Flexible automatic distribution device for deformed bar materials

A material distributing device and bar material technology, applied in metal processing, etc., can solve problems affecting processing quality and production efficiency, difficulty in completing order tasks on time, recruitment and management difficulties, etc., to reduce the impact of human factors and labor input, ease Difficulties in recruitment and management, and the effect of improving utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with drawings and embodiments.

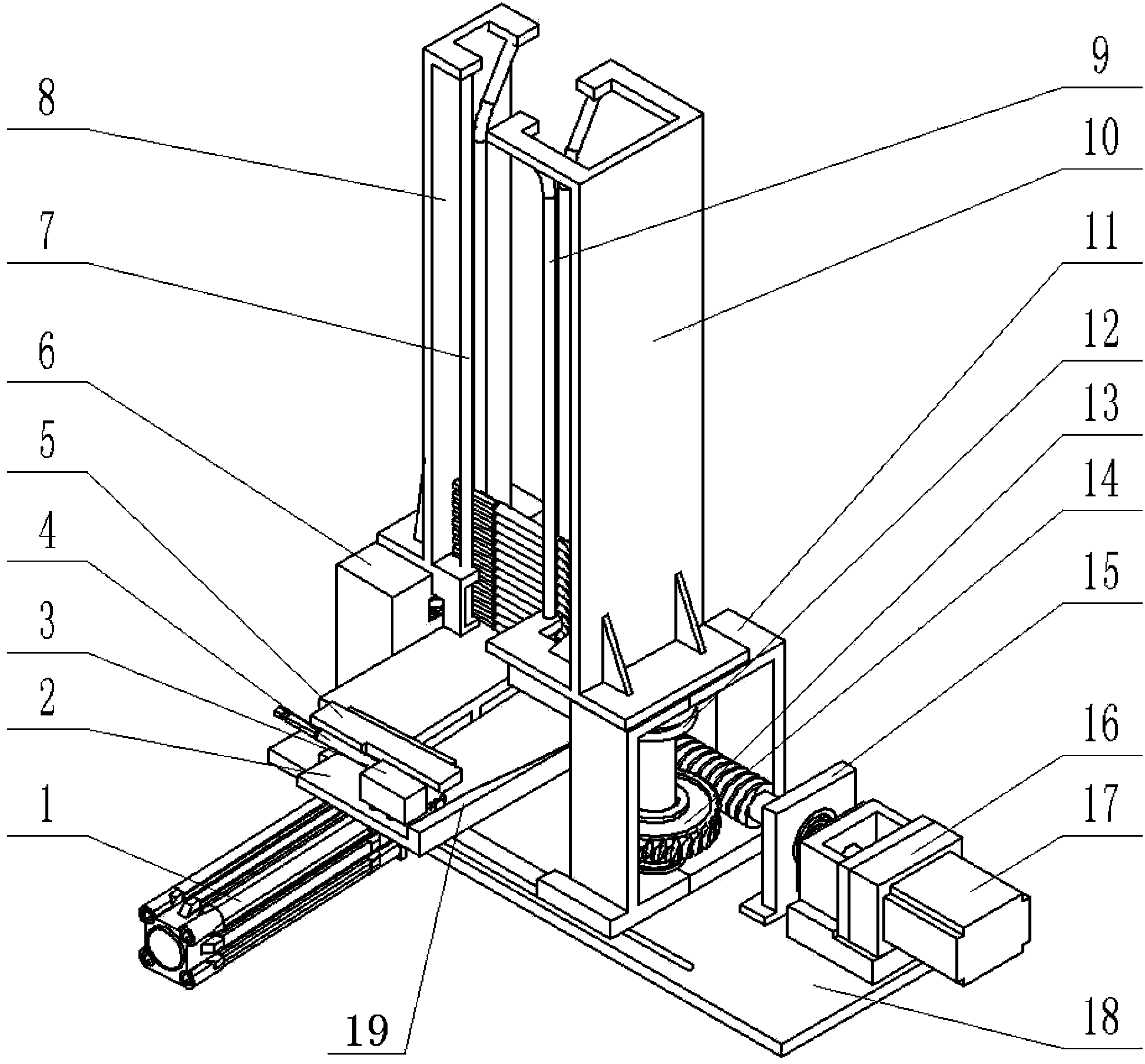

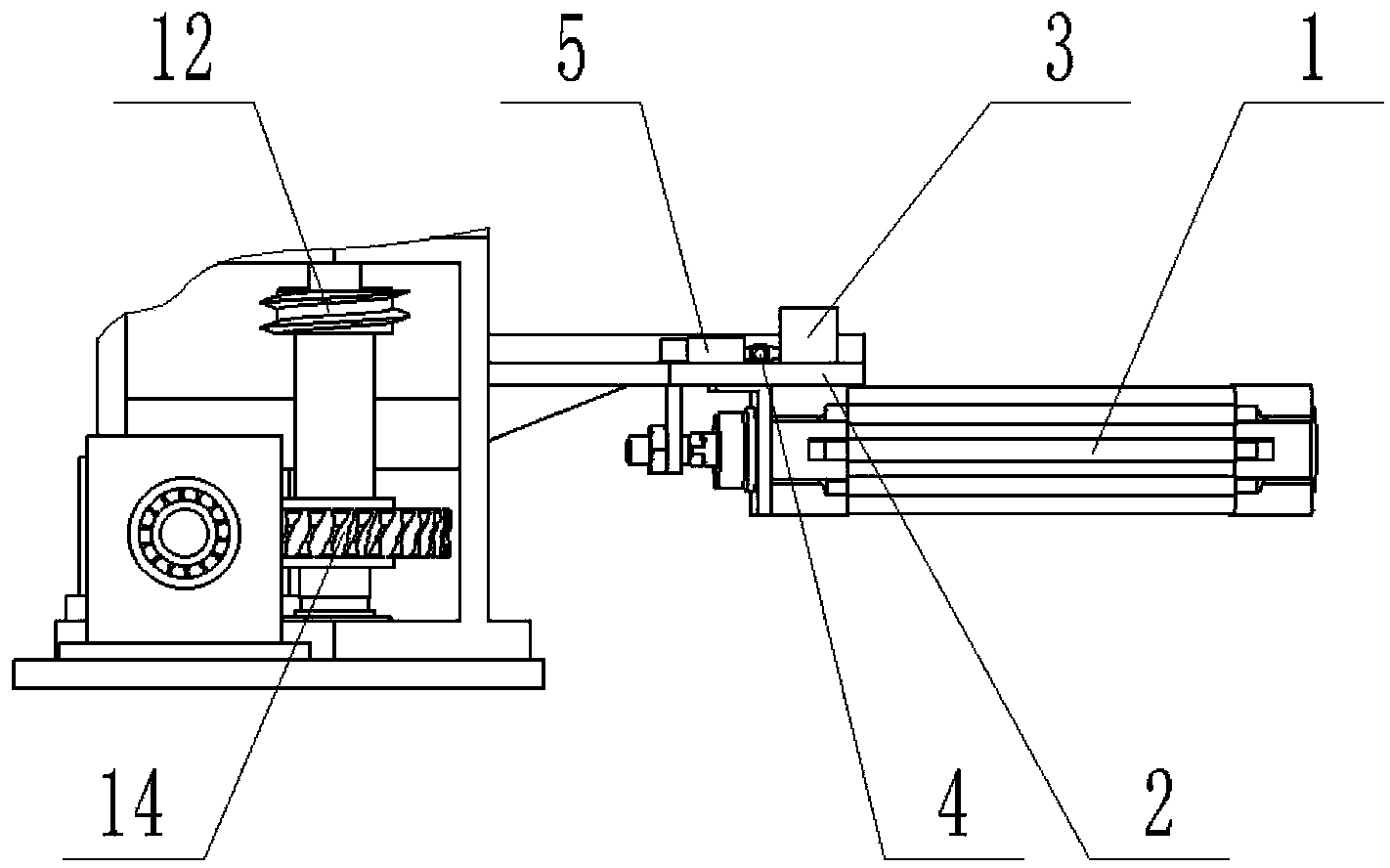

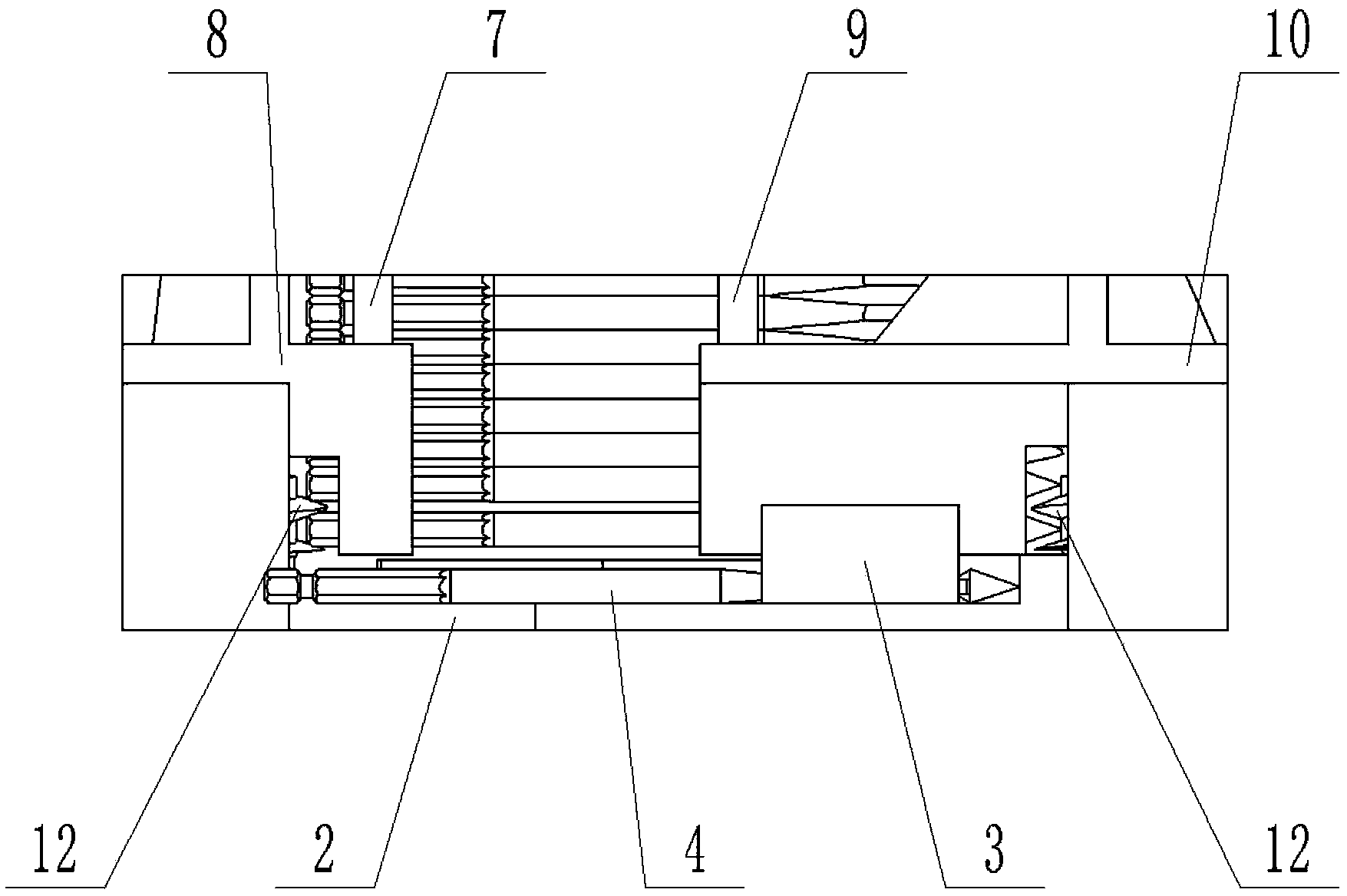

[0030] as attached figure 1 And attached figure 2 As shown, the present invention includes a flexible storage mechanism, a servo distribution mechanism and a pneumatic pushing mechanism. The structure is described in detail below. Wherein, the servo distributing mechanism includes a left screw housing 6, a right screw housing 11, two distributing screws 12, a worm 13, two worm wheels 14, two bearing supports 15, two worm bearings, A motor base 16, a servo motor 17, a base 18 and four screw bearings; the direction of the extended side on the rectangular base 18 is fixedly installed with a bearing support 15, a left screw box 6, a piece of pusher from left to right Bottom plate 2, a right screw housing 11, a bearing support 15 and a motor base 17; the two ends of the worm 13 are respectively fixed on the two bearing supports 15 through two worm bearings; the servo mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com