Method for controlling feeding and discharging of mobile robot serving two numerically controlled machines

A mobile robot, CNC machine tool technology, applied in the direction of digital control, electrical program control, etc., can solve the problem of fixed reclaiming position, achieve accurate loading and unloading, improve work efficiency, and save labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

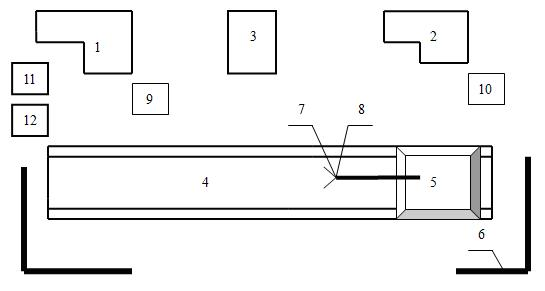

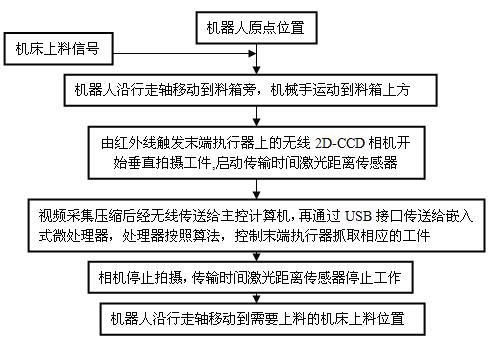

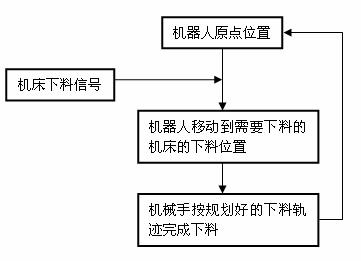

[0015] Such as figure 1 As shown in the site layout, two CNC machine tools are arranged on one side of the robot's walking axis, and the loading and unloading table is placed in the middle of the two CNC machine tools. The robot is installed on the walking axis, and the wireless 2D-CCD camera and the transmission time laser distance sensor are installed. On the end effector, a safety guardrail is set at both ends of the walking axis, and a vision support is installed near the three-jaw chucks of the two CNC machine tools. The embedded microprocessor adopts Samsung S3C2440 ARM9, the embedded operating system is Linux system, and the wireless 2D-CCD adopts the original American Linksys WVC210 Remote-controlled, and its wireless communication standard is 802.11b or 802.11g. Take, load and unload.

[0016] Grabbing of workpieces to be processed. CNC machine tool 1 (or 2) sends out a feeding signal, which is transmitted to the wireless receiver through the serial port communicat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com