Automatic chip insertion machine

A chip inserter, fully automatic technology, applied in sustainable manufacturing/processing, electrical components, climate sustainability, etc., can solve the problems of high risk, difficult manual operation, easy to damage chip inserts, etc., to reduce the size of the equipment , Solve the effect of wire winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

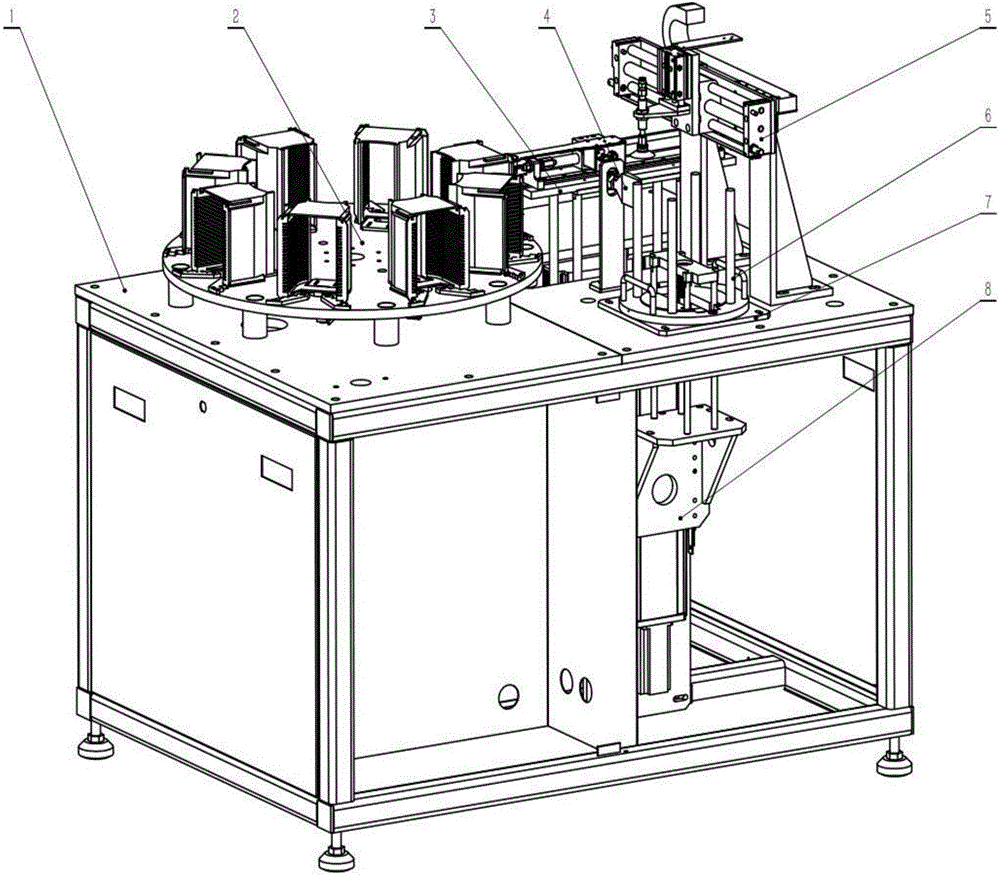

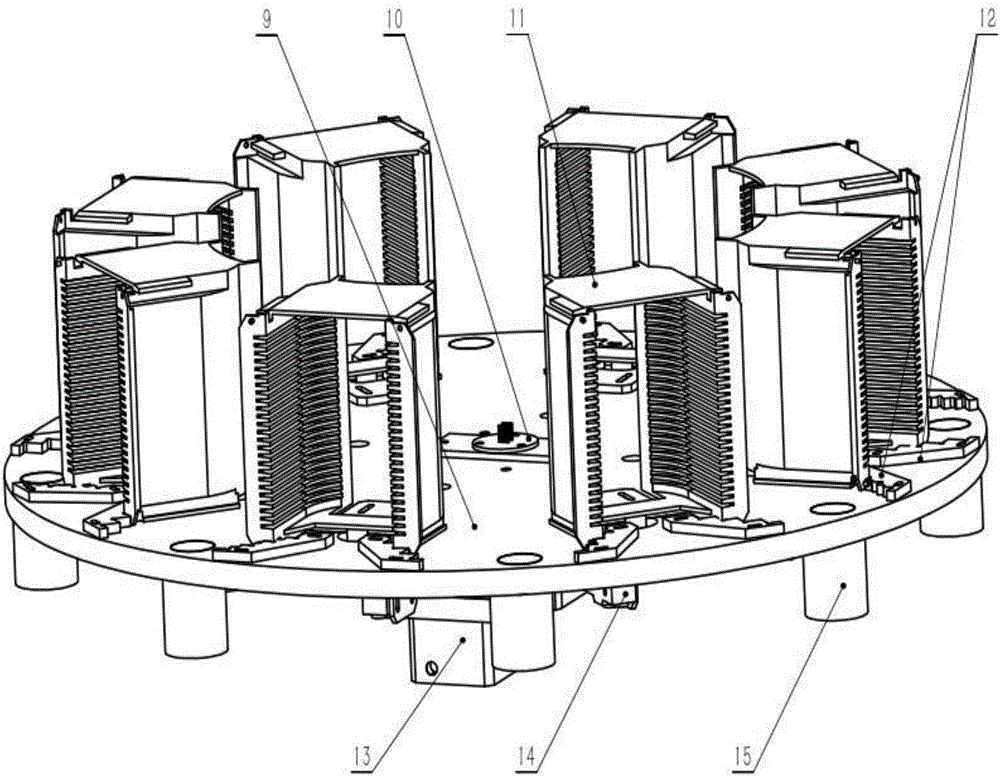

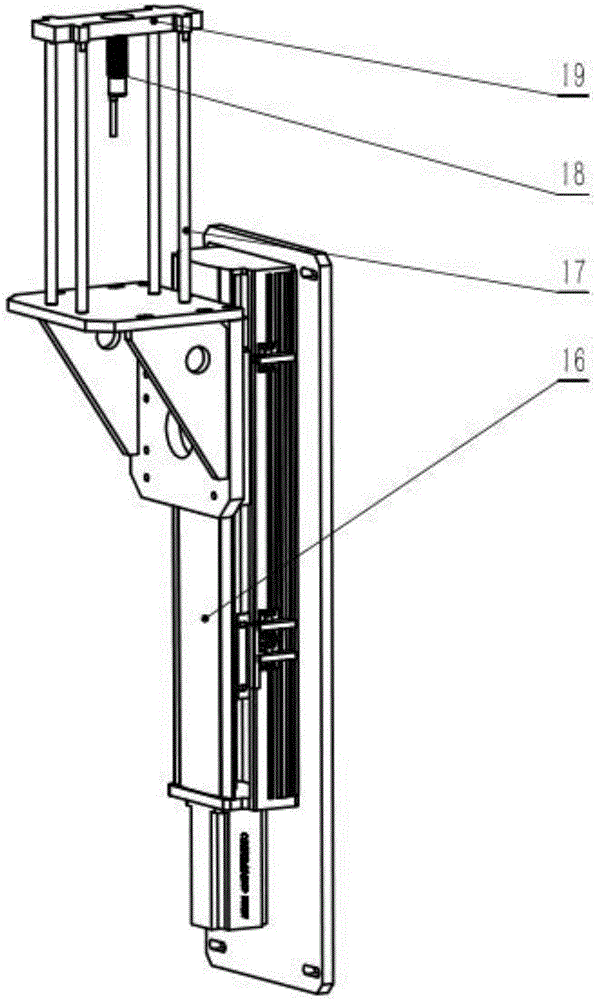

[0018] refer to figure 1 , figure 2 , image 3 , Figure 4 with Figure 5 , the present invention comprises equipment frame 1, blue tool rotating device 2, silicon wafer into blue device 3, blowing port 4, sucker pick-up device 5, silicon wafer box 6, fixed bottom plate 7, silicon wafer elevating device 8; Said equipment A tool rotating device 2 is installed on the left side of the upper end face of the frame 1, and the tool rotating device 2 includes a rotating disk 9, a conductive slip ring 10, a bearing box 11, a positioning block 12 of the bearing box, a hollow turntable 13, and a micro switch 14 and button switch 15, the conductive slip ring 10 is connected with the hollow turntable 13, the hollow turntable 13 is connected with the rotating disk 9, and the bearing box positioning block 12 is fixed on the rotating disk 9 by bolts; the lower right end of the equipment frame 1 is installed with Wafer lifting device 8, bottom plate 7 is installed on the upper right end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com