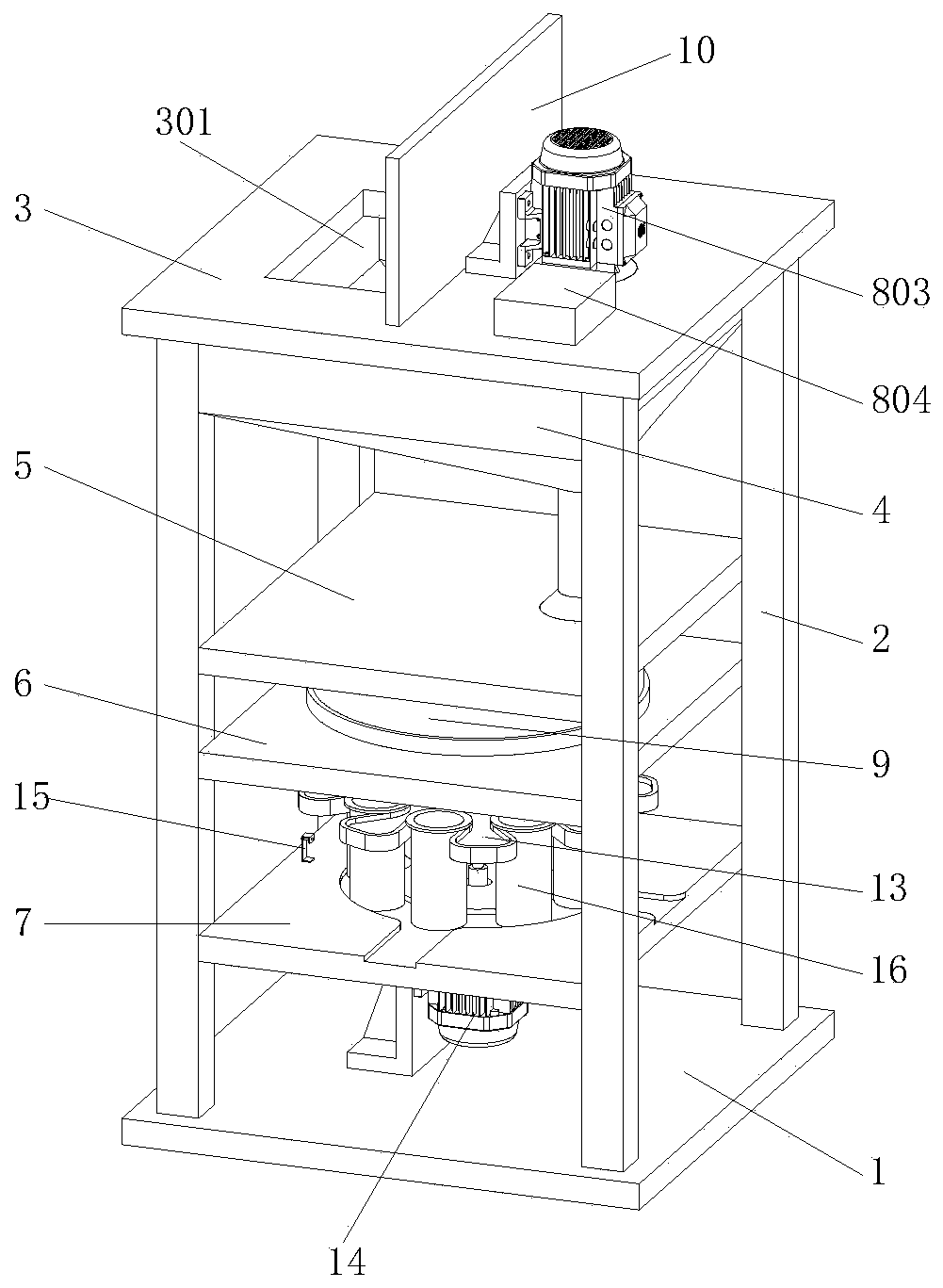

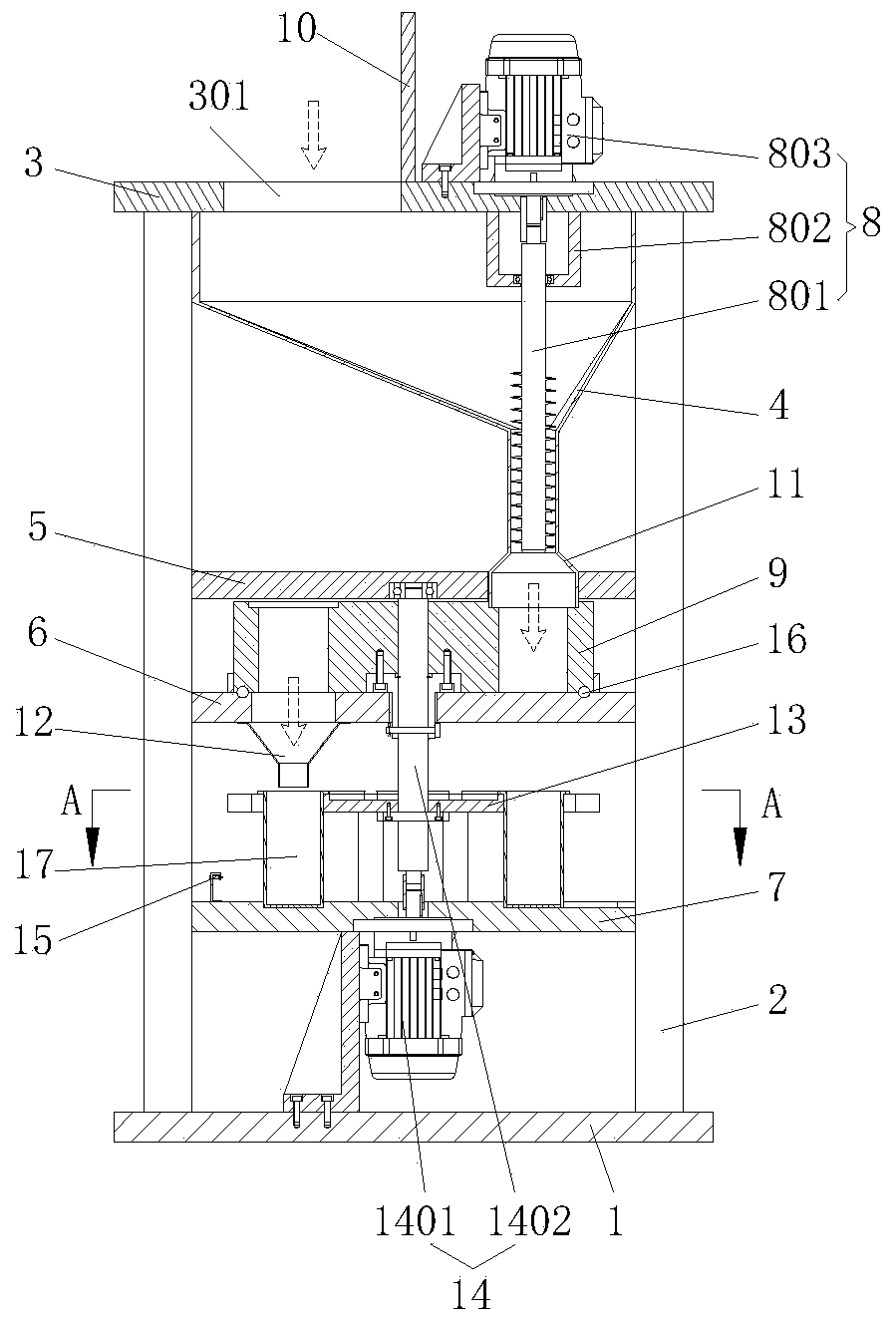

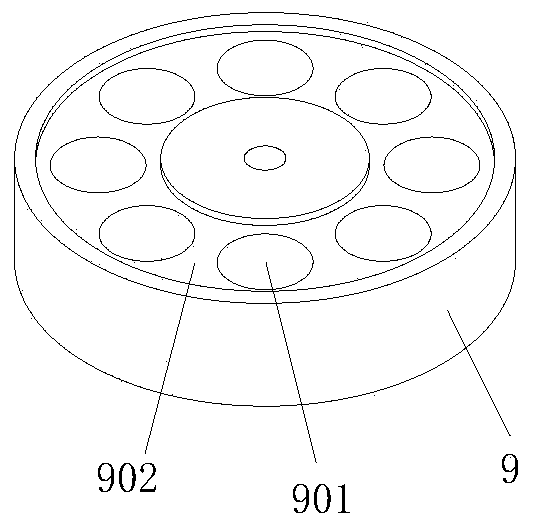

Particle material distributing machine

InactiveCN110979766ARealize continuous equal dosingIncrease productivitySolid materialEngineeringMechanical engineering

The invention discloses a particle material distributing machine. The material distributing machine comprises a base, stand columns fixed to four corners of a top face of the base and a top plate fixed to top ends of the stand columns, wherein a feeding hopper, a feeding plate, a discharging plate and a bearing plate are fixedly connected with the inner side of the top of the stand column in sequence from top to bottom, a feeding device is arranged in the feeding hopper, a storage hopper embedded in the feeding plate is arranged at a bottom end of the feeding hopper, a material distributing disc is movably arranged on a top surface of the discharging plate, a plurality of material distributing cavities distributed in a circumferential array mode are formed in the material distributing disc, the material distributing cavities are sequentially and alternately located under the storage hopper, a discharging hopper is fixed to the side, away from the storage hopper, of a bottom face of thedischarging plate, the material distributing cavities are sequentially and alternately located over the discharging hopper, and a charging disc located below the discharging hopper is arranged abovethe bearing plate. The material distributing machine is advantaged in that automatic material distributing of particle materials is achieved, labor intensity of workers is effectively reduced, material distributing and charging are synchronously conducted, quantitative split charging accuracy is high, and production efficiency is greatly improved.

Owner:周莉莉

Automatic pipe cutting equipment

PendingCN111922767AGuaranteed stabilityImprove cutting efficiencyMetal working apparatusStructural engineeringMachine

The invention discloses automatic pipe cutting equipment. Through the arrangement of a pipe distributing mechanism, pipes on a pipe warehouse rack can be distributed one by one; through the arrangement of a material transferring and centering mechanism, the pipes can be transferred to the discharging side of a feeding rack, and transverse centering and positioning are achieved; through the arrangement of a feeding and centering mechanism, the pipes on the discharging side of the feeding rack can be vertically centered and positioned and sent out to next equipment; through the arrangement of amaterial supporting mechanism, the pipes conveyed by the feeding and centering mechanism can be stably supported, pipe feeding and cutting are assisted, and the stability of the pipes in the front-section cutting process is guaranteed; and through the arrangement of the material supporting mechanism, the pipes on the discharging side of a cutting machine can be stably supported, pipe feeding and cutting are assisted, and the stability of the pipes in the rear-section cutting process is guaranteed. Thus, the automatic pipe cutting equipment can achieve the procedures of automatic distributing,centering and positioning, feeding, material supporting, material receiving, feeding and cutting and the like of the pipes, and the mechanization degree and the automation degree are high.

Owner:佛山汇百盛激光科技有限公司

Die cutting device and method

ActiveCN104760077ARealize automatic material distributionContinuous operationMetal working apparatusContinuous operationMaterial Separation

The invention provides a die cutting device and a method. The device comprises a frame, a conveying mechanism and a die cutting mechanism, wherein the dir cutting mechanism has a feed part and a discharge part mounted on the frame; the conveying mechanism conveys a basal material to be cut to pass through the die cutting mechanism; and the feed part and the discharge part are respectively positioned at the two sides of the die cutting mechanism. The device is characterized by further comprising a mold release towing mechanism and an ejection mechanism; the mold release towing mechanism is positioned below the discharge part, and downwards tows the cut basal material from the discharge part; the ejection device is arranged between the discharge part and the mold release towing mechanism, and has a projection; and the projection can be corresponding to the cut basal material at the inner side, and is outwards projected on the cut basal material. After an automatic film die cutting device is applied, the automatic material separation after the die cutting and the continuous operation can be realized, one person is only needed to operate, the working efficiency is improved, and the labor is saved.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

Packing device

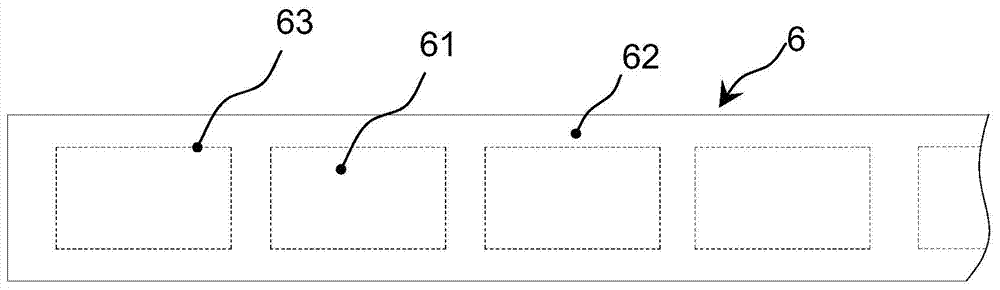

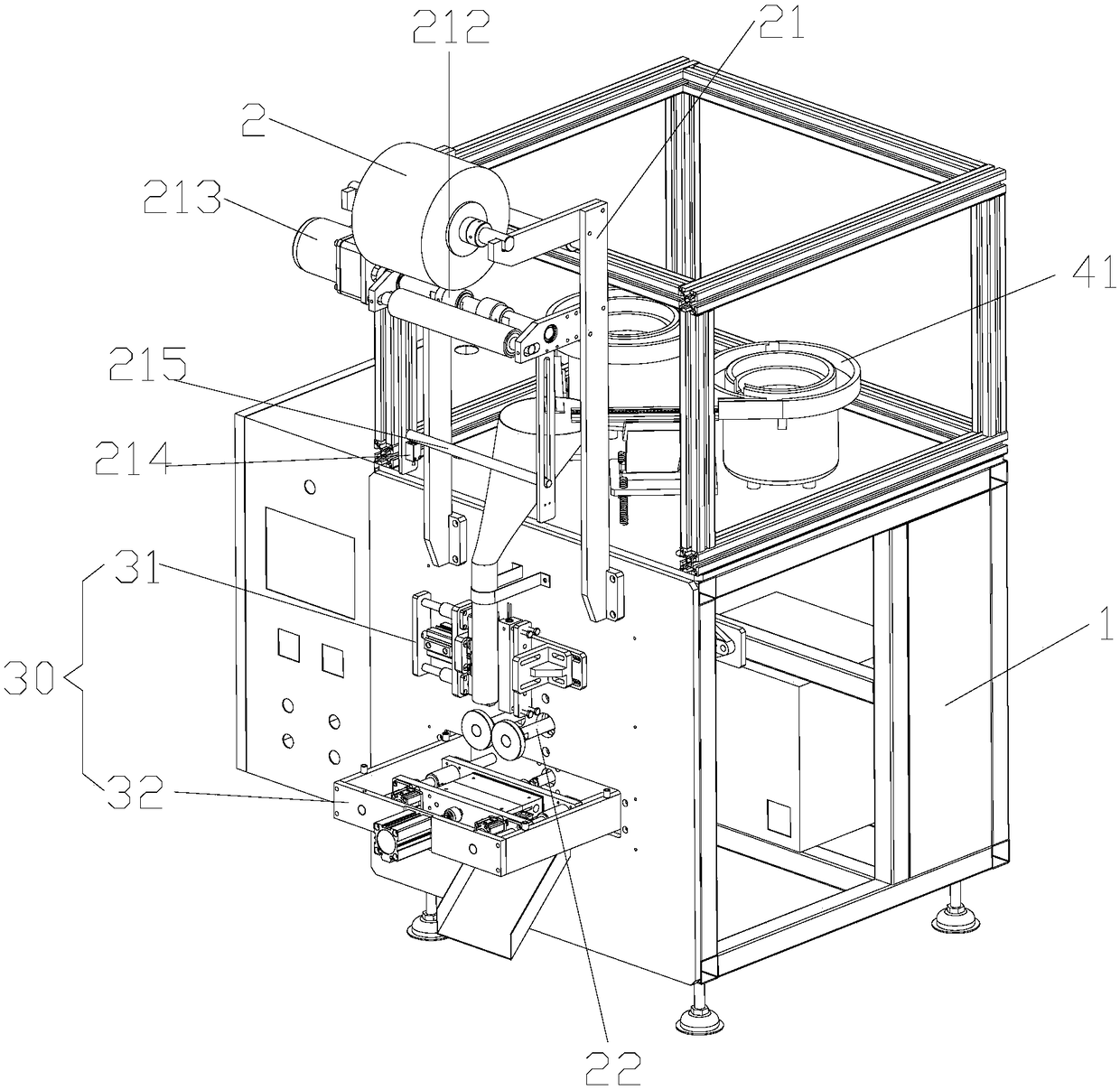

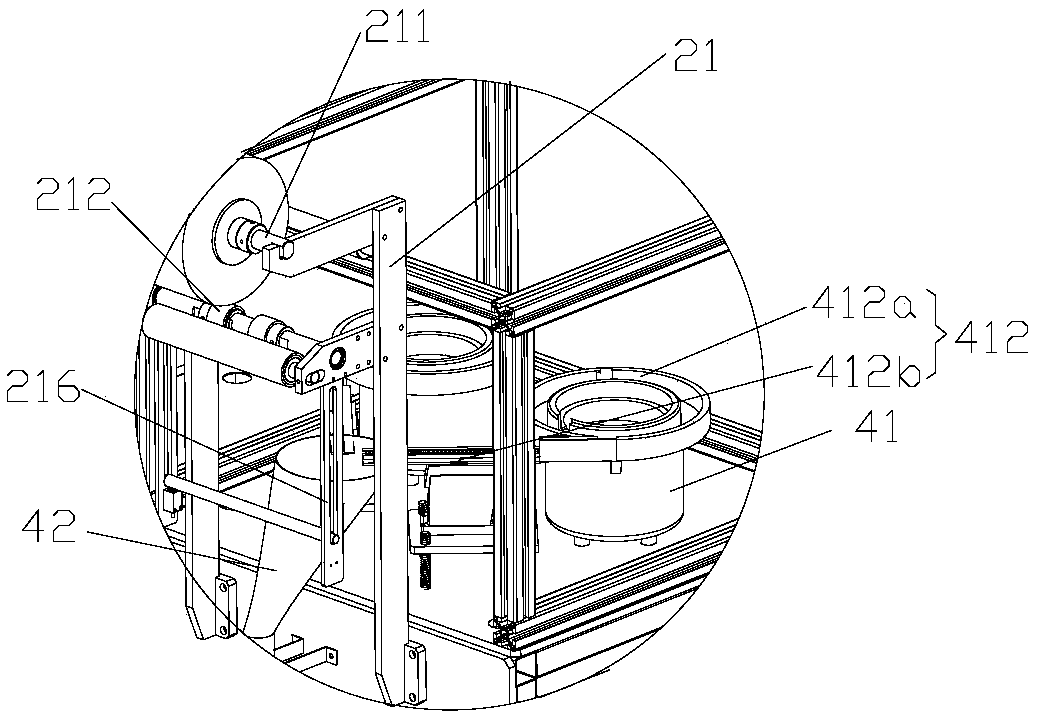

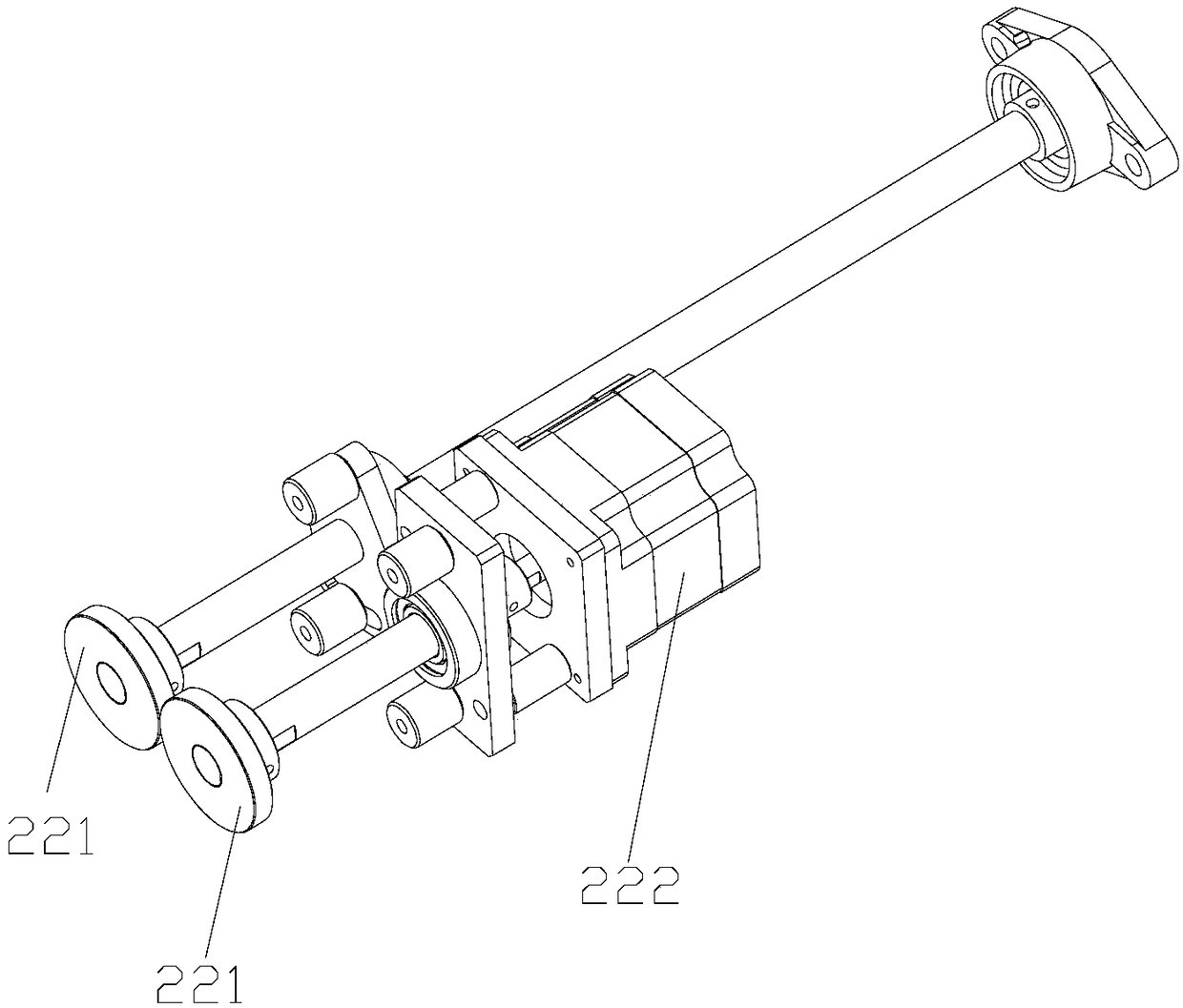

PendingCN109502093ANo wasteRealize automatic material distributionWrapper twisting/gatheringSuccessive articlesEngineeringMechanical engineering

Owner:GREE ELECTRIC APPLIANCES WUHAN +1

Automatic steel ball distributing device

InactiveCN105329659ARealize automatic material distributionReduce noiseConveyor partsSteel ballEngineering

The invention provides an automatic steel ball distributing device which comprises a hopper used for containing steel balls, a first guiding pipe, an adapter, a second guiding pipe, a separating block, a third guiding pipe, a pushing mechanism and a cam lifting mechanism. A discharging port is formed in the bottom of the hopper. The upper end of the first guiding pipe is arranged in the discharging port and movably connected with the discharging port. The lower end of the first guiding pipe is movably connected with the upper end of the adapter. The lower end of the adapter is fixedly connected with the upper end of the second guiding pipe. The lower end of the second guiding pipe is fixedly connected with the separating block. A separating cavity is formed in the separating block. The hopper, the first guiding pipe, the adapter, the second guiding pipe and the separating cavity are communicated to form a feeding channel. The cam lifting mechanism is connected with the first guiding pipe. The separating block is provided with a feeding port, a discharging port and a pushing port. The automatic steel ball distributing device has the advantages of being small in size, low in cost, low in noise, adjustable in speed and high in efficiency.

Owner:SHENZHEN IN CUBE AUTOMATION +1

Automatic screw assembling device and method

PendingCN107855766ASave dispensing timeReduce total timeMetal working apparatusEngineeringMechanical engineering

The invention discloses an automatic screw assembling device. The automatic screw assembling device comprises a distributing mechanism and an assembling mechanism and further comprises a moving mechanism, wherein the distributing mechanism outputs screws regularly; the assembling mechanism comprises at least one execution unit which assemblies the screws onto a workpiece, the assembling mechanismfurther comprises a fetching unit which is connected with the execution units, and the fetching unit corresponds to the discharging end of the distributing mechanism; and the moving mechanism is connected with the assembling mechanism and drives the assembling mechanism to move between the fetching position and the assembling positions. According to the automatic screw assembling device of the structure, the fetching unit corresponds to the distributing mechanism and can fetch a plurality of screws at the same time, and the screws are hit into the assembling positions through the multiple execution units; and the fetching unit is arranged and can move under driving of the moving mechanism, so that the problem that the distributing mechanism and the assembling positions are not located in the same position is solved.

Owner:ZHEJIANG TENGEN ELECTRIC

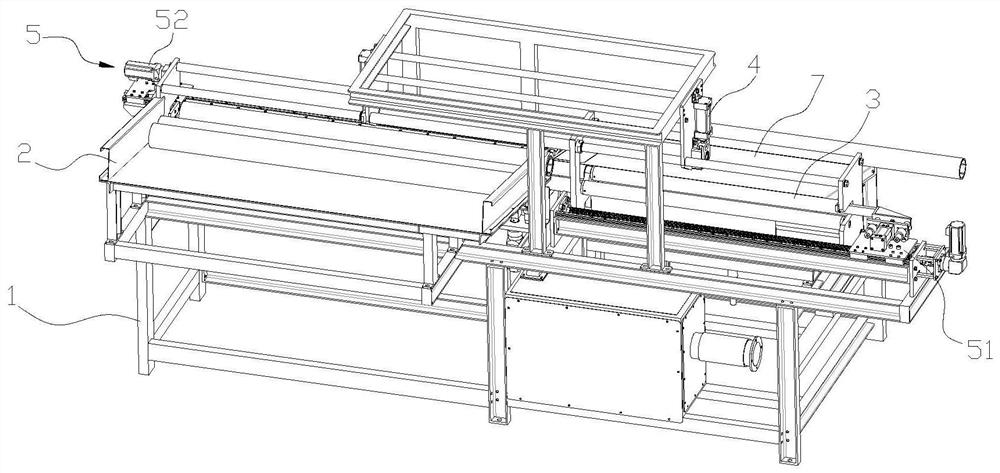

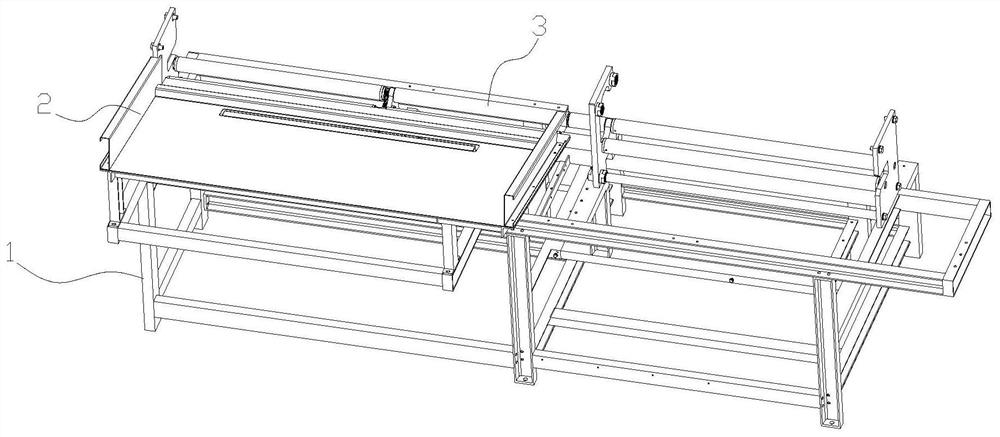

Automatic slitting equipment for pipes

InactiveCN112077912AAvoid concentrated stressReduce chippingMetal working apparatusControl systemControl engineering

The invention discloses automatic slitting equipment for pipes, and relates to the technical field of pipe processing. The automatic slitting equipment comprises a control system and a rack and further comprises a feeding mechanism, a bearing roller mechanism, a clamping roller mechanism, a conveying mechanism, a cutting mechanism and a discharging mechanism which are arranged on the rack; the bearing roller mechanism is used for bearing and driving pipes to synchronously rotate; the bearing roller mechanism is sequentially provided with a feeding station and a cutting station in the length direction of the bearing roller mechanism; the feeding mechanism is used for conveying the pipes to the feeding station; the conveying mechanism is used for conveying the pipes from the feeding stationto the cutting station; the clamping roller mechanism is used for being matched with the bearing roller mechanism to jointly clamp the pipes; the cutting mechanism is used for cutting off the pipes; the discharging mechanism is used for moving the cut-off pipes out of the cutting station; and a control system is used for controlling operation of all the mechanisms. The pipes are synchronously rotated during tool feeding of a tool, so that the pipes are stressed uniformly, the edge breakage probability is greatly reduced, the rejection rate is decreased, the processing efficiency is improved, and the automation degree is high.

Owner:GUANGZHOU ZHI JIAN GENERAL EQUIP MFG CO LTD

Labeling device

InactiveCN107235199AIncrease productivityReduce manufacturing costSortingArticle feedersEngineeringHardness

The invention discloses a labeling device suitable for plastic films. The labeling device comprises a first conveyor belt, a labeling unit, an adapting plate and a discharge unit. The first conveyor belt conveys the labeled plastic films to the discharge unit to be discharged. The discharge unit comprises two transmission assemblies. Each transmission assembly comprises a driving roller, a driven roller and at least three transmission wire ropes. Each driving roller drives the corresponding driven roller through the at least three transmission wire ropes. The two transmission assemblies are vertically arranged side by side and a gap is reserved between the two transmission assemblies so that the plastic films can pass. The transmission wire ropes of the upper transmission assembly and the lower transmission assembly are arranged in a staggered manner, belt conveying of a traditional conveyor belt is replaced with the transmission wire ropes which are vertically arranged in the staggered manner, the hardness of the plastic films is increased to a certain degree when the plastic films are discharged, the setting function is played, and the problems that the plastic films are too light or too soft and consequently deformation, folding and messy stacking are caused when the plastic films discharged, and even the plastic films are twisted into rolling wheels of the conveyor belt.

Owner:FORESIGHT OPTICAL (XIAMEN) LTD

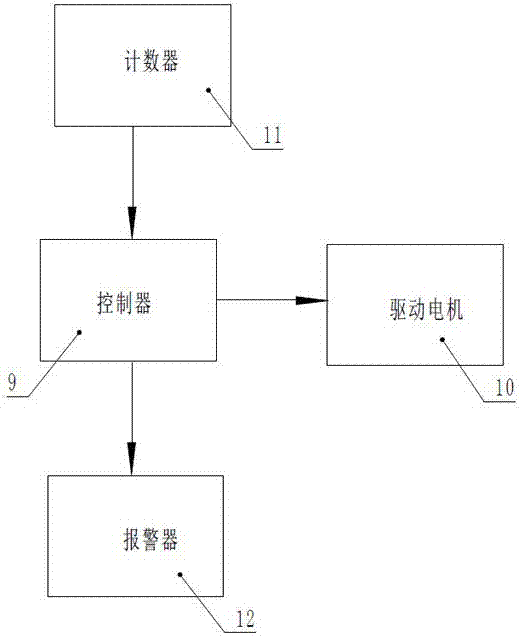

Integrated automatic detection and material dividing device

The invention discloses an integrated automatic detection and material dividing device which includes a feeding mechanism, a material conveying mechanism, a detection mechanism, a material dividing mechanism and a control mechanism. The feeding mechanism is arranged on the upper part of the material conveying mechanism, so that material falling is facilitated by using gravity. The detection mechanism is a weighing mechanism, the weighing mechanism includes a weighing pan, and the weighing pan is further provided with a weighing sensor. The material dividing mechanism includes a flip plate, theflip plate is connected with a motor through a coupling, the flip plate is fixed to the weighing plate, and the weighing mechanism and the material dividing mechanism are arranged in an integrated mode and installed together at a material conveying opening of the material conveying mechanism. The control mechanism is electrically connected with the weighing sensor and the motor separately. The integrated automatic detection and material dividing device has the characteristics of simple structure, small size, low cost and high efficiency, and high quality control and extremely low error rate for different materials can be achieved; the integrated automatic detection and material dividing device is suitable for a variety of work scenarios, and is more suitable for material dividing of batching, sorting and dispersing materials; and the integrated automatic detection and material dividing device can be arranged in a multi-channel mode, multiple levels of qualified discharge channels canbe reasonably arranged according to different needs, and the work efficiency is improved.

Owner:广东博菲特智能科技有限公司

Die cutting device for mobile phone film

InactiveCN107775724AAchieve separationRealize automatic material distributionMetal working apparatusAgricultural engineeringWaste collection

The invention relates to a mobile phone film die-cutting device, which includes a workbench, on which a feeding mechanism, a die-cutting mechanism and a waste collection mechanism are sequentially arranged according to the incoming material direction of the raw material film. There is a discharge opening through the plate-shaped structure on the top, the discharge opening is located between the die-cutting mechanism and the waste collection mechanism, a sloping plate is arranged below the discharge opening, the sloping plate is inclined, and a direction is arranged above the discharge opening. For the push rod facing down, the raw material film is located between the discharge port and the push rod, and the end of the push rod faces the discharge port downward, and can push the raw material film through the discharge port and drop to the inclined plate for collection. The invention can realize automatic material distribution after die cutting, improve work efficiency and save manpower.

Owner:徐下兵

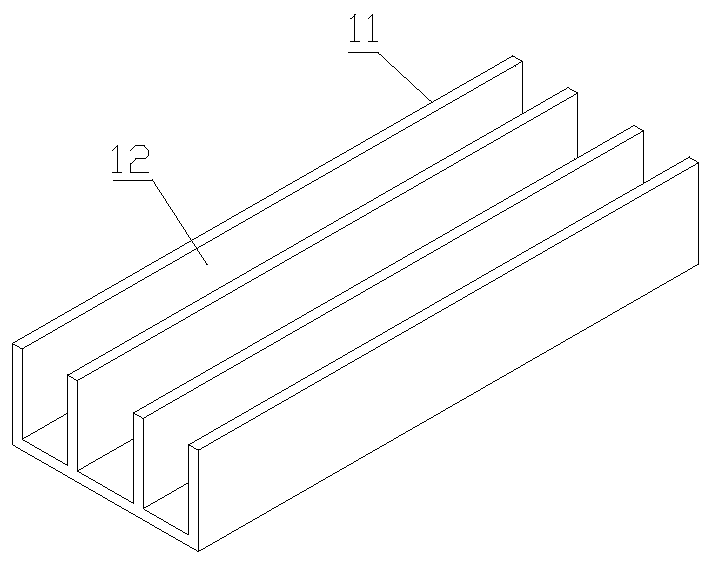

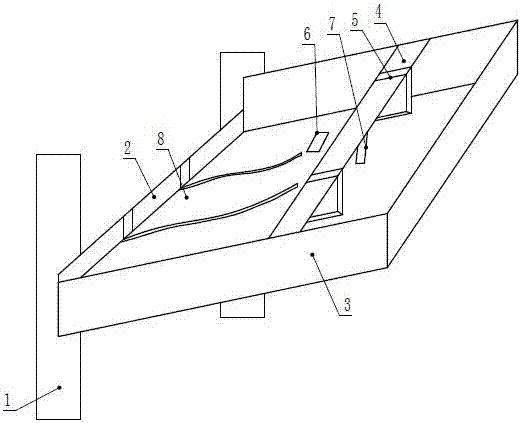

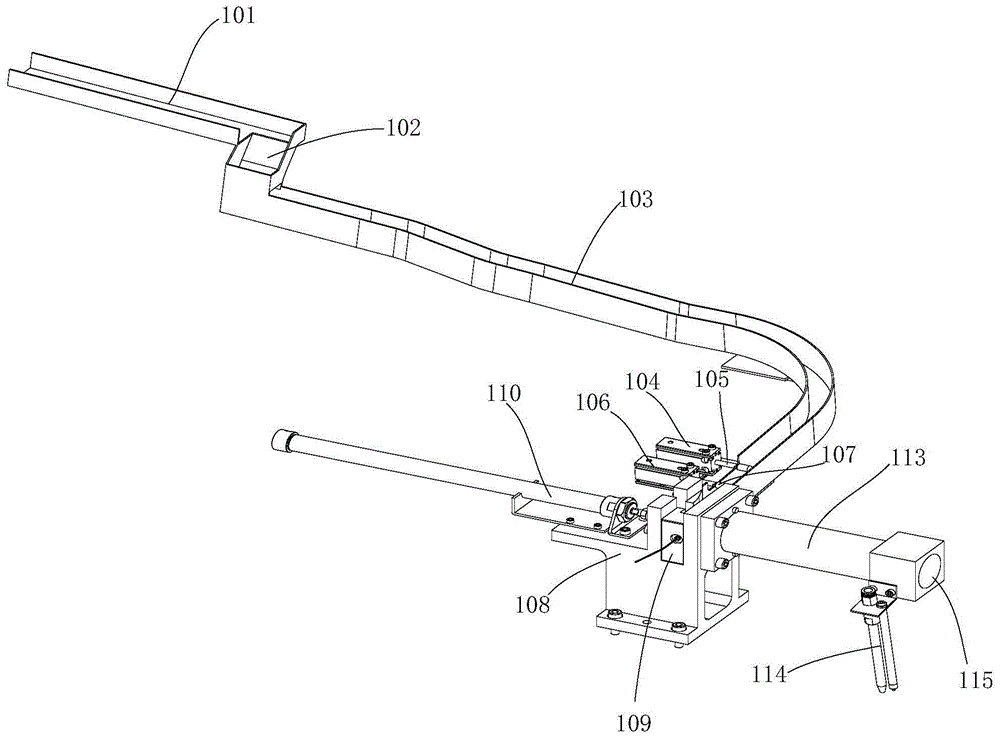

Automatic feeding system for cam blank

The invention relates to an automatic feeding system for a cam blank, which comprises a modeling material channel, wherein the modeling material channel is equipped with an adjusting device, and mainly comprises two modeling rails that are parallel to each other in a transmission direction; shapes of the two opposite side faces on the two modeling rails are matched with outlines of curved surfaces on the two sides of a flange part of the cam blank; a space for accommodating the flange part of the cam blank is reserved between the two modeling rails; and the adjusting device is used for adjusting a pointing direction of the axial front-rear end of the cam blank conveyed on the modeling material channel. According to the automatic feeding system, the automatic and accurate feeding and blanking of the cam blank are realized, so that the pointing direction of the axial front-rear end of the cam blank output from a discharge end of the automatic feeding system, and a pointing direction of a tip point of a flange can correspond to technological requirements of the cam blank in a subsequent procedure during a processing course; an effect of an error due to manual adjustment on the shape of the cam blank entering the subsequent procedure is avoided; and the shape uniformity of cam products can be ensured.

Owner:BEIJING BEINEI ENGINE PARTS

Rotary crayon end cover loading device

PendingCN110039294ARealize automatic delivery and supplyRealize automatic material distributionMetal working apparatusMechanical engineering

The invention discloses a rotary crayon end cover loading device. The rotary crayon end cover loading device comprises a supplied material conveying mechanism, an automatic material splitting mechanism and an assembling mechanism; the automatic material splitting mechanism comprises a bin plate, an end cover falling groove body, and an opening and closing plate, through a first driving mechanism,the opening and closing plate is driven to move back and forth, a material splitting hole in the opening and closing plate corresponds to a falling groove in the upper portion or a through hole in thelower portion, the assembling mechanism comprises a turnover block, an end cover assembling head, a turnover mounting frame and a push plate, through a second driving mechanism, the turnover block isdriven to rotate, through a limiting assembly, the turnover block is limited from rotating only within the 90-degree range, when the turnover block is in the vertical state, an end cover assembling head on the turnover block is in abut joint with the through hole in the bin plate, when the turnover block is in the horizontal state, through a third driving mechanism, the end cover assembling headis driven to synchronously move, and assembling of the end cover and a downstream pen container is achieved. The device has the advantages that automatic feeding and loading, automatic arranging and splitting and automatic assembling of the end covers can be achieved.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

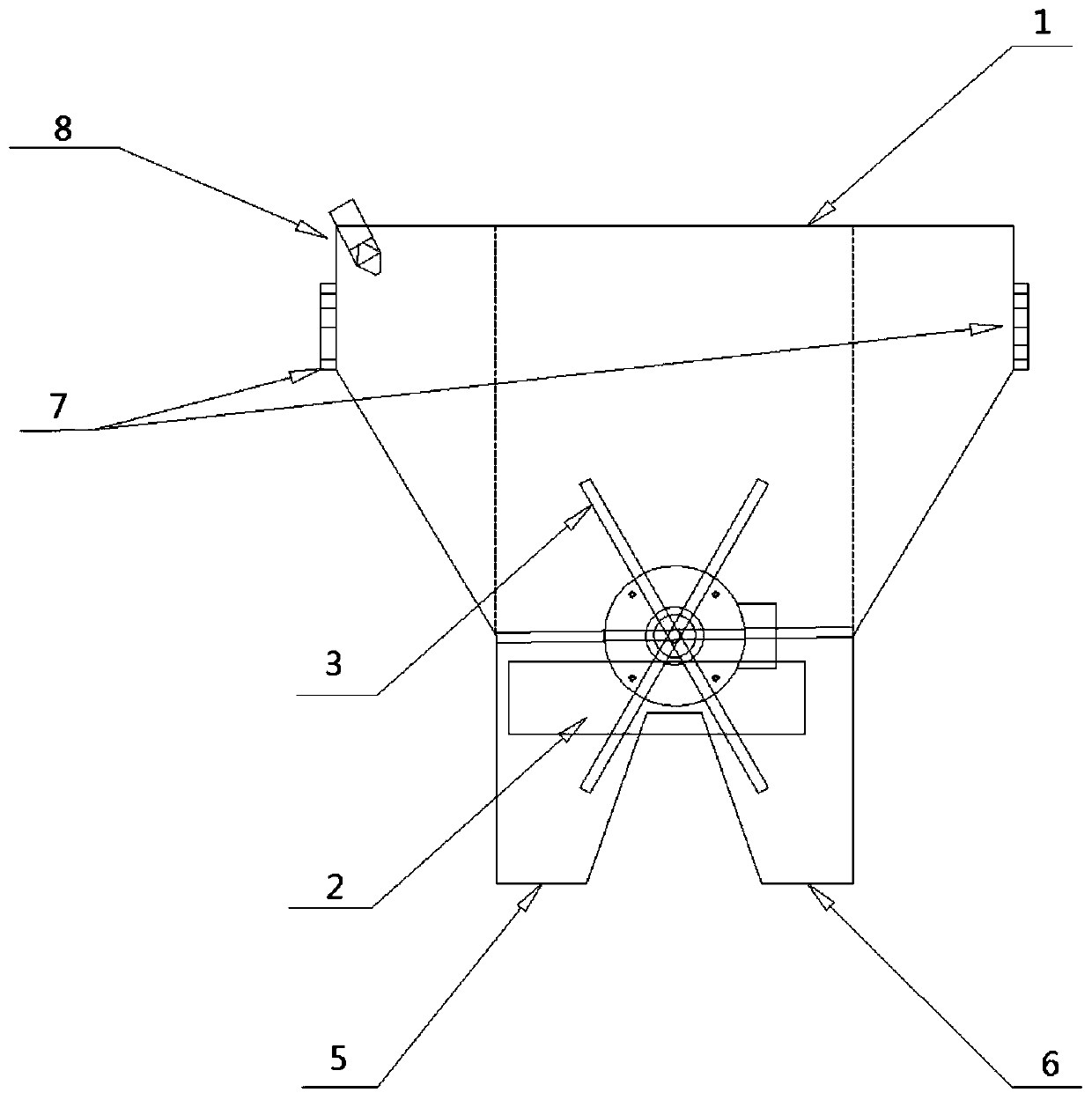

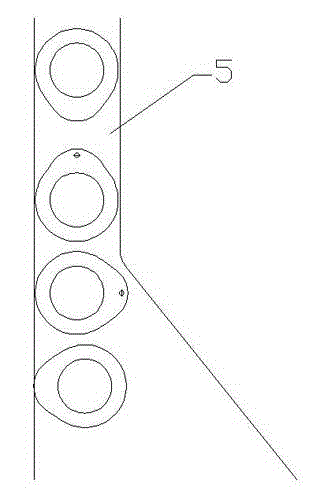

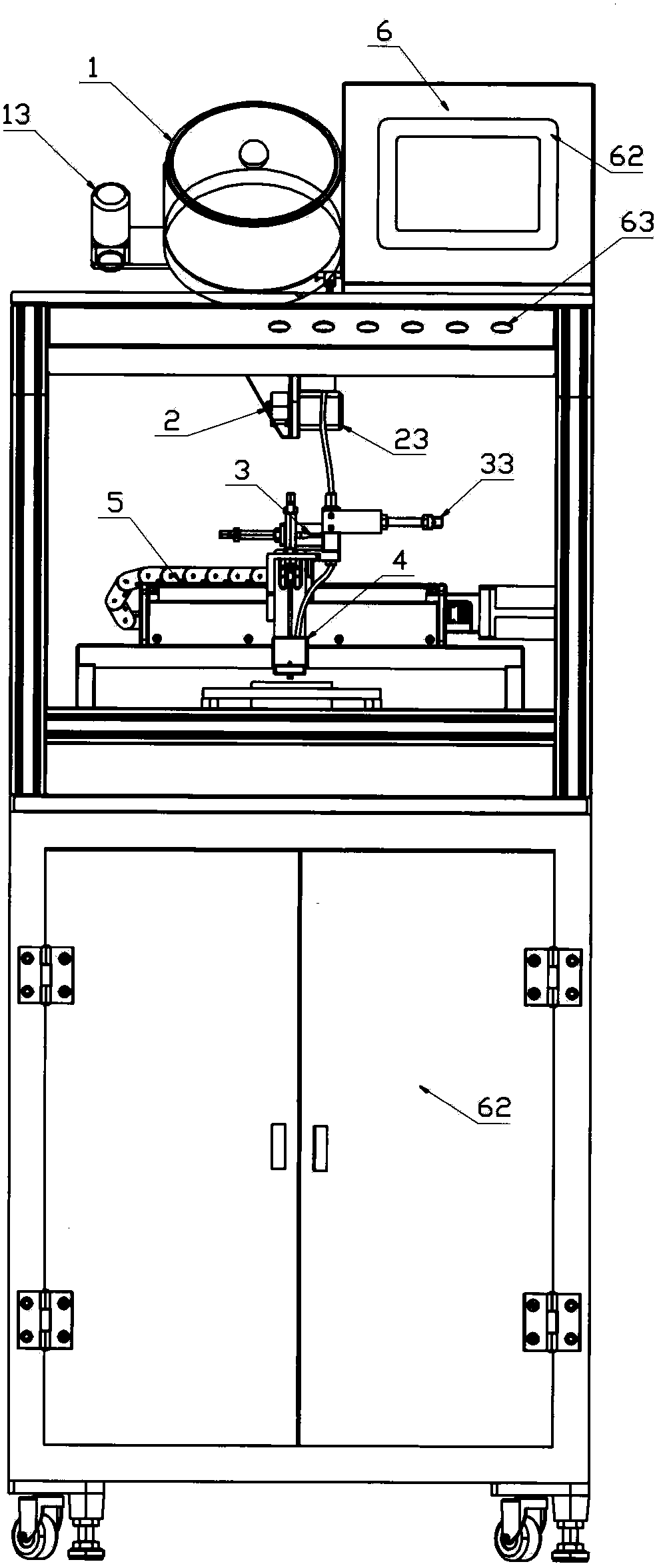

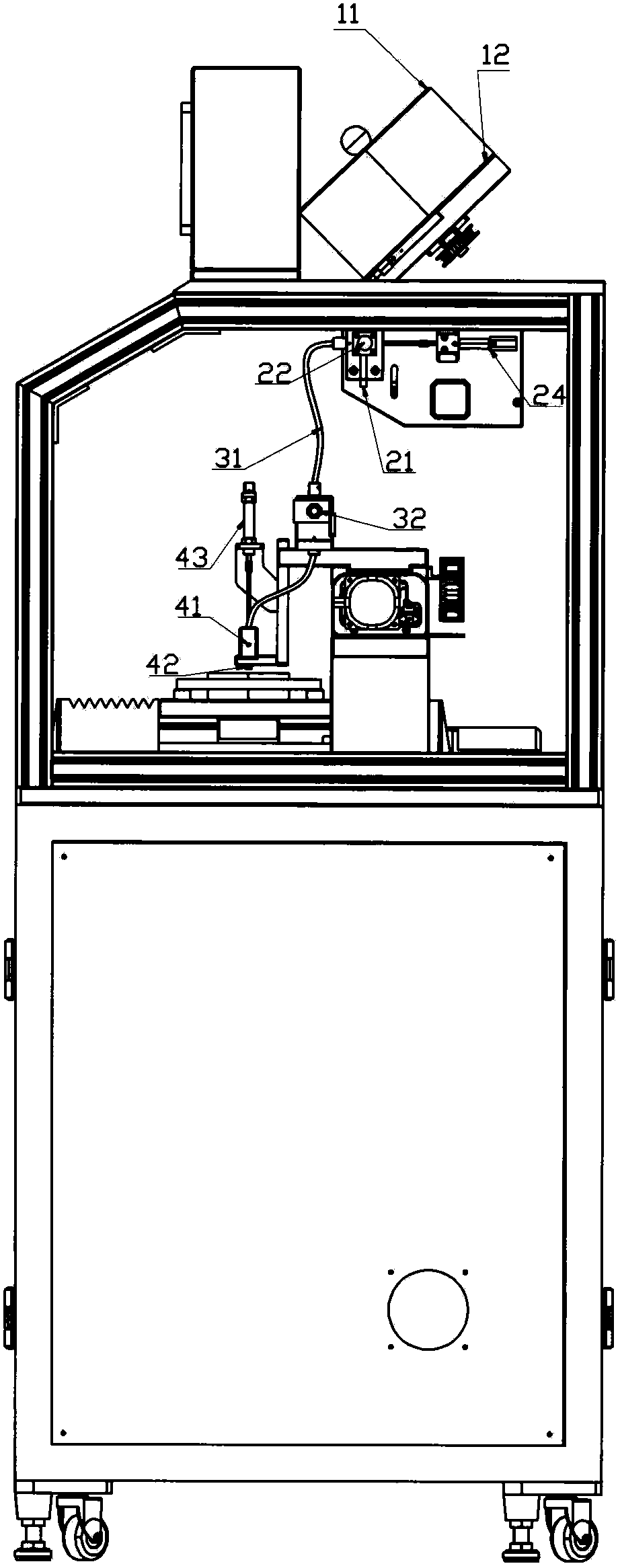

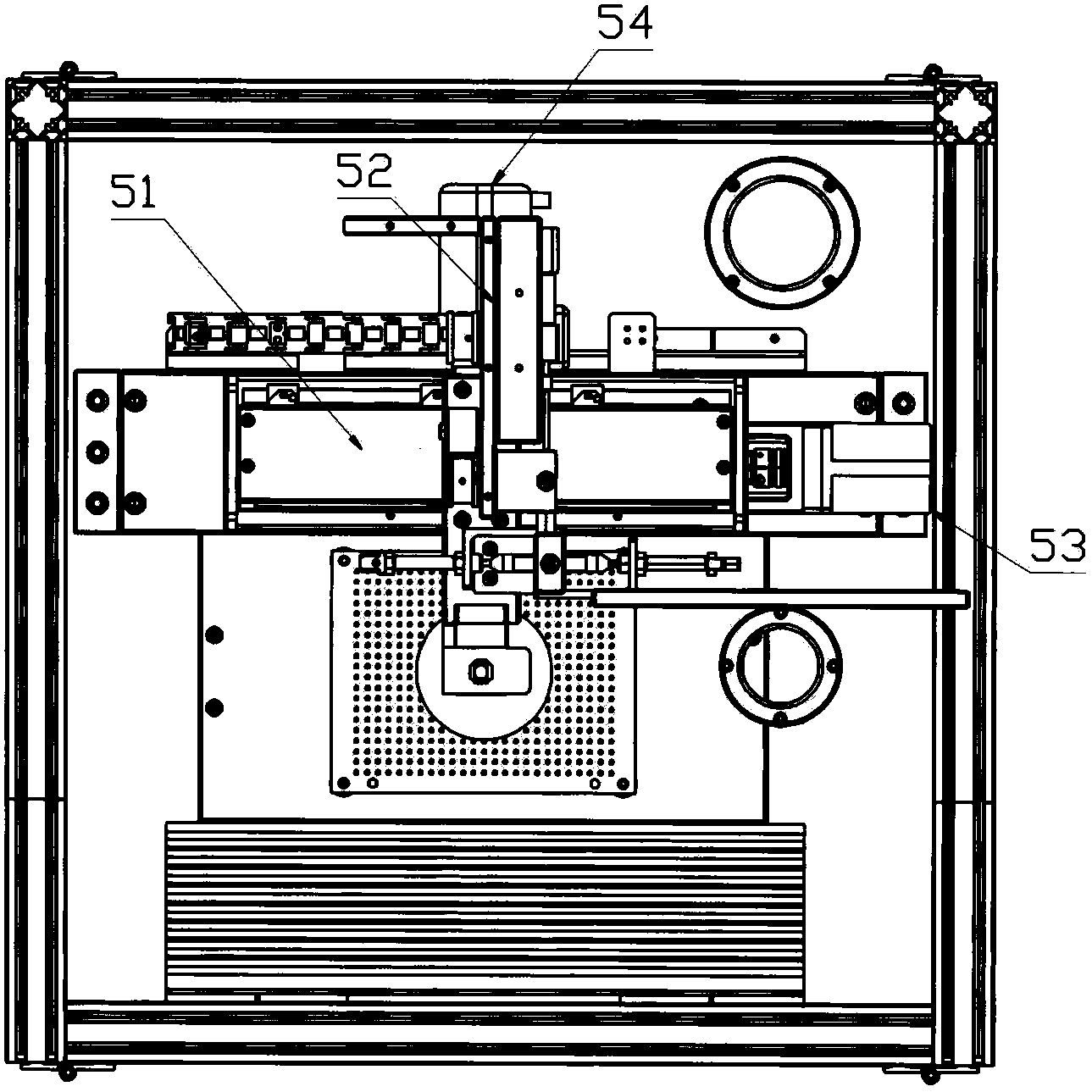

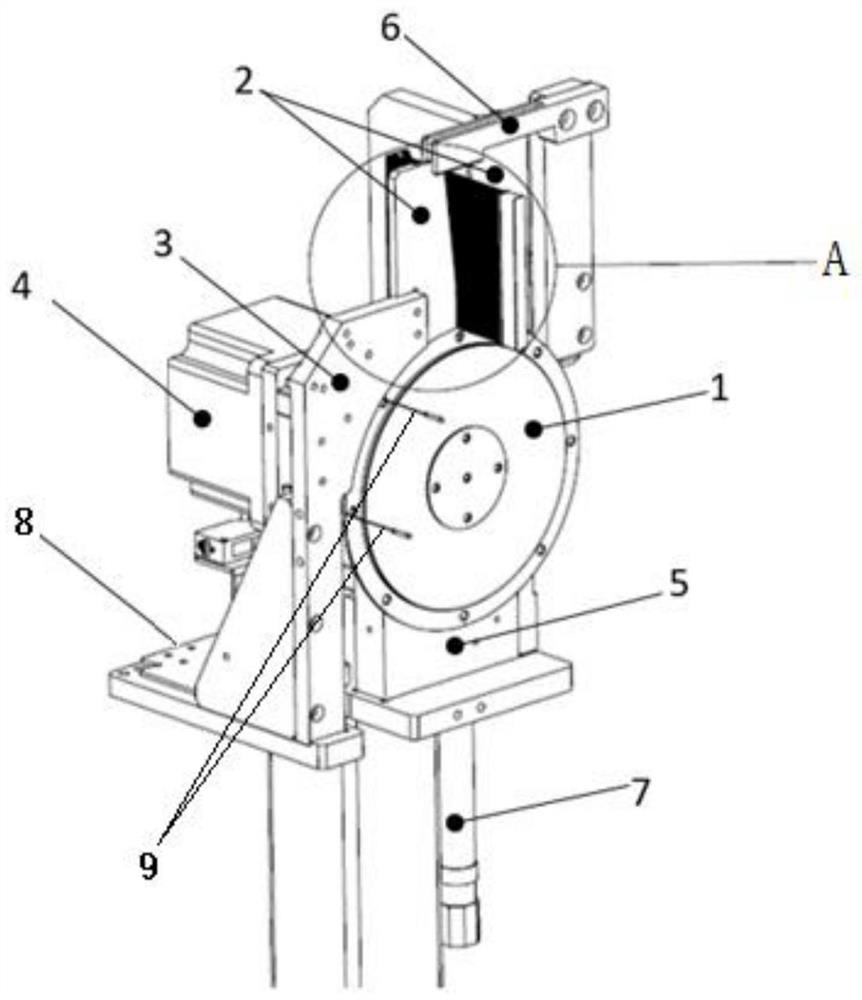

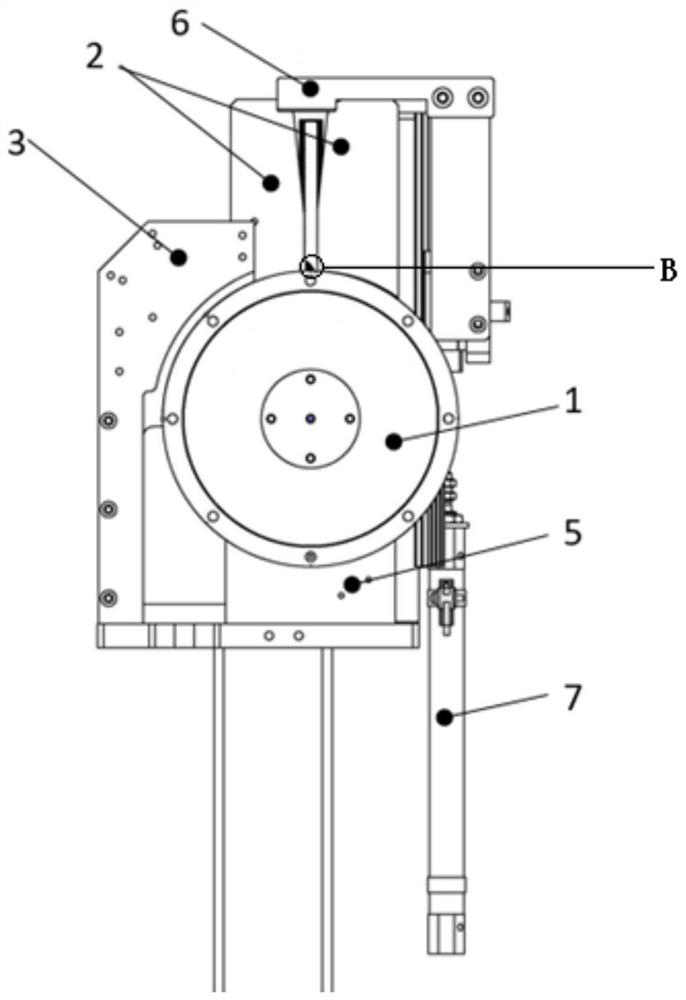

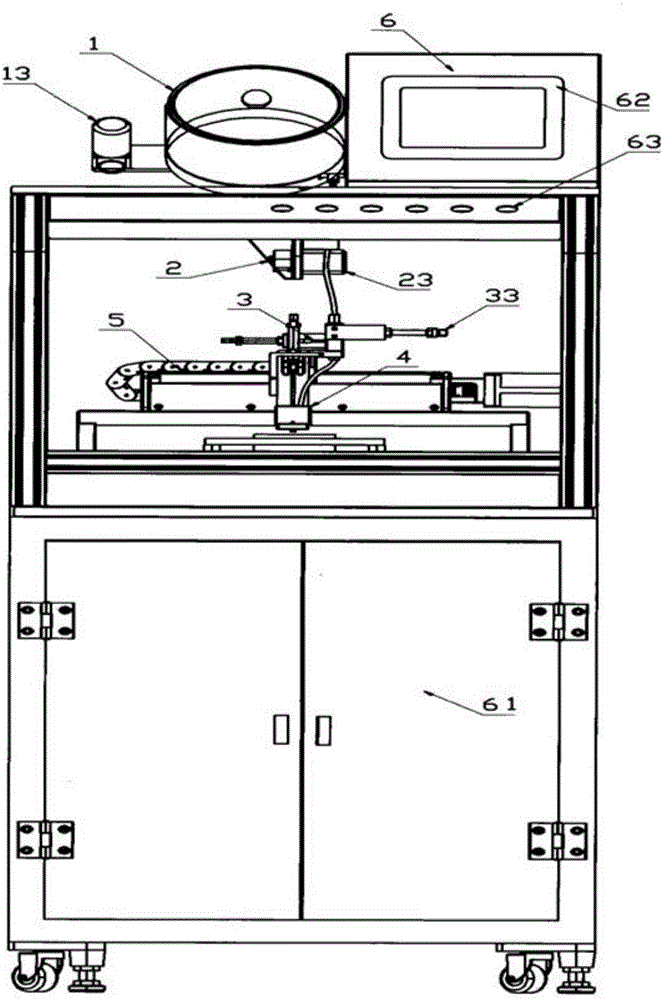

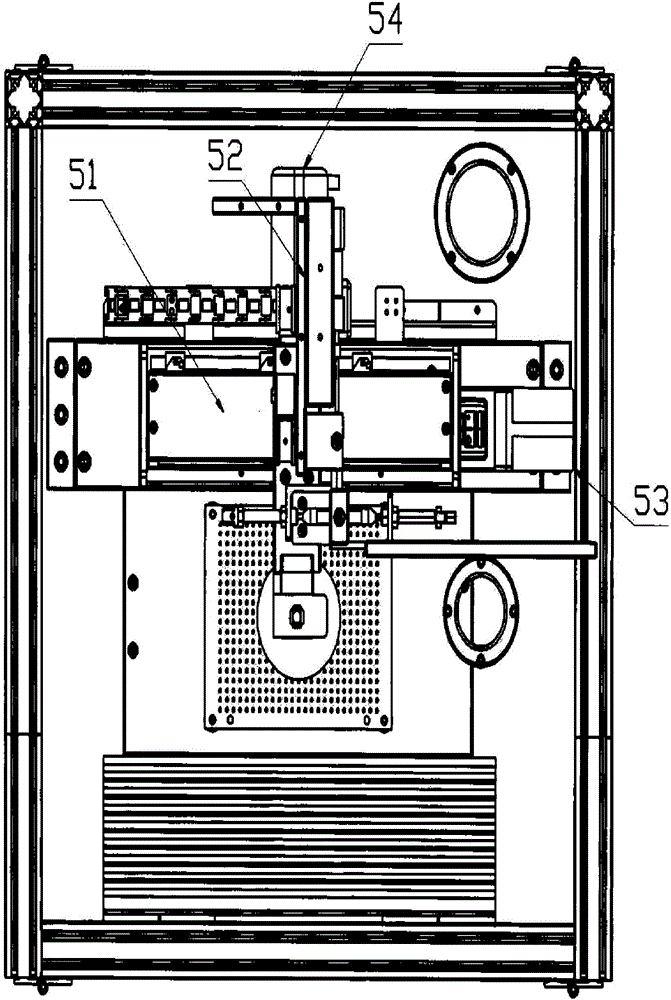

Automatic disk inserting machine

The invention discloses an automatic disk inserting machine with a ceramic ferrule for automatically inserting disks and locating. The automatic disk inserting machine comprises a distributing device (1), a head and tail recognition device (2), an automatic dislocation device (3), a disk inserting device (4), a two-axis mobile device (5) and a control device (6); the distributing device comprises a charging basket, a distributing plate and a drive motor; the head and tail recognition device comprises a head and tail recognition sensor, a head and tail reversing device, a drive motor and a pushing cylinder; the automatic dislocation device comprises a storage pipe, a dislocation mechanism, a dislocation cylinder and the like; the disk inserting device comprises a sensor, a sideslip type production positioning runner and a pressing mechanism; the two-axis mobile device comprises an X axis, a Y axis, an X-axis servo motor and a Y-axis servo motor; the control device comprises a PLC (programmable logic controller), a human-computer interface, a button, etc. According to the automatic disk inserting machine provided by the invention, the assembly of the parts can improve the efficiency, reduce the human cost and achieve the aim of the automatic production positioning of the ceramic ferrule.

Owner:昆山迎翔光电科技有限公司

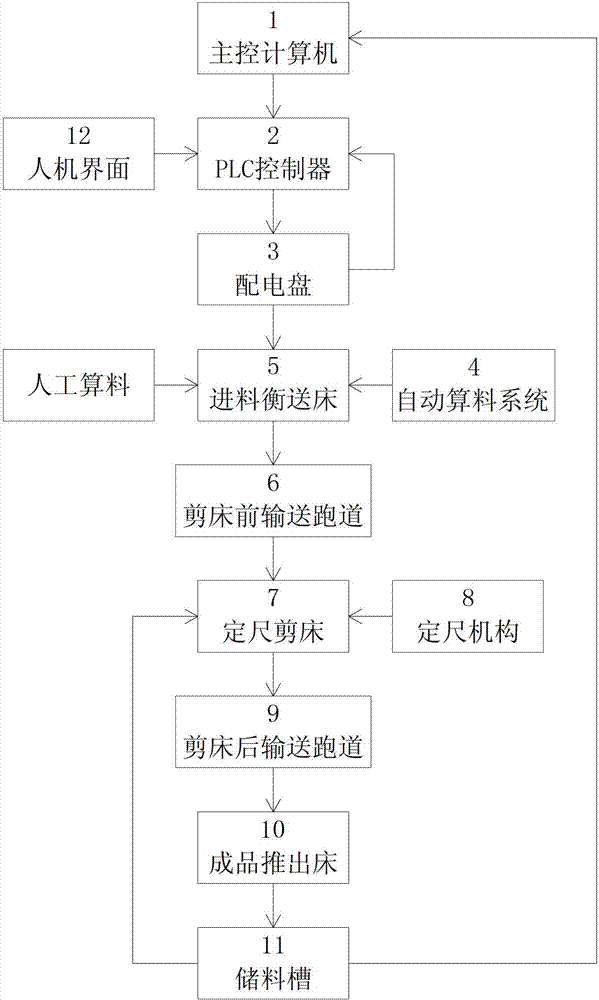

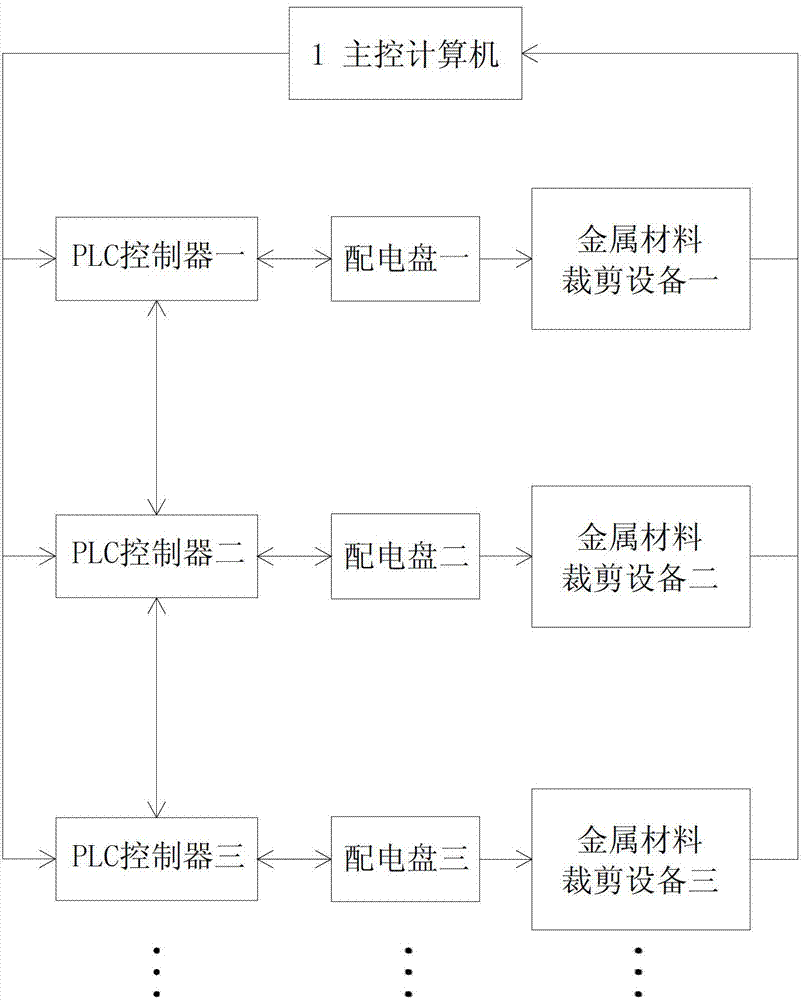

Numerical control metal material cutting device with function of combining factory management system

InactiveCN103197610ANovel structureSimple structureNumerical controlNumerical controlProgrammable logic controller

The invention relates to the machinery cutting device technical field, in particular to a numerical control metal material cutting device with a function of combining a factory management system. The numerical control metal material cutting device with the function of combining the factory management system comprises a metal material cutting device, a programmable logic controller (PLC), a switchboard, a master control computer and electronic management system software, wherein the metal material cutting device is connected with the PLC through a circuit, and the electronic management system software is operated on the master control computer. The master control computer calculates metal material cutting parameters needed by client orders through the electronic management system software, generates a cutting detail table and a cutting drawing, and sends dispatching signals to the PLC after rank calculation. After receiving the dispatching signals, the PLC combines with the switchboard to control the metal material cutting device to conduct sequential cutting according to instructions, returns messages to the master control computer if failures happen in the cutting process, and returns finishing messages to the master control computer after cutting is finished. The numerical control metal material cutting device with the function of combining the factory management system saves labor cost and manual calculation time, lowers calculation error rates, and can conveniently calculate cost and grasp quality and accuracy of end products.

Owner:DARREY MACHINERY SHANGHAI

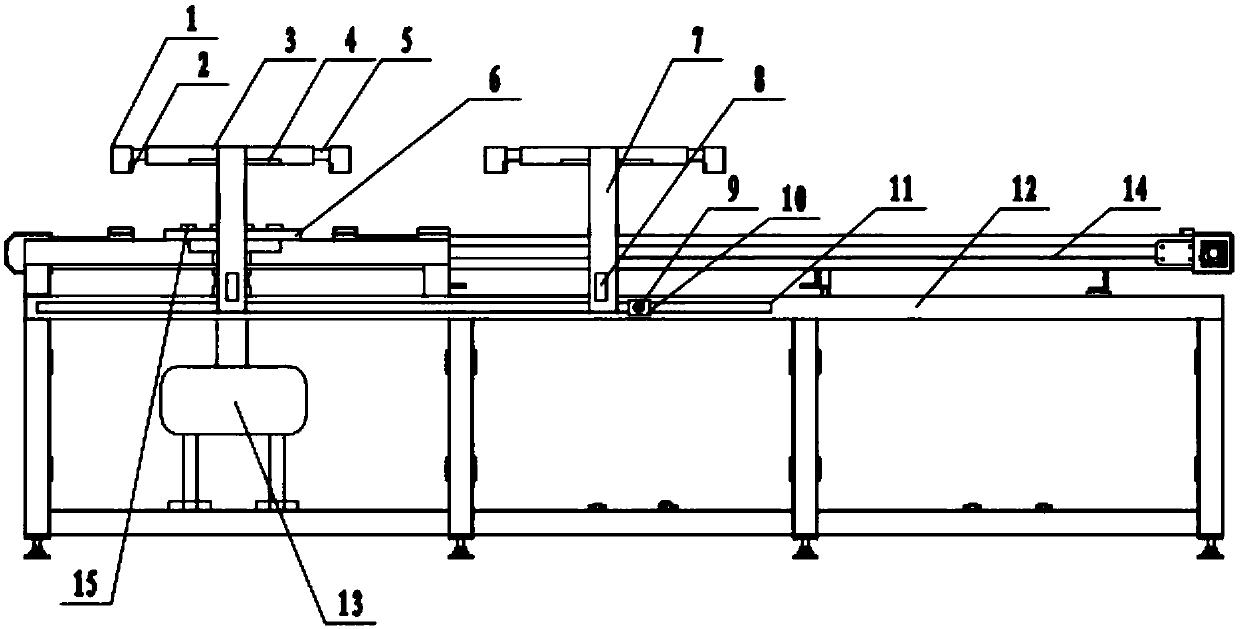

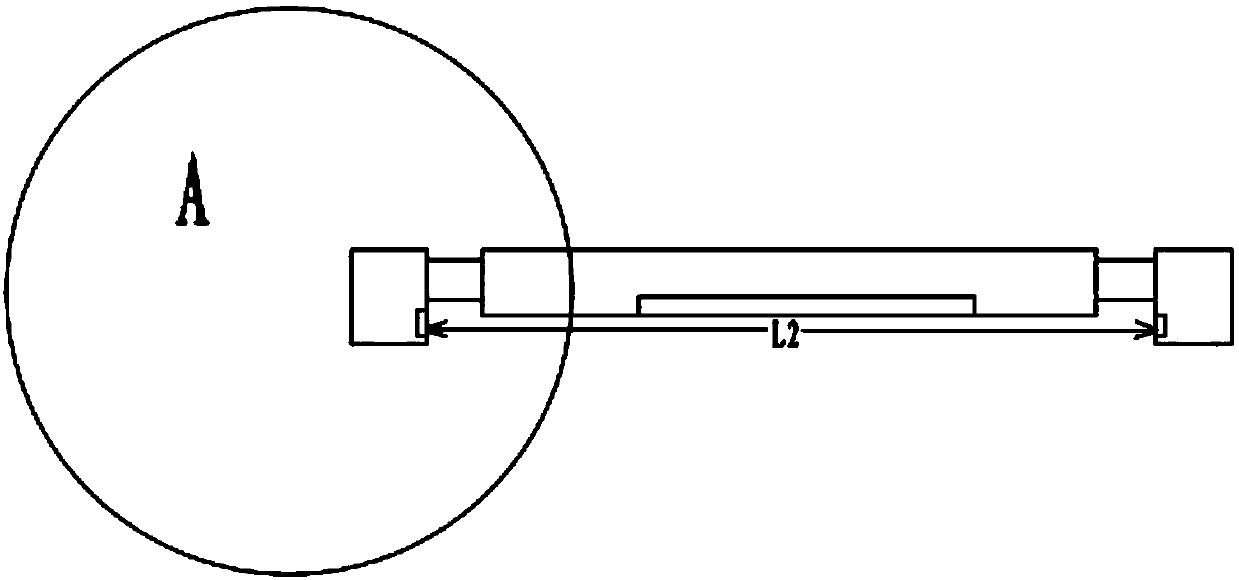

Corrugated board dividing machine and using method thereof

InactiveCN107856922ARealize automatic material distributionReduce labor intensityPackaging automatic controlGlass fiberCardboard

The invention relates to a corrugated cardboard distributor and a method for using the same, which belong to the technical field of glass fiber production equipment. There is a slideway on one side, a bracket is arranged in the slideway, a corrugated cardboard gripper is arranged on the top of the bracket, and a block is arranged in the slideway near one end of the conveying mechanism. The corrugated cardboard gripper includes a crossbar, and both ends of the crossbar are provided with The grab block, the distance from the bottom edge of the grab block to the bottom edge of the crossbar is L1, L1 is (1 / 2‑1) times the thickness of the corrugated board, the distance L2 between the inner sides of the two grab blocks is equal to the width of the corrugated board, and the crossbar There is a sensor I at the bottom and a motor on the bracket. Both the sensor I and the motor are connected to the PLC controller; the gripping block and the cross bar are connected by a telescopic rod, and the inner side of the gripping block is provided with a sensor II, and the sensor II is connected to the PLC controller . The invention adopts the corrugated cardboard grab block to realize the automatic material separation of the corrugated cardboard, reduces labor intensity and improves production efficiency.

Owner:TAISHAN FIBERGLASS ZOUCHENG

Wheel disc dividing device for disc part unloading

InactiveCN108657792ARealize automatic material distributionEasy to useConveyorsConveyor partsEngineeringMechanical engineering

Owner:WUHU KAIDE MACHINERY MFG

A kind of hand threading needle material distributing mechanism

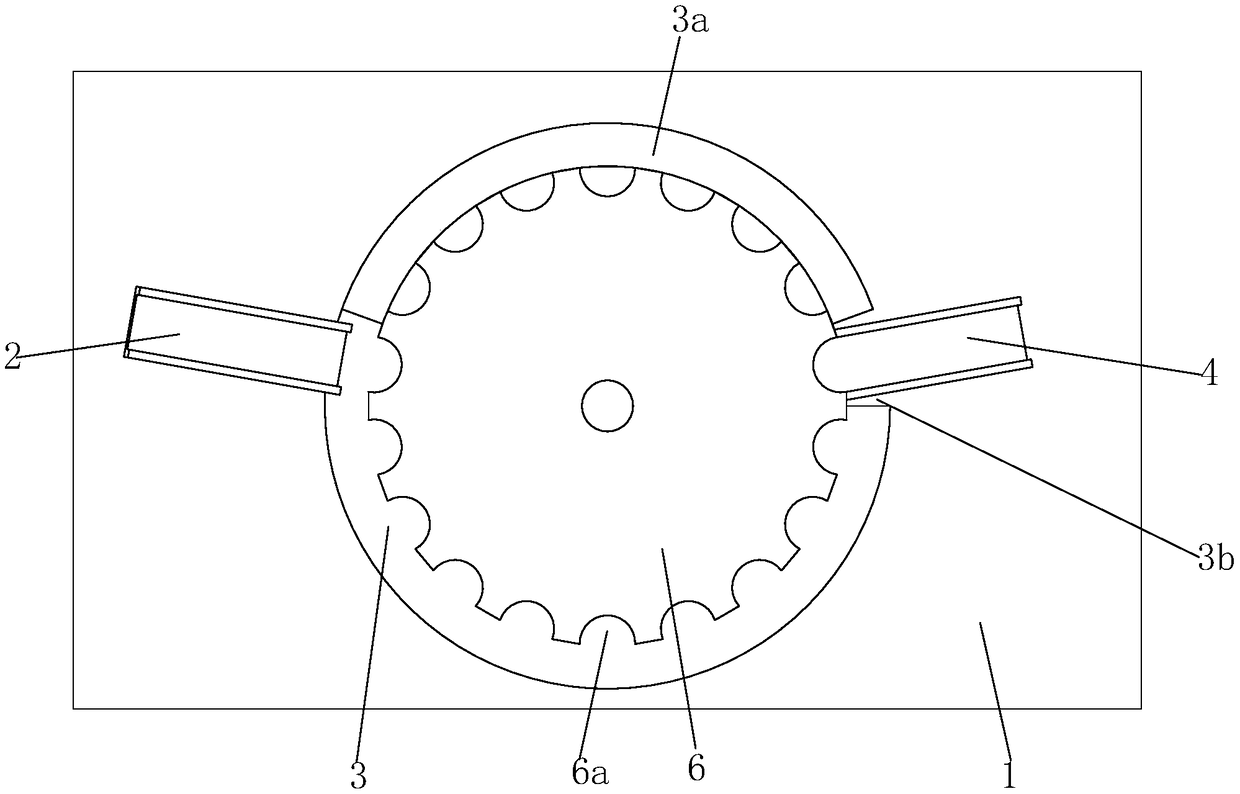

ActiveCN110745564BRealize automatic material distributionReduce material costsLabelling deformable materialsDe-stacking articlesCircular discDrive shaft

The invention provides a hand-piercing needle material distribution mechanism, which includes a support plate and a material distribution disc installed on the support plate, a material guide plate, a material retaining plate, a driving motor and a material pressing mechanism. The drive shaft is fixedly connected to the center of the disc, and the outer edge of the distributing disc is provided with a plurality of distributing grooves that are evenly distributed and can accommodate a hand-threaded needle. The groove bottom of the groove is close to the edge of the material distribution disc, and the hand piercing needle at the lower end of the V-shaped groove can be against the outer edge of the material distribution disc. The arc-shaped edge that fits in the gap with the outer edge of the distribution disc, the pressing mechanism includes a pressing cylinder fixed on the support plate and a pressing block that is connected with the pressing cylinder and can be pressed in the V-shaped groove for hand-threading needles. The hand-threaded needle material distribution mechanism realizes the automatic material distribution of the hand-threaded needle through the cooperation of the material distribution disc, the material guide plate and the material pressing mechanism, the material distribution cost is low, and the automation of the hand-threaded needle feeding is realized.

Owner:大工智能装备(深圳)有限公司

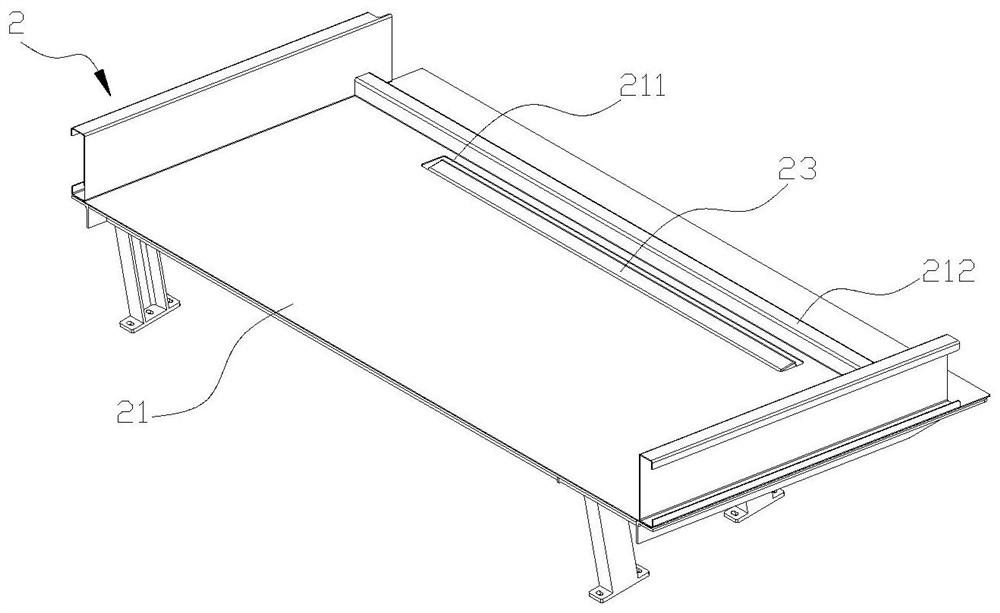

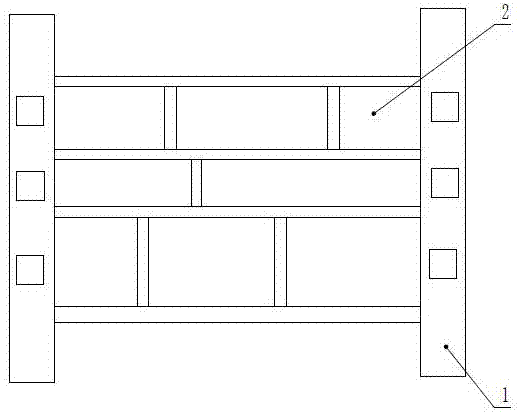

Material frame

InactiveCN107539797AImprove efficiencyRealize automatic material distributionControl devices for conveyorsLoading/unloadingEngineeringDrive motor

The invention discloses a material frame, and relates to the technical field of material supplies. The material frame comprises frame rods on the two side edges, multiple material cells are arranged between the frame rods, and the material frame is characterized in that a detachable material hopper is arranged on the frame rods, an outlet of the material hopper inclines towards the direction of the frame rods, a transverse rod is arranged on the material hopper, a size measuring device is arranged below the transverse rod, a baffle is arranged behind the size measuring device, a lifting leveris arranged on the inner surface of the transverse rod, and is controlled by a drive motor on the outer surface of the transverse rod, multiple material channels are arranged between the transverse rod and the outlet of the material hopper, and each material channel is in abut joint with the material cells. Compared with the prior art, the problem that manual material storage is low in efficiencyis solved.

Owner:柳州劲胜科技有限公司

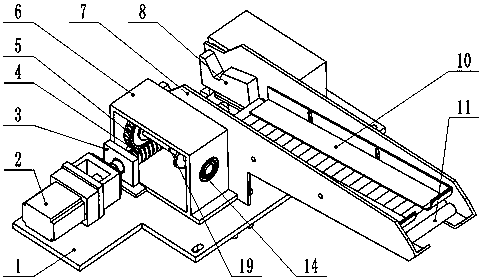

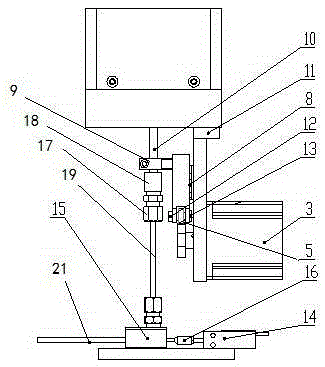

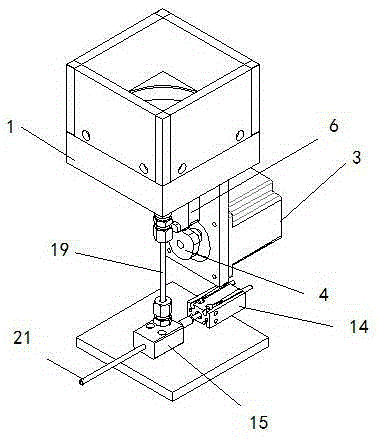

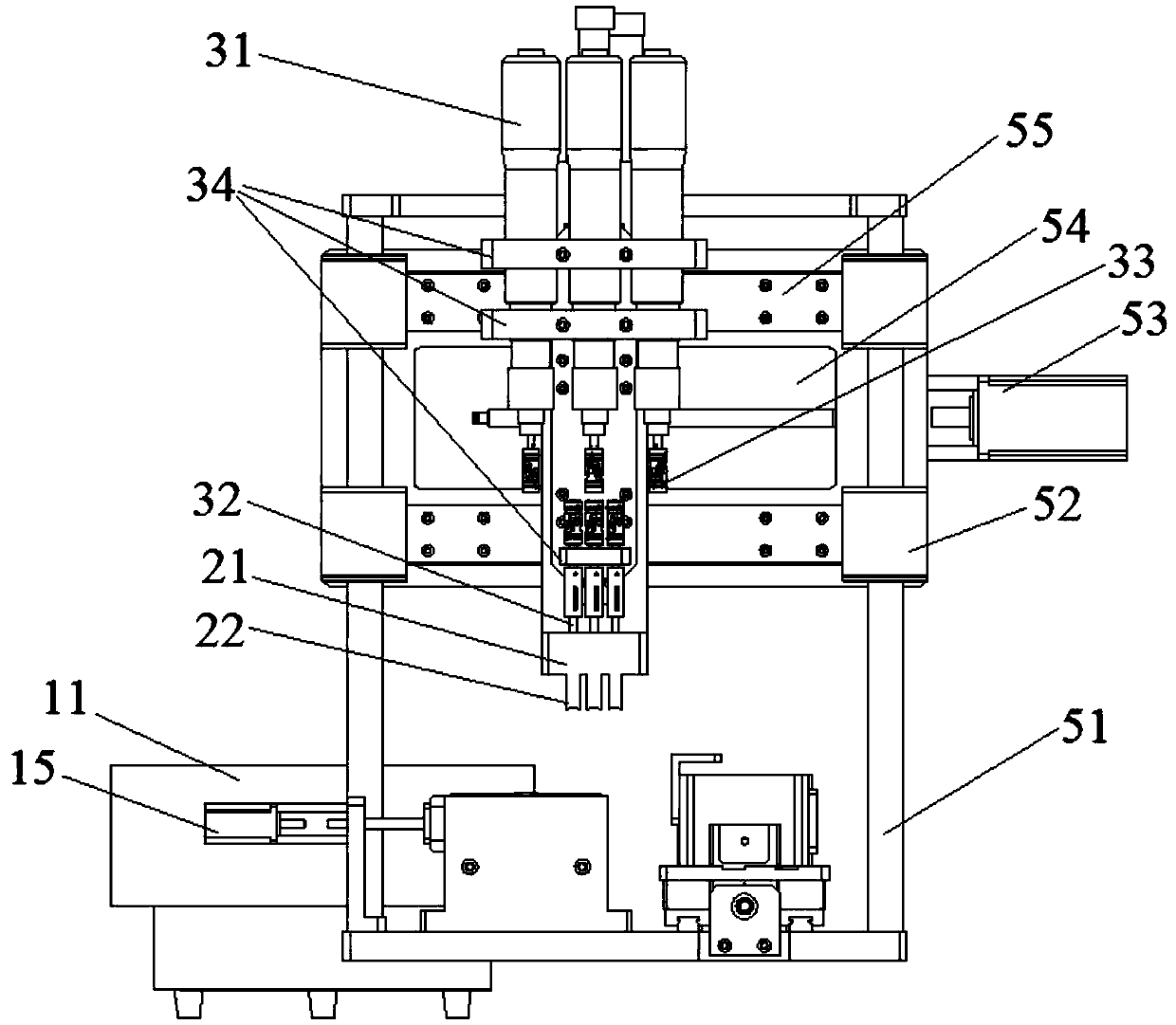

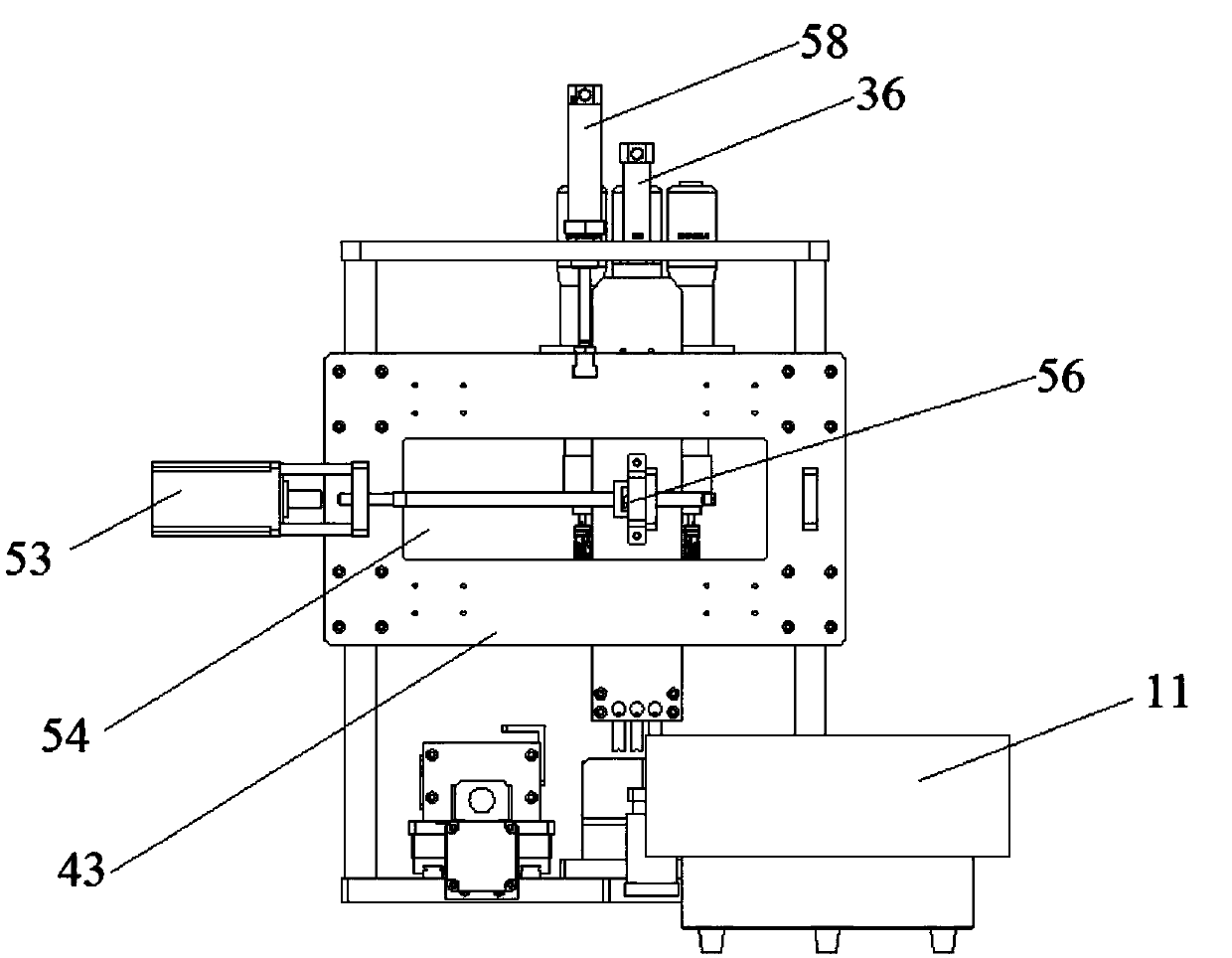

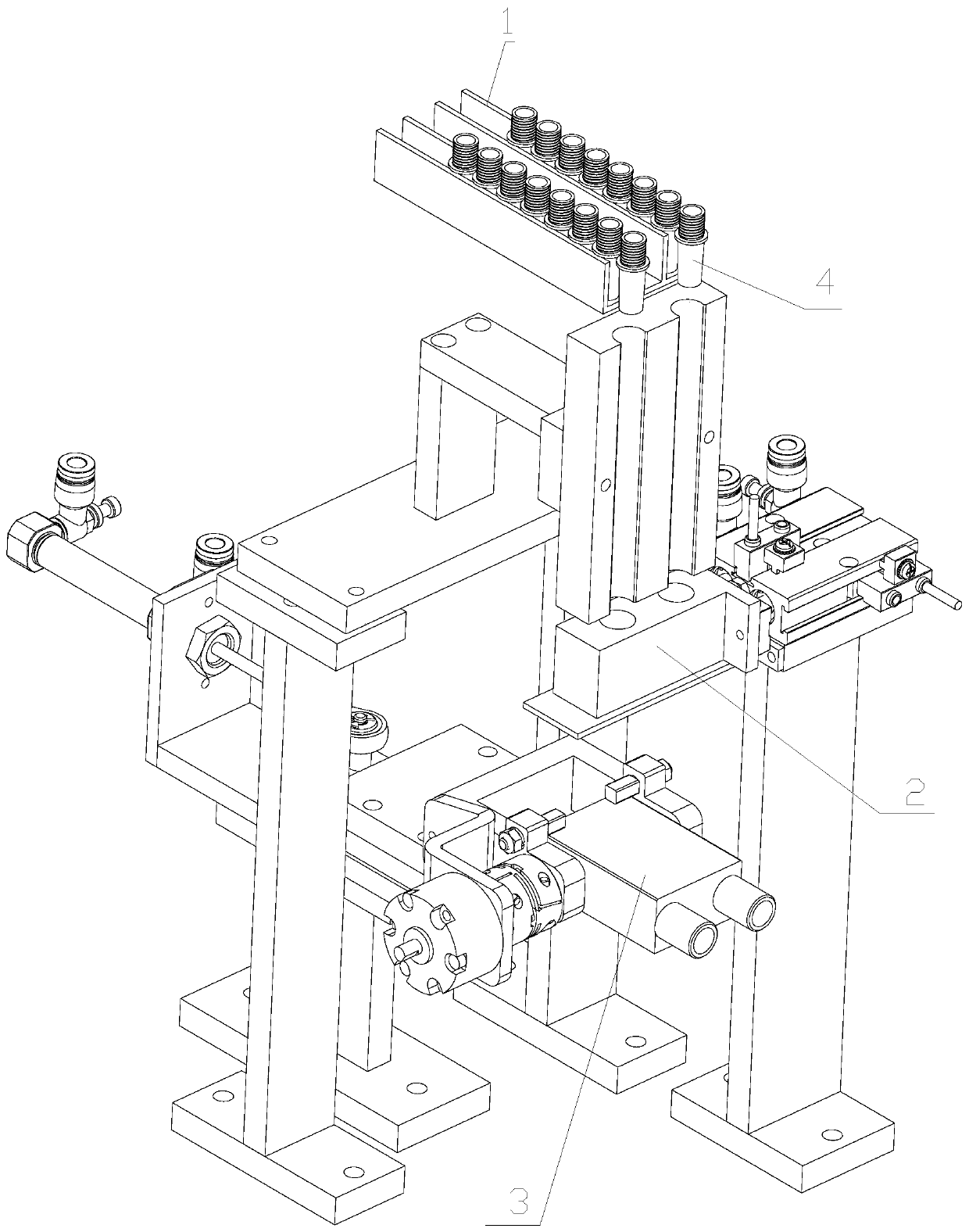

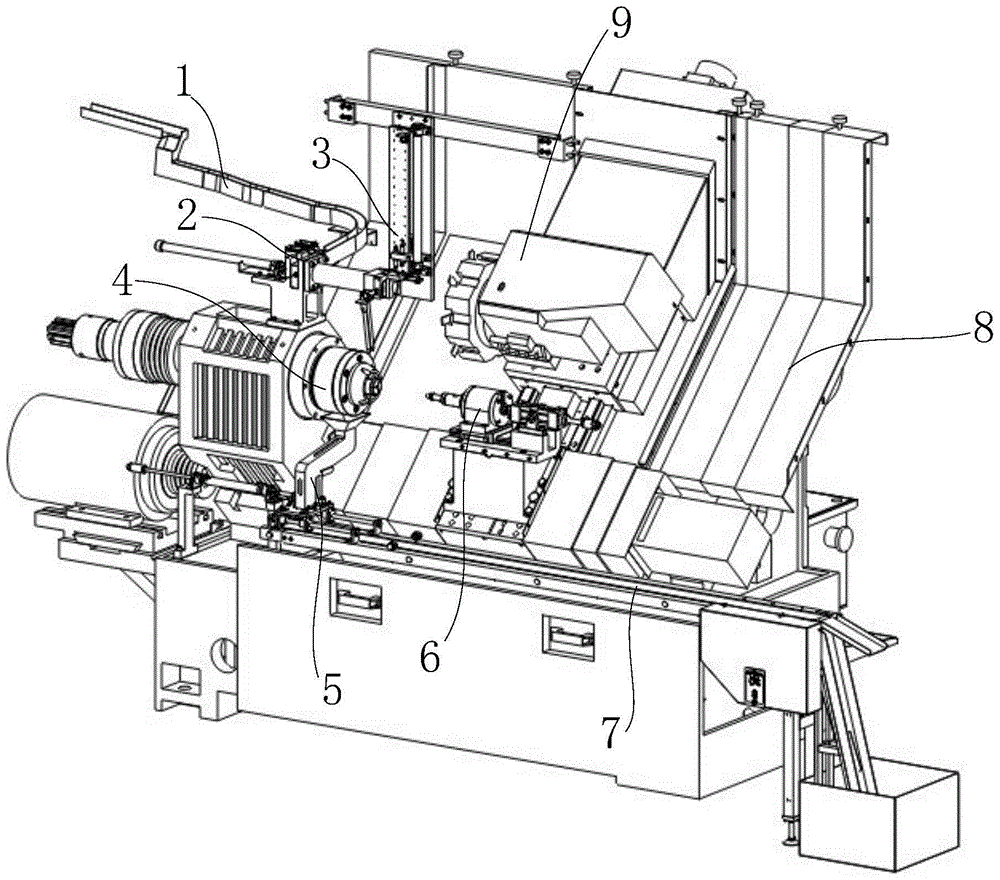

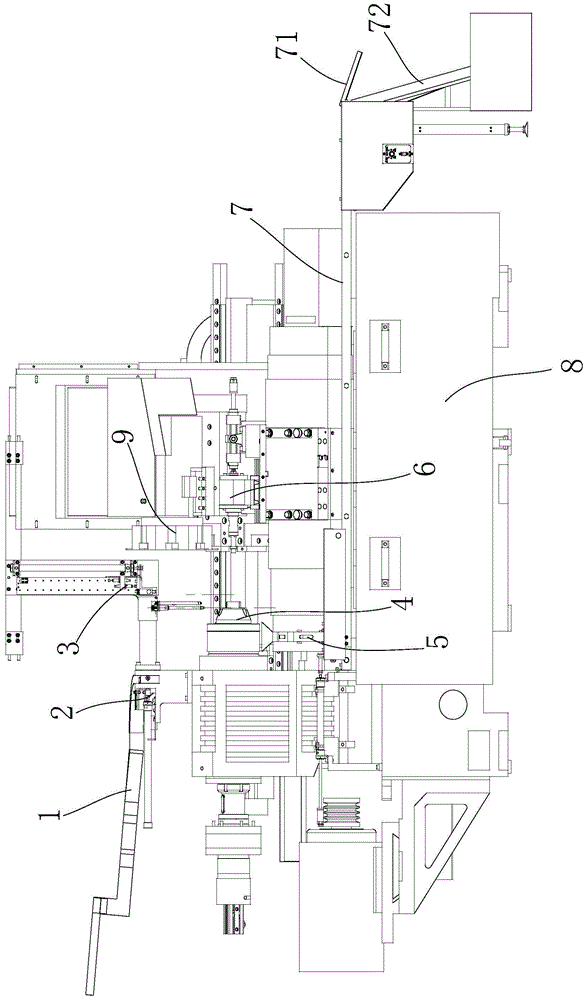

A CNC lathe

ActiveCN105345037BAchieve horizontal movementGuaranteed coaxialityWork clamping meansMetal working apparatusNumerical controlEngineering

The invention provides a numerical control lathe. The numerical control lathe comprises a lathe body. A main shaft and a tailstock are coaxially arranged on the lathe body. The numerical control lathe further comprises a feeding and distributing mechanism, a material pushing mechanism and a clamping mechanism. The clamping mechanism is located above a machining station or on one side of the machining station. The material pushing mechanism is located between the feeding and distributing mechanism and the clamping mechanism. The feeding and distributing mechanism distributes a workpiece out. The material pushing mechanism pushes the workpiece to the clamping mechanism. The clamping mechanism positions the workpiece between the main shaft and the tailstock. According to the numerical control lathe, feeding, discharging and machining can be automatic in the whole process, and automatic distributing, grabbing feeding and accurate positioning are achieved; and due to the main shaft rotating at a high speed, the workpiece can be expanded and disengaged, and the positioning precision and rigidity of the workpiece are ensured through the tail stock. According to the lathe, logistics and operation cabinet personnel are reduced, the machining efficiency is improved, the workpiece clamping and machining quality is improved, the yield is higher than 99%, and meanwhile installation and maintenance are convenient.

Owner:CHONGQING OUBOTE INTELLIGENT ROBOT TECH CO LTD

Die-cutting device and method

ActiveCN104760077BRealize automatic material distributionContinuous operationMetal working apparatusEngineeringContinuous operation

The invention provides a die cutting device and a method. The device comprises a frame, a conveying mechanism and a die cutting mechanism, wherein the dir cutting mechanism has a feed part and a discharge part mounted on the frame; the conveying mechanism conveys a basal material to be cut to pass through the die cutting mechanism; and the feed part and the discharge part are respectively positioned at the two sides of the die cutting mechanism. The device is characterized by further comprising a mold release towing mechanism and an ejection mechanism; the mold release towing mechanism is positioned below the discharge part, and downwards tows the cut basal material from the discharge part; the ejection device is arranged between the discharge part and the mold release towing mechanism, and has a projection; and the projection can be corresponding to the cut basal material at the inner side, and is outwards projected on the cut basal material. After an automatic film die cutting device is applied, the automatic material separation after the die cutting and the continuous operation can be realized, one person is only needed to operate, the working efficiency is improved, and the labor is saved.

Owner:ANHUI JINGZHUO OPTICAL DISPLAY TECH CO LTD

Intelligent material dividing mechanism

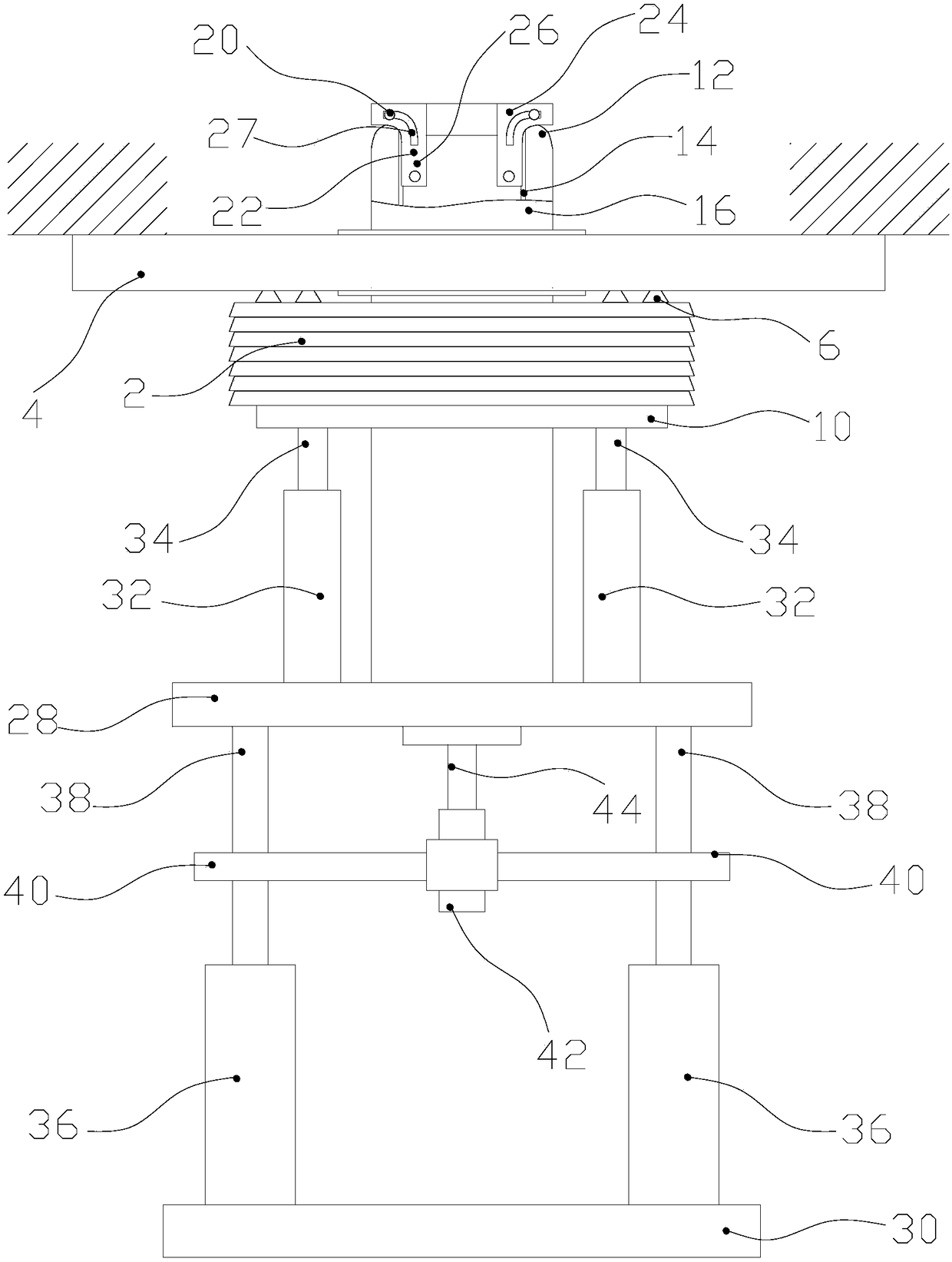

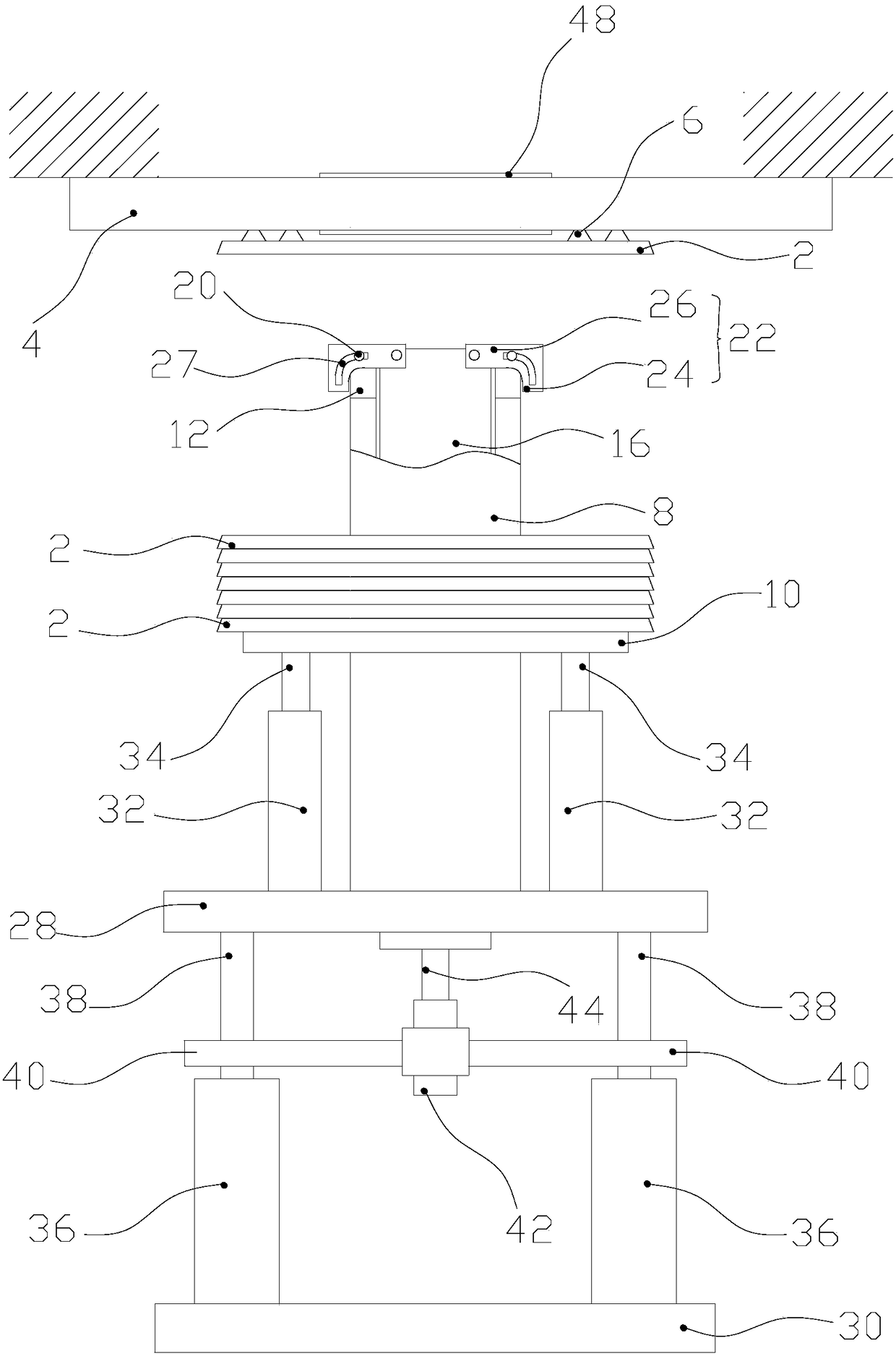

ActiveCN108557492ARealize automatic material distributionDe-stacking articlesMechanical engineeringEngineering

The invention discloses an intelligent material dividing mechanism used for material dividing of sheet-shaped workpieces with center holes. The intelligent material dividing mechanism is characterizedby comprising a horizontally arranged top plate (4), a material accumulating pipe (8) located under the top plate (4) and driven by a second power device to rise and fall, at least two openings (12)formed in the top of the material accumulating pipe (8), a supporting plate (22) arranged in the openings (12), and a first power device used for driving workpieces (2) located on the material accumulating pipe (8) to move upwards. The intelligent material dividing mechanism can achieve automatic separation of the workpiece (2) automatically accumulated on the most top of the material accumulatingpipe (8) and other workpieces (2), and therefore automatic material dividing is completed so as to solve the problems in the prior art.

Owner:郑玉锋

Heat preservation cotton sliver distributing device

ActiveCN112777342ARealize automatic material distributionReduce labor intensityArticle separationEngineeringHeat conservation

The invention discloses a heat preservation cotton sliver distributing device. The device comprises a conveying mechanism, a horizontal moving mechanism capable of moving front and back is installed on a rack of the conveying mechanism, and a material taking mechanism capable of moving left and right is installed on the horizontal moving mechanism. The material taking mechanism comprises a plurality of plug pin modules and a power source, the plug pin modules are arranged left and right and slidably mounted on a rack of the horizontal moving mechanism, the power source is arranged on the rack of the horizontal moving mechanism and used for enabling the plug pin modules at the two sides to move left and right relatively, and the plug pin modules are divided into two or three groups; and a material pushing mechanism which moves back and forth is installed at the position, located above the material taking mechanism, of the horizontal moving mechanism, and the pointing direction of the plug pin modules in the material taking mechanism and the pointing direction of the material pushing mechanism are both opposite to the conveying direction of the conveying mechanism. In the color steel insulation board production process, insulation cotton slivers can be automatically laid at the left sides and the right sides of two color steel boards, the labor intensity of operators is reduced, time and labor are saved, the production efficiency is improved, and the requirement for mass production of color steel insulation boards can be met.

Owner:辽宁鑫硕智能机械有限公司

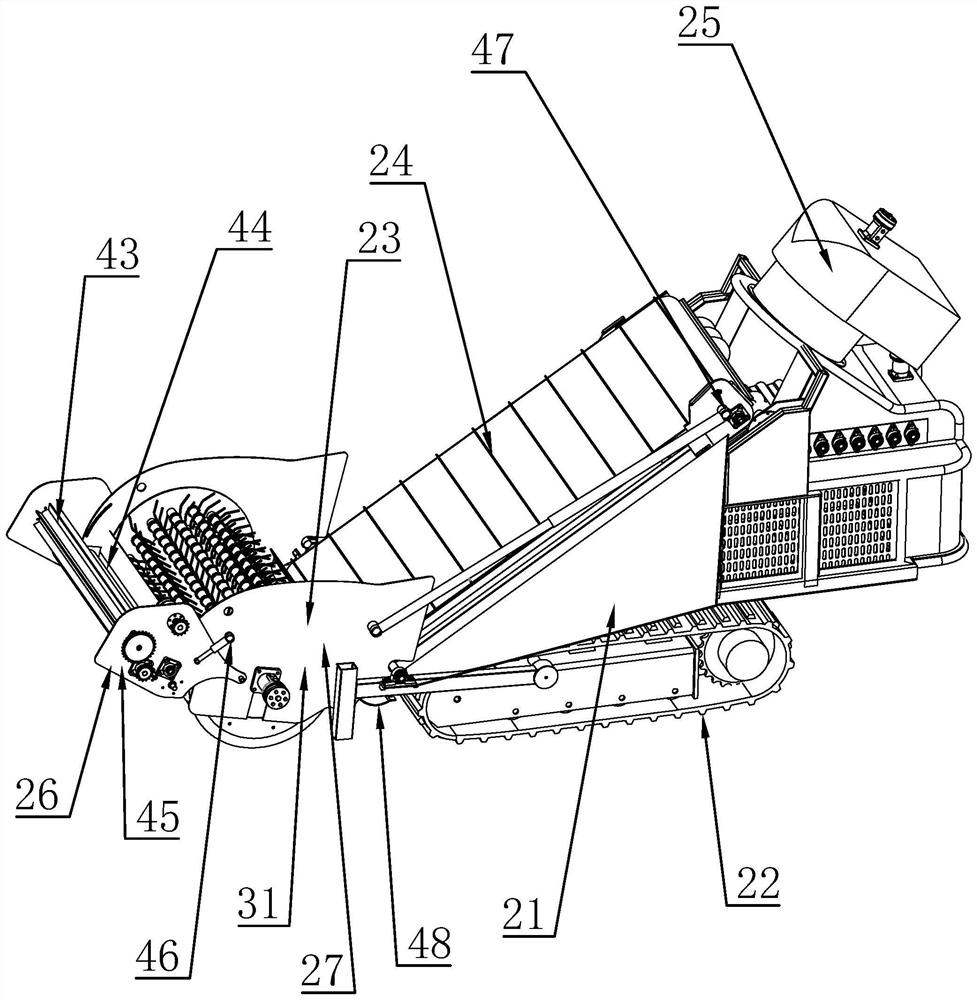

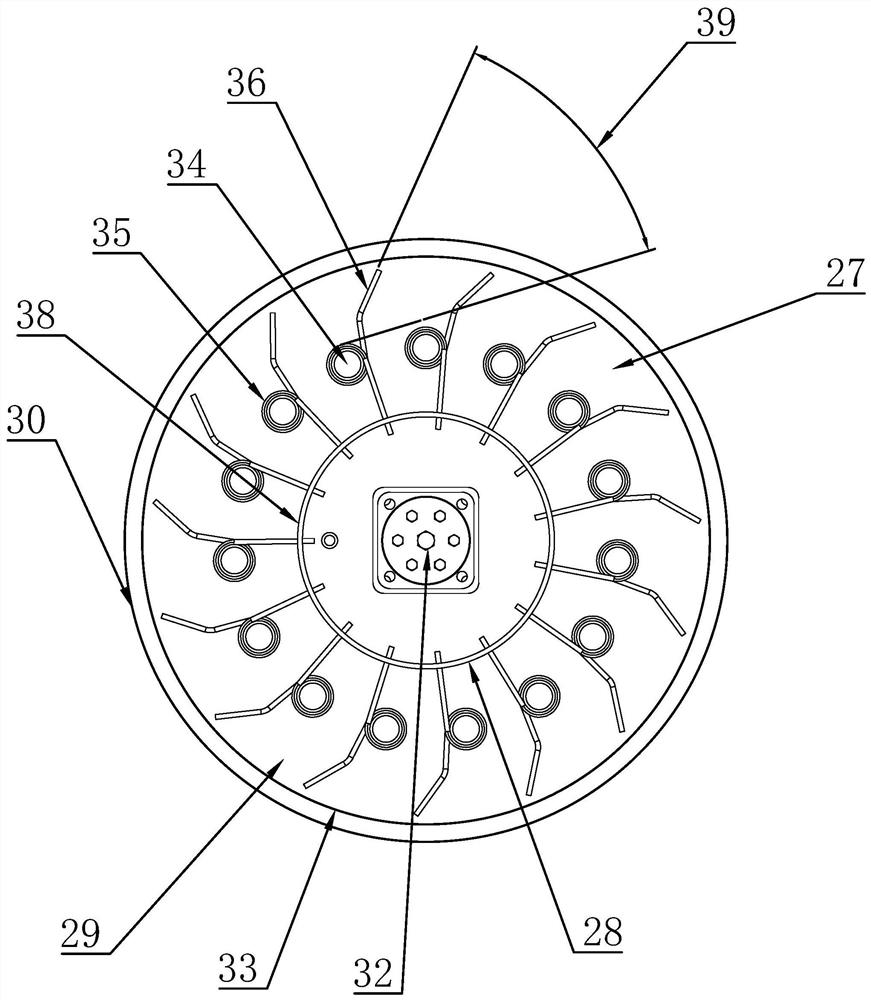

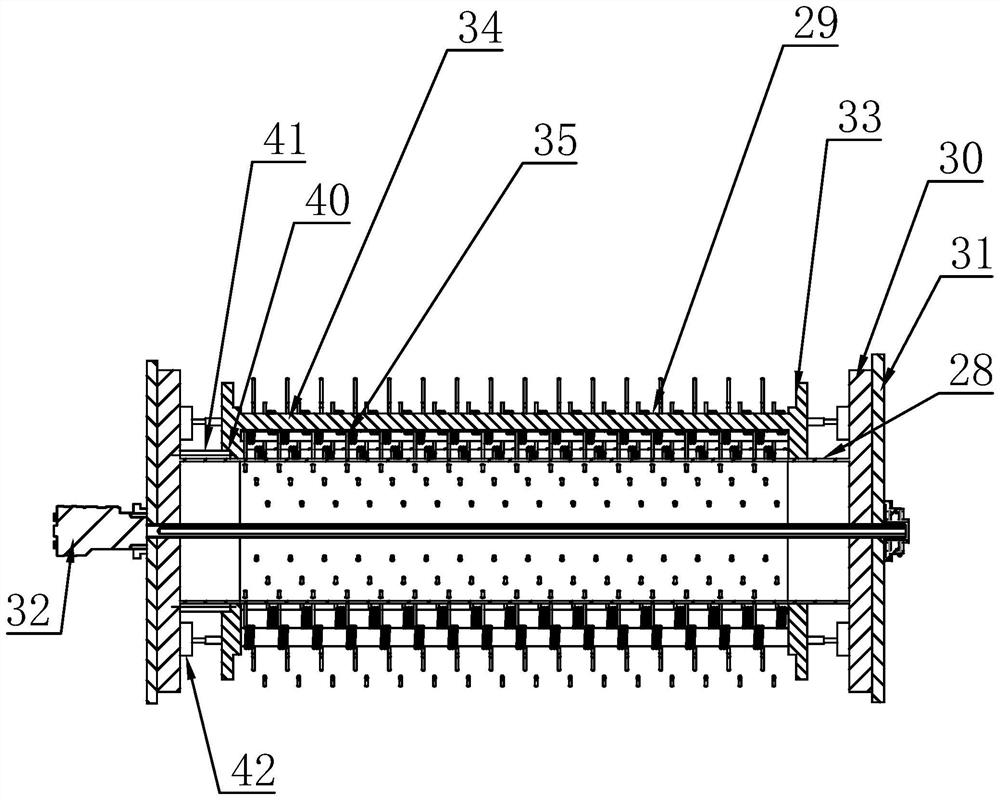

Green soybean harvester

ActiveCN113016342AEasy to adjustEasy to operateSievingGas current separationAgricultural cropsAgricultural engineering

The invention provides a green soybean harvester, and belongs to the technical field of crop harvesting devices. The green soybean harvester solves the problems of an existing green soybean harvester. A green soybean picking structure of the green soybean harvester comprises a rotating shaft and a green soybean picking barrel, wherein the rotating shaft can rotate circumferentially; the green soybean picking barrel comprises two fixing plates and green soybean picking rollers which are arranged between the two fixing plates and fixedly connected with the fixing plates; the rotating shaft is sleeved with the green soybean picking barrel; the green soybean picking barrel is fixedly connected with the rotating shaft; the plurality of green soybean picking rollers are arranged in the circumferential direction of the rotating shaft; the green soybean picking rollers are sleeved with a plurality of comb teeth in the length direction of the green soybean picking rollers; the green soybean picking rollers are sleeved with the middles of the comb teeth; the two ends of each comb tooth are provided with a first supporting foot and a second supporting foot respectively; the first supporting feet extend outwards away from the rotating shaft; the second supporting feet are inserted into positioning holes which are formed in the rotating shaft and correspond to the second supporting feet in the diameter direction of the rotating shaft; green soybean picking angles are formed between the first supporting feet and the rotating direction of the green soybean picking barrel; and the green soybean picking structure is further provided with a green soybean picking angle adjusting mechanism for adjusting the green soybean picking angles. The green soybean harvester is high in universality and more efficient in green soybean picking.

Owner:JINHUA ACAD OF AGRI SCI

Purification plate machining, cutting and separating device

InactiveCN113492231AAdjust cutting widthEasy to operateMetal sawing devicesGear wheelElectric machinery

The invention relates to the technical field of purification plates, in particular to a purification plate machining, cutting and separating device. The purification plate machining, cutting and separating device comprises a workbench, a cutting seat is mounted on the workbench, a carrier roller is arranged on the inner bottom face of the cutting seat, a clamping roller is mounted on the inner wall of the cutting seat, two sets of pressing strips are arranged above the clamping roller, a plurality of mounting grooves are formed in the inner bottom face of the cutting seat, steering mechanisms are mounted in the mounting grooves, a discharging port is formed in the side wall of the cutting seat, cylinders are mounted on the two sides of the cutting seat, a cross beam is mounted at the tops of the cylinders, and two mounting plates are mounted on the lower surface of the cross beam. When the cutting width of a purification plate needs to be adjusted, a third motor is controlled to drive a third gear to rotate, a threaded cylinder rotates along with the third gear, the threaded cylinder can transversely move along a lead screw, the threaded cylinder and a first-stage bearing are relatively fixed in position, the first-stage bearing and a movable table are fixedly connected through a fixed block, then the movable table can transversely move, and then the cutting width of the purification plate can be adjusted by adjusting the position of a cutting mechanism.

Owner:重庆骊联森净化设备科技有限公司

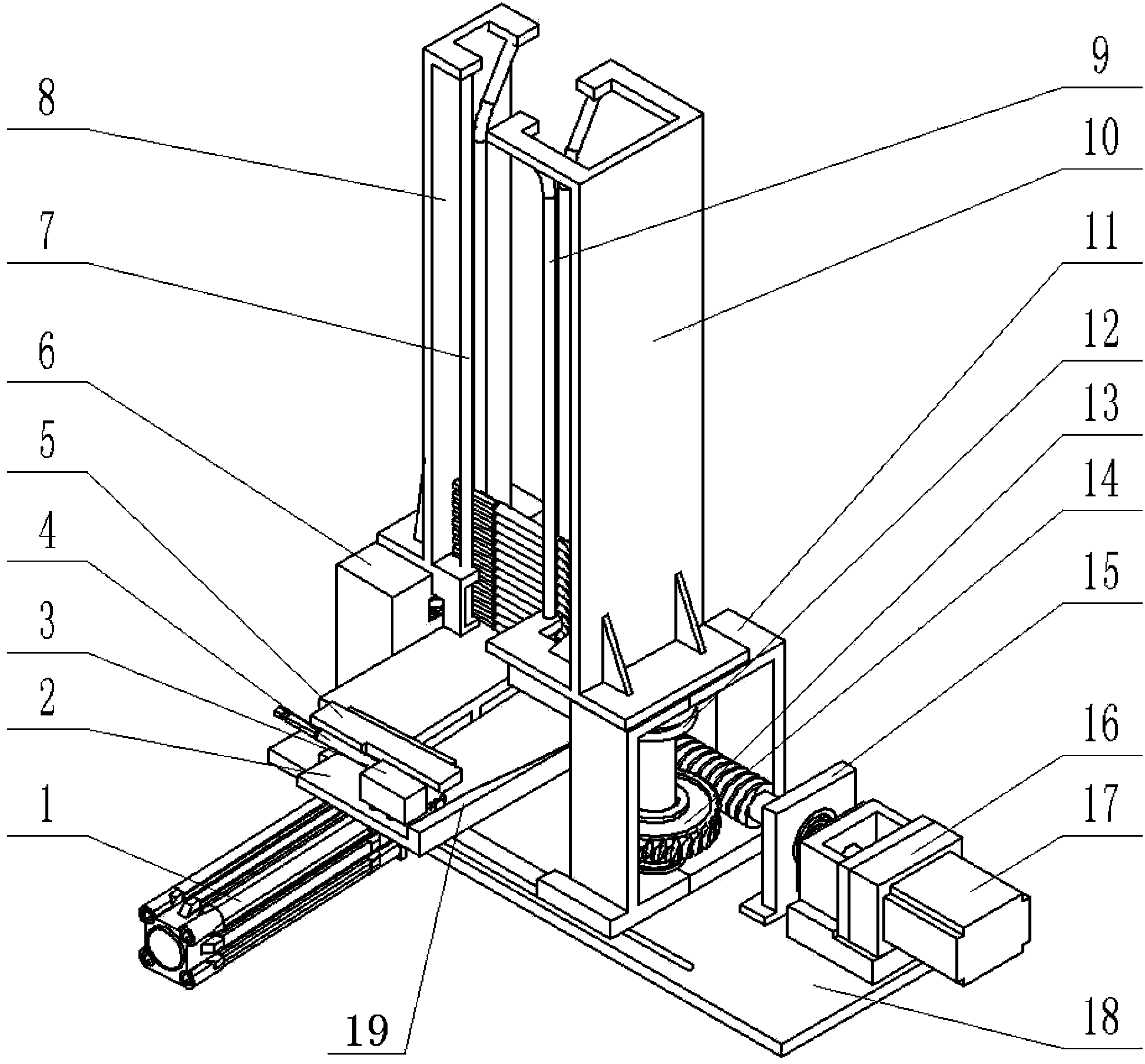

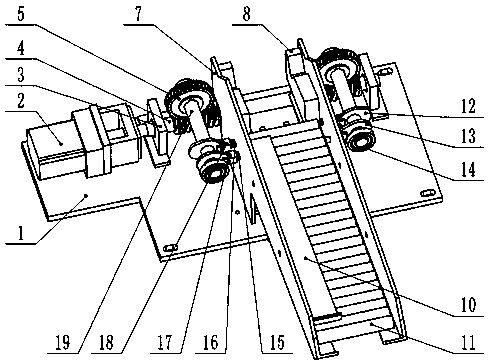

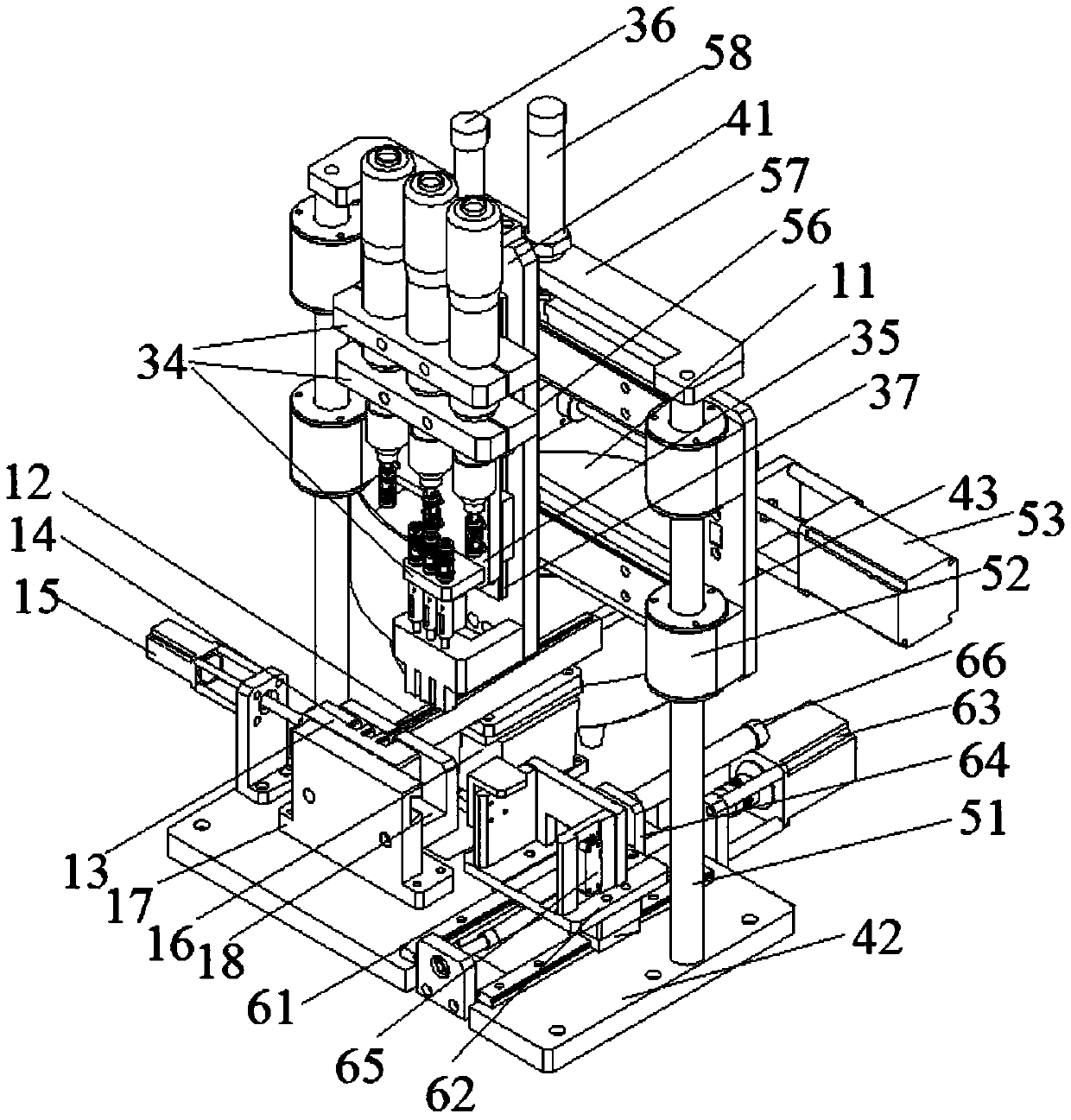

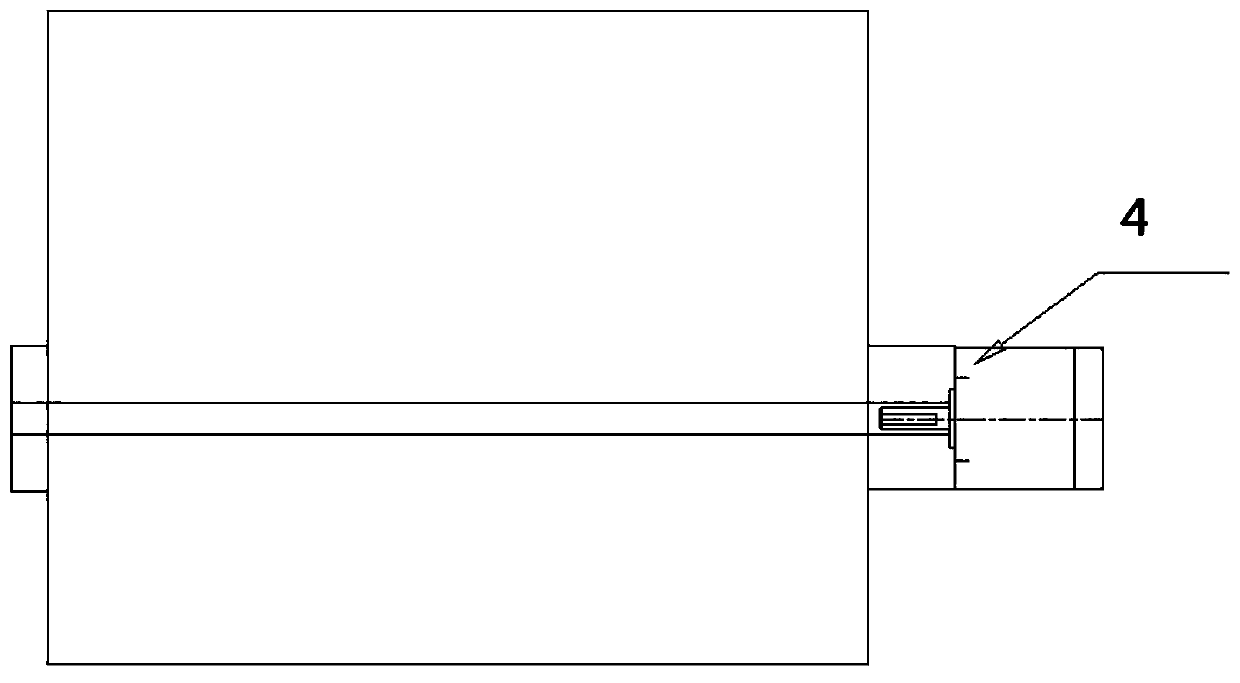

Automatic insertion machine

InactiveCN103803307BRealize automatic material distributionRealize the purpose of positioning the plug-in diskStacking articlesHuman–machine interfaceProgrammable logic controller

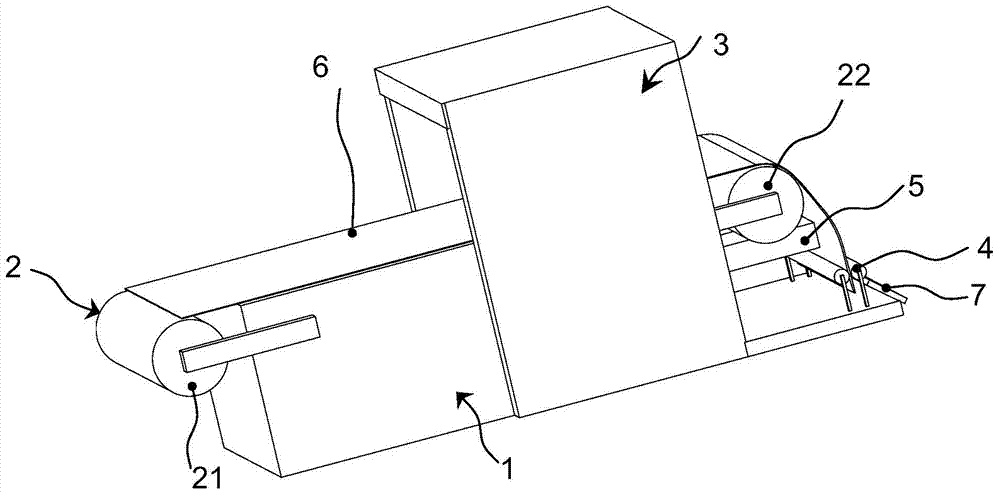

The invention discloses an automatic disk inserting machine with a ceramic ferrule for automatically inserting disks and locating. The automatic disk inserting machine comprises a distributing device (1), a head and tail recognition device (2), an automatic dislocation device (3), a disk inserting device (4), a two-axis mobile device (5) and a control device (6); the distributing device comprises a charging basket, a distributing plate and a drive motor; the head and tail recognition device comprises a head and tail recognition sensor, a head and tail reversing device, a drive motor and a pushing cylinder; the automatic dislocation device comprises a storage pipe, a dislocation mechanism, a dislocation cylinder and the like; the disk inserting device comprises a sensor, a sideslip type production positioning runner and a pressing mechanism; the two-axis mobile device comprises an X axis, a Y axis, an X-axis servo motor and a Y-axis servo motor; the control device comprises a PLC (programmable logic controller), a human-computer interface, a button, etc. According to the automatic disk inserting machine provided by the invention, the assembly of the parts can improve the efficiency, reduce the human cost and achieve the aim of the automatic production positioning of the ceramic ferrule.

Owner:昆山迎翔光电科技有限公司

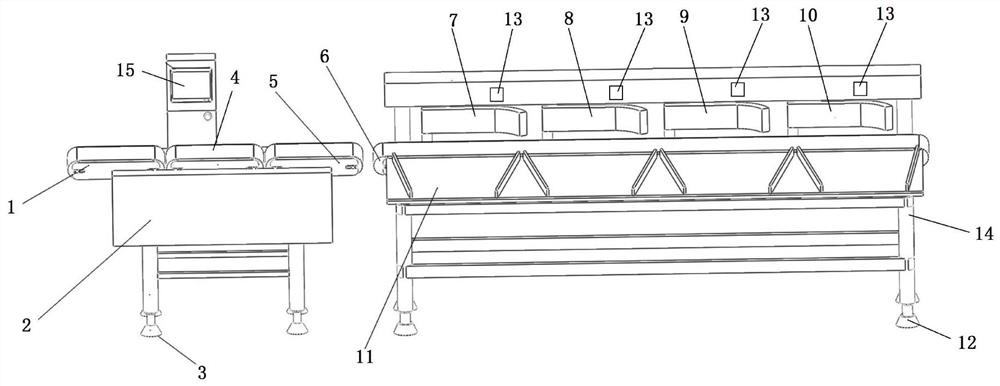

Automatic yarn splitting machine

The invention provides an automatic yarn splitting machine comprising a first support and a second support. A yarn feeding conveying belt device, a weighing and yarn feeding integrated conveying beltdevice and a yarn discharging conveying belt device are arranged on the first support; a yarn splitting conveying belt device is arranged on the second support; a baffle is connected to the upper sidewall of the second support; the baffle is provided with a first yarn splitting kicking and conveying shifting piece device, a second yarn splitting kicking and conveying shifting piece device, a third yarn splitting kicking and conveying shifting piece device and a fourth yarn splitting kicking and conveying shifting piece device; infrared sensors are arranged above the devices; and the infraredsensors, the yarn feeding conveying belt device, the weighing and yarn feeding integrated conveying belt device, the yarn discharging conveying belt device, the yarn splitting conveying belt device, the first yarn splitting kicking and conveying shifting piece device, the second yarn splitting kicking and conveying shifting piece device, the third yarn splitting kicking and conveying shifting piece device and the fourth yarn splitting kicking and conveying shifting piece device are connected with a controller respectively. By means of the automatic yarn splitting machine, the problems that inthe prior art, the labor intensity of manual yarn splitting is large, and yarn splitting errors are prone to occurring are solved.

Owner:苏州淮龙科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com