Heat preservation cotton sliver distributing device

A material dividing device and sliver technology, applied in pile separation, thin material handling, object separation, etc., can solve the problems of low production efficiency, inability to meet the requirements of mass production of color steel insulation boards, and high labor intensity of operators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

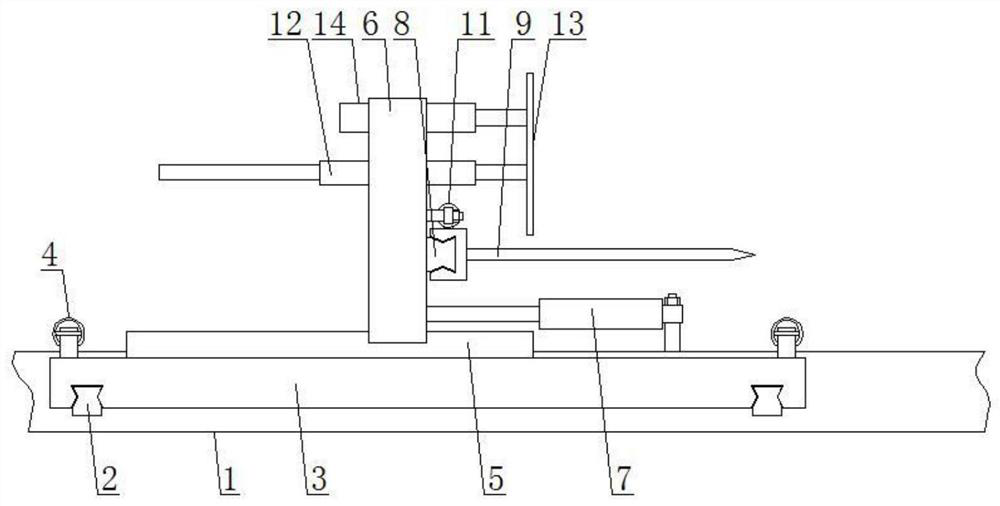

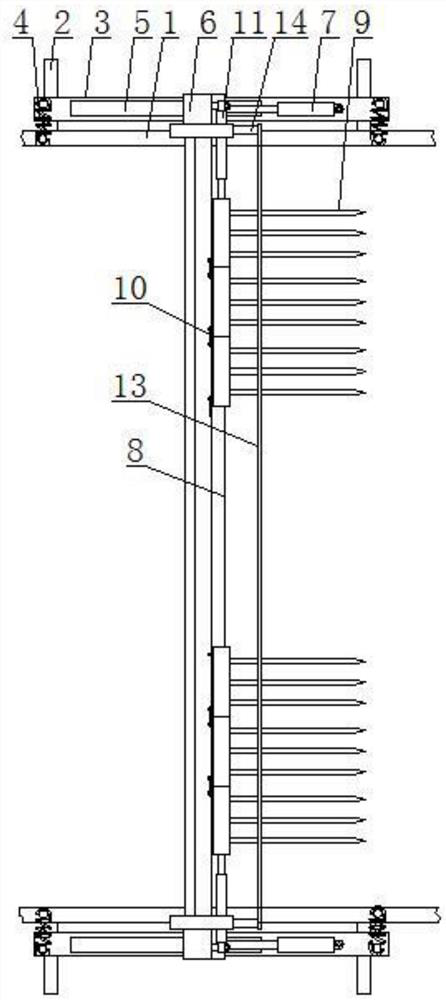

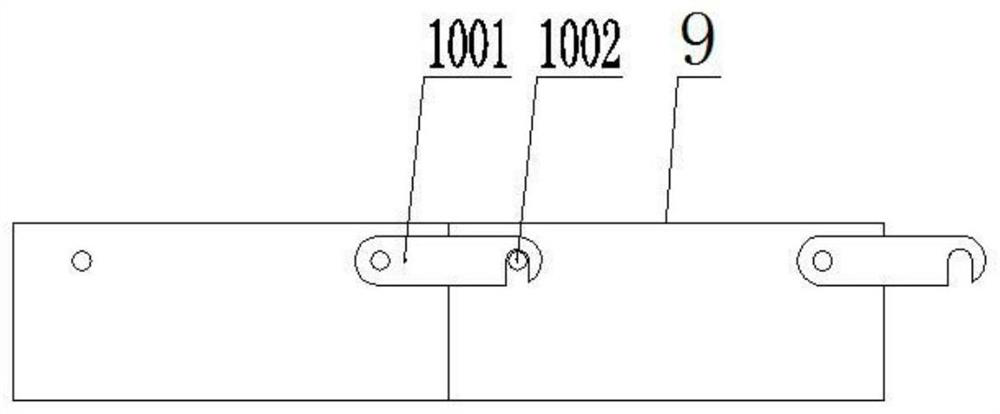

[0019] Such as Figure 1-Figure 3 As shown, a thermal insulation cotton sliver distributing device includes a conveying mechanism, a balance frame 3 sliding left and right is installed on the conveying mechanism frame 1 through the first slideway 2, and between the two sides of the conveying mechanism frame 1 and the balance frame 3 The extension springs 4 are respectively connected between them, and a translation mechanism that moves forward and backward is installed on the balance frame 3. The translation mechanism includes a translation mechanism frame 6 installed on the conveying mechanism frame 1 through the second slideway 5 and a mechanism connected to the conveying mechanism machine. The first cylinder 7 between the frame 1 and the translation mechanism frame 6 is installed on the translation mechanism frame 6 to move left and right. The material retrieval mechanism includes six left and right arrangements and is installed on the The pin modules 9 on the translation me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com