Deeply digging, cultivating and seeding unit

A unit and subsoiling technology, which is applied in the direction of tillage machines, agricultural machinery and equipment, agricultural machinery and implements, etc. It can solve problems such as blockage, entanglement, and the diameter of surface crops and weeds are easy to be chopped.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

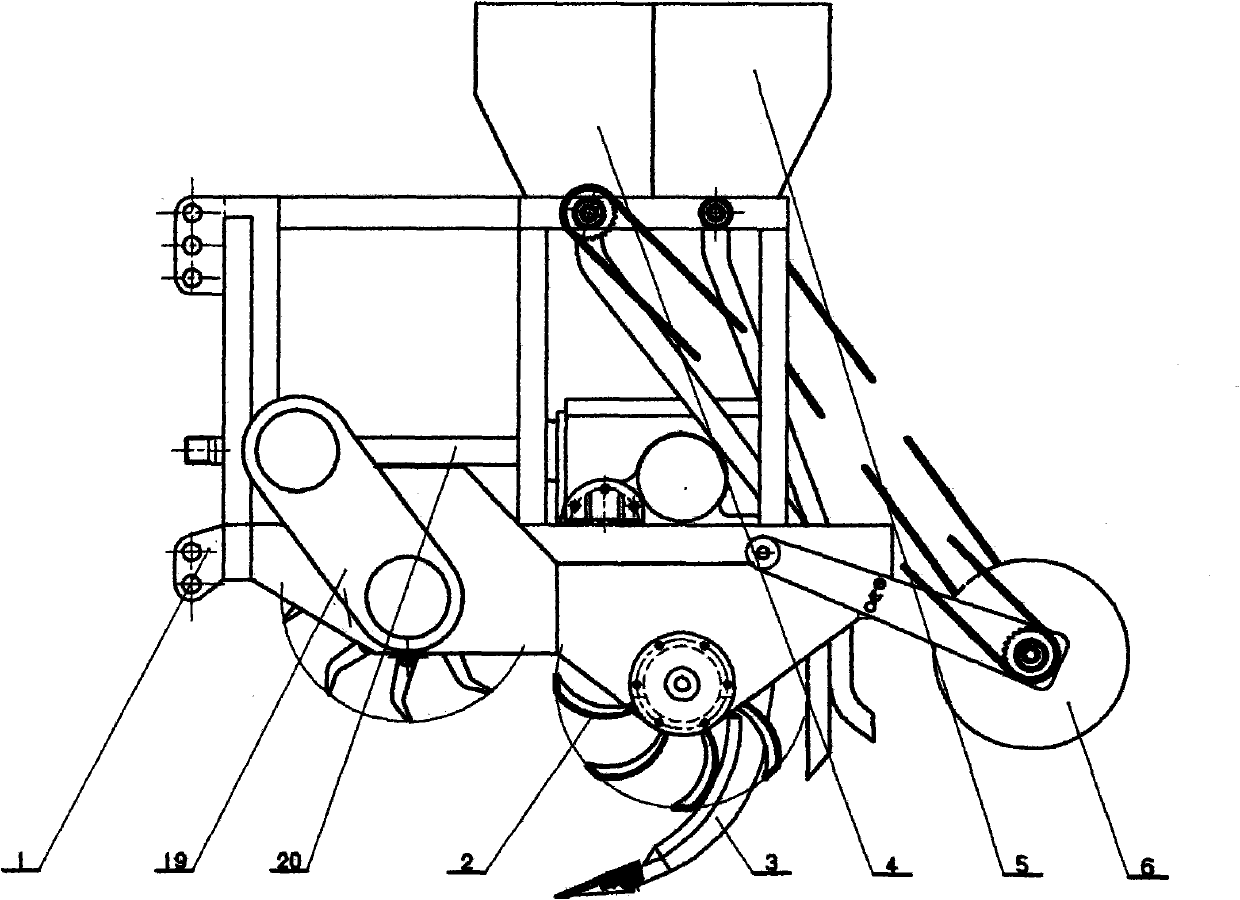

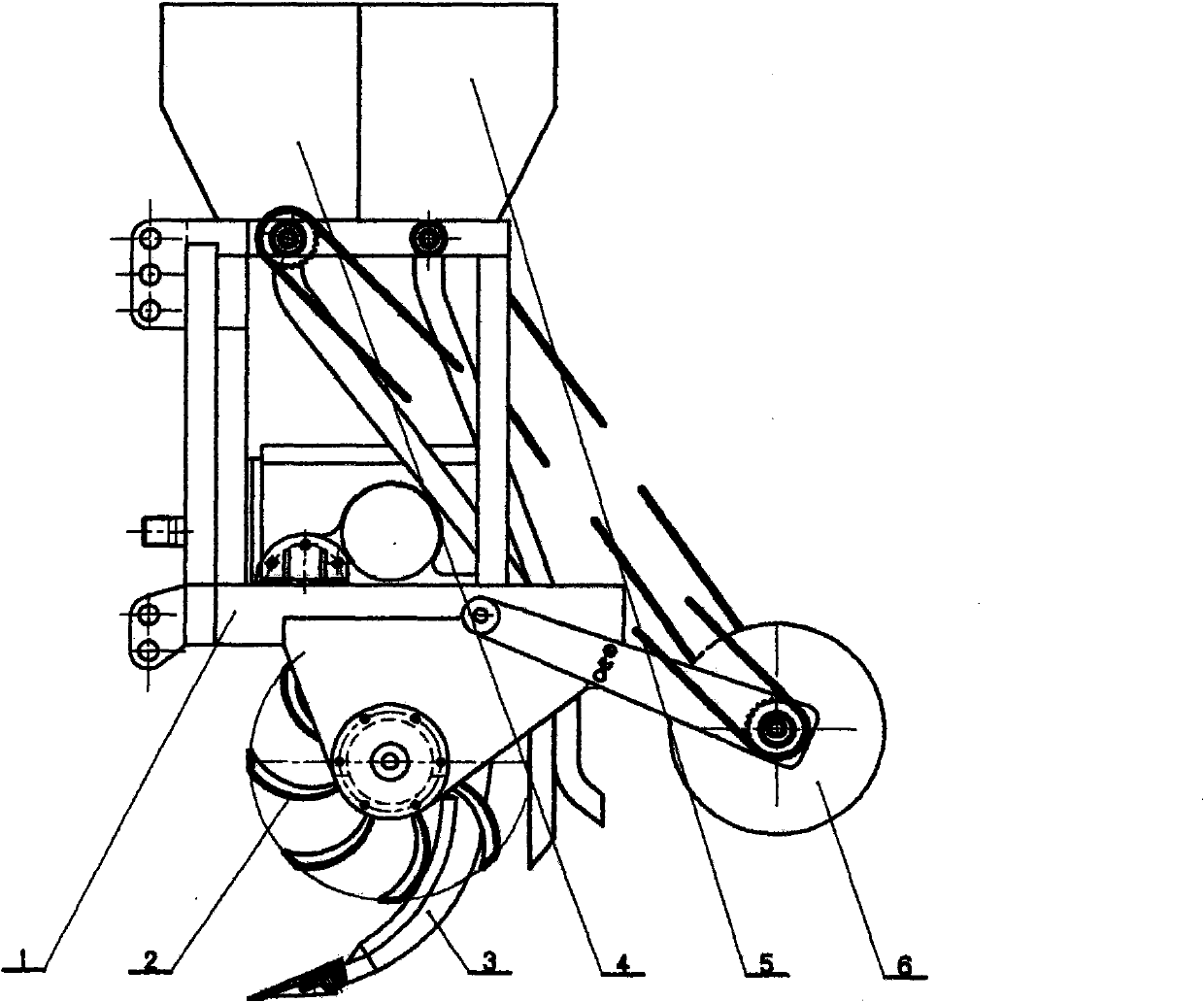

[0017] The subsoiling plowing and sowing unit of the present invention is mainly composed of frame 1, rotary tiller 2, subsoiling shovel 3, fertilizer applicator 4, seeder 5, suppressor 6 and stalk returning machine 19 etc., specific implementation is as follows:

[0018] 1. The straw returning machine 19 is directly installed on the frame in front of the rotary tiller 2, and a transmission shaft 20 is installed between the straw returning machine 19 and the rotary tiller 2, and the power output by the tractor is transmitted to the straw returning machine Rotary tiller 2 is passed to rotary tiller 2 through transmission shaft 20 again after machine 19; figure 1 ).

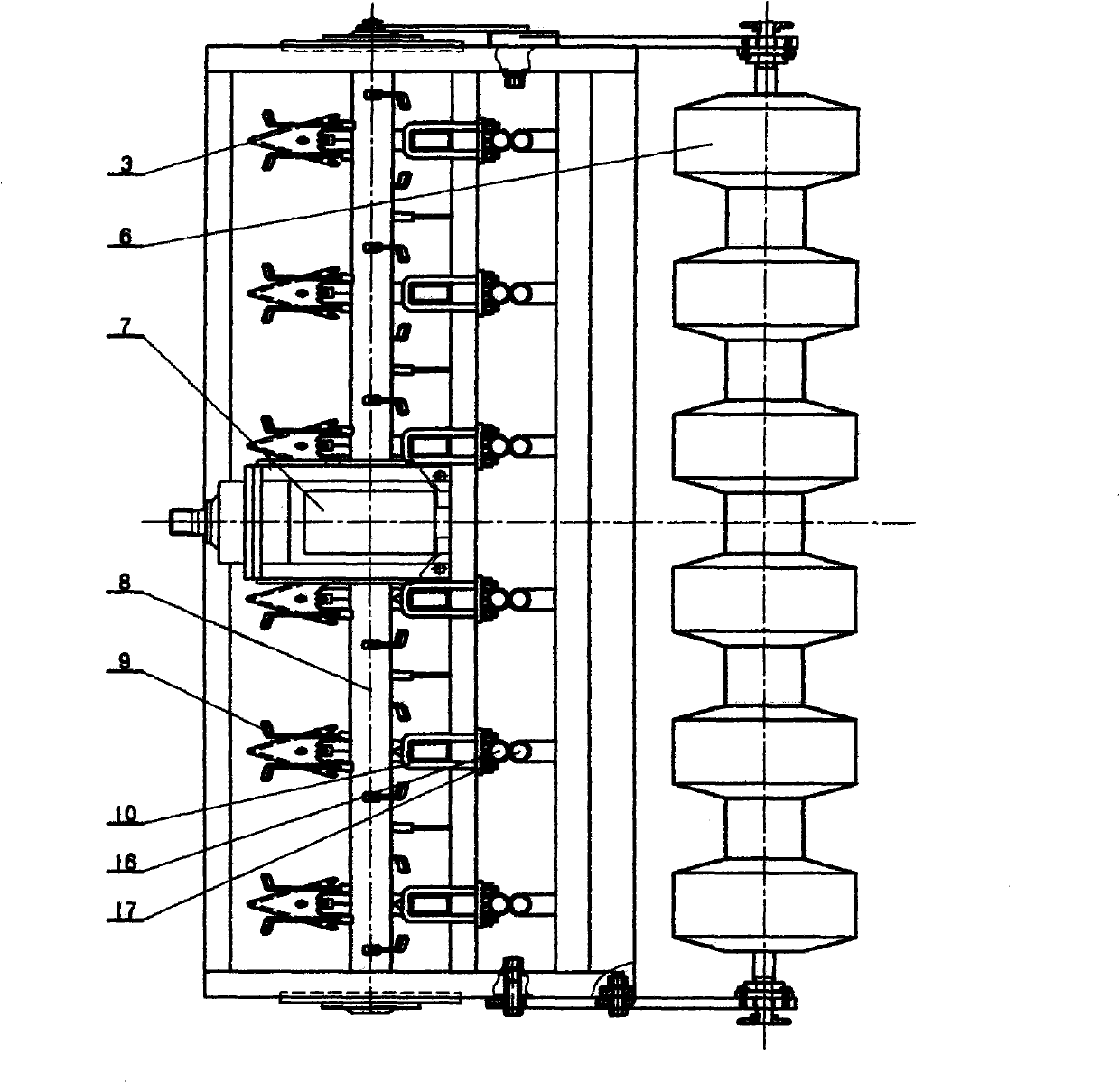

[0019] 2. The subsoiling shovel 3 is fixed on the crossbeam of the frame 1 through the U-shaped bolt 10 (installed on the front or rear of the rotary blade shaft 8), and the two adjacent rotary blades in the rotary tiller 2 9 through the gap (see image 3 ), the installation height of the subsoiling shovel 3 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com