Automatic insertion machine

A disk insertion machine and automatic technology, which is applied to the stacking, transportation and packaging of objects, can solve the problems of low efficiency of pure manual work, and achieve the effect of simple structure, high efficiency and production capacity, and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

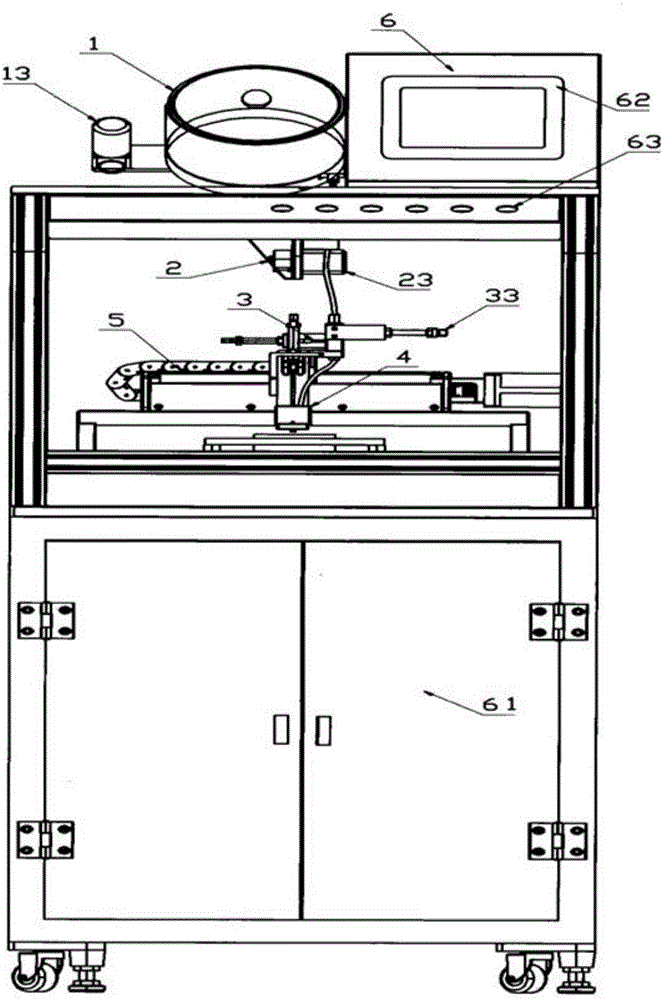

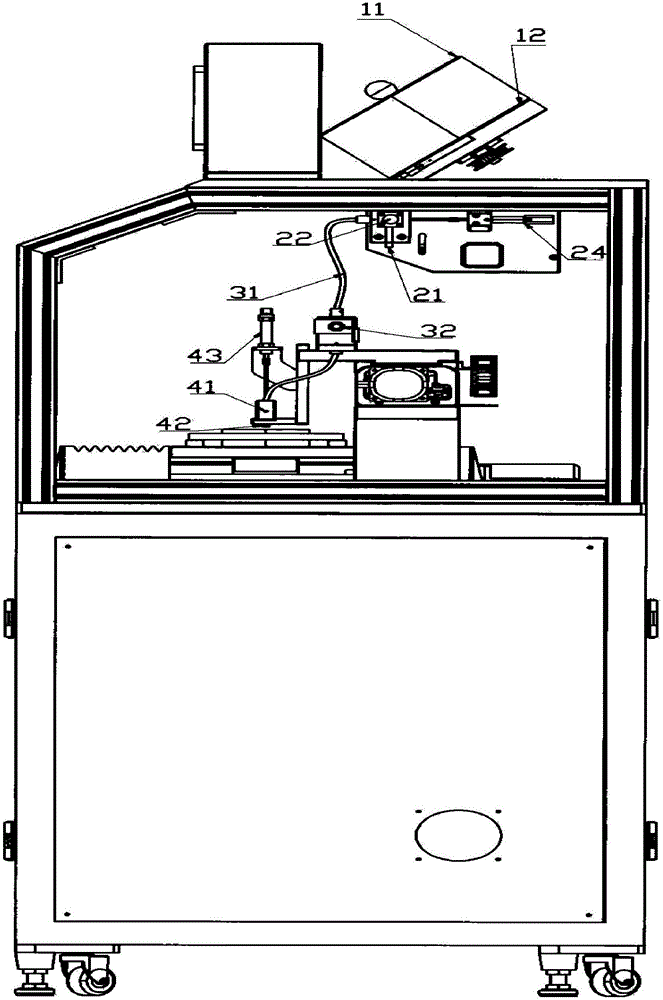

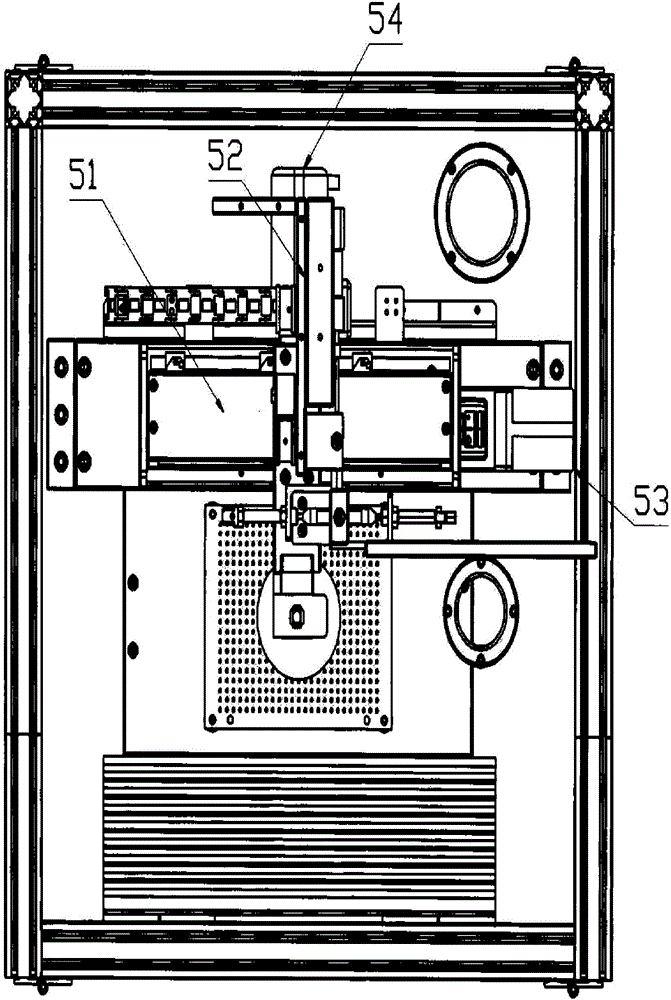

[0028] Below in conjunction with the accompanying drawings, the technical solutions involved in the present invention are clearly and completely described, as figure 1 , figure 2 , image 3 As shown, the present invention discloses an automatic disk insertion positioning assembly, and its working process is as follows:

[0029] As shown in the figure, the entire assembly is controlled by PLC61, and parameter adjustment is realized by man-machine interface 62. First, pour the product into the charging barrel 11, which is circular, and the bottom is equipped with a distribution tray 12 with a distribution groove on the edge of the center of the circle. The distribution tray 12 is connected to the drive motor 13, press the button 63 to start, and the The motor 13 drives the material distribution plate 12 to rotate. There is a material distribution trough on the material distribution plate. The products falling into the material distribution trough will be sorted and sent to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com