Rapid unpowered bearing lifting mechanism

A lifting mechanism and power technology, applied in the direction of lifting frame, lifting device, etc., can solve the problems of increasing the limit of equipment use range, increasing the workload of maintaining batteries, etc., and achieving the effect of accurate loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The technical scheme of the present invention will be described in further detail below in conjunction with accompanying drawing and embodiment:

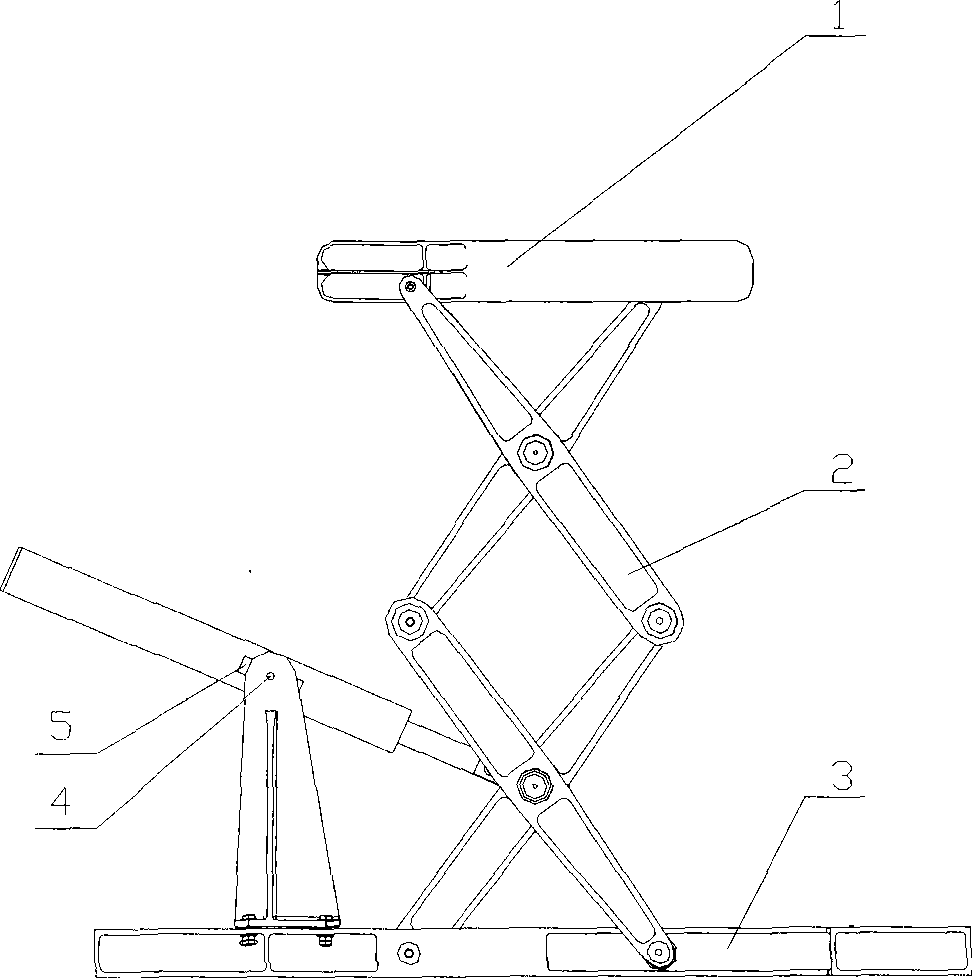

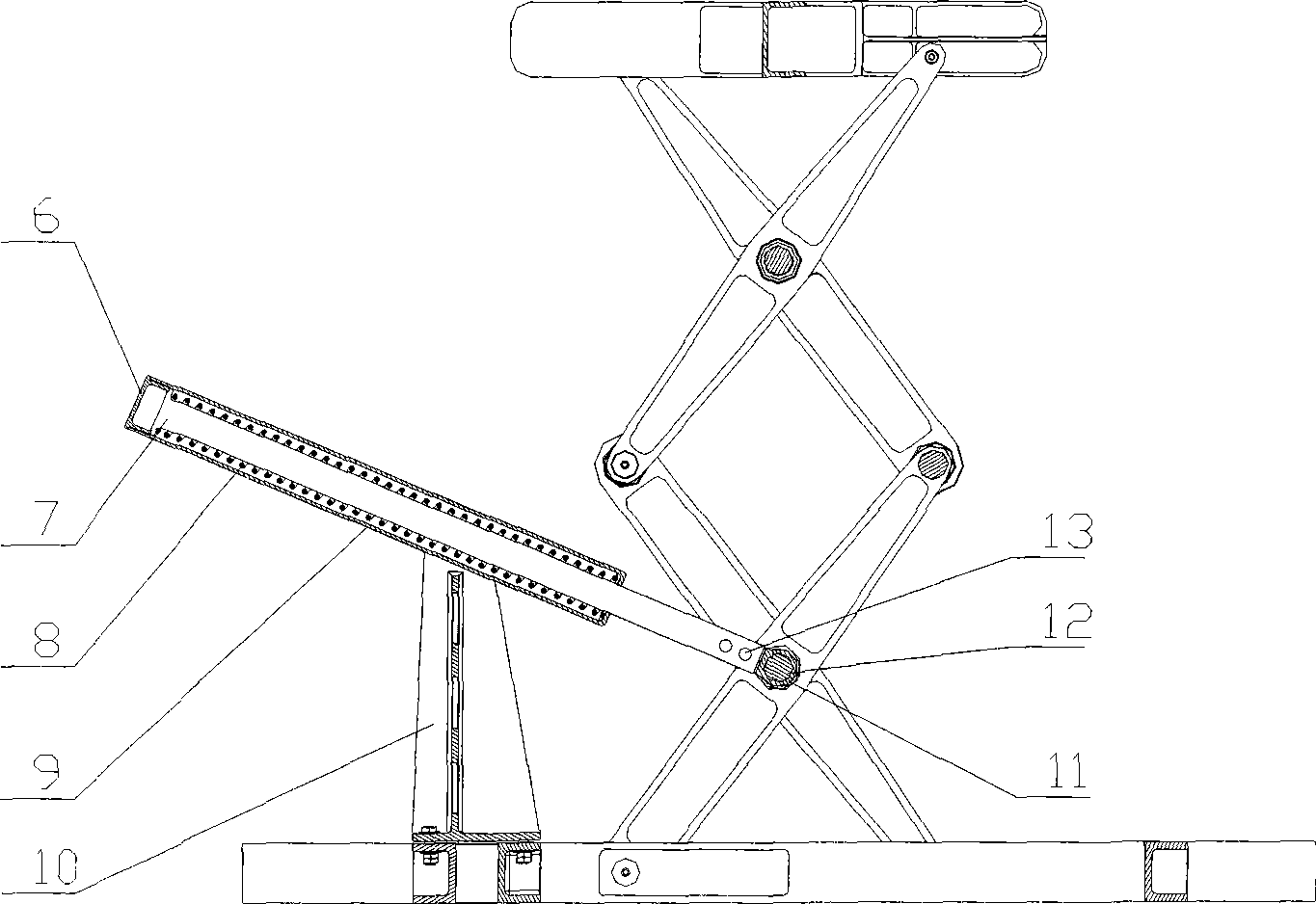

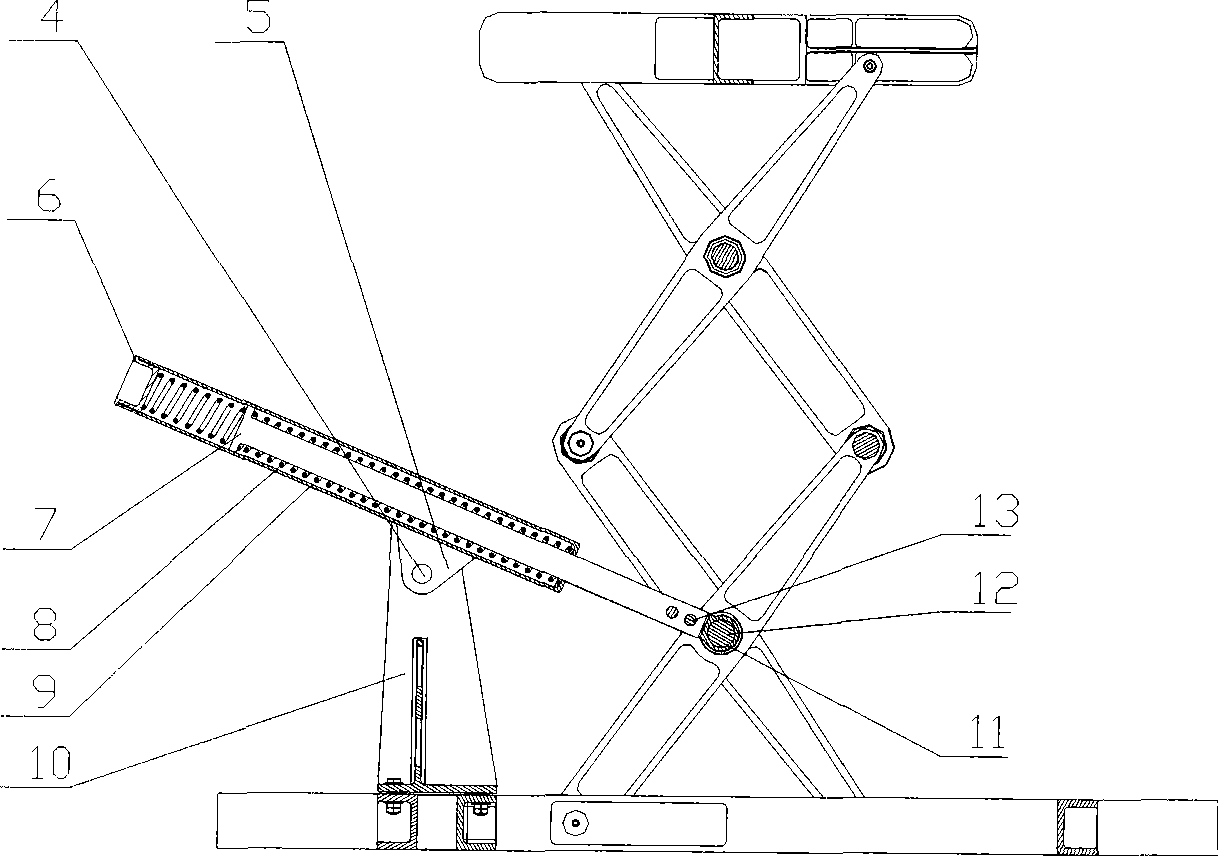

[0012] See attached Figure 1~2 As shown, this fast non-powered load-bearing lifting mechanism includes an object-bearing platform 1, two sets of scissor lifting arms 2, and a chassis 3. It is characterized in that: one end of the actuating rod 7 of the two actuating cylinders 6 passes through the actuating cylinder The power supply connector 11 is connected with the connection shaft 12 at the cross point of the two groups of scissor lift arms 2 bottoms, the power supply connector 11 of the actuator is connected with the actuating rod 7 through the connecting pin 13, and the power supply connector 11 of the actuator is Structural parts with double lugs or single lugs are mainly to balance the upward component of the spring force provided by the spring in the actuator with the load on the loading platform and the structural we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com